Analysis of the performance and cooling uniformity of mobile cold storage

-

摘要:

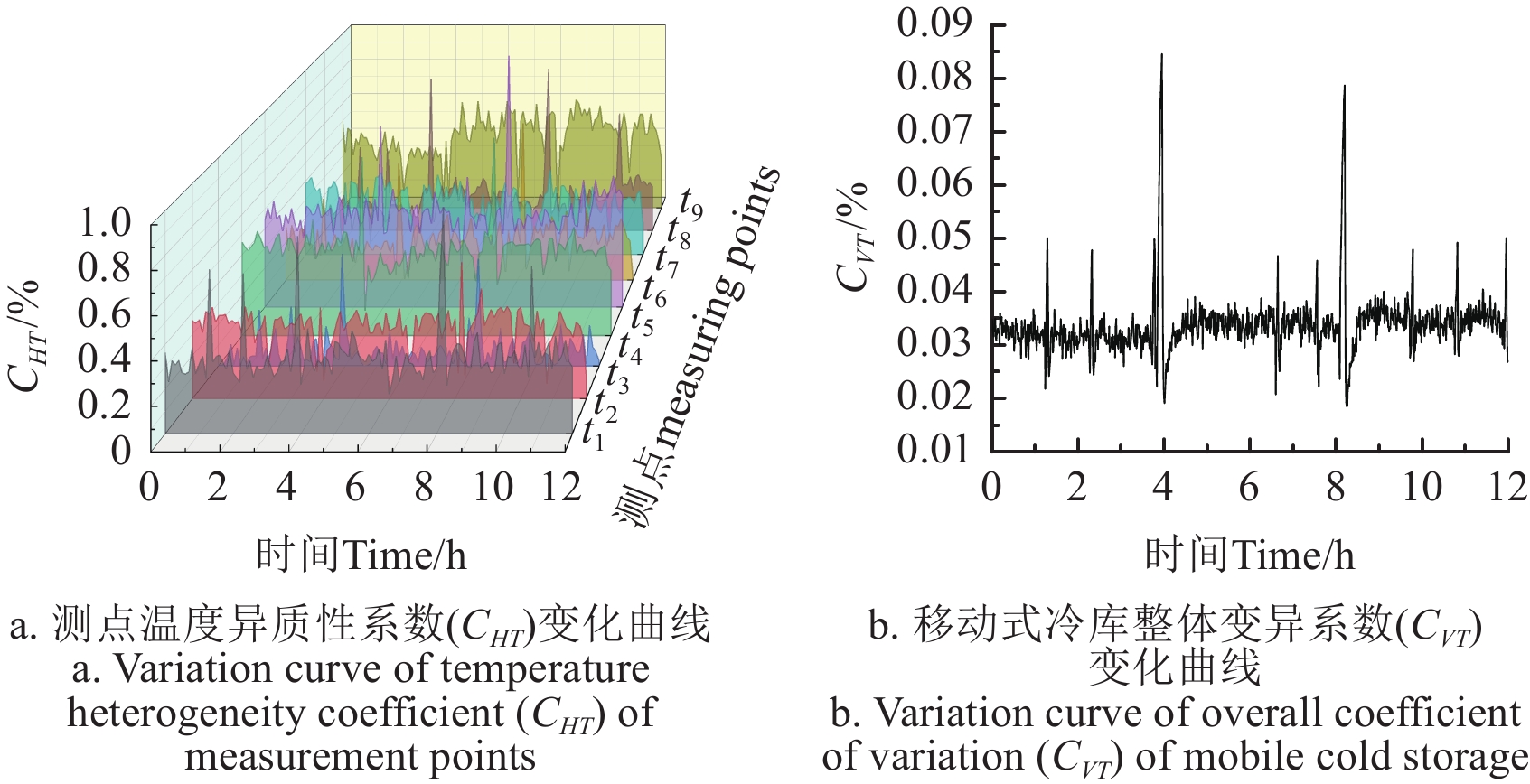

针对果蔬冷链运输过程中采摘后的“最先一公里”的保鲜问题,该研究开发了一种移动式冷库。该设备用于田间果蔬预冷以及冷藏,以消除果蔬采摘后的田间热和呼吸热。对该设备冷库库板的导热热阻、机组制冷系数以及冷库内部的冷却均匀性进行了性能试验研究,并采用温度异质性系数和温度变异系数用以评价冷库内部的冷却均匀性。结果表明,冷库板的导热热阻为3.98 m2·°C/W,制冷一体机的制冷系数为2.07,具有较高的导热热阻以及制冷系数,有利于设备的节能运行;设备运行过程中冷库门侧左上角测点处具有较低的温度异质性系数为0.08 %,制冷机组侧右上角测点处具有较高的温度异质性系数为0.48 %,冷库整体的温度变异系数为0.034%,不论是温度异质性系数还是温度变异系数均低于0.5 %,可以认为该冷库具有较高的冷却均匀性,将有利于降低果蔬预冷过程的损腐率。

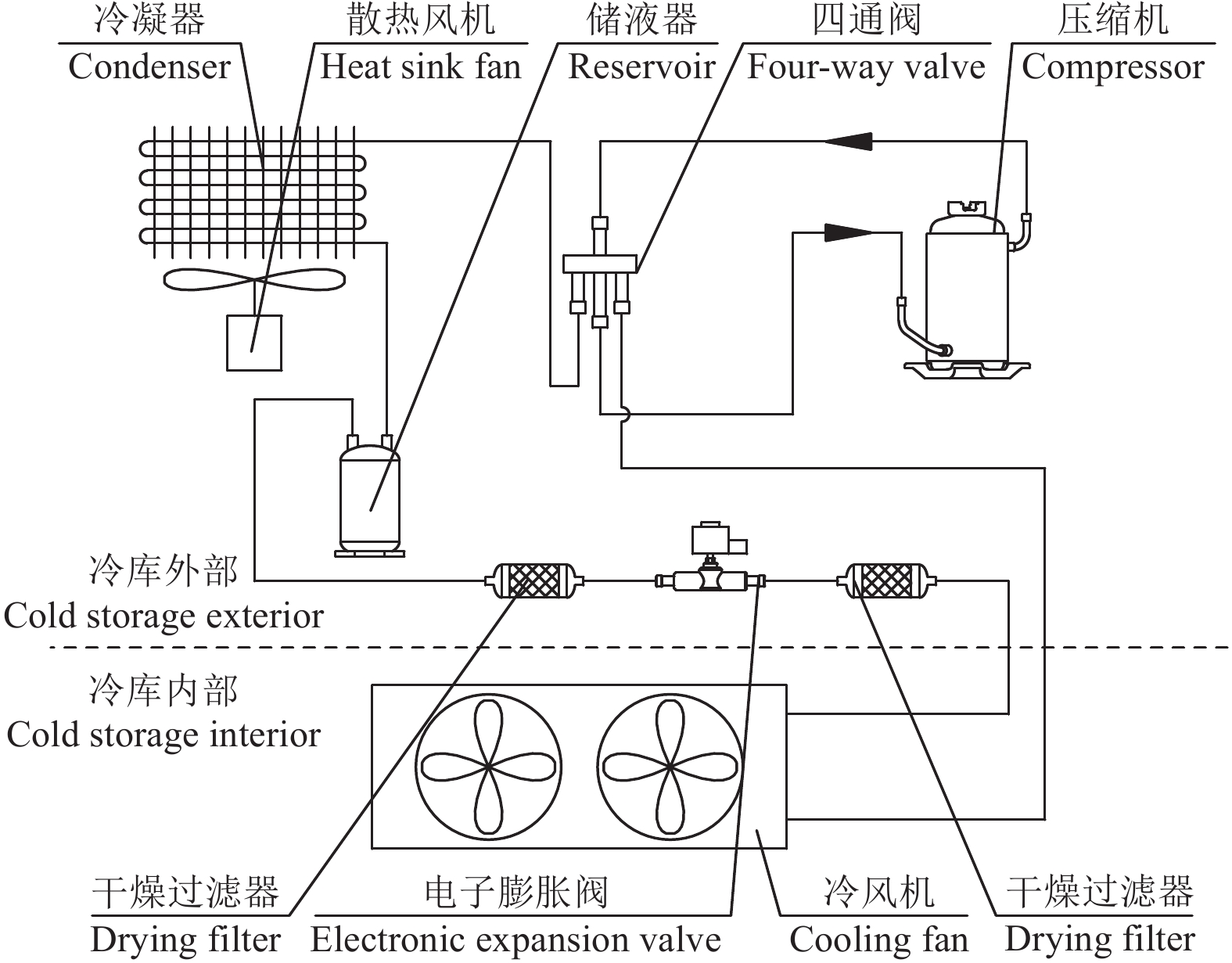

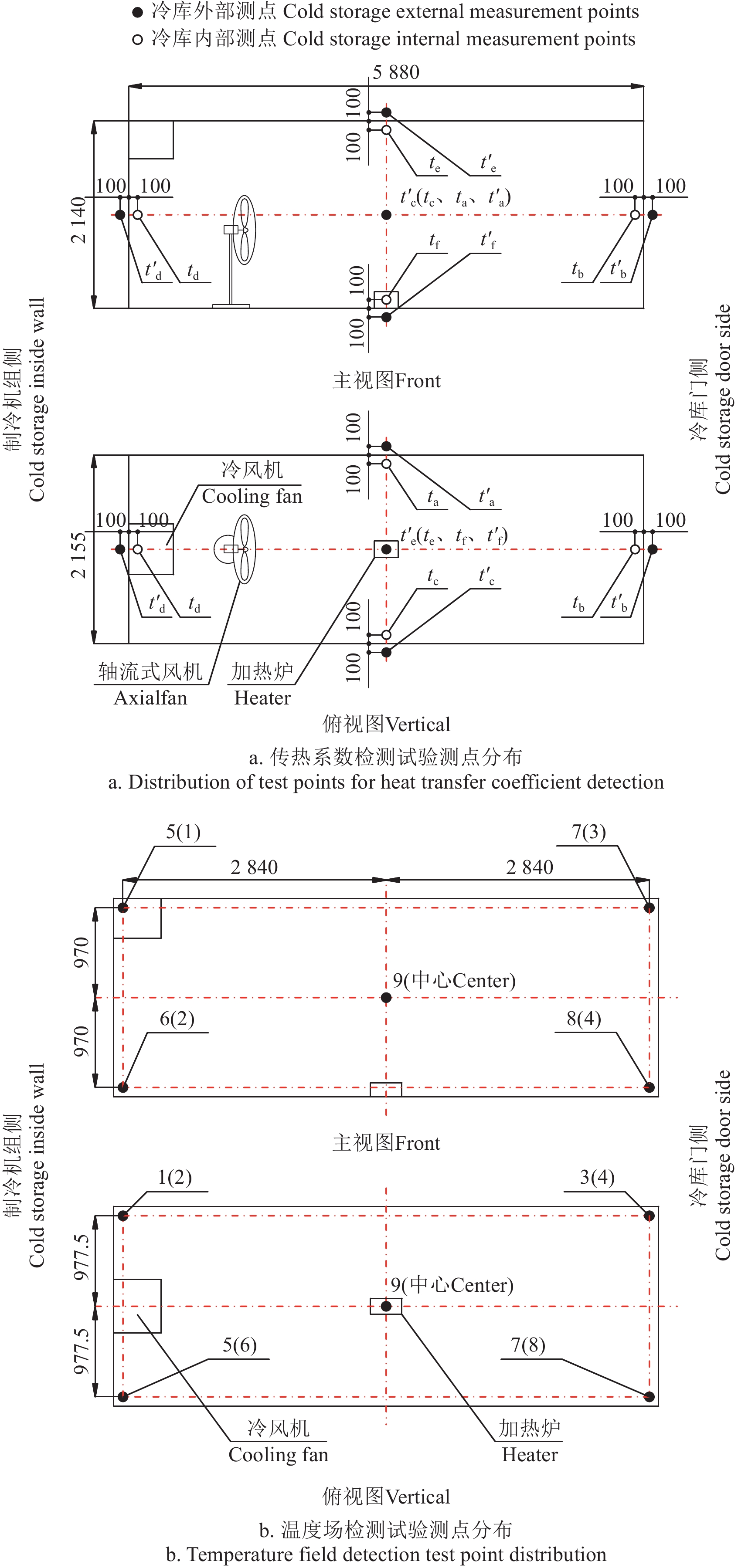

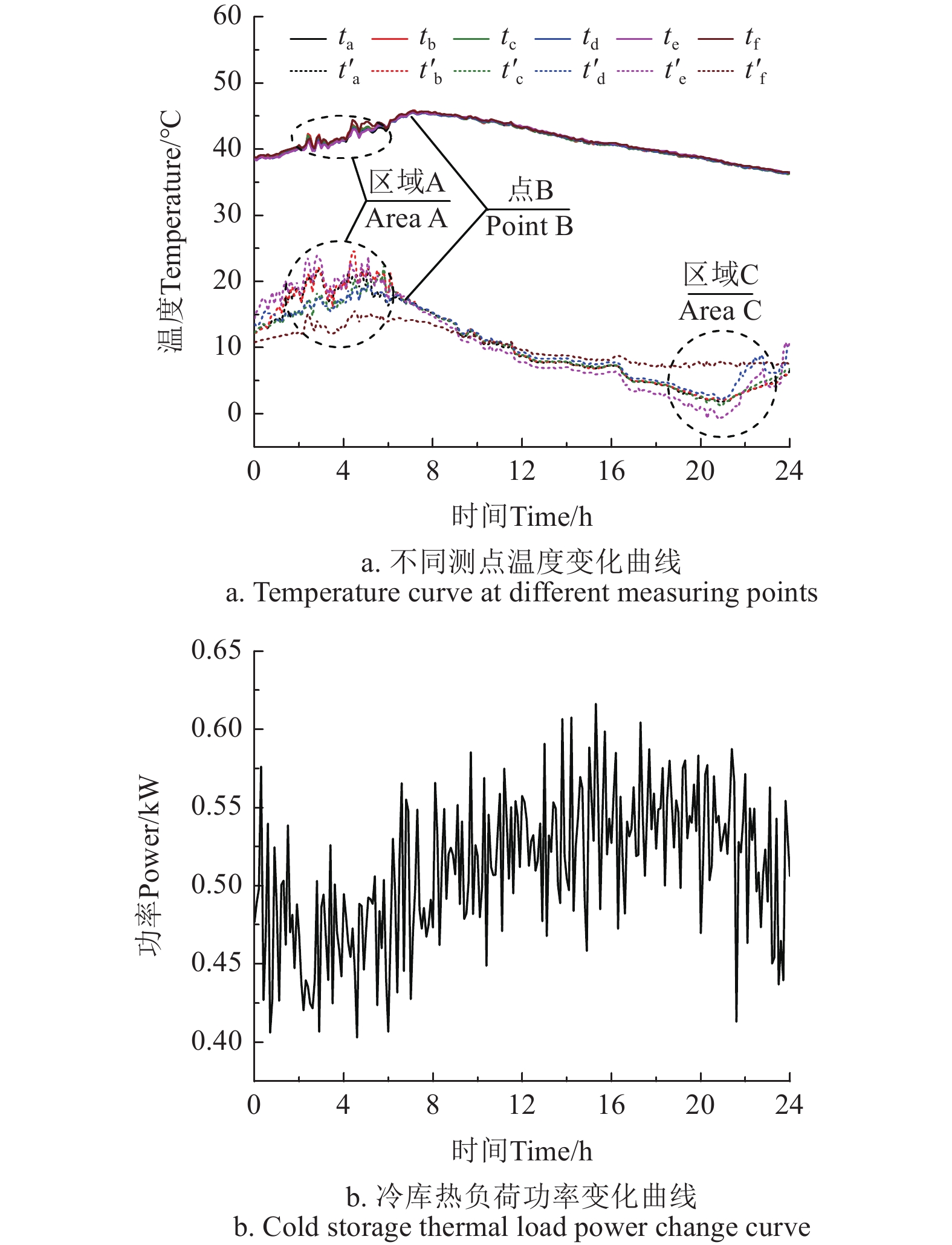

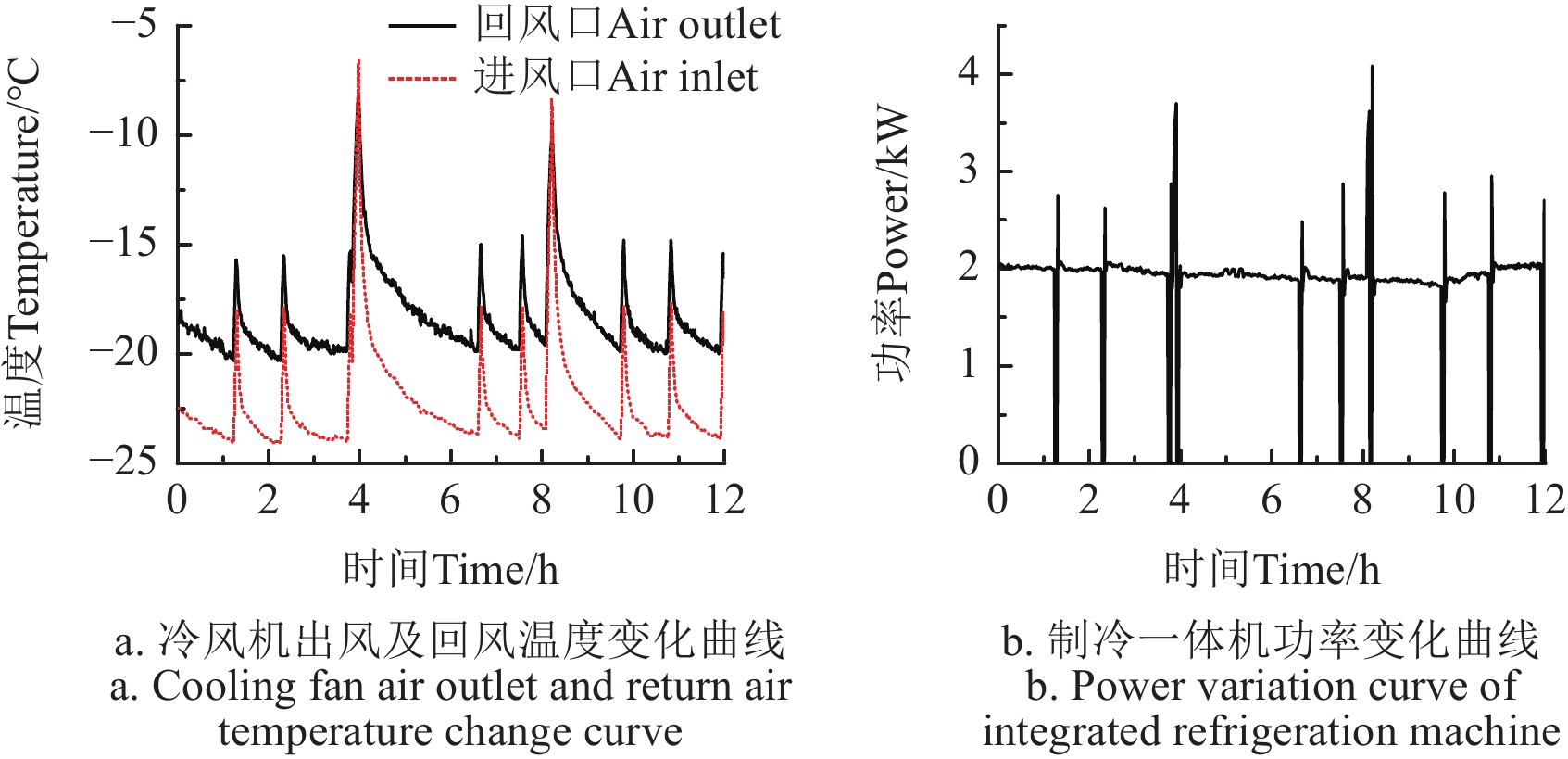

Abstract:Fruits and vegetables still have vital signs after harvest. Their field heat and respiration of biological entities can greatly dominate the quality of fresh products for a better shelf life. This study aims to keep the fruit and vegetable fresh in the first kilometer after picking during cold chain transportation. An integrated equipment system of mobile cold storage and refrigeration was developed for the precooling and storage of fruits and vegetables in fields, in order to eliminate the field heat and respiratory heat after picking. The performance of the equipment was analyzed from three aspects: the thermal resistance of cold storage panels, the coefficient of performance of the integrated refrigeration, and the cooling uniformity inside the cold storage. Among them, the cooling uniformity was also evaluated using temperature heterogeneity and variation coefficients. Two experiments were carried out to verify the performance and cooling uniformity of mobile cold storage. The heat balance method was used to measure the thermal resistance. Notably, the integrated refrigeration machine was also shut down during the experiment. The temperature difference between the inside and outside of the cold storage was maintained by the external heater and axial fan. Temperature measurement points were arranged 100 mm away from the geometric center of the inside and outside of the cold storage. At the same time, there were eight measuring points 100 mm from three sides of the cold storage top angle inside the cold storage, one of which was arranged in the geometric center of the cold storage. As such, the temperature field distribution was measured to calculate the performance and cooling uniformity of the mobile cold storage, according to the flow and heat transfer characteristics. The results showed that the high thermal resistance of the cold storage panels is 3.98 m2·℃/W and the coefficient of performance of the integrated refrigeration machine is 2.07, which were conducive to the energy-saving operation of the equipment. There was a small overall fluctuation (about 0.1%) of the temperature heterogeneity coefficient at each measurement point in the process of equipment operation. The largest overall fluctuation was lower than 1%, only when the integrated refrigeration machine was shut down and defrosted. The temperature heterogeneity coefficient was lower at the upper left corner of the cold storage door (0.08 %), and higher at the upper right corner of the refrigeration unit (0.48 %). The temperature coefficient of variation was 0.034% in the integrated refrigeration machine. Both the temperature heterogeneity and variation coefficients were lower than 0.5 %. Therefore, cold storage with high cooling uniformity can be beneficial to reduce the decay rate of fruits and vegetables in the process of pre-cooling.

-

0. 引 言

随着农业装备不断向现代化、智能化和规模化发展[1],工业机器人的应用范围扩展至农业装备领域是必然趋势。旋转矢量(rotate vector,RV)减速器具有体积小、传动比范围大、质量轻、精度保持稳定、效率高等特点,农业机械经常需要大比例减速的情况,常选用RV减速器[2]。RV减速器作为农业机器人及农业机械的核心传动部件,其健康状况直接决定了传动精度、可靠性、生产效率和农机寿命。然而,由于RV减速器结构复杂,且在实际工作中工况多变,作业环境恶劣,随时发生故障[3]。RV减速器故障严重时会导致生产停滞,造成巨大的经济损失。因此,研究农业机器人RV减速器的故障诊断方法,及早发现并处理故障,缩短维护时间,对保障机器人安全运行、提高企业生产效率和经济效益具有重大意义。

振动信号能够有效反映部件的健康状态,在故障诊断中得到广泛应用[4]。近年来,许多学者对此开展了研究,提出了神经网络[5]、深度学习[6]、时频分析[7]、盲反卷积[8]等方法。汪久根等[9]采用残差网络提高了RV减速器不同故障的分类准确率。YIN等[10]开发了一种基于知识和数据双驱动的传输网络用于RV减速器故障诊断。彭鹏等[11]提出了一种抗干扰的 RV 减速器故障识别卷积神经网络模型。韩特等[12]在深度特征嵌入空间下构建特征图,通过标签传播算法生成伪标签,利用信息熵评估健康状态概率的分布。上述关于RV减速器的故障诊断精度较高,主要采用神经网络、深度学习、机械学习等算法,但是此类算法的实现需要大量不同类型的数据支撑。而基于时域、频域或时频域的分析方法能够在少量数据的支撑下完成故障诊断。XIE等[13]提出了一种基于电流信号的瞬时频率趋势图与参数自适应变分模态分解算法相结合的RV减速器故障诊断方法,实现了RV减速器太阳轮故障特征提取。GUO等[14]将计算阶跟踪和同步平均相结合识别了RV减速器行星齿轮齿根裂纹故障。雷亚国等[15]利用脊线提取完成RV减速器振动信号的平稳数据截取,有效提取了RV减速器行星轮的故障信息。由于RV减速器因润滑、制造误差和不合理受力会引起各种机械故障,使得实际运行中裂纹、点蚀等故障往往同时或先后出现,传感器采集的信号往往是多个故障源相互耦合的结果,使故障诊断变得非常困难。文献[13-15]提出的故障诊断方法适于单一故障诊断,对RV减速器复合故障检测能力下降甚至失效。因此,如何在复合故障相互耦合以及往复运动、时变转速工况下,精确分离提取耦合故障特征是RV减速器故障诊断领域亟待攻克的难题。盲源分离(blind source separation,BSS)技术可以在传输通道未知的情况下,从混合信号中把多个信号源分离出来。独立成分分析(independent component analysis,ICA) [16]和稀疏分量分析(sparse component analysis,SCA) [17] 是常用的以信号处理技术求解BSS问题。ICA算法的前提是源信号是统计独立的,且每个独立分量必须符合非高斯分布。而现代机械设备难以满足统计独立性的假设,但SCA方法的稀疏性假设相对容易满足。

SCA算法中,聚类方法是混合矩阵估计的首选。WANG等[18]提出了一种两阶段的聚类算法,从而提高了混合矩阵的估计精度。NORSALINA等[19]引入自适应时频阈值提高混合矩阵估计的精度。DING等[20]利用同步压缩S变换估计含谐波传输阻抗的混合矩阵。密度峰值聚类算法(density peak clustering,DPC)考虑局部密度和相对距离绘制决策图,快速识别簇中心并完成聚类。 DPC具有唯一输入参数,无需先验知识和迭代[21]。在解决振动源数目估计方面有一定的潜力。SCA算法还包括了源信号的恢复,主流方法有两类:一是通过优化逼近L0范数的函数恢复源信号。BU等[22]使用光滑的连续函数来近似L0范数。ZHANG等[23]用复三角函数逼近L0范数。但是上述方法具有源信号射入方向越近恢复精度越低。二是压缩感知(compressed sensing,CS)重构算法[24],该方法使用L1范数优化取代L0范数优化恢复源信号,避免了L0范数优化的NP-Hard问题。正交匹配追踪算法(orthogonal matching pursuit,OMP)克服匹配追踪算法的缺陷,在算法迭代过程中,残差能够与已经选择的原子正交,保证相同索引不会被重复选择,迭代过程在有限的次数内收敛[25],在重构信号算法的研究中发挥了重要作用。

结合上述分析,本文提出一种基于时频图像脊线提取与改进稀疏分量分析相结合的RV减速器复合故障盲提取方法,旨在实现往复运动、时变转速、故障源数目未知工况下的RV减速器复合故障诊断。首先使用时频图像脊线提取(ridge extraction from time-frequency images,RETF)从时频图中提取脊线,完成对平稳信号的同步截取,然后利用sinC函数改进形态滤波(sinC-morphological filtering,SMF)、DPC和OPM相结合的盲源分离方法(SMF-DPC-OMP)实现平稳信号复合故障的分离提取,采用SMF对观测信号进行滤波降噪处理,在提高信噪比的同时突出信号的冲击分量,并对滤波后的信号进行密度峰值聚类处理,得到聚类中心,构建传感矩阵;接着将滤波后的信号转换到频域以满足SCA的稀疏性要求;最后利用OMP算法在频域重构源信号,在提高计算速度和适应性的同时,实现复合故障特征的提取。

1. 盲分离的数学模型

盲源分离是指在源信号和信号传输通道均未知的情况下,仅依赖传感器拾取的观测信号恢复和估计源信号的技术[26]。含噪声SCA的数学模型为

Xm×t=Am×nSn×t+Vm×t (1) 式中X为观测矩阵,即采集到的振动信号;A为混合矩阵;S是具有稀疏性的未知源信号;V为噪声或其他随机干扰成分;m为传感器数量;n为源信号数量;t为观测时间,s。

2. 基于时频图像的脊线提取

短时傅里叶变换(short-time fourier transform,STFT)是有效捕获时变频率的方法之一,其定义为[27]

Q(t,f)=∫Rx(τ)hσ(τ−t)e−j02π fτdτ (2) 式中x(τ) 为多分量信号;Q(t,f)是信号的时频表达(time frequency representation,TFR);hσ(τ−t)是长度为τ的高斯窗;R为实数集;t为时间;f为频率;j表示复数。

从TFR中提取时频脊线估计瞬时频率(instantaneous frequency,IF)是完全非参数的,并且能适应不同的情况。有效的脊线提取方法是寻找TFR的最大位置[27],其定义如下:

¯D(t)=argmax (3) 式中 \overline {{D}} (t) 表示得到的脊线,是理论 {{D}}(t) 的估计, J 是频率的集合,N 为信号截止时间。RETF算法的具体实现步骤如下:

1)初始化参数,并创建一个预存矩阵{{\boldsymbol{K}}_i};

2)对时域信号x\left( t \right)进行STFT变换,得到其时频分布Q\left( {t,f} \right);

3)寻找并标记最大能量点\left[ \begin{gathered} {t_0} \\ {f_0} \\ \end{gathered} \right],将该点存储为{\boldsymbol{K}}矩阵的第一列;

4)使Q\left( {{t_0},f} \right)在最大值点{t_0}附近时刻归0,即Q\left( {{t_0},f} \right) = 0,f \in \left[ {{f_0} - \Delta f,{f_0} + \Delta f} \right],其中\Delta f为滤波带宽惩罚参数,控制滤波带宽;

5)在Q\left( {{t_0},f} \right)的邻域内寻找下一个最大能量点 \left[ \begin{gathered} t_{0}' \\ f_{0}' \\ \end{gathered} \right] = \ {\mathrm{\max}} _{\left( {{t_\alpha },{f_\alpha }} \right)}Q\left( {t,f} \right) 。 {t_\alpha } \in \left[ {{t_0} - 1,{t_0} + 1} \right] ,{f_\alpha } \in \left[ {f_0} -F,{f_0} + F \right],H为选定的窗参数,控制迭代中 \overline {{D}} (t) 增量的平滑程度,H越小, \overline {{D}} (t) 增量越平滑;

6)将 \left[ \begin{gathered} t_0' \\ f_0' \\ \end{gathered} \right] 存储为{\boldsymbol{K}}矩阵的下一列;

7)使Q\left( {t_0',f} \right)在最大值点t_0'附近时刻归0,即Q\left( {t_0',f} \right) = 0,f \in \left[ {{f_0} - \Delta f,{f_0} + \Delta f} \right];

8)如果时间指标{t_\alpha }和频率指标{f_\alpha }未达到TFR矩阵的边界,返回步骤5);否则返回步骤1),并创建一个新的预存矩阵{{\boldsymbol{K}}_{i + 1}};

9)当剩余TFR能量小于阈值\varepsilon 时停止算法(每一个预存矩阵,即是一条时频脊线)。

3. 基于SMF-DPC-OMP的盲源分离

3.1 基于\sin C函数的改进形态滤波降噪

3.1.1 构建\sin C结构元素

\sin C函数又称辛格函数,定义如下:

\sin C\left( x \right) = \frac{{\sin \left( {{\text{π}}x} \right)}}{{{\text{π}}x}} (4) 本文选取 \sin C 函数作为结构元素时主要定义长度L和主瓣比p。长度是指整个图像的长度,主瓣比是指从中间截取整个图像的百分比。图1为L = 20、 p = 50\text{%} 的 {\mathrm{sin}} C 结构元素。

3.1.2 构建平均组合滤波器

形态滤波器的构建主要包括结构元素和形态算子。结构元素的选择包括结构元素的形状、长度、高度(振幅)等。在处理一维信号时 ,结构元素的形状一般有线形、三角形、半圆形、正弦等,本文选择 sin C函数作为结构元素 ,结合形态算子腐蚀Θ、膨胀\oplus 、形态开○和形态闭●,构建基于sinC函数的SMF平均组合滤波器。

设原信号f\left( n \right)和结构元素g\left( m \right)为分别定义在F\left( {1,2, \ldots ,n - 1} \right)和G = \left( {1,2, \ldots, m - 1} \right)上的离散函数, N \geqslant M。则f\left( n \right)关于g\left( m \right)的腐蚀运算、膨胀运算、开运算和闭运算[28]分别为

(f\Theta g)(n) = \min[f(n + m) - g(m)] (5) (f \oplus g)(n) = \max [f(n - m) + g(m)] (6) (f \circ g){\kern 1pt} (n) = (f\Theta g \oplus g)(n) (7) (f \bullet g){\kern 1pt} (n) = (f \oplus g\Theta g)(n) (8) 通常使用形态开和形态闭的级联形式去除信号中的正、负噪声。TANG[28]为了去除信号中的正、负噪声,定义了形态闭-开(closing-opening,CO)和开-闭(opening-closing,OC)滤波器:

{\mathrm{CO}}{\kern 1pt} (f(n)) = (f \bullet g \circ g)(n) (9) {\mathrm{OC}}{\kern 1pt} (f(n)) = (f \circ g \bullet g)(n) (10) 为了抑制统计偏倚,本文采用结合OC和CO的平均组合滤波器[28]:

y(n) = [{\mathrm{OC}}(f(n) + {\mathrm{CO}}(f(n)]/2 (11) 3.1.3 基于\sin C的平均组合滤波器效果验证

为了验证基于{\mathrm{sin}}\; C 函数的SMF滤波效果,生成模拟轴承外圈故障的仿真信号并添加信噪比(signal-to-noise ratio,SNR)为−3 dB的白噪声。图2为含噪声的仿真信号及滤波后的时域波形图,SMF降噪后的信噪比为0.7 dB,说明SMF较好的滤除干扰噪声,突显了信号的冲击特性。

将本文的SMF滤波器与文献[29]中的直线型滤波器(幅值为0,长度为10)进行对比,滤波器参数及滤波效果如图3所示。分析图3可知无论滤波器的参数如何选择,SMF的滤波后的信噪比总是要优于直线型滤波器。

3.2 基于DPC-OMP的盲源分离

3.2.1 DPC理论

DPC算法主要基于2个假设:1)聚类中心周围是低密度的点;2)聚类中心与密度较高的样本点之间的距离较大。设数据集U{{ = }}\left\{ {{u_1},{u_2}, \cdots, {u_R}} \right\}, {u_i}{{ = }}{\left( {{u_{i1}},{u_{i2}}, \cdots, {u_{io}}} \right)^{\mathrm{T}}} ,其中i = 1,2, \cdots ,R,{u_{ij}}表示数据点i的j维属性,j = 1,2, \cdots ,O;R为总体样本数。

1)计算局部密度\rho

对于每个数据点{u_i},i = 1,2, \cdots ,R,局部密度{\rho _i}可以被认为是距离点{u_i}较近的点的数量,{\rho _i}的定义如下[30]:

{\rho _i} = \sum\limits_{j,j \ne i} {\chi \left( {{d_{ij}} - {d_c}} \right)} (12) 式中\chi \left( x \right)为分段函数,x < 0时,\chi \left( x \right){\text{ = }}1,否则\chi \left( x \right){\text{ = 0}};{d_{ij}}表示i和j之间的距离(通常为欧氏距离),{d_c}表示截断距离。

2)计算最近邻距离\delta

每个点的最近邻距离{\delta _i} 为

{\delta _i} = \left\{ \begin{gathered} \mathop {\min \left( {{d_{ij}}} \right)}\limits_{j:{\rho_j} > {\rho_i}} ,{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\rho _i} < \max \left( \rho \right) \\ \mathop {\max \left( {{d_{ij}}} \right)}\limits_j ,{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\rho _i} = \max \left( \rho \right) \\ \end{gathered} \right. (13) 对于密度较低的样本点,计算该样本点与高于其密度的最近样本点之间的距离;而对于密度最高的样本点,则计算该点与最远样本点之间的距离。

3)选取聚类中心 V

聚类中心定义为同时具有高密度{\rho _i}和较大距离{\delta _i}的点{x_i},令{V_i} = {\rho _i}{\delta _i},取 V > \dfrac{2}{N}\displaystyle\sum\limits_{i = 1}^N {{V_i}} 为聚类中心。由于聚类对象为RV故障信号,{V_i}大多为0。为保证不遗漏正确的聚类中心,因此选取大于均值2倍的数据点为聚类中心。

3.2.2 压缩感知重构算法

利用压缩感知重构算法中的OMP算法对源信号进行重构。将 m 个长度为 t 的观测信号表示为 {\boldsymbol{y}} = ({y_{11}}, {y_{12}}, \cdots {y_{1\;t}}, \cdots ,{y_{m1}},{y_{m2}}, \cdots {y_{mt}})^{\mathrm{T}} 。

利用聚类中心 {\boldsymbol{V}}(m \times n) 构造传感矩阵 {\boldsymbol{W}} 。根据压缩感知模型,当混合信号长度为 mt \times 1 ,其传感矩阵 {\boldsymbol{W}} 的长度为 mt \times nt 。利用傅里叶变换正交矩阵 {{\boldsymbol{E}}_{t \times t}} 扩充矩阵 {\boldsymbol{V}} 的元素值,变换关系为 {{\boldsymbol{B}}_{ij}} = {{\boldsymbol{E}}_{t \times t}}{{\boldsymbol{V}}_{ij}} ,具体变换如式(14)所示。

{\boldsymbol{y}} = \left[ \begin{gathered} {{\boldsymbol{{\boldsymbol{B}}}}_{11}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{12}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \cdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{1n}} \\ {{\boldsymbol{B}}_{21}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{21}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \cdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{2n}} \\ {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \vdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \vdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \vdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \vdots \\ {{\boldsymbol{B}}_{m1}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{m2}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \cdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{mn}} \\ \end{gathered} \right]{\boldsymbol{x}} (14) {\boldsymbol{x}} = {({x_{11}},{x_{12}}, \cdots ,{x_{1\;t}}, \cdots ,{x_{n1}},{x_{n2}}, \cdots ,{x_{nt}})^{\mathrm{T}}} 的长度是 (nt \times 1) 。至此,盲源分离的重构模型构建完成。

OMP是一种常用的压缩感知重构算法。首先在每次迭代过程中对所有选定的原子进行Schmidt正交化,以确保每次迭代的结果都是最优解。利用OMP算法进行重构的核心思想是构造频域感知矩阵。具体算法步骤如下:

1)初始化残差 {r_0} ,迭代次数 \ell ,傅立叶正交变换矩阵 {{\boldsymbol{E}}_{t \times t}} ,并根据 {{\boldsymbol{B}}_{ij}} = {{\boldsymbol{E}}_{t \times t}}{{\boldsymbol{V}}_{ij}} 构造传感矩阵 {\boldsymbol{W}}{\kern 1pt} {\kern 1pt} {\text{ = }}{\kern 1pt} {\kern 1pt} {\kern 1pt} \left[ \begin{gathered} {{\boldsymbol{B}}_{11}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{12}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \cdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{1n}} \\ {{\boldsymbol{B}}_{21}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{21}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \cdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{2n}} \\ {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \vdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \vdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \vdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \vdots \\ {{\boldsymbol{B}}_{m1}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{m2}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \cdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{mn}} \\ \end{gathered} \right] ;

2)使用内积法计算传感矩阵 {\boldsymbol{W}} 的列向量与残差{r_i}的投影系数,并记录最大投影系数相对应的位置 {{\boldsymbol{\beta}} _i} ,随后将最大投影系数所对应的传感矩阵 {\boldsymbol{W}} 的列置0;

3)使用最小二乘法计算本次迭代的重构信号的估计值 {x_i} = {({{\boldsymbol{\beta}} _i}^{\mathrm{T}} \cdot {{\boldsymbol{\beta}} _i})^{ - 1}} \cdot {{\boldsymbol{\beta}} _i}^{\mathrm{T}} \cdot {{\boldsymbol{r}}_i} ;

4)更新残差 {r_{i + 1}} = {r_i} - {x_i} ,并重复步骤2),直到迭代结束;

5)使用 {E_{t \times t}} 做逆傅立叶变换得到维数为 (kt \times 1) 的时域信号 x ,并根据聚类中心的维数k,将维数为 (kt \times 1) 的时域信号 x 分割为k个维数为\left( {t \times 1} \right)的时域信号,从而完成信号的盲源分离。

3.3 本文算法总流程

1)平稳阶段截取:提取一组观测信号x\left( t \right)并进行STFT得到其时频表达Q\left( {t,f} \right)。随后提取时频脊线并截取恒速时段信号,获得平稳信号{x_1}\left( t \right);

2)信号预处理:构造基于 \sin C 结构元素的平均组合滤波器,并对平稳信号{x_1}\left( t \right)进行滤波降噪,得到滤波信号{x_2}\left( t \right);

3)估计混合矩阵:对滤波信号{x_2}\left( t \right)进行DPC得到聚类中心,即混合矩阵;

4)源信号重构:利用步骤3)的混合矩阵构造传感矩阵,使用OMP算法在频域重构源信号;

5)故障识别:对重构源信号进行快速傅里叶变换(fast Fourier transform,FFT)处理,根据分离信号频谱中的频率进行故障识别。

本文算法的总体流程图如图4所示。

4. 试验验证

4.1 试验介绍

试验信号来自于模拟农业机器人单关节臂往复运动的RV减速器试验台,如图5所示。将2个型号为333B30的PCB加速度传感器相互垂直安装于减速器保持架上拾取信号。水平方向为传感器1,垂直方向为传感器2。其中,试验台基座7上安装减速器保持架4,通过减速器保持架4装RV减速器5,型号为SV-X2MH100C-B2 LN的电机6输出轴通过RV减速器5连接关节臂1。图6为故障齿轮的实物图,图6a为太阳轮磨损图,图6b为行星轮磨损图。

试验选用RV40E型减速器并以针轮固定的方式固定于试验台,减速比121、行星齿轮数目为2,太阳轮齿数{Z_1} = 12,行星轮齿数{Z_2} = 42,摆线轮齿数{Z_3} = 39,针轮齿数{Z_4} = 40。采集系统包括NI-USB9234采集卡与单向加速度传感器,采样频率为25.6 kHz。试验预设摆臂运动范围为0°~90°(单次抬升或下降90°),运行速度为100°/s。RV减速器的各个特征频率计算式见表1。

表 1 RV减速器各零件的工作频率Table 1. Working frequency of each part of RV reducer名称Name 计算公式Calculation formula 电机主轴转速

Motor spindle speed {n_1}/(r·min−1){n_1} = 60f/P 太阳轮转频

Sun gear rotation frequency {f_1}/Hz{f_1} = {n_1}/60 行星轮转频

Planetary gear rotation frequency {f_2}/Hz{f_2} = \dfrac{{{z_1}{z_4}}}{{({z_3} - {z_4})\left( {{z_1} + {z_2}{z_4}} \right)}}{f_1} 一级啮合频率

First stage engagement frequency {f_{1c}}/Hz{f_{1c}} = \dfrac{{{z_1}{z_2}{z_4}}}{{{z_1} + {z_2}{z_4}}}{f_1} 注:P为伺服电机磁极对数,{{\textit{z}}_1}为太阳轮齿数,{{\textit{z}}_2}为行星轮齿数,{{\textit{z}}_3} 为摆线轮齿数,{{\textit{z}}_4} 为针轮齿数。

Note: P is the number of magnetic poles of the servo moto, {{\textit{z}}_1} is the number of solar gear, {{\textit{z}}_2} is the number of planetary gear, {{\textit{z}}_3} is the number of cycloidal gear, and {{\textit{z}}_4} is the number of needle gear.行星轮故障频率{f_p}为行星轮相对于行星架的旋转频率,{f_p} = {f_2} - {f_3};太阳轮故障频率{f_s}为太阳轮相对于行星架的旋转频率,{f_s} = {f_1} + {f_3}。由于摆臂转速=100(°)/s =0.27 Hz,即支撑盘转频{f_3}=0.27 Hz。根据表1及太阳轮故障频率计算式计算可得太阳轮故障频率{f_s}为38.34 Hz,行星轮故障频率{f_p}为10.83 Hz。

4.2 试验信号分析

由传感器1和传感器2采集的2组信号都具有相同的运动状态,即同时加速或同时减速。因此本文在平稳阶段选取水平方向传感器1的振动信号用以分析机械臂的运动状态。图7为选取的振动信号进行STFT获得的时频图。可以看出,由于RV减速器的瞬时冲击过大,无法通过时频图区分出机械臂的3种运动状态,即启动加速阶段,恒速运动阶段以及减速停滞阶段。

时频图中的脊线对应时频域中能量最大的路径,可以近似看作设备瞬时频率的时频轨迹。对时频图进行脊线提取,结果如图8所示。分析脊线走势能够较为清楚地区分机械臂的不同运行阶段,包括启动加速阶段,平稳运行阶段以及减速停滞阶段(后续分析均为此阶段)。图9a为水平方向传感器1采集信号的时域波形,图9b为垂直方向传感器2采集信号的时域波形。图9时域波形体现了机械臂启动、平稳到停止整个工作过程幅值的变化。依据图8中脊线的平稳阶段区间,在图9中标注同步截取相应时段的时域振动信号(后续分析皆是截取后的振动信号)。

图10a为截取平稳阶段传感器1的信号波形,图10b为截取平稳阶段传感器2信号波形。对图10振动信号进行SMF处理,对图10振动信号进行SMF处理,传感器2的滤波前后的信号波形对比如图11所示,从图11b中能够观测到故障所导致的冲击更加明显。

对滤波后的信号进行包络谱分析,如图12所示,传感器1和传感器2滤波信号的频谱分别如图12a、12b所示。分析图12a、12b发现,太阳轮与行星轮的故障特征频率成分完全混合在一起,故障类型判断困难。

经SMF-DPC-OMP算法处理的频谱如图13所示,图13a的频率谱线集中在37.5 Hz及其倍频,与太阳轮理论计算故障频率38.34 Hz接近,故可推断图13a为太阳轮故障。图13b的频率谱线分布在10.94 Hz及其倍频,与行星轮理论计算故障频率10.83 Hz逼近,故识别其为行星轮故障。相比图12,图13中的频率混合现象已经完全被消除,说明本文方法可实现复合故障的完全分离。采用文献[29]提出的结合形态滤波与稀疏分量分析(MF-SCA)的盲分离算法进行对比进一步验证本文方法的有效性,结果如图14所示,分析可见,图14a、14b均存在太阳轮和行星轮故障特征频率,说明MF-SCA方法无法有效实现RV减速器复合故障的分离。与MF-SCA方法相比,SMF-DPC-OMP算法能够节省约75%的时间运行成本。

5. 结 论

本文结合时频图像脊线提取、\sin C函数改进形态滤波和密度峰值聚类改进的稀疏分量分析各算法的优点,提出一种新的往复运动、变转速工况的RV减速器复合故障盲分离方法。通过RETE算法提取的脊线解决旋转机械变转速的问题,利用SMF-DPC-OMP实现了RV减速器复合故障的分离提取。试验台采集的RV减速器的太阳轮和行星轮磨损复合故障信号的分析结果显示,本文方法能够有效地完成复合故障的盲分离任务,主要结论如下:

1)RETE算法能够在变转速工况导致时频图较为模糊的情况下,识别出RV减速器的运动状态;

2)SMF-DPC-OMP算法能够在故障源数目未知的情况下,有效完成复合故障的盲分离任务;

3)与MF-SCA方法比较,SMF-DPC-OMP算法能够节省约75%的时间运行成本,使得频谱更为简洁,抑制精细侧频和干扰分量。

本文今后的工作将重点放在欠定条件下的故障提取上,或者进一步将该算法推广到旋转机械声信号的故障诊断中。

-

表 1 主要试验装置和仪器型号与参数

Table 1 Models and parameters of main test equipments and instruments

装置及仪器

Devices and equipments型号

Model性能参数

Performance parameters移动式冷库主体结构

The main structure of

mobile cold storage− 箱体外形尺寸:

6058 mm×2435 mm×2550 mm

箱体内部尺寸:

5880 nn×2115 mm×2140 mm压缩机

CompressorNTZ068A4 LR1A 运转功率:1.873 kW 冷凝器

Condenser− − 冷风机

Cooling fan− 功率:135 W,风量:2670 m3/h 热电偶

ThermocoupleTT-T-24-SLE 温度范围:−267~150 °C 数据采集仪

Data acquisition

instrumentGM10 60通道/s 风速仪

AnemometerFluke 量程:0.20~20 m/s,精

度:±0.01 m/s−5%测量值加热炉

Heater− 功率:0.8535 kW 轴流风机

Axial fan− 功率:380W,

风量:57.55 m3/h -

[1] 中华人民共和国国家统计局. 2012年−2021年水果年产量[EB/OL]. [2022-11-01].https: //data.stats.gov.cn/easyquery.htm?cn=C01&zb=A0D0K&sj=2021. [2] Han J W, Zuo M, Zhu W Y, et al. A comprehensive review of cold chain logistics for fresh agricultural products:Current status, challenges, and future trends[J]. Trends in Food Science & Technology, 2021, 109:536-551. Han J W, Zuo M, Zhu W Y, et al. A comprehensive review of cold chain logistics for fresh agricultural products: Current status, challenges, and future trends[J]. Trends in Food Science & Technology, 2021, 109: 536-551.

[3] 冯雅蓉. 预冷方式对红玛瑙樱桃果实冷藏期间真菌多样性的影响[J]. 食品科学,2020,41(11):214-221. FENG Yarong. Pre-cooling methods affect the diversity of fungal communities on red agate cherry fruit during cold storage[J]. Food Science, 2020, 41(11): 214-221. (in Chinese with English abstract doi: 10.7506/spkx1002-6630-20190524-290 Feng Yarong. Pre-cooling Methods Affect the Diversity of Fungal Communities on Red Agate Cherry Fruit during Cold Storage[J]. Food Science, 2020, 41(11): 214-221. (in Chinese with English abstract) doi: 10.7506/spkx1002-6630-20190524-290

[4] 谌英敏,王贺,苏勤,等. 基于GA-BPNN的采后蜜桃预冷效果预测模型[J]. 农业工程学报,2021,37(23):264-272. CHEN Yingmin, WANG He, SU Qin, et al. Prediction model of post-harvest peach pre-cooling effectiveness based on GA-BPNN[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2021, 37(23): 264-272. (in Chinese with English abstract doi: 10.11975/j.issn.1002-6819.2021.23.031 Chen Yingmin, Wang He, Su Qin, et al. Prediction model of post-harvest peach pre-cooling effectiveness based on GA-BPNN[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(23): 264-272. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2021.23.031

[5] GUSTAVSSON J, CEDERBERG C, SONESSON U, et al. Global food losses and food waste:extent, causes and prevention[R]. Food and Agriculture Organization of the United Nations:Rome, Italy, 2011. GUSTAVSSON J, CEDERBERG C, SONESSON U, et al. Global food losses and food waste: Extent, causes and prevention [R]. Food and Agriculture Organization of the United Nations: Rome, Italy, 2011.

[6] 刘广海,马平川,李庆庭,等. 冷链专用蓄冷托盘设计与控温运输性能测试[J]. 农业工程学报,2021,37(16):295-302. LIU Guanghai, MA Pingchuan, LI Qingting, et al. Design of special cold chain pallet and its temperature-controlled transport performance test[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2021, 37(16): 295-302. (in Chinese with English abstract doi: 10.11975/j.issn.1002-6819.2021.16.036 Liu Guanghai, Ma Pingchuan, Li Qingting, et al. Design of special cold chain pallet and its temperature-controlled transport performance test[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(16): 295-302. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2021.16.036

[7] HAN J W, RUIZ-GARCIA L, QIAN J P, et al. Food packaging:a comprehensive review and future trends[J]. Comprehensive Reviews in Food Science and Food Safety, 2018, 17(4):860-877. doi: 10.1111/1541-4337.12343 HAN J W, RUIZ-GARCIA L, QIAN J P, et al. Food packaging: a comprehensive review and future trends[J]. Comprehensive Reviews in Food Science and Food Safety, 2018, 17(4): 860-877. doi: 10.1111/1541-4337.12343

[8] 李洋,张欣硕,李馨男,等. 纳米复合相变蓄冷材料的制备及蓄冷特性分析[J]. 农业工程学报,2022,38(23):284-292. LI Yang, ZHANG Xinshuo, LI Xinnan, et al. Preparation of nanocomposite phase change cold storage materials and analysis of cold storage characteristics[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2022, 38(23): 284-292. (in Chinese with English abstract Li Yang, Zhang Xinshuo, Li Xinnan, et al. Preparation of nanocomposite phase change cold storage materials and analysis of cold storage characteristics[J]. Transactions of the Chinese Society of Agricultural Engineering, 2022, 38(23): 284-292. (in Chinese with English abstract)

[9] DEFRAEYE T, CRONJÉ P, BERRY T, et al. Towards integrated performance evaluation of future packaging for fresh produce in the cold chain[J]. Trends in Food Science & Technology, 2015, 44(2):201-225. DEFRAEYE T, CRONJÉ P, BERRY T, et al. Towards integrated performance evaluation of future packaging for fresh produce in the cold chain[J]. Trends in Food Science & Technology, 2015, 44(2): 201-225.

[10] ELANSARI A M, FENTON D L, CALLAHAN C W. Chapter 6-Precooling[M].Postharvest Technology of Perishable Horticultural Commodities. Woodhead Publishing. 2019:161-207. ELANSARI A M, FENTON D L, CALLAHAN C W. Postharvest Technology of Perishable Horticultural Commodities [M]. Woodhead Publishing. 2019: 161-207.

[11] 张鹏,袁兴铃,薛友林,等. 精准温度控制对枸杞鲜果贮藏品质和香气成分的影响[J]. 农业工程学报,2021,37(18):322-330. ZHANG Peng, YUAN Xingling, XUE Youlin, et al. Effects of precise temperature control on the storage quality and aroma components of fresh goji fruit[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2021, 37(18): 322-330. (in Chinese with English abstract Zhang Peng, Yuan Xingling, Xue Youlin, et al. Effects of precise temperature control on the storage quality and aroma components of fresh goji fruit[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(18): 322-330. (in Chinese with English abstract)

[12] 杨涛,郜海燕,张润光,等. 加压氮气对草莓采后生理及贮藏品质的影响[J]. 农业工程学报,2020,36(15):282-290. YANG Tao, GAO Haiyan, ZHANG Runguang, et al. Effects of pressurized nitrogen on strawberry postharvest physiology and storage quality[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2020, 36(15): 282-290. (in Chinese with English abstract doi: 10.11975/j.issn.1002-6819.2020.15.034 Yang Tao, Gao Haiyan, Zhang Runguang, et al. Effects of pressurized nitrogen on strawberry postharvest physiology and storage quality[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(15): 282-290. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2020.15.034

[13] KADER A A. Postharvest Technology of Horticultural Crops[M]. Oakland:University of California (Agriculture and Natural Resources), 2002. KADER A A. Postharvest Technology of Horticultural Crops [M]. Oakland: University of California (Agriculture and Natural Resources), 2002.

[14] 季丽丽,梁芸志,陈存坤,等. 不同温度差压预冷及其对西葫芦冷藏效果的影响[J]. 农业工程学报,2018,34(1):287-293. JI Lili, LIANG Yunzhi, CHEN Cunkun, et al. Forced-air pre-cooling of different temperatures and its effects on cold storage of Cucurbita pepo[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2018, 34(1): 287-293. (in Chinese with English abstract Ji Lili, Liang Yunzhi, Chen Cunkun, et al. Forced-air pre-cooling of different temperatures and its effects on cold storage of Cucurbita pepo[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(01): 287-293. (in Chinese with English abstract)

[15] 吕恩利,陈明林,刘妍华,等. 喷淋预冷工艺参数对荔枝降温特性的影响[J]. 农业工程学报,2018,34(24):292-298. LYU Enli, CHEN Minglin, LIU Yanhua, et al. Effects of different spray precooling parameters on cooling characteristics of litchi[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(24): 292-298. (in Chinese with English abstract doi: 10.11975/j.issn.1002-6819.2018.24.035 Lü Enli, Chen Minglin, Liu Yanhua, et al. Effects of different spray precooling parameters on cooling characteristics of litchi[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(24): 292-298. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2018.24.035

[16] 鲁玲,康宁波,刘贵珊,等. 真空预冷结合微孔膜包装对鲜枸杞贮藏品质的影响[J]. 农业工程学报,2021,37(10):245-252. LU Ling, KANG Ningbo, LIU Guishan, et al. Storage quality of fresh Lycium barbarum by vacuum precooling and microporous membrane packaging[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2021, 37(10): 245-252. (in Chinese with English abstract Lu Ling, Kang Ningbo, Liu Guishan, et al. Storage quality of fresh Lycium barbarum by vacuum precooling and microporous membrane packaging[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(10): 245-252. (in Chinese with English abstract)

[17] MUKAMA M, AMBAW A, BERRY T M, et al. Energy usage of forced air precooling of pomegranate fruit inside ventilated cartons[J]. Journal of Food Engineering, 2017, 215:126-133. doi: 10.1016/j.jfoodeng.2017.07.024 MUKAMA M, AMBAW A, BERRY T M, et al. Energy usage of forced air precooling of pomegranate fruit inside ventilated cartons[J]. Journal of Food Engineering, 2017, 215: 126-133. doi: 10.1016/j.jfoodeng.2017.07.024

[18] 韦晓洁,万兴龙,李雪. 基于农产品“最先一公里”的移动式产地预冷模式[J]. 全国流通经济,2022(2):28-30. WEI Xiaojie, WAN Xinglong, LI Xue. A mobile pre-cooling mode in origin based on "the first kilometer" of agricultural products[J]. China Circulation Economy, 2022(2): 28-30. (in Chinese with English abstract doi: 10.3969/j.issn.1009-5292.2022.02.008 Wei Xiaojie, Wan Xinglong, Li Xue. A mobile pre-cooling mode in origin based on "the first kilometer" of agricultural products[J]. China Circulation Economy, 2022, (02): 28-30. (in Chinese with English abstract) doi: 10.3969/j.issn.1009-5292.2022.02.008

[19] 朱晶玉,谭锋,左建冬,等. 移动式冷库的研究与开发[J]. 冷藏技术,2017,40(1):50-53. ZHU Jingyu, TAN Feng, ZUO Jiandong, et al. Research and development of mobile cold storage[J]. Journal of Refrigeration Technology, 2017, 40(1): 50-53. (in Chinese with English abstract Zhu Jingyu, Tan Feng, Zuo Jiandong, et al. Research and Development of Mobile Cold Storage [J]. Journal of Refrigeration Technology, 2017, 40(01): 50-53. (in Chinese with English abstract)

[20] ZHAO H, LIU S, TIAN C, et al. An overview of current status of cold chain in China[J]. International Journal of Refrigeration, 2018, 88:483-495. doi: 10.1016/j.ijrefrig.2018.02.024 ZHAO H, LIU S, TIAN C, et al. An overview of current status of cold chain in China[J]. International Journal of Refrigeration, 2018, 88: 483-495. doi: 10.1016/j.ijrefrig.2018.02.024

[21] 马志艳,石敏. 基于CFD小型冷库预冷过程的数值模拟[J]. 低温与超导,2021,49(7):67-73. MA Zhiyan, SHI Min. Numerical simulation of precooling process of small - scale cold storage based on CFD[J]. Cryogenics & Superconductivity, 2021, 49(7): 67-73. (in Chinese with English abstract Ma Zhiyan, Shi Min. Numerical simulation of precooling process of small - scale cold storage based on CFD[J]. Cryogenics & Superconductivity, 2021, 49(07): 67-73. (in Chinese with English abstract)

[22] 王冠邦,张信荣. 冷库预冷流动传热物理场分布研究[J]. 工程热物理学报,2021,42(3):668-675. WANG Guanbang, ZHANG Xinrong. Study on distribution of physical fields regarding to airflow and heat transfer of room cooling[J]. Journal of Engineering Thermophysics, 2021, 42(3): 668-675. (in Chinese with English abstract Wang Guanbang, Zhang Xinrong. Study on Distribution of Physical Fields Regarding to Airflow and Heat Transfer of Room Cooling[J]. Journal of Engineering Thermophysics, 2021, 42(03): 668-675. (in Chinese with English abstract)

[23] 邓浩,尹青春,林玉钦,等. 不同预冷方式对红毛丹贮藏品质的影响[J]. 食品工业,2021,42(1):1-4. DENG Hao, YI Qingchun, LIN Yuqin, et al. Effect of different precooling methods on quality of rambutan[J]. The Food Industry, 2021, 42(1): 1-4. (in Chinese with English abstract Deng Hao, Yi Qingchun, Lin Yuqin, et al. Effect of Different Precooling Methods on Quality of Rambutan[J]. The Food Industry, 2021, 42(01): 1-4. (in Chinese with English abstract)

[24] 时文林,赵雅琦,闫志成,等. 不同预冷方式对甜玉米储藏品质的影响[J]. 食品科学,2022,43(15):218-226. SHI Wenlin, ZHAO Yaqi, YAN Zhicheng, et al. Effects of different precooling methods on storage quality of sweet corn[J]. Food Science, 2022, 43(15): 218-226. (in Chinese with English abstract doi: 10.7506/spkx1002-6630-20210816-197 Shi Wenlin, Zhao Yaqi, Yan Zhicheng, et al. Effects of Different Precooling Methods on Storage Quality of Sweet Corn[J]. Food Science, 2022, 43(15): 218-226. (in Chinese with English abstract) doi: 10.7506/spkx1002-6630-20210816-197

[25] 刘琼瑜, 肖波, 吴耀森, 等. 二次冷凝融霜冷库预冷荔枝的降温特性研究[J]. 保鲜与加工, 2023, 23(2): 7-14. Liu Qiongyu, Xiao Bo, WU Yaosen, et al. Study on cooling characteristics of pre-cooled litchi in cold storage with secondary condensation and defrosting[J]. Storage and Process, 2023, 23(02): 7-14. (in Chinese with English abstract)

[26] 李燕, 刘贵珊, 何建国, 等. 预冷方式对长枣保鲜效果的影响[J]. 食品科学 , 2022, 43 (23): 261-268. LI Yan, LIU Guishan, HE Jianguo, et al. Effect of precooling treatments on postharvest preservation of ‘Lingwu Long’ Jujube[J]. Food Science , 2022, 43 (23): 261-268. (in Chinese with English abstract)

[27] 尉迟斌, 卢士勋, 周祖毅. 实用制冷与空调工程手册(第2版) [M]. 北京: 机械工业出版社, 2011. [28] 郑贤德. 制冷原理与装置(第2版) [M]. 北京: 机械工业出版社, 2019. [29] DEHGHANNYA J, NGADI M, VIGNEAULT C. Mathematical modeling of airflow and heat transfer during forced convection cooling of produce considering various package vent areas[J]. Food Control, 2011, 22(8):1393-1399. doi: 10.1016/j.foodcont.2011.02.019 DEHGHANNYA J, NGADI M, VIGNEAULT C. Mathematical modeling of airflow and heat transfer during forced convection cooling of produce considering various package vent areas[J]. Food Control, 2011, 22(8): 1393-1399. doi: 10.1016/j.foodcont.2011.02.019

[30] 张翔,韩佳伟,杨信廷,等. 不同构造冷藏车厢体的冷却性能模拟与对比[J]. 制冷学报,2018,39(2):89-98. ZHANG Xiang, HAN Jiawei, YANG Xinting, et al. Simulation and comparison of cooling performances of refrigerated vehicles with different structures[J]. Journal of Refrigeration, 2018, 39(2): 89-98. (in Chinese with English abstract Zhang Xiang, Han Jiawei, Yang Xinting, et al. Simulation and Comparison of Cooling Performances of Refrigerated Vehicles with Different Structures[J]. Journal of Refrigeration, 2018, 39(02): 89-98. (in Chinese with English abstract)

-

期刊类型引用(4)

1. 郭俊杰,郭正红. 基于深度置信网络的旋转机械在线故障诊断. 计算机测量与控制. 2025(01): 60-68 .  百度学术

百度学术

2. 刘喜庆,张文豪,潘真真. 基于DAL的工业机器人RV齿轮箱故障识别分析. 现代工业经济和信息化. 2024(09): 217-219 .  百度学术

百度学术

3. 高国泽,郭瑜,赵博涵,王红伟. 基于瞬时角速度信号窄带解调的RV减速器针齿故障检测. 振动与冲击. 2024(22): 155-161+208 .  百度学术

百度学术

4. 孙长胜,曹浩男. 基于VMD和CNN方法的电机传动系统故障诊断研究. 机械管理开发. 2024(12): 75-77 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: