Analysis and experiments of the cutting parameters for seabuckthorn branches double movable blades

-

摘要:

为探明沙棘枝条最优切割参数,解决针对国内沙棘专用机械收获装备空缺问题,该研究设计了双动刀沙棘枝条切割试验台并开展沙棘枝条切割试验,确定了切割装置关键结构参数,基于LabVIEW开发了沙棘枝条切割特性测控系统和数据采集软件。通过单因素试验探究平均切割速度、刀具滑切角、刀刃高度和动刀组数对单位直径峰值力及单位面积切割功耗的影响;采用Box-Behnken多因素试验设计方法,以平均切割速度、枝条喂入速度和刀具滑切角为试验因素,以单位直径峰值力和单位面积切割功耗为评价指标建立回归模型。试验结果表明,评价指标随着平均切割速度、刀具滑切角和刀刃高度的增大而减小,在双动刀时比单动刀时数值更小。通过响应曲面法优化回归模型,确定最优切割参数组合为平均切割速度0.45 m/s、枝条喂入速度0.64 m/s、刀具滑切角9.4°,该组合下单位直径峰值力为53.33 N/mm,单位面积切割功耗为69.87 kJ/m2,模型误差小于5%,切割参数优化结果准确。研究结果可为后续沙棘枝条收获装备的研发提供数据支撑。

Abstract:Seabuckthorn is one of the most important ecological cash crops in modern agriculture. The existing seabuckthorn forests in China are accounted for more than 90% of the world's total crop area. However, the current manual harvesting cannot fully meet the large-scale production in recent years, because the fruits can be clustered in the thorny branches. It is also a high demand for seabuckthorn harvesting machinery rather than manual ones. In this study, the movable double blades cutting device was developed to investigate the effect of the cutting parameters on the harvesting performance of seabuckthorn branches. The optimal combination of cutting parameters was also achieved after the experiment and simulation. The sample branches were four years old, 300 mm in length, with a moisture content of 43.13% to 53.83% (average 47%). The test instruments included the self-developed double blades cutting test device, a video recorder, and a digital camera. The cutting test device consisted of three units (the cutting, branch feeding, and control unit). The single factor and orthogonal tests were also carried out to verify the simulation. The experimental factors in the single factor tests were the average cutting speed (0.4-0.8 m/s), sliding cutting angle of the blade (7.5°, 15°, and 22.5°), blade height (35, and 70 mm), and the number of the movable blade (single, double), where the average cutting speed was set at 5 levels. A regression model was established for the orthogonal tests. The Box-Behnken method was designed with a three-factor, three-level test scheme. The average cutting speed (0.4-0.6 m/s), branch feeding speed (0.5-0.7 m/s), and sliding cutting angle of the blade (7.5°, 15°, and 22.5°) were selected as the experimental factors, whereas, the peak cutting force per unit diameter and cutting power consumption per unit area were set as the evaluation indexes. Response surface analysis was used to optimize the regression model. The experimental results show that the evaluation indexes decreased with the increase in average cutting speed, sliding cutting angle of blade, and blade height. The values of these indexes were smaller for the double movable blades, compared with the single ones. The average cutting speed and sliding cutting angle of blade presented the highly significant effects on the evaluation indexes ( P<0.01), while the branch feeding speed shared a non-significant effect on the evaluation indexes ( P>0.05). The key factor for the quality of the cutting section was the average cutting speed when the branch feeding speed was determined. The optimal combination of cutting parameters for the double movable blades was: the average cutting speed of 0.45 m/s, the branch feeding speed of 0.64 m/s, and the sliding cutting angle of 9.4°. Specifically, the peak force per unit diameter was 53.33 N/mm, and the cutting power consumption per unit area was 69.87 kJ/m2 under the combination. Three groups of verification tests were carried out for the experimental optimization. The relative error of the regression model was less than 5%, indicating the reliable optimization of cutting parameters. Therefore, the optimized conditions were reasonable in this case. The optimized parameters (such as the average cutting speed, branch feeding speed, and sliding cutting angle of the blade) can be expected to effectively reduce the peak force per unit diameter for the cutting power consumption saving per unit area. The finding can provide the data support for the subsequent development of seabuckthorn harvesting equipment.

-

Keywords:

- mechanization /

- experiment /

- cutting /

- seabuckthorn branch /

- reciprocating type /

- double movable blades

-

0. 引 言

沙棘属胡颓子沙棘属,为针状落叶形灌木,是中国生态经济作物之一[1]。沙棘抗旱耐寒,可在盐渍化土地生存[2-4]。国内现有沙棘林200多万hm2,占世界沙棘总面积90%以上,其中新疆现有的沙棘资源约4万hm2,是中国最大的沙棘产业基地[5-6]。沙棘果实属于浆果,短柄、薄皮,丛生于带刺的果枝,易粘结,很难采摘[7]。由于缺乏沙棘专用收获机械,目前国内沙棘采收方法主要为冻果震落采收、手工器具采收和剪枝采收等几种方式[8-9]。这些人工采收方式采摘效率低、破碎率高,对果树损伤较大,造成近50%的果实被浪费,采摘成本占总成本的50%~70%,成为制约其产业化发展的瓶颈,对机械化采收装备的需求日益迫切[10]。沙棘机械化收割技术的研究在国内研究较少,前期需完成沙棘切割器的研究,而明确沙棘枝条的切割参数对相关装备研发具有重要指导意义。

俄罗斯、加拿大和德国等国家已经设计出包括树干振摇式[11]、树枝振摇式[12-14]、真空吸收式[15-16],激素催熟式[17]和整枝采收式[18]沙棘收获机械,对于相关枝条切割参数的研究却鲜有报道。开展作物切割参数试验研究时,由于直接获取田间试验数据往往受限于可重复性、数据采集难度、种植模式、季节气候等外界因素[19],因此部分学者利用自制的切割装置对蓖麻[20]、油菜[21]、王草[22]、棉花[23-24]、甘蔗[25-26]、玉米[27]、工业大麻[28]等茎秆作物进行了切割试验。往复式双动刀切割的相关研究主要集中在茶叶[29]、油葵[30]、苹果枝条[31]、小麦[32]、苎麻[33-34]、芦蒿[35]等作物。

切割刀具的材料性能及几何尺寸、茎秆本身的物料参数、切割速度等均会对切割过程产生影响[36-37]。本文在借鉴前人研究的基础上,设计了往复式双动刀沙棘枝条切割试验台并开发切割试验测控系统和配套数据采集软件,通过建立数学建模及运动仿真分析,分析了试验台关键机构运动特性,探讨了切割根数、枝条直径、刀具滑切角、平均切割速度、刀刃高度和动刀组数对单位直径峰值力及单位面积切割功耗的影响,采用Box-Behnken试验方法得出沙棘枝条往复式双动刀切割最优参数组合。

1. 材料与方法

1.1 试验枝条样本

试验样本采自新疆兵团九师额敏县170团沙棘种植地,品种为深秋红,树龄4 a,种植行距210 cm,株距155 cm,采样果树20棵,采用理论机采位置下生长状况良好、果实较多、无病虫害、无明显缺陷的枝),样本长度300 mm(图1)。采样结束后,立即用密封标本袋将试验样本进行密封保存并标号。参照GB/T 1931[38]采用烘干法测定枝条含水率,烘干前测定沙棘枝条样本质量,精度为0.001 g;在(103 ± 2)℃下烘干8 h后再次测量质量;以后每隔2 h测量1次,前后2次测量的质量差不超过0.002 g视为烘干完成,计算其含水率。经测定,试验期间(3 d)枝条的含水率为43.13%~53.83%,平均含水率47%。

1.2 双动刀切割试验台

为实现试验样本切割、输送及切割过程测控功能,本文设计和搭建了沙棘枝条双动刀切割试验台,如图2a所示。试验台总体上由切割装置、沙棘枝条喂入输送装置和测控装置三部分构成。

![]() 图 2 双动刀切割试验台1.防护网罩 2.切割装置 3.测控装置 4.传动机构 5.拉压力传感器 6.动态扭矩传感器 7.切割电机及变频器8.切割刀具 9.输送装置 10.夹具 11.输送电机、减速器及变频器Figure 2. Double movable blades cutting test bench1. Protective net cover 2. Cutting device 3. Measurement and control device 4. Drive mechanism 5. Pulling pressure sensor 6. Dynamic torque sensor 7. Cutting motor and inverter 8. Cutting tool 9. Conveying device 10. Sample fixture 11. Conveying motor, reducer and frequency converter 注: A 、B 、C 、D 、E 、F 、D’ 、E’ 、F’ 为初始位置机构运动副,A0、B0、C0、E0、F0为下一位置机构运动副;t0 为曲柄长度,mm;l为摆杆长度,mm;r为连杆长度,mm;α为主轴转角,(°);β为曲柄与摆杆夹角,(°);γ为连杆摆动角度,(°);θ为摆杆EF与Y轴夹角,(°)。Note: A, B, C, D, E, F, D’, E’, F’ are the initial position mechanism motion sub, A0, B0, C0, E0, F0 are the next position mechanism motion sub; t0 is the crank length, mm; l is the pendulum length, mm; r is the linkage length, mm; α is the spindle rotation angle, (°); β is the crank and pendulum angle, (°); γ is the swing angle of the linkage, (°); θ is the angle between the pendulum EF and Y axis, (°).

图 2 双动刀切割试验台1.防护网罩 2.切割装置 3.测控装置 4.传动机构 5.拉压力传感器 6.动态扭矩传感器 7.切割电机及变频器8.切割刀具 9.输送装置 10.夹具 11.输送电机、减速器及变频器Figure 2. Double movable blades cutting test bench1. Protective net cover 2. Cutting device 3. Measurement and control device 4. Drive mechanism 5. Pulling pressure sensor 6. Dynamic torque sensor 7. Cutting motor and inverter 8. Cutting tool 9. Conveying device 10. Sample fixture 11. Conveying motor, reducer and frequency converter 注: A 、B 、C 、D 、E 、F 、D’ 、E’ 、F’ 为初始位置机构运动副,A0、B0、C0、E0、F0为下一位置机构运动副;t0 为曲柄长度,mm;l为摆杆长度,mm;r为连杆长度,mm;α为主轴转角,(°);β为曲柄与摆杆夹角,(°);γ为连杆摆动角度,(°);θ为摆杆EF与Y轴夹角,(°)。Note: A, B, C, D, E, F, D’, E’, F’ are the initial position mechanism motion sub, A0, B0, C0, E0, F0 are the next position mechanism motion sub; t0 is the crank length, mm; l is the pendulum length, mm; r is the linkage length, mm; α is the spindle rotation angle, (°); β is the crank and pendulum angle, (°); γ is the swing angle of the linkage, (°); θ is the angle between the pendulum EF and Y axis, (°).沙棘枝条的送料方式是切割装置静止不动,沙棘枝条通过输送装置喂入切割装置。切割装置由切割传动机构、切割电机及变频器、切割刀具和机架组成。切割电机选用三相交流异步电机,通过变频器进行速度控制,驱动切割传动机构,使刀具进行往复切割运动。输送装置主要包括输送电机及减速器、变频器、沙棘枝条样本夹具和带式输送机。输送电机通过链传动将动力输入到主轴,主轴通过滚筒带动传送带运行,夹持着沙棘枝条样本的夹具均布在传送带上,随着传送带的平稳运行喂入到切割部件中。测控装置由笔记本电脑、S型拉压力传感器及其变送器、动态扭矩传感器及其变送器、24 V直流电源组成,可以实时采集试验台工作时动态扭矩传感器和拉压力传感器的信号并保存数据,拉压力传感器及动态扭矩传感器安装位置如图2b所示。双动刀切割试验台技术参数如表1所示。

表 1 试验台主要技术参数Table 1. Main technical parameters of test bench参数Parameters 数值Value 切割速度Cutting speed/(m·s-1) 0~2 枝条喂入速度Branch feeding speed/(m·s-1) 0~2 切割电机功率Power of cutting motor/kW 7.5 枝条输送电机功率Power of branch feeding motor/kW 3 切割幅宽Cutting width/mm 1500 割茬高度Stubble height/mm 200 拉压力量程Tensile force range/N 0~5000(±0.2) 扭矩量程Torque range/(N·m) 0~200(±0.1) 传感器采集频率Acquisition frequency of sensor/kHz 10 数据采集通道数Number of data acquisition channel 3 试验台的切割传动机构(图2b)采用空间曲柄滑槽-摇杆滑块机构[33],结构简图如图2c所示。切割电机带动切割主轴旋转,驱动连接在曲柄上的连杆做偏心运动,由于上、下摇杆中间部位固定在机身上,将连杆在竖直平面内的运动转换为水平平面内的摆动,进而转换为水平直线运动,驱动上、下动刀进行反向切割,完成双动刀往复式切割。若拆卸下摇杆并固定下动刀,该机构仍可驱动上摇杆,并驱动上动刀往复运动,这时切割机构转换为单动刀切割。

该传动机构可分解为1组对心曲柄滑块机构和2组滑槽连杆机构,如图2d和2e(由于2组滑槽连杆机构关于X轴对称,取下动刀进行分析)。该机构满足以下函数关系:

yF(γ)=r⋅(sinγ−√2cosγ−cos2γ) (1) β(α)=arctant⋅sinα+√l2−t2cos2α−√l2−t2r (2) 联立式(1)~(2)可得关于α的动刀切割位移函数为

yF(α)=yF[β(α)] (3) 正弦机构从动件运动过程中无冲击,正负运动对称性强。而由式(3)绘出的函数图像与接近正弦波形,表明下动刀的切割轨迹符合理想正弦运动规律,机构在结构上对称,所以此结论同样适用于上动刀。

为验证机构合理性,本文通过SolidWorks Motion对机构模型进行运动学仿真,并考虑重力和装配间隙等因素产生的影响。

参考已有研究成果[21,25],为清晰呈现该机构运动规律,设定切割主轴转速为30 r/min,仿真时间为5 s,得到刀具(仿真对象取下动刀)的位移-时间(图3a)、速度-时间(图3b)和加速度-时间(图3c)曲线。规定行程中点为空间坐标系原点,选取初始位置时下动刀上与行程中点重合的点为参考点,各量在参考点位于XOZ平面右侧时为正值,反之则为负值。

仿真结果表明,位移-时间曲线呈现明显的正弦函数波形且平滑,与理论分析结果一致;速度-时间曲线波形与位移-时间曲线波形相仿但存在一定的突变,速度范围为±119 mm/s;在重力和装配间隙的影响下,加速度-时间曲线有明显的突变,正弦函数拟合结果达到设计预期(R2=0.483),该条件下机构满足试验需求。由此说明,该机构设计合理。

1.3 刀具参数

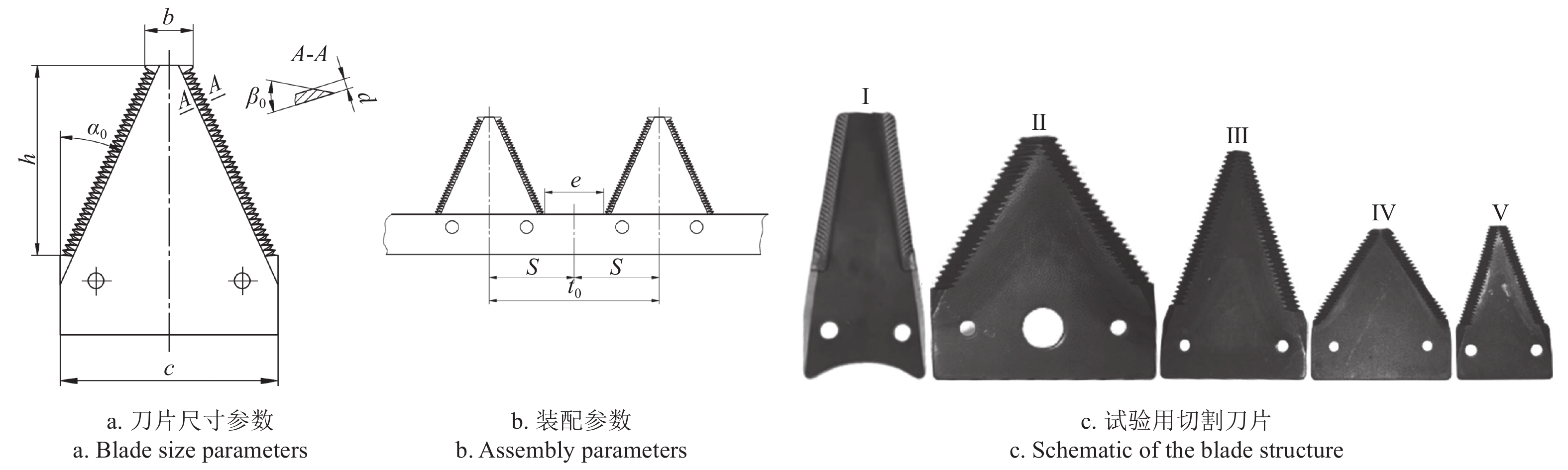

本文旨在探究往复式单、双动刀切割装置在不同切割速度和枝条喂入速度下,刀片尺寸对切割功耗及切割效果的影响,而国内鲜有沙棘枝条专用切割装置的研究,所以参考其他茎秆作物收割刀片进行验证性研究。

根据刀片间距(上刀片间距t1、下刀片间距t2)和切割行程S的关系,往复式切割器分为a型和b型2种[39],a型切割器的切割行程与刀片间距相等,b型切割器的切割行程则为刀片间距的1/2,即:

a型:Sa=t1=t2 (4) b型:Sb=t12=t22 (5) 往复式双动刀切割器为b型。动刀片是切割器的主要工作部件,刀片刃口有光刃和齿刃两种。由于沙棘植株是顶生或侧生,沙棘枝条生长姿态较为复杂,枝条喂入切割器时并不是有序的理想状态,这就使得沙棘枝条容易在高速的切割过程中产生偏移或者滑脱,造成碎果或者漏切。为了避免产生这种现象,本文采用齿刃刃口的刀片作为动刀片。

参考其他茎杆作物收割机双动刀刀片的几何结构,本文采用具有六角形外形的梯形动刀片(图4a)。刃口为梯形,保证修整之后刀身仍然能保持原来的高度。如图4b所示,单个刀片的切割行程若小于刀片底宽,就会产生切割盲区。为避免初始切割速度为0,应保证底边间距e>0。试验所用的5种尺寸的刀片如图4c所示,材料为T9碳素工具钢,刃口淬火(淬火硬度50~60 HRC)。

![]() 图 4 试验用切割刀片及尺寸参数注:h为刀刃高度,mm;b为前桥宽,mm;c为刀片底宽,mm;刀片厚度d为2 mm;α0为滑切角,(°);刃口楔角β0为36°;t0为刀片节距,mm;底边间距e为14 mm;S为割刀行程,mm;Ⅰ为7.5°滑切角70 mm刃高动刀,Ⅱ为22.5°滑切角70 mm刃高动刀,Ⅲ为15°滑切角70 mm刃高动刀,Ⅳ为22.5°滑切角35 mm刃高动刀,Ⅴ为15°滑切角35 mm刃高动刀。Figure 4. Test cutting blades and their dimensional parametersNote: h is the blade height, mm; b is the front bridge width, mm; c is the blade bottom width, mm; blade thickness d is 2 mm; α0 is the sliding cutting angle, (°); blade wedge angle β0 is 36°; t0 is the blade pitch, mm; bottom edge spacing e is 14 mm; S is the cutter stroke, mm; Ⅰ: 7.5° slip cutting angle and 70 mm blade height, Ⅱ: 22.5° slip cutting angle and 70 mm blade height, Ⅲ: 15° slip cutting angle and 70 mm blade height, Ⅳ: 22.5° slip cutting angle and 35 mm blade height, Ⅴ: 15° slip cutting angle and 35 mm blade height.

图 4 试验用切割刀片及尺寸参数注:h为刀刃高度,mm;b为前桥宽,mm;c为刀片底宽,mm;刀片厚度d为2 mm;α0为滑切角,(°);刃口楔角β0为36°;t0为刀片节距,mm;底边间距e为14 mm;S为割刀行程,mm;Ⅰ为7.5°滑切角70 mm刃高动刀,Ⅱ为22.5°滑切角70 mm刃高动刀,Ⅲ为15°滑切角70 mm刃高动刀,Ⅳ为22.5°滑切角35 mm刃高动刀,Ⅴ为15°滑切角35 mm刃高动刀。Figure 4. Test cutting blades and their dimensional parametersNote: h is the blade height, mm; b is the front bridge width, mm; c is the blade bottom width, mm; blade thickness d is 2 mm; α0 is the sliding cutting angle, (°); blade wedge angle β0 is 36°; t0 is the blade pitch, mm; bottom edge spacing e is 14 mm; S is the cutter stroke, mm; Ⅰ: 7.5° slip cutting angle and 70 mm blade height, Ⅱ: 22.5° slip cutting angle and 70 mm blade height, Ⅲ: 15° slip cutting angle and 70 mm blade height, Ⅳ: 22.5° slip cutting angle and 35 mm blade height, Ⅴ: 15° slip cutting angle and 35 mm blade height.1.4 测控装置

测控系统包括电机控制和数据采集模块。电机控制部分的功能应该包含对电机速度调节、正反向控制等。数据采集模块实时监测和采集沙棘枝条切割数据。试验要求测控系统数据采集内容包括:切割力、切割扭矩、时间等。按照功能组成,试验台硬件部分分为切割监测单元和机械驱动单元,分别对应测控系统中的数据采集模块和电机控制模块,控制系统结构如图5所示。

1.5 数据采集与处理

沙棘切割试验数据自动采集软件可以采集不同试验条件下的切割数据,主要有初始化模块、用户操作模块、索取数据命令模块、接收数据模块、处理数据模块以及退出程序模块,如图6所示。各模块借助串口实现与试验台传感器的连接,读取并实时显示计算机处理后传感器所发送的数据,包括扭矩(显示的扭矩为动态扭矩传感器的实际测量值减去空载状态下的扭矩值)、拉压力(显示的拉压力为2个S型拉压力传感器的实际测量值减去空载状态下的切割力值的平均值)等,并将所接收的扭矩以及拉压力数据显示在波形图表内,用户可据此分析刀具工作状态。此外,系统还针对波形图设置截图保存功能以及数据保存功能,退出程序时,数据以文本形式保存。

本系统主要有初始化模块、用户操作模块、索取数据命令模块、接收数据模块、处理数据模块以及退出程序模块,如用户可在系统界面选择所连接的串口,然后打开串口,数据就会实时显示在界面中,用户还可以在软件界面内点击截图并保存按钮,根据需要截取任意时刻的波形图。

1.6 试验方法

1.6.1 试验因素确定

往复切割式切割器作业的关键技术参数包括机器前进速度、刀片运动速度和切割器机构参数等[29,39],结合上文确定的刀具参数,本文主要考虑5个试验因素,分别为平均切割速度、刀具滑切角、刀刃高度、动刀组数及枝条喂入速度。

1.6.2 评价指标

试验采用的评价指标为单位直径峰值力和单位面积切割功耗。

在切割过程中,数据采集系统实时采集并记录拉压力传感器的切割力信号及扭矩传感器的扭矩信号,通过后续对切割力及扭矩数据的处理,可获单位直径峰值力和单位面积切割功耗,分别由式(6)及式(7)计算。

pq=Fqmax (6) w = \frac{{4\omega \cdot \int {M\left( t \right){\text{d}}t} }}{{\pi {d^2}T}} (7) 式中pq为沙棘枝条单位直径峰值力,N/mm;Fqmax为沙棘枝条峰值切割力,N;dm为沙棘枝条样本直径,mm;w为单位面积切割功耗,kJ/m2;ω为切割传动机构曲柄转动角速度,rad/s;M为扭矩传感器扭矩随时间变化曲线函数;t为时间变量,s;T为切割总时间,s。

1.6.3 试验步骤

在测试之前,对各执行装置、数据采集软件、各元器件连接情况等进行检查;将沙棘枝条样本插入输送带夹具的开孔圆筒中,用水平快速夹具将其紧固;启动切割电机,调整切割机转速;开启数据采集软件,通过PC端进行数据采集;调整进料装置的进料速率,使沙棘枝条样本按试验要求的速度送入切割器内;数据采集系统收集并存储切割力及切割扭矩等信息。使输送电机反转,返回到合适位置,观察、记录割茬截面状态;每组试验结束后,将输送带及切割器下方的沙棘枝条割茬清扫干净,每个水平进行3组试验,采集信息后,再根据试验设计顺序进行后续试验。

1.6.4 单因素试验

为探究各影响因素对沙棘枝条切割效果的影响,设计4组单因素试验,各因素和水平如表2所示。为保证试验安全,在平均切割速度单因素试验中,设定切割速度v范围0.4~0.8 m/s,并以0.1 m/s为梯度设置5个水平;在其他试验时,取平均切割速度为0.6 m/s。根据现有切割刀具的滑切角设计以及相关经验,进行刀具滑切角试验时,分别设置7.5°、15°和22.5°为滑切角α0的3个水平;在进行其他试验时,滑切角为15°。刀刃高度分别为35和70 mm,在进行其他试验时,将刀刃高度定为70 mm。动刀组数分别为单动刀和双动刀,在进行其他试验时,设定为双动刀。在进行单因素试验时,3根枝条为一组,枝条直径为14 mm,喂入速度设定为0.6 m/s,每组重复3次。

表 2 单因素试验因素水平表Table 2. Factors and levels of single factor tests水平

Levels平均切割速度

Average cutting speed vc/(m∙s −1)刀具滑切角

Sliding cutting angle of blade α0/(°)刀刃高度

Flute length h/mm动刀组数

Number of movable blades1 0.4 7.5 35 单动刀 2 0.5 15 70 双动刀 3 0.6 22.5 4 0.7 5 0.8 1.6.5 正交试验

根据单因素试验结果,选定了平均切割速度、枝条喂入速度以及刀具滑切角作为为多因素试验的因素,其因素水平表如表3所示。在切割过程中,切割线速度与枝条喂入速度的切割速比会对切割功耗和切割效果产生影响,所以多因素试验在选取水平时考虑2个因素之间的交互作用。根据Box-Behnken原理,设计3因素的3个水平正交试验。试验中2根枝条设置为一组,每个试验方案重复3次,试验方案与结果如表5所示。

表 3 正交试验因素水平表Table 3. Factors and levels of orthogonal tests水平Levels 平均切割速度

Average cutting speed vc/(m∙s−1)枝条喂入速度

Stalk feeding speed vf/(m∙s−1)刀具滑切角

Sliding cutting angle of blade α0/(°)−1 0.4 0.5 7.5 0 0.5 0.6 15 1 0.6 0.7 22.5 2. 结果与分析

2.1 单因素试验结果与分析

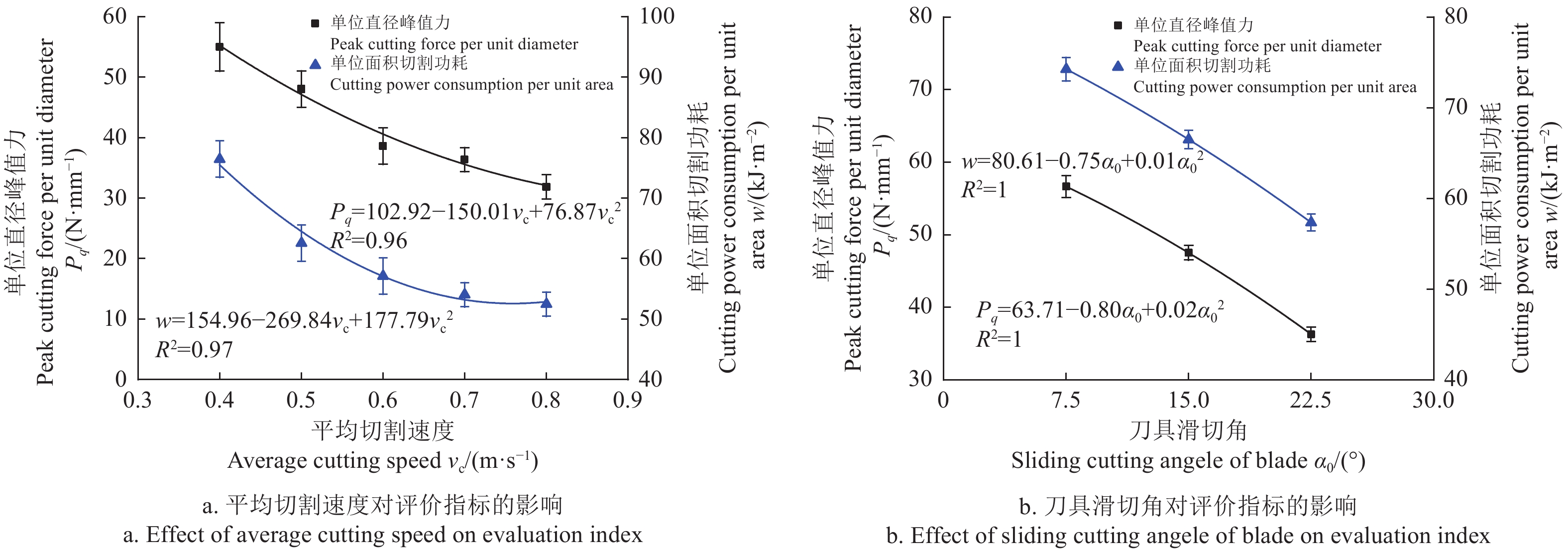

平均切割速度的试验结果如图7a所示。由图可知,总体呈下降趋势且逐渐变缓。这是由于沙棘枝条在被切割前存在被挤压的过程,该过程消耗的时间随着平均切割速度的增大逐步缩短,当平均切割速度持续增大,挤压过程消耗时间变化逐渐缓慢,从而造成评价指标减小趋势逐渐变缓,最终趋于稳定。

通过对记录的切割过程的摄像图像分析发现,切割速度为0.4 m/s(图8a)和0.5 m/s(图8b)时,由于喂入速度过快,刀具在接触韧皮部后发生了一定程度的滑移,造成韧皮部发生严重破损,严重时由于沙棘枝条不能被完全切割,被输送装置推倒在切割器刀梁上强制折断,造成割茬呈现斜面甚至出现劈裂。出现以上情况时,割茬截面积的增大不但增加了切割功耗,同时切断过程中刀片的滑移会影响刀具的使用寿命。而当切割速度为0.6 m/s(图8c)、0.7 m/s(图8d)和0.8 m/s(图8e)时,沙棘枝条能够被刀具一次切断,滑移现象明显改善,此时沙棘枝条韧皮部破损程度小,割茬截面较为平整。

刀具滑切角试验结果(图7b)表明,随着刀具滑切角增加,评价指标均呈下降态势。这是由于当刀具滑切角增大时,沙棘枝条样本沿刀具刃口的滑移量会变大,切割作用增强,因此评价指标呈现减小的趋势。

不同刀具滑切角下沙棘枝条割茬截面情况如图9所示,当刀具滑切角分别为7.5°、15°和22.5°时,刀具滑切角对割茬截面质量的影响并不明显,切割刃口均保持较好的平整度。

刀刃高度及动刀组数的试验结果如表4所示。试验结果表明,随着刀刃高度的增大,评价指标均呈下降的态势。刀刃高度增加,实际切割刀刃长度有所增加,进而切割效果增强,因此评价指标有减小的趋势。双动刀的评价指标数值均低于单动刀。采用双动刀时,相同时间内上、下动刀的相对位移增加,节省了一定功耗。因此动刀组数增加,评价指标有减小的趋势。

表 4 刀刃高度及动刀组数对评价指标的影响Table 4. Effect of blade height and number of movable blade sets on evaluation index试验序号

Test No.刀刃高度

Blade height

h动刀组数

Number of moving

blade sets水平

LevelsPq/

(N·mm−1)w/

(kJ·m−2)水平

LevelsPq/

(N·mm−1)w/

(kJ·m−2)1 35 mm 57.4 75.9 单动刀 90.0 112.3 2 70 mm 47.1 67.4 双动刀 47.1 63.8 2.2 正交试验结果与分析

2.2.1 正交试验结果

正交试验方案及结果如表5所示。利用Design-Expert 13软件对表5的试验结果进行二次多项式回归拟合,得到单位直径峰值力与单位面积切割功耗预估模型,如式(8)~(9)所示。

表 5 正交试验设计方案及结果Table 5. Design scheme and results of orthogonal tests试验号Test No. A B C Pq/(N·mm−1) w/(kJ·m−2) 1 0 0 0 48.1 63.7 2 0 1 1 44.9 59.9 3 0 1 −1 54.5 71.4 4 −1 0 −1 54.6 71.5 5 0 0 0 49.9 65.9 6 0 −1 −1 54 70.8 7 −1 0 1 45.8 61.0 8 0 0 0 48.1 63.7 9 0 −1 1 47.3 62.8 10 0 0 0 49.7 65.6 11 1 1 0 49.4 65.3 12 1 −1 0 47.9 63.5 13 1 0 1 40.5 54.6 14 1 0 −1 46.5 61.8 15 0 0 0 48.1 63.7 16 −1 1 0 55.1 72.1 17 −1 −1 0 53.4 70.1 注:A,B,C为平均切割速度、枝条喂入速度和刀具滑切角的水平值。 Note:A, B, C are the level values of average cutting speed,stalk feeding speed and sliding cutting angle of blade. \begin{aligned} P_q = & 48.78 - 3.07A + 0.16B - 3.89C - 0.05AB + \\ & 0.7AC - 0.73BC - 0.33{A^2} + 3{B^2} - 1.6{C^2} \end{aligned} (8) \begin{aligned} w = & 64.52 - 3.45A + 0.06B - 4.76C + 2AB + \\ & 1.05AC - 0.88BC - 0.62{A^2} + 3.6{B^2} - 1.9{C^2} \end{aligned} (9) 2.2.2 方差分析

对两个评价指标的预测模型进行回归方差分析,结果如表6所示。数据表明,模型的显著水平P值均小于0.01,回归模型极显著;两个评价指标的失拟项P值均大于0.05,回归模型失拟项不显著,说明模型拟合性较好,可用于后续最优切割参数优化分析。

表 6 回归方程方差分析Table 6. Analysis of the variance of the peak cutting torque regression equation来源

Sources单位直径峰值力Peak cutting force per unit diameter Pq 单位面积切割功耗Cutting power consumption per unit area w 平方和

Sum of squares自由度

Freedom均方值

Mean squareF P 平方和

Sum of squares自由度

Freedom均方值

Mean squareF P 模型Model 247.74 9 27.53 25.27 0.0002** 352.47 9 39.16 29.10 < 0.0001** A 75.64 1 75.64 69.44 < 0.0001** 95.22 1 95.22 70.75 < 0.0001** B 0.2113 1 0.2113 0.1939 0.6730 0.0313 1 0.0313 0.0232 0.8832 C 120.90 1 120.90 110.98 < 0.0001** 181.45 1 181.45 134.83 < 0.0001** AB 0.0100 1 0.0100 0.0092 0.9264 0.1600 1 0.1600 0.1189 0.7404 AC 1.96 1 1.96 1.80 0.2217 4.41 1 4.41 3.28 0.1132 BC 2.10 1 2.10 1.93 0.2073 3.06 1 3.06 2.28 0.1752 A2 0.4516 1 0.4516 0.4146 0.5402 1.63 1 1.63 1.21 0.3073 B2 37.83 1 37.83 34.73 0.0006** 54.64 1 54.64 40.60 0.0004** C2 10.81 1 10.81 9.93 0.0161* 15.16 1 15.16 11.26 0.0121* 残差Residual 7.63 7 1.09 9.42 7 1.35 失拟Lack of fit 4.14 3 1.38 1.58 0.3261 4.33 3 1.44 1.14 0.4354 误差 Error 3.49 4 0.8720 5.09 4 1.27 总和Total sum 255.36 16 361.90 16 注:P<0.01(极显著,**),0.01≤P<0.05(显著,*),P>0.05(不显著)。 Note: P<0.01(highly significant,**), 0.01≤P<0.05(significant,*), P>0.05(not significant). 两个评价指标模型决定系数R2值分别为0.9701和0.9740,表明分别有97.01%和97.4%的评价指标变化取决于选定的试验因素。

各因素对单位直径峰值力的影响如下:平均切割速度和刀具滑切角一次项P值小于0.01,对单位直径峰值力的影响极显著;枝条喂入速度二次项P值小于0.01,对单位直径峰值力的影响极显著;刀具滑切角二次项P值小于0.05,对单位直径峰值力的影响显著;其余项P值均大于0.05,对单位直径峰值力的影响不显著。

各因素对单位面积切割功耗的影响如下:平均切割速度和刀具滑切角一次项P值小于0.01,对单位面积切割功耗的影响极显著;枝条喂入速度二次项P值小于0.01,对单位面积切割功耗的影响极显著;刀具滑切角二次项P值小于0.05,对单位面积切割功耗的影响显著;其余项P值均大于0.05,对单位面积切割功耗的影响不显著。

通过以上分析可知,各因素对沙棘枝条切割性能评价指标影响的程度由大到小为刀具滑切角、平均切割速度、枝条喂入速度。

通过逐步回归分析,剔除式(8)~(9)中的不显著项,保留显著项(P<0.05),简化模型得:

P_q = 48.78 - 3.07A - 3.89C + 3{B^2} - 1.6{C^2} (10) w = 64.52 - 3.45A - 4.76C + 3.6{B^2} - 1.9{C^2} (11) 各因素交互作用对评价指标的影响如图10所示。随着平均切割速度和刀具滑切角的增大、枝条喂入速度的减小,单位直径峰值力和单位面积切割功耗减小,符合单因素试验获得的相关结论。

将沙棘枝条切割性能评价指标的最小值作为优化目标,并限定Fmin>0,Tmin>0,其余试验因素水平均限定在−1~1内,通过响应曲面法,利用Design-Expert 13软件对式(10)和式(11)进行优化求解,得到往复式双动刀沙棘枝条切割装置最优参数组合:平均切割速度0.45 m/s、枝条喂入速度0.64 m/s、刀具滑切角9.4°,此时单位直径峰值力为53.33 N/mm,单位面积切割功耗为69.87 kJ/m2。

2.3 验证试验

为检验通过响应曲面法获得的往复式双动刀沙棘枝条切割器最优切割参数的准确性,选择其他3组不同切割参数对评价指标预测模型开展验证试验,每组试验重复3次,所选参数与试验结果如表7所示。由试验结果可知,通过式(10)和式(11)计算的评价指标预测值与试验获得的评价指标实际值的误差低于5%,试验值与预测值拟合性较好,求解的最优参数准确可靠。

表 7 试验验证结果Table 7. Results of verifying tests序号

No.vc/(m∙s−1) vf/(m∙s−1) α0/(°) Pq/(N·mm−1) w/(kJ·m−2) 预测值

Predictive value实际值

Measured value误差

Erros/%预测值

Predictive value实际值

Measured value误差

Erros/%1 0.5 0.5 15 45.8 47.2 3.0 62.6 65.1 3.8 2 0.4 0.6 15 51.9 53.1 2.2 68.0 71.4 4.7 3 0.6 0.5 22.5 43.2 41.6 3.8 58.0 56.7 2.2 3. 讨 论

本文设计的双动刀沙棘枝条切割试验台相较于万能电子试验机,在进行切割性能试验时,能够以较高平均切割速度完成沙棘枝条切割,考虑了切割时惯性力对切割性能的影响,更接近实际作业状态;能够改变枝条喂入速度这一运行参数,可模拟沙棘收获机械在田间的行驶速度变化,具有探究平均切割速度与枝条喂入速度的交互作用对切割性能影响的能力。

本文选定单位直径峰值力和单位面积切割功耗为评价指标,消除了因刀具倾角变化导致最大切割厚度变化及沙棘枝条切割部位由于茎杆节造成的直径差异对试验结果的影响。此外,不同于以峰值切割力或切割功耗为评价指标的单一定性分析,通过响应面法分析Box-Behnken试验数据,本文选定的评价指标从定量和定性两个方面来分析双动刀切割器运行参数及刀具几何参数对沙棘枝条切割性能及切割效果的影响,明确刀具滑切角与平均切割速度对沙棘枝条切割性能影响显著(P<0.01),枝条喂入速度确定时平均切割速度为影响切割截面质量的主要因素。

优化改进方面:该测试台在进行切割试验时的工作环境处于室内,在切割过程中表现出较好的鲁棒性,这与田间作业机具在复杂地形行驶时高强度振动的实际工况有所差异,下一步研究需考虑外界环境对切割过程产生的振动激励,优化试验方案;分析平均切割速度对切割截面质量的影响发现,枝条喂入速度与平均切割速度的比值是双动刀沙棘枝条切割器的一个重要参数,后续可引入切割速比这一参数开展相关影响研究;在刀具参数的选择上,本文只采用通用刀具进行验证性研究,要使双动刀沙棘切割器性能达到更好的效果,还需要开展沙棘专用刀具的研制工作。

4. 结 论

1)本文设计并搭建了往复式双动刀沙棘枝条切割试验台,采用空间曲柄滑槽-摇杆滑块机构作为切割传动机构,并通过建立数学模型以及SolidWorks Motion进行仿真分析,验证其运动特性满足正弦波形;基于Lab VIEW开发了沙棘切割试验数据自动采集软件以满足试验数据采集需求。

2)单因素试验探究了刀具滑切角、平均切割速度、刀刃高度及动刀组数对单位直径峰值力和单位面积切割功耗的影响。试验结果表明,评价指标随着平均切割速度、刀具滑切角和刀刃高度的增大而减小,双动刀比单动刀时的更小。

3)正交试验各因素对评价指标影响的主次顺序为:刀具滑切角、平均切割速度、枝条喂入速度,与单因素试验结果相符;通过响应曲面法得到双动刀沙棘枝条最优切割参数组合为平均切割速度0.45 m/s、枝条喂入速度0.64 m/s、刀具滑切角9.4°,此时,单位直径峰值力为53.33 N/mm,单位面积切割功耗为69.87 kJ/m2。经试验验证,模型误差低于5%,证明拟合性较好,模型可靠。

-

图 2 双动刀切割试验台

1.防护网罩 2.切割装置 3.测控装置 4.传动机构 5.拉压力传感器 6.动态扭矩传感器 7.切割电机及变频器8.切割刀具 9.输送装置 10.夹具 11.输送电机、减速器及变频器

Figure 2. Double movable blades cutting test bench

1. Protective net cover 2. Cutting device 3. Measurement and control device 4. Drive mechanism 5. Pulling pressure sensor 6. Dynamic torque sensor 7. Cutting motor and inverter 8. Cutting tool 9. Conveying device 10. Sample fixture 11. Conveying motor, reducer and frequency converter 注: A 、B 、C 、D 、E 、F 、D’ 、E’ 、F’ 为初始位置机构运动副,A0、B0、C0、E0、F0为下一位置机构运动副;t0 为曲柄长度,mm;l为摆杆长度,mm;r为连杆长度,mm;α为主轴转角,(°);β为曲柄与摆杆夹角,(°);γ为连杆摆动角度,(°);θ为摆杆EF与Y轴夹角,(°)。Note: A, B, C, D, E, F, D’, E’, F’ are the initial position mechanism motion sub, A0, B0, C0, E0, F0 are the next position mechanism motion sub; t0 is the crank length, mm; l is the pendulum length, mm; r is the linkage length, mm; α is the spindle rotation angle, (°); β is the crank and pendulum angle, (°); γ is the swing angle of the linkage, (°); θ is the angle between the pendulum EF and Y axis, (°).

图 4 试验用切割刀片及尺寸参数

注:h为刀刃高度,mm;b为前桥宽,mm;c为刀片底宽,mm;刀片厚度d为2 mm;α0为滑切角,(°);刃口楔角β0为36°;t0为刀片节距,mm;底边间距e为14 mm;S为割刀行程,mm;Ⅰ为7.5°滑切角70 mm刃高动刀,Ⅱ为22.5°滑切角70 mm刃高动刀,Ⅲ为15°滑切角70 mm刃高动刀,Ⅳ为22.5°滑切角35 mm刃高动刀,Ⅴ为15°滑切角35 mm刃高动刀。

Figure 4. Test cutting blades and their dimensional parameters

Note: h is the blade height, mm; b is the front bridge width, mm; c is the blade bottom width, mm; blade thickness d is 2 mm; α0 is the sliding cutting angle, (°); blade wedge angle β0 is 36°; t0 is the blade pitch, mm; bottom edge spacing e is 14 mm; S is the cutter stroke, mm; Ⅰ: 7.5° slip cutting angle and 70 mm blade height, Ⅱ: 22.5° slip cutting angle and 70 mm blade height, Ⅲ: 15° slip cutting angle and 70 mm blade height, Ⅳ: 22.5° slip cutting angle and 35 mm blade height, Ⅴ: 15° slip cutting angle and 35 mm blade height.

表 1 试验台主要技术参数

Table 1 Main technical parameters of test bench

参数Parameters 数值Value 切割速度Cutting speed/(m·s-1) 0~2 枝条喂入速度Branch feeding speed/(m·s-1) 0~2 切割电机功率Power of cutting motor/kW 7.5 枝条输送电机功率Power of branch feeding motor/kW 3 切割幅宽Cutting width/mm 1500 割茬高度Stubble height/mm 200 拉压力量程Tensile force range/N 0~5000(±0.2) 扭矩量程Torque range/(N·m) 0~200(±0.1) 传感器采集频率Acquisition frequency of sensor/kHz 10 数据采集通道数Number of data acquisition channel 3 表 2 单因素试验因素水平表

Table 2 Factors and levels of single factor tests

水平

Levels平均切割速度

Average cutting speed vc/(m∙s −1)刀具滑切角

Sliding cutting angle of blade α0/(°)刀刃高度

Flute length h/mm动刀组数

Number of movable blades1 0.4 7.5 35 单动刀 2 0.5 15 70 双动刀 3 0.6 22.5 4 0.7 5 0.8 表 3 正交试验因素水平表

Table 3 Factors and levels of orthogonal tests

水平Levels 平均切割速度

Average cutting speed vc/(m∙s−1)枝条喂入速度

Stalk feeding speed vf/(m∙s−1)刀具滑切角

Sliding cutting angle of blade α0/(°)−1 0.4 0.5 7.5 0 0.5 0.6 15 1 0.6 0.7 22.5 表 4 刀刃高度及动刀组数对评价指标的影响

Table 4 Effect of blade height and number of movable blade sets on evaluation index

试验序号

Test No.刀刃高度

Blade height

h动刀组数

Number of moving

blade sets水平

LevelsPq/

(N·mm−1)w/

(kJ·m−2)水平

LevelsPq/

(N·mm−1)w/

(kJ·m−2)1 35 mm 57.4 75.9 单动刀 90.0 112.3 2 70 mm 47.1 67.4 双动刀 47.1 63.8 表 5 正交试验设计方案及结果

Table 5 Design scheme and results of orthogonal tests

试验号Test No. A B C Pq/(N·mm−1) w/(kJ·m−2) 1 0 0 0 48.1 63.7 2 0 1 1 44.9 59.9 3 0 1 −1 54.5 71.4 4 −1 0 −1 54.6 71.5 5 0 0 0 49.9 65.9 6 0 −1 −1 54 70.8 7 −1 0 1 45.8 61.0 8 0 0 0 48.1 63.7 9 0 −1 1 47.3 62.8 10 0 0 0 49.7 65.6 11 1 1 0 49.4 65.3 12 1 −1 0 47.9 63.5 13 1 0 1 40.5 54.6 14 1 0 −1 46.5 61.8 15 0 0 0 48.1 63.7 16 −1 1 0 55.1 72.1 17 −1 −1 0 53.4 70.1 注:A,B,C为平均切割速度、枝条喂入速度和刀具滑切角的水平值。 Note:A, B, C are the level values of average cutting speed,stalk feeding speed and sliding cutting angle of blade. 表 6 回归方程方差分析

Table 6 Analysis of the variance of the peak cutting torque regression equation

来源

Sources单位直径峰值力Peak cutting force per unit diameter Pq 单位面积切割功耗Cutting power consumption per unit area w 平方和

Sum of squares自由度

Freedom均方值

Mean squareF P 平方和

Sum of squares自由度

Freedom均方值

Mean squareF P 模型Model 247.74 9 27.53 25.27 0.0002** 352.47 9 39.16 29.10 < 0.0001** A 75.64 1 75.64 69.44 < 0.0001** 95.22 1 95.22 70.75 < 0.0001** B 0.2113 1 0.2113 0.1939 0.6730 0.0313 1 0.0313 0.0232 0.8832 C 120.90 1 120.90 110.98 < 0.0001** 181.45 1 181.45 134.83 < 0.0001** AB 0.0100 1 0.0100 0.0092 0.9264 0.1600 1 0.1600 0.1189 0.7404 AC 1.96 1 1.96 1.80 0.2217 4.41 1 4.41 3.28 0.1132 BC 2.10 1 2.10 1.93 0.2073 3.06 1 3.06 2.28 0.1752 A2 0.4516 1 0.4516 0.4146 0.5402 1.63 1 1.63 1.21 0.3073 B2 37.83 1 37.83 34.73 0.0006** 54.64 1 54.64 40.60 0.0004** C2 10.81 1 10.81 9.93 0.0161* 15.16 1 15.16 11.26 0.0121* 残差Residual 7.63 7 1.09 9.42 7 1.35 失拟Lack of fit 4.14 3 1.38 1.58 0.3261 4.33 3 1.44 1.14 0.4354 误差 Error 3.49 4 0.8720 5.09 4 1.27 总和Total sum 255.36 16 361.90 16 注:P<0.01(极显著,**),0.01≤P<0.05(显著,*),P>0.05(不显著)。 Note: P<0.01(highly significant,**), 0.01≤P<0.05(significant,*), P>0.05(not significant). 表 7 试验验证结果

Table 7 Results of verifying tests

序号

No.vc/(m∙s−1) vf/(m∙s−1) α0/(°) Pq/(N·mm−1) w/(kJ·m−2) 预测值

Predictive value实际值

Measured value误差

Erros/%预测值

Predictive value实际值

Measured value误差

Erros/%1 0.5 0.5 15 45.8 47.2 3.0 62.6 65.1 3.8 2 0.4 0.6 15 51.9 53.1 2.2 68.0 71.4 4.7 3 0.6 0.5 22.5 43.2 41.6 3.8 58.0 56.7 2.2 -

[1] 胡建忠. 我国自然分布的沙棘属植物资源[J]. 植物学研究,2021,10(4):453-467. [2] 汤东,程平,杨建军,等. 天山北坡山前植物对干旱胁迫的生理响应[J]. 干旱区研究,2021,38(6):1683-1694. doi: 10.13866/j.azr.2021.06.20 [3] WANG C, CHU X, ZHAN J, et al. Factors contributing to efficient forest production in the region of the three-north shelter forest program, China[J]. Sustainability, 2019, 12(1):1-19. doi: 10.3390/su12010302 WANG C, CHU X, ZHAN J, et al. Factors contributing to efficient forest production in the region of the three-north shelter forest program, China[J]. Sustainability, 2019, 12(1): 1-19. doi: 10.3390/su12010302

[4] BAL L M, MEDA V, NAIK S, et al. Sea buckthorn berries:A potential source of valuable nutrients for nutraceuticals and cosmeceuticals[J]. Food Research International, 2011, 44(7):1718-1727. doi: 10.1016/j.foodres.2011.03.002 BAL L M, MEDA V, NAIK S, et al. Sea buckthorn berries: A potential source of valuable nutrients for nutraceuticals and cosmeceuticals[J]. Food Research International, 2011, 44(7): 1718-1727. doi: 10.1016/j.foodres.2011.03.002

[5] Wu Q, Zhao H. Soil and water conservation functions of sea-buckthorn and its role in controlling and exploiting Loess Plateau[J]. Forestry Studies, 2000(2):50-56. Wu Q, Zhao H. Soil and water conservation functions of sea-buckthorn and its role in controlling and exploiting Loess Plateau[J]. Forestry Studies, 2000(2): 50-56.

[6] 方贵平,毕金峰,刘春海,等. 中国四个地区代表性沙棘果实综合品质评价[J]. 农业工程学报,2022,38(21):249-260. FANG Guiping, BI Jinfeng, LI Chunhai, et al. Evaluation of the comprehensive quality of sea buckthorn fruit in four areas of China[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022, 38(21): 249-260. (in Chinese with English abstract doi: 10.11975/j.issn.1002-6819.2022.21.029 FANG Guiping, BI Jinfeng, LI Chunhai, et al. Evaluation of the comprehensive quality of sea buckthorn fruit in four areas of China[J]. Transactions of the Chinese Society of Agricultural Engineering, 2022, 38(21): 249-260. doi: 10.11975/j.issn.1002-6819.2022.21.029

[7] 王志强. 沙棘果实采收、采后处理与加工[J]. 农业工程技术,2021,41(17):42,44. doi: 10.16815/j.cnki.11-5436/s.2021.17.023 [8] 彭俊,孙世鹏,傅隆生. 机械振动式沙棘采收的动力学研究[J]. 农机化研究,2017,39(1):32-37. PENG Jun, SUN Shipeng, FU Longsheng. Research on dynamic characteristics of vibratory harvesting for sea buckthorn[J]. Journal of Agricultural Mechanization Research, 2017, 39(1): 32-37. (in Chinese with English abstract doi: 10.3969/j.issn.1003-188X.2017.01.007 PENG Jun, SUN Shipeng, FU Longsheng. Research on Dynamic Characteristics of Vibratory Harvesting for Sea Buckthorn[J]. Journal of Agricultural Mechanization Research, 2017, 39(1): 32-37. doi: 10.3969/j.issn.1003-188X.2017.01.007

[9] 王敏,曹肆林,何义川,等. 机械振动式沙棘采收机的设计[J]. 农机化研究,2013,35(1):109-111. WANG Ming, CAO Silin, HE Yichuan, et al. The design of sea buckthorn picker of mechanical vibration type[J]. Journal of Agricultural Mechanization Research, 2013, 35(1): 109-111. (in Chinese with English abstract doi: 10.3969/j.issn.1003-188X.2013.01.027 WANG Ming, CAO Silin, HE Yichuan, et al. The Design of Sea Buckthorn Picker of Mechanical Vibration Type [J]. Journal of Agricultural Mechanization Research, 2013, 35(01): 109-111. doi: 10.3969/j.issn.1003-188X.2013.01.027

[10] 朱新辉,李丽. 阿勒泰地区沙棘采收机械化存在的问题及建议[J]. 新疆农机化,2011(01):49+52. doi: 10.13620/j.cnki.issn1007-7782.2011.01.020 [11] GAETKE R. TRIQUAR E. First results with an improved sea buckthorn harvesting technology[C]//Cultivation and utilization of wild fruit crops. German:Bernhard Thalacker Verlag Gmbh & Co, 1993:37-41. GAETKE R. TRIQUAR E. First results with an improved sea buckthorn harvesting technology[C]// Cultivation and utilization of wild fruit crops. German: Bernhard Thalacker Verlag Gmbh & Co, 1993: 37-41.

[12] BANTLE M, PIERRE R, WULFSOHN D. Mechanical harvesting trials on Western Canadian native fruits[C]//CSAE Annual Meeting. Mansonville, Canada:CSAE Paper, 1996:96-403. BANTLE M, PIERRE R, WULFSOHN D. Mechanical harvesting trials on Western Canadian native fruits[C]// CSAE Annual Meeting. Mansonville, Canada: CSAE Paper, 1996: 96-403.

[13] MANN D D, PETKAU D, CROWE T, et al. Removal of sea buck-thorn (Hippophae rhamnoides L.) berries by shaking[J]. Canadian Biosystems Engineering, 2001, 43(2):23-28. MANN D D, PETKAU D, CROWE T, et al. Removal of sea buck-thorn (Hippophae rhamnoides L. ) berries by shaking[J]. Canadian Biosystems Engineering, 2001, 43(2): 23-28.

[14] OLANDER S. A review of berry harvest machine development in Sweden[C]//I International Symposium on Mechanical Harvesting and Handling Systems of Fruits and Nuts 965. Leaven:ISHS Acta Horticulturae, 2012:171-177. OLANDER S. A review of berry harvest machine development in Sweden[C]//I International Symposium on Mechanical Harvesting and Handling Systems of Fruits and Nuts 965. Leaven: ISHS Acta Horticulturae, 2012: 171-177.

[15] SHEPHERD C B, LAPPLE C E. Flow pattern and pressure drop in cyclone dust collection[J]. Industrial and engineering chemistry, 1939, 31(8):972-984. doi: 10.1021/ie50356a012 SHEPHERD C B, LAPPLE C E. Flow pattern and pressure drop in cyclone dust collection[J]. Industrial and Engineering Chemistry, 1939, 31(8): 972-984. doi: 10.1021/ie50356a012

[16] FU L, SU H, LI R, et al. Harvesting technologies for sea buckthorn fruit[J]. Engineering in Agriculture, Environment and Food, 2014, 7(2):64-69. doi: 10.1016/j.eaef.2013.10.002 FU L, SU H, LI R, et al. Harvesting technologies for sea buckthorn fruit[J]. Engineering in Agriculture, Environment and Food, 2014, 7(2): 64-69. doi: 10.1016/j.eaef.2013.10.002

[17] DEMENKO V, LEVINSKY M, MIKITYIK O. Abscisic acid, ethylene, growth and fruit drop in sea buckthorn[J]. Acta Horticulturae, 1986, 179:639-644. DEMENKO V, LEVINSKY M, MIKITYIK O. Abscisic acid, ethylene, growth and fruit drop in sea buckthorn[J]. Acta Horticulturae, 1986, 179: 639-644.

[18] OLANDER, S A review of berry harvest machine development in Sweden[J]. Acta Horticulturae, 2012, 965:171-177. OLANDER S. A review of berry harvest machine development in Sweden[J]. Acta Horticulturae, 2012, 965: 171-177.

[19] 赵湛,李耀明,徐立章,等. 超级稻单茎秆切割力学性能试验[J]. 农业机械学报,2010,41(10):72-75. ZHAO Zhan, LI Yaoming, XU Lizhang, et al. Experiment on cutting mechanical property of single super rice stalk[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(10): 72-75. (in Chinese with English abstract ZHAO Zhan, LI Yaoming, XU Lizhang, et al. Experiment on Cutting Mechanical Property of Single Super Rice Stalk[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(10): 72-75.

[20] 孔凡婷,王德福,石磊,等. 圆盘切割式蓖麻采摘装置设计与试验[J]. 农业工程学报,2021,37(23):1-9. KONG Fanting, WANG Defu, SHI Lei, et al. Design and experiment of disc-cutting picking device of castor[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(23): 1-9. (in Chinese with English abstract doi: 10.11975/j.issn.1002-6819.2021.23.001 KONG Fanting, WANG Defu, SHI Lei, et al. Design and experiment of disc-cutting picking device of castor[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(23): 1-9. doi: 10.11975/j.issn.1002-6819.2021.23.001

[21] 冉军辉,沐森林,李海同,等. 油菜联合收获机往复式双动割刀行星轮驱动器设计与试验[J]. 农业工程学报,2020,36(9):17-25. RAN Junhui, MU Senlin, LI Haitong, et al. Design and test of planet gear driver of reciprocating double-acting cutter for rapeseed combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(9): 17-25. (in Chinese with English abstract doi: 10.11975/j.issn.1002-6819.2020.09.002 RAN Junhui, MU Senlin, LI Haitong, et al. Design and test of planet gear driver of reciprocating double-acting cutter for rapeseed combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(9): 17-25. doi: 10.11975/j.issn.1002-6819.2020.09.002

[22] 郇晓龙,尤泳,王德成,等. 王草收获机旋转刀盘式平茬切割装置设计与试验[J]. 农业机械学报,2022,53(5):112-124. XUAN Xiaolong, YOU Yong, WANG Decheng, et al. Design and experiment of rotary cutter disc type flat stubble cutting device for king grass harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(5): 112-124. (in Chinese with English abstract XUAN Xiaolong, YOU Yong, WANG Decheng, et al. Design and Experiment of Rotary Cutter Disc Type Flat Stubble Cutting Device for King Grass Harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(05): 112-124.

[23] 宋占华,宋华鲁,耿爱军,等. 棉花秸秆双支撑切割性能试验[J]. 农业工程学报,2015,31(16):37-45. SONG Zhanhua, SONG Hualu, GENG Aijun, et al. Experiment on cutting characteristics of cotton stalk with double supports[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(16): 37-45. (in Chinese with English abstract doi: 10.11975/j.issn.1002-6819.2015.16.006 SONG Zhanhua, SONG Hualu, GENG Aijun, et al. Experiment on cutting characteristics of cotton stalk with double supports[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(16): 37-45. doi: 10.11975/j.issn.1002-6819.2015.16.006

[24] 宋占华,宋华鲁,闫银发,等. 棉花秸秆往复式切割器动刀片优化设计[J]. 农业工程学报,2016,32(6):42-49. SONG Zhanhua, SONG Hualu, YAN Yinfa, et al. Optimizing design on knife section of reciprocating cutter bars for harvesting cotton stalk[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(6): 42-49. (in Chinese with English abstract SONG Zhanhua, SONG Hualu, YAN Yinfa, et al. Optimizing design on knife section of reciprocating cutter bars for harvesting cotton stalk[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(06): 42-49.

[25] 莫瀚宁,李尚平,邱辰,等. 刀盘轴向振动和切割参数对甘蔗收获机切割质量的影响[J]. 农业工程学报,2022,38(18):62-71. MO Hanning, LI Shangping, QIU Chen, et al. Effects of the blade disk vibration in axial and cutting parameters on the cutting quality of sugarcane harvesters[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022, 38(18): 62-71. (in Chinese with English abstract doi: 10.11975/j.issn.1002-6819.2022.18.007 MO Hanning, LI Shangping, QIU Chen, et al. Effects of the blade disk vibration in axial and cutting parameters on the cutting quality of sugarcane harvesters[J]. Transactions of the Chinese Society of Agricultural Engineering, 2022, 38(18): 62-71. doi: 10.11975/j.issn.1002-6819.2022.18.007

[26] 白秋薇,简真,吴永烽,等. 基于切割压力的甘蔗收割机刀盘高度自动调节装置[J]. 农业工程学报,2021,37(3):19-26. BAI Qiuwei, JIAN Zhen, WU Yongfeng, et al. Automatic height-adjustment for a cutter disk on a sugarcane harvester using cutting pressure[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(3): 19-26. (in Chinese with English abstract doi: 10.11975/j.issn.1002-6819.2021.03.003 BAI Qiuwei, JIAN Zhen, WU Yongfeng, et al. Automatic height-adjustment for a cutter disk on a sugarcane harvester using cutting pressure[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(3): 19-26. doi: 10.11975/j.issn.1002-6819.2021.03.003

[27] 李耀明,秦同娣,陈进,等. 玉米茎秆往复切割力学特性试验与分析[J]. 农业工程学报,2011,27(1):160-164. LI Yaoming, QIN Tongdi, CHEN Jin, et al. Experimental study and analysis on mechanical property of corn stalk reciprocating cutting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(1): 160-164. (in Chinese with English abstract doi: 10.3969/j.issn.1002-6819.2011.01.025 LI Yaoming, QIN Tongdi, CHEN Jin, et al. Experimental study and analysis on mechanical property of corn stalk reciprocating cutting [J]. Transactions of the Chinese Society of Agricultural Engineering, 2011, 27(1): 160-164. doi: 10.3969/j.issn.1002-6819.2011.01.025

[28] 周杨. 工业大麻圆盘切割装置的设计与试验研究[D]. 北京: 中国农业科学院, 2017. ZHOU Yang. Design and Experimental Research of Hemp Plate Cutter[D]. Beijing: Chinese Academy of Agricultural Sciences, 2017.

[29] 韩余,宋志禹,陈巧敏,等. 弧型往复双动式采茶切割器优化与试验[J]. 农业工程学报,2022,38(24):35-43. HAN Yu, SONG Zhiyu, CHEN Qiaomin, et al. Optimization and experiment of arc type reciprocating double-acting tea picking cutter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022, 38(24): 35-43. (in Chinese with English abstract doi: 10.11975/j.issn.1002-6819.2022.24.004 HAN Yu, SONG Zhiyu, CHEN Qiaomin, et al. Optimization and experiment of arc type reciprocating double-acting tea picking cutter[J]. Transactions of the Chinese Society of Agricultural Engineering, 2022, 38(24): 35-43. doi: 10.11975/j.issn.1002-6819.2022.24.004

[30] 靳伟,丁幼春,白圣贺,等. 油葵收获机拨禾板式割台装置研制[J]. 农业工程学报,2021,37(3):27-36. JIN Wei, DING Youchun, BAI Shenghe, et al. Design and experiments of the reel board header device for an oil sunflower harvester[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(3): 27-36. (in Chinese with English abstract doi: 10.11975/j.issn.1002-6819.2021.03.004 JIN Wei, DING Youchun, BAI Shenghe, et al. Design and experiments of the reel board header device for an oil sunflower harvester[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(3): 27-36. doi: 10.11975/j.issn.1002-6819.2021.03.004

[31] 康峰,仝思源,张汉石,等. 苹果枝条往复式切割剪枝参数分析与试验[J]. 农业工程学报,2020,36(16):9-16. KANG Feng, TONG Siyuan, ZHANG Hanshi, et al. Analysis and experiments of reciprocating cutting parameters for apple tree branches[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(16): 9-16. (in Chinese with English abstract doi: 10.11975/j.issn.1002-6819.2020.16.002 KANG Feng, TONG Siyuan, ZHANG Hanshi, et al. Analysis and experiments of reciprocating cutting parameters for apple tree branches[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(16): 9-16. doi: 10.11975/j.issn.1002-6819.2020.16.002

[32] 侯加林,蒋韬,吴彦强,等. 小麦秸秆往复式切割试验台设计与应用[J]. 农业机械学报,2014,45(S1):101-106. HOU Jialin, JIANG Tao, WU Yanqiang, et al. Design and experiment of wheat straw cutting reciprocating test bench[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(S1): 101-106. (in Chinese with English abstract doi: 10.6041/j.issn.1000-1298.2014.S0.017 HOU Jialin, JIANG Tao, WU Yanqiang, et al. Design and Experiment of Wheat Straw Cutting Reciprocating Test Bench[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(S1): 101-106. doi: 10.6041/j.issn.1000-1298.2014.S0.017

[33] 沈成,陈巧敏,李显旺,等. 双动刀苎麻茎秆切割试验台设计与试验[J]. 中国农机化学报,2013,34(5):114-118,145. SHEN Cheng, CHEN Qiaomin LI Xianwang, et al. Design and experiment on double-knife ramie stalk cutting test bench[J]. Journal of Chinese Agricultural Mechanization, 2013, 34(5): 114-118,145. (in Chinese with English abstract SHEN Cheng, CHEN Qiaomin LI Xianwang, et al. Design and experiment on double-knife ramie stalk cutting test bench[J]. Journal of Chinese Agricultural Mechanization, 2013, 34(05): 114-118,145.

[34] 沈成,李显旺,张彬,等. 苎麻茎秆台架切割试验与分析[J]. 农业工程学报,2016,32(1):68-76. SHEN Cheng, LI Xianwang, ZHANG Bin, et al. Bench experiment and analysis on ramie stalk cutting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(1): 68-76. (in Chinese with English abstract SHEN Cheng, LI Xianwang, ZHANG Bin, et al. Bench experiment and analysis on ramie stalk cutting[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(1): 68-76.

[35] 施印炎,汪小旵,章永年,等. 芦蒿有序收获机往复切割力影响因素试验与分析[J]. 中国农机化学报,2018,39(12):46-53. SHI Yinyan, WANG Xiaochan, ZHANG Yongnian, et al. Test and analysis on the influence factors of reciprocating cutting force of Artemisia Selengensis harvester[J]. Journal of Chinese Agricultural Mechanization, 2018, 39(12): 46-53. (in Chinese with English abstract doi: 10.13733/j.jcam.issn.2095-5553.2018.12.08 SHI Yinyan, WANG Xiaochan, ZHANG Yongnian, et al. Test and analysis on the influence factors of reciprocating cutting force of Artemisia Selengensis harvester. [J]. Journal of Chinese Agricultural Mechanization, 2018, 39(12): 46-53. doi: 10.13733/j.jcam.issn.2095-5553.2018.12.08

[36] MCRANDAL D M. Impact cutting behavior of forage crops mathematical model and laboratory tests[J]. Journal of Agricultural Engineering Research, 1978, 23(3):313-328. doi: 10.1016/0021-8634(78)90104-X MCRANDAL D M. Impact cutting behavior of forage crops mathematical model and laboratory tests[J]. Journal of Agricultural Engineering Research, 1978, 23(3): 313-328. doi: 10.1016/0021-8634(78)90104-X

[37] FINNER M F. Particle movement through the cutter-head of a cylindrical type forage harvester[J]. Transactions of the American Society of Agricultural Engineers, 1975, 18(6):1017-1020. doi: 10.13031/2013.36728 FINNER M F. Particle movement through the cutter-head of a cylindrical type forage harvester[J]. Transactions of the American Society of Agricultural Engineers, 1975, 18(6): 1017-1020. doi: 10.13031/2013.36728

[38] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会 GB/T1931-2009, 木材含水率测定方法[S]. 北京: 中国标准出版社, 2009. [39] 中华人民共和国国家质量监督检验检疫总局农业机械-切割器: GB/T1209.1-2009[S]. 北京: 中国标准出版社, 2010. -

期刊类型引用(5)

1. 冼海英,肖波,姚小萌,窦韦强. 黄土高原生物结皮覆盖下表层土壤有机碳组分对模拟气候暖湿化的响应. 应用生态学报. 2025(01): 132-140 .  百度学术

百度学术

2. 黄艳平,罗贵文,高林海,付金霞,李志. 东北平原土体厚度和土壤水分的空间变异. 水土保持研究. 2025(03): 108-118 .  百度学术

百度学术

3. 李斯佳,王冰,王子昊,张秋良. 基于PLUS-InVEST模型的大兴安岭农林交错区碳储量时空变化及驱动力分析. 农业工程学报. 2024(21): 232-241 .  本站查看

本站查看

4. 张龙江,陈国平,林伊琳,赵俊三,刘俸汝,彭苏芬. 基于MOP-PLUS-InVEST模型的碳储量多情景模拟及驱动机制分析. 农业工程学报. 2024(22): 223-233 .  本站查看

本站查看

5. 夏楠 ,李安澜 ,全伟琳 ,唐梦迎 ,唐玉倩 ,徐战江 . 基于GTWR的中国近地面臭氧污染及驱动因素分析. 农业工程学报. 2024(23): 283-293 .  本站查看

本站查看

其他类型引用(0)

下载:

下载: