Design and experiment of stalk pressing type cotton field mulch film collectors

-

摘要:

针对棉秆回收需求和现有滚筒式地膜捡拾机构可靠性差、缠膜严重、回收地膜含膜率低等问题,该研究设计了一种压秆式棉田地膜回收机,可一次性完成拾膜、脱膜以及除杂作业。结合相关作业性能要求,通过运动学和动力学分析确定了束秆盒、拾膜滚筒和脱膜机构的结构参数,并完成了关键部件的工作参数分析。为验证机具捡拾除杂作业性能,以机具前进速度、钩齿入土深度、拾膜滚筒转速为试验因素,拾膜率、含膜率为试验指标,进行了三因素三水平响应面试验,得到各因素的响应面模型,分析了各因素对作业效果的影响,并对各因素进行优化。试验结果表明,当拾膜滚筒转速为65 r/min,机具前进速度为5 km/h,钩齿入土深度为50 mm时作业效果最佳,以优化后的结果进行验证试验,结果表明,平均拾膜率为86.8 %,平均含膜率为14.9 %,研究结果可为后续留秆收膜机具的设计提供参考。

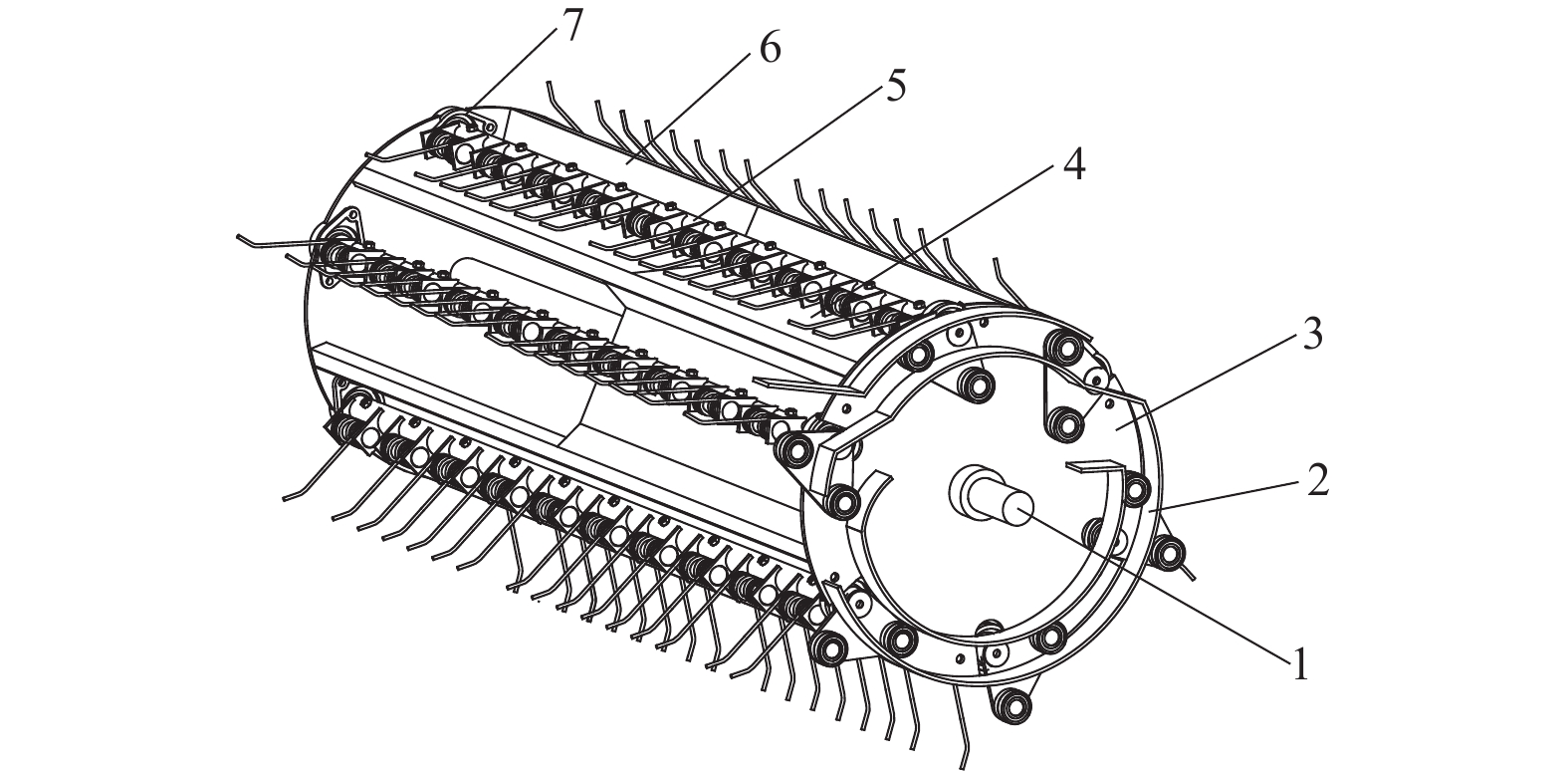

Abstract:A mulch film collector is one type of picking mechanism in the recycling of mulch film at present. However, the conventional configuration cannot fully meet large-scale production, such as severe film clamping, the requirement for cotton stalks crushing, and low film content. The existing drum-type pickup mechanism of mulch film has also serious film enwinding and a low film content rate of recovered mulch film. In this study, a mulch film recycling machine was developed with the stalk pressing type in the cotton field. The mulch film pickup mechanism with drum type was selected along with the one-film and six-row machine cotton harvesting and planting mode in Xinjiang. The cotton stalks' recycling and reliability greatly contributed to the resource utilization of cotton stalks. A box was added to bundle the stalk. A guided pickup roller of mulch film was built with anti-winding and impurity cleaning functions. A pneumatic film removal device was also added to rapidly remove the film. The film picking, film stripping and contamination removal operation were realized in the improved device at one time. The structural parameters of the stalk box, mulch film picking roller and film removal mechanism were also determined using kinematic and kinetic analysis. The working parameters of key components were analyzed after optimization. The front tilt angle of the stalk box was designed to be 30° considering the congestion and the forward resistance of the machine. The motion position and oscillation of the hook teeth at each station of the film pickup roller were combined to clarify the motion trajectory of the roller center. The mathematical model of the slide profile curve was established using the analytical method. The kinetic analysis of the film pickup roller was carried out, where the rotation speed range of the roller was determined to be 41-68 r/min. A systematic investigation was implemented to explore the relationship between the full pressure at the outlet of the film removal hood and the rotation speed of the film removal shaft using aerodynamics. The rotation speed of the film removal impeller was 980 r/min. To verify the operational performance of the device, A three-factor, three-level response surface test was conducted with the machine advancing velocity, the depth of hook-tooth into the soil and the rotation speed of the film pickup roller as the test factors, and the film pickup rate and the film content rate as the test indexes. The response surface model of each factor was established to optimize for better operational performance. The test results showed that the significant effects of the test factors on the film pickup rate were ranked as the rotation speed of the film pickup roller, the machine advancing velocity, and the depth of hook-tooth into soil. The significant effects of the test factors on the film content rate were the rotation speed of the film pickup roller, the depth of hook-tooth into soil, and the machine's advancing velocity. The best operation was achieved, when the rotation speed of the film pickup roller was 65 r/min, the machine advancing velocity was 5 km/h, and the depth of hook-tooth into the soil was 50 mm. The optimized performance was verified for the average film pickup rate was 86.8 % and the average film content rate was 14.9 %. The findings can provide a strong reference to design the subsequent machines for the stalk-collect mulch film.

-

Keywords:

- agricultural machinery /

- design /

- experiment /

- stalk pressing /

- roller /

- guide /

- mulch film

-

0. 引 言

目前,许多传统薄膜材料的原料如聚乙烯(polyethylene,PE),聚氯乙烯(polyvinyl chloride, PVC),聚丙烯(polypropylene,PP)等石油基聚合物,由于其在土壤中极低的自然降解率,所堆积的残留物会破坏土壤结构,造成所谓的“白色污染”,并随着时间的推移通过生态系统的循环最终威胁到我们人类的健康[1-3]。针对这一现状,合理回收传统用膜及开发使用新型绿色生物可降解材料是当下控制和缓解的两种办法。但对于回收传统膜来说,由于较大的回收难度和较高的经济成本,阻碍了这一行动的实施[4]。因此,为了避免“白色污染”的进一步扩大,研制出具备传统石油基材料相同性能的绿色新型可生物降解材料是目前最优的方案。近年来,环境友好型材料得到了广泛关注和研究,其中的可生物降解材料能被微生物完全分解且不会对环境造成破坏,因此可以取代石油衍生物材料,解决环境污染问题。可生物降解材料,例如聚己内酯(polycaprolactone,PCL),聚乳酸(polylactic acid,PLA),聚乙烯醇(polyvinyl alcohol,PVA)等是常见的化工合成材料。其中,PVA由于其具备优异的生物安全性和可降解性以及较强的力学性能,使其成为了薄膜领域在内的众多领域的研究热点[5]。然而,由于PVA分子结构中含有的大量亲水性的羟基基团,使得PVA膜在潮湿环境下容易吸收空气中的水分而发生溶胀,进而影响膜的性能,限制了PVA在特定环境下的应用[6]。此外,PVA膜由于其不具备阻隔紫外线的能力,在用于特定包装材料及农业用膜时,紫外线的辐射作用会加速薄膜的老化,甚至直接危害到农作物的生长。因此,提升PVA薄膜的耐水性和光学性能是促进其广泛应用的必要条件。

木质素(Lignin)是植物木质结构中三大主要成分之一,同时也是为数不多能够替代石油基多元醇提供芳香基化合物的可再生资源[7]。木质素主要是在化学制浆过程中作为一种废料产生的,但只有将近3.5%被用于生产高附加值产品[8]。因此探索木质素在高值化产品的应用对资源有效利用具有重要价值[9-10]。大量研究表明,木质素中含有大量的苯环,羰基和酚羟基,能够消除自由基使其具有一定的紫外吸收特性,同时赋予了生物相容性和可降解性等优点[11],且具备疏水基团如苯环,烷基链等。如ZHANG等 [12]将PVA与木质素进行共混后,木质素膜的机械性能和耐水性能都得到显著提升。IZAGUIRRE等[13]将木质素与壳聚糖(chitosan)进行共混后,共混膜的抗氧化性和阻隔紫外的能力得到了加强。因此,木质素的添加能够赋予和提高薄膜材料的性能。

水性聚氨酯(waterborne polyurethane,WBPU)是一种将传统溶剂型聚氨酯换以H2O作为介质使聚氨酯分散在其中的新型聚氨酯体系,其不仅具有传统溶剂基聚氨酯优良的耐磨性和机械性能[14-15],在作为填料分散在其他组分体系中凭借着可调节性的软硬段使其赋予了材料新的柔韧特效[16],而且具有环保、安全可靠的特点使其在生物医药等方面大放异彩。

因此,本文采取用微波法对木质素进行液化,将木质素液化物L(D)与PVA进行共混,并向体系中加入WBPU,制备L(D)/WBPU/PVA共混膜,对共混膜进行系统分析并探讨L(D)和WBPU对共混膜性能的影响。

1. 材料与方法

1.1 试验试剂

丙三醇、聚乙二醇-600(PEG-600)、木质素(脱碱)和水性聚氨酯(固含量为40%)均为分析纯,均由上海麦克林生化科技有限公司提供;浓硫酸(98%溶液)由广州化学试剂厂提供;聚乙烯醇

1799 型(醇解度98%~99%)由上海阿拉丁生化科技有限公司提供;无水乙醇(≥99.7%)购买于西陇科学股份有限公司。1.2 仪器设备

试验中主要使用的仪器设备:微波合成萃取仪,XM-MC-1,祥鹄科技有限公司;真空抽滤机,HQ-12CL-Ⅰ,祥鹄科技有限公司;旋转蒸发仪,Hei-VAP Advantage,Heidolph,德国;红外光谱仪,TENSOR27,Bruker,德国;X射线衍射仪,D8 ADVANCE,Brucker,德国;紫外分光光度计,UV-3300PC,MAPADA,中国上海;万能材料试验机,34SC-1,INSTRON,美国;台式扫描电镜,ProX,PHENOM,荷兰。

1.3 木质素的液化

将木质素放入120 ℃的烘箱进行脱水干燥处理120 min。之后,称取6 g木质素、24 g聚乙二醇-600(PEG-600)和6 g丙三醇放入圆底烧瓶中,在恒温磁力搅拌器上充分搅拌后,用移液枪吸取0.493 mL浓硫酸精准滴入混合试剂中以防止影响试验数据结果,继续搅拌一定时间后将烧瓶转移至微波合成萃取仪中 [17]。设置微波液化仪参数,仪器功率设置为600 W,反应时间设置在20 min,反应温度设置为160 ℃。待木质素液化结束后将其自然冷却至70 ℃,再将其进行真空抽滤,以除去残留固体,同时利用适量乙醇溶液把附着在烧瓶内的残留物冲洗后一并倒入漏斗中进行抽滤,待抽滤瓶中无液体滴漏后停止抽滤,将抽滤完成的混合液体移至旋蒸瓶中除去杂质乙醇。同时将抽滤后的滤纸放入60 ℃烘箱中干燥并进行后续称量。

木质素的液化率计算可按照式(1)进行计算:

W=W1−W2W1×100% (1) 式中,W为液化率,%;W1为木质素液化前的质量,g;W2为木质素未被液化的质量,g。

分别称量干燥后的空白滤纸和带有未被液化的木质素的滤纸,得出的质量分别为0.31 g和1.06 g,根据公式(1)可得木质素的液化率约为87%,该结果较为明显的看出大部分木质素已被液化。

1.4 LD/WBPU/PVA共混膜的制备

本文采用溶液浇筑法来制备L(D)/WBPU/PVA共混膜。首先准确称量20 g PVA倒入单口烧瓶中并加入380 mL去离子水,再将其放入油浴锅中加热,加热温度为90 ℃,并在瓶口安装冷凝管,磁力搅拌约2 h后制得PVA质量分数为5%的澄清溶液,之后,停止加热,待溶液冷却至60 ℃时,按照表1的配比,向PVA溶液中分别加入不同含量L(D)的和WBPU,并在该温度下磁力搅拌2 h,直至共混液充分混合。随后,取65 mL共混溶液放入180 mm×130 mm的玻璃板上,在室温下铺平晾凉,期间做好除泡处理,每组重复4次,静置48 h后可得到完整的共混膜样品,其中所制样品的各种配比及其命名详见表1。

表 1 不同L(D)、WBPU添加量占比Table 1. Different L (D) , WBPU addition% 薄膜名称

Film nameL(D) WBPU PVA 0 0 5%L(D)/PVA 5 0 10%L(D)/PVA 10 0 15%L(D)/PVA 15 0 20%L(D)/PVA 20 0 25%L(D)/PVA 25 0 9:1 L(D)/WBPU/PVA 15 1.67 8:2 L(D)/WBPU/PVA 15 3.75 7:3 L(D)/WBPU/PVA 15 6.43 6:4 L(D)/WBPU/PVA 15 10 5:5 L(D)/WBPU/PVA 15 15 注:L(D)为木质素液化物,PVA为聚乙烯醇,WBPU为水性聚氨酯,数字为L(D):WBPU掺比,实际添加量为占比×PVA质量,下同。 Note:L(D) is lignin (Dealkaline) liquefaction, PVA is polyvinyl alcohol, WBPU is waterborne polyurethane, the data is the blending ratio of L(D):WBPU, the actual addition amount is proportion × PVA mass, same below. 1.5 共混膜的表征

1.5.1 红外光谱图谱测定

采用红外光谱仪记录PVA膜和共混膜的FTIR-ATR光谱,分辨率为4 cm−1,范围为4 000~600 cm−1,扫描16次。

1.5.2 扫描电镜分析(SEM)

将膜的表平面和拉伸断截面用金溅射导电后,在10 kV下用Phenom ProX 扫描电镜观察。

1.5.3 薄膜透光性及厚度测定

将薄膜裁成适当尺寸,采用紫外可见分光光度计测定在200~400 nm波长范围内共混膜的抗紫外性能和在400~800 nm波长范围内共混膜的不透明度和透光率。取完整均匀的共混膜,使用精度为0.001 mm的厚度测试仪在薄膜上随机取5个点,测定其厚度并计算平均值、标准差。依照式(2)计算特定波长下(600 nm)共混膜的不透明度[18]。

不透明度=AbsX×100% (2) 式中,Abs为600 nm处共混膜的吸光度,X为共混膜的平均厚度,mm。

1.5.4 薄膜XRD表征测定

使用配备45 kV和200 mA CuKα辐射的X射线衍射仪收集XRD光谱,并在8°~80°范围内以10(°)/min的扫描速率进行扫描。

1.5.5 薄膜拉伸性能测定

采用万能材料试验机测试薄膜的拉伸性能。将样品分别裁成三组尺寸为75 mm×4 mm的哑铃状薄膜以进行拉伸强度测试,测试夹具为间距50 mm,速度设为0.05 m/min,计算每个样品的平均值和标准偏差。

1.5.6 薄膜的耐水性测定

从每张薄膜上割出2个尺寸为50 mm×50 mm的矩形薄膜。在60 ℃的真空烘箱中干燥24 h后,对样品的重量进行称量(W0),然后将其浸入100 mL去离子水中,浸没24 h后,使用滤纸去除样品表面多余的水,称量样品质量(Wt)。之后,放入60℃的烘箱中干燥24 h后,重新对此时的薄膜称量(Wd)。薄膜样品的吸水率(Wa)和水解率(Ws)使用以下公式测定[19]。

Wa=Wt−W0W0×100% (3) Ws=W0−WdW0×100% (4) 2. 结果与分析

2.1 共混膜红外光谱(FTIR)分析

L(D)、WBPU、PVA能否以任意比例混合是证明三者具有良好相容性的有效依据。因此,对加入不同百分比液化物量的L(D)/PVA共混膜和掺杂了不同百分比含量WBPU的L(D)/WBPU/PVA共混膜都分别进行FTIR测试。结果如图1a所示,在纯PVA膜中,3 275 cm−1和2 939 cm−1的峰分别为-OH和-CH2的收缩振动,1 654 cm−1处的峰为-C=O的收缩振动,在1 420 cm−1处的峰为-C-H的平面振动,1 087 cm−1处的峰则是-C-O的收缩振动。在L(D)/PVA共混膜中,所有的样品均具有木质素液化物和PVA特征官能团的吸收峰,但其位置和峰形大小都有一定的改变。在1 420 cm−1附近的峰为次甲基的吸收峰,峰形随着L(D)的加入从尖变宽,强度相对变弱,这表明L(D)和PVA具有较强的氢键作用[20]。同时,随着L(D)含量不断增加,3 275 cm−1处的羟基峰总体上朝着高波数方向移动,在20%时为最大,这表明L(D)与PVA之间发生了相互作用。

图1b为不同WBPU含量混膜的红外光谱图。3 368 cm−1附近宽峰为聚氨酯结构中的N-H和L(D)与PVA结构中羟基的吸收峰伸缩。1 731 cm−1附近则来自L(D)液化物与WBPU结构中-C=O的伸缩振动,且随着WBPU含量的增大,削弱了PVA中分子间的氢键作用,造成了PVA羟基峰逐渐蓝移[21-22]。同时由于固定含量PVA中的羟基数量不足,无法与WBPU中大量的羰基形成氢键,造成了能用于伸缩振动的羰基数目逐渐增多,对应的特征峰强度逐渐提高[23]。随着WBPU的不断加入,在1 087 cm−1附近属于PVA的-C-O伸缩振动强度呈现出从尖又强向着宽而弱变化,结晶度也随之衰弱。从以上结果表明,WBPU与L(D)/PVA具有较为不错的相容性。

2.2 共混膜扫描电镜(SEM)分析

由图2a可知,5%纯PVA膜的表面平整光滑,无明显颗粒,且拉伸断截面较为紧密、富有纹理。与纯PVA膜相比,L(D)/PVA膜表平面呈现出相似的特征,说明L(D)均匀分散在PVA基质中,形成了连续均匀相[24]。同时,随着木质素的不断加入,膜的拉伸断截面富有纹理且具有线条感,说明两者具有良好的生物相容性,膜的致密性好。但是随着木质素含量加到20%之后,膜的拉伸断截面的线条开始出现了一定程度上的紊乱,说明在分散过程中L(D)会出现一定程度的团聚现象,这可能会影响到膜的拉伸性能。

与2a图中的共混膜相比,随着WBPU含量的比例不断提高,图2b中L(D)/WBPU/PVA共混膜的断截面从有纹理愈发转变为粗糙状,在WBPU质量分数≥6.43%时尤为明显,且平面出现了较为明显的白色聚集体和复杂的结构交互,这在一定情况下会影响膜的综合性能。因此,WBPU的添加比例应该控制在6.43%以内,确保其能够均匀的分散在L(D)/PVA体系中[21,25]。

2.3 共混膜的光学性能分析

薄膜透明度是衡量透射光占入射光百分比强度的一项光学性能,也是评价薄膜材料性能好坏的特征[24]。从表2中可以清晰地观察到共混膜的厚度随着L(D)百分比的加入而逐渐提升,表明L(D)与PVA能够呈现稳定的相容,这与前面红外的分析基本吻合,且在可见光区的透明度较好。

表 2 不同薄膜的厚度及不透明度Table 2. Thickness and opacity of different films薄膜名称

Film name厚度

Thickness/mm吸光度Absorbance

(600 nm)Abs不透明度

Opaqueness/%PVA 0.115±0.007 0.0736 0.64±0.04 5%L(D)/PVA 0.117±0.007 0.1344 1.15±0.07 10%L(D)/PVA 0.127±0.019 0.2124 1.67±0.25 15%L(D)/PVA 0.135±0.020 0.2421 1.79±0.27 20%L(D)/PVA 0.142±0.014 0.2771 1.95±0.19 25%L(D)/PVA 0.157±0.018 0.3010 1.92±0.22 9:1 L(D)/WBPU/PVA 0.149±0.011 0.5392 3.61±0.28 8:2 L(D)/WBPU/PVA 0.160±0.011 0.6493 4.06±0.27 7:3 L(D)/WBPU/PVA 0.191±0.014 1.0047 5.26±0.38 6:4 L(D)/WBPU/PVA 0.223±0.016 1.3836 6.21±0.46 5:5 L(D)/WBPU/PVA 0.245±0.014 1.8714 7.63±0.45 然而,WBPU的加入所呈现的现象则与其不同。在WBPU的比例小于3.75%时,共混膜的厚度也随着WBPU含量的增加而逐渐提升,但在超过3.75%后其厚度增加的幅度较大,这或许能进一步证实在WBPU质量分数时≥6.43%时,WBPU与L(D)/PVA基底存在着一定的相分离。所有的薄膜样品不透明度小于8,可以认为共混膜是透明的,如果应用于食品包装可以避免消费者对食品外观的误判。

不同L(D)和WBPU含量的共混膜样品如图3所示,可以直观看出L(D)的加入使得共混膜呈现褐色,共混膜的颜色会随着L(D)含量的增加而加深,且WBPU的加入会加深L(D)中的褐色。

紫外辐射对自然界动植物以及塑料制品造成一定程度影响,因此生产出能够较大程度在紫外光区吸收紫外光的产品具有很高的市场价值[26]。由图4共混膜紫外-可见光图谱可知,纯PVA膜在紫外区的吸收很小,例如在400 nm处时其透光率达到81.44%,而加入5%L(D)后共混膜的透光率降低至34.53%,这是由于PVA特殊的分子结构中不存在不饱和键,而恰好属于芳香族化合物的木质素,其骨架结构中的羰基以及不饱和共轭双键等能够对紫外线进行有效吸收[27],同时木质素中还具备特有的酚羟基,使其能够形成吸收紫外的共轭反应[28]。因此,共混膜吸收紫外的能力会随着L(D)的不断加入而增强,当L(D)含量为25%时,共混膜在400 nm处的透光率仅为1.64%,这能够说明L(D)能够明显改善共混膜的抗紫外性能。WBPU的加入同样使得共混膜的抗紫外能力得到了增强,在400 nm处,15%L(D)/PVA共混膜的透光率为7.69%,而加入了3.75%WBPU后,其光透过率降至1.57%,这可能是因为WBPU与L(D)形成了某种紫外光稳定体系,并随着WBPU含量的不断增加,400nm处的透光率接近于0。L(D)和WBPU的加入提升了共混膜的抗紫外性及抗老化性,这一特性可以应用于阻碍紫外线的包装薄膜和农业用膜[29]。但两者的加入都在某种程度上影响到了对可见光的透过率,这将在后续的研究中进行改善。

2.4 共混膜X射线衍射(XRD)分析

从图5a中可以看出纯PVA聚合物的特征衍射峰的分别出现在2θ=19.2°和26.3°。

当加入L(D)时,L(D)/PVA共混膜衍射图谱形状与纯PVA膜的无太大差异,说明L(D)均匀分散在PVA体系中。基于图5a的分析,图5b中L(D)/WBPU/PVA共混膜的XRD图谱中多出了一个2θ=22.6°的衍射峰,不难理解这属于WBPU硬段的结晶所导致的特征衍射信号峰[30]。当两者比例随着WBPU的不断增加,属于WBPU的衍射信号为缓慢增强,这可能是因为WBPU含量较低时,较高含量的L(D)会阻碍WBPU有序硬段间相互作用,但随着WBPU含量较高时,固定含量的L(D)反而促进了与WBPU链段间的相互作用,促使无规则软段部分结晶化,有序硬段部分增强[31]。同时在2θ=26.3°所展现的特征信号峰的强度也随之逐渐变弱,原因在于WBPU的加入能够一定程度的削弱L(D)/PVA分子间的强相互作用力,从而间接导致了共混膜的结晶度降低。

2.5 共混膜拉伸性能分析

拉伸性能好坏是衡量薄膜抗拉扯能力和断裂程度的重要参考标准,同时也是力学表征试验的基础因素。图6展示了两种共混膜的力学拉伸性能。

由图6a可知,随着L(D)含量的不断加入,L(D)/PVA共混膜的拉伸性能呈现的变化趋势为先升后降,且当加入到15%的L(D)时,共混膜的拉伸强度达到顶峰(46.23 MPa),与纯PVA膜的拉伸强度(42.07 MPa)相比提升了10.60%。这是由于低含量的L(D)加入,其特有的空间网络结构与PVA混合发生相互作用后,导致共混膜形成了一种刚性结构,同时两者之间还能够形成分子间氢键,从而提升了拉伸性能[32]。继续提高L(D)比例至20%~25%时强度则有所下降,其原因可能是共混膜中过多的L(D)无法与PVA基体很好的结合,削弱了两者之间的相互作用,同时L(D)形成了一定程度的堆积[24],最终造成了膜拉伸强度的下降。断裂伸长率也呈现出相同的趋势。

与上述分析的情况不同,图6b所展示的共混膜相对于未加入WBPU的共混膜来说整体的拉伸强度下降幅度很大,且随着WBPU的不断加入,拉伸强度也呈现下降趋势,这是因为WBPU中某些链段能够代替L(D)和PVA分子间和分子内氢键作用与L(D)和PVA分子间氢键进行相互作用,削弱了L(D)和PVA分子间的作用力[33-34]。同时L(D)/WBPU/PVA共混膜的断裂伸长率与未添加WBPU的L(D)/PVA共混膜相比,均低于后者,且随着WBPU的不断增加,断裂伸长率也随之降低,直至WBPU的添加量≥10%时才开始回升。分析认为,是由于引入的L(D)使得WBPU中硬段含量上升,分子之间的交联度增强,降低了共混膜随拉伸强度变化而发生形变的能力,导致膜的脆性变大,断裂伸长率下降[34-35]。后来的回升则是由于共混膜中的L(D)不足以充当过多的WBPU硬段。

2.6 共混膜耐水性分析

图7a展示了L(D)的含量对共混膜吸水性和水溶性的影响规律。

PVA是强亲水性材料容易吸水膨胀,但随着L(D)的加入其吸水性逐渐降低,当加入15%的L(D)时,共混膜的吸水率从532%降低至362%,其耐水性提升了32%,这是因为L(D)进行液化后,部分羟基被酯化不与羰基产生共轭效应,与水形成氢键的能力变小,同时液化后的产物还有酚羟基,导致疏水性能的增加[36]。而水溶性的变化走势较为复杂,呈现出微弱的降-升-降的变化。相比于纯PVA膜,加入5%L(D)的共混膜其水溶性从42%下降至35%,但当L(D)含量高于5%时,膜的水溶性在35%附近波动。造成这一现象的原因可能是由于L(D)疏水性造成的,同时还与L(D)本身复杂的刚性分子结构有这一定联系[37]。

而加入WBPU的水溶性则没有这种复杂变化。由图7b可知,L(D)/WBPU/PVA共混膜与L(D)/PVA共混膜对比整体的吸水性和水溶性都明显降低。随着WBPU的不断加入,吸水性为降低的走势,其中5:5L(D)/WBPU/PVA共混膜的吸水率甚至降至170%,水溶性也降至18%,耐水性相较于纯PVA膜来说提升了68%。这是因为WBPU吸水性低且具有很强的尺寸稳定性,交联作用下削弱了PVA中大量的羟基氢键的形成[24];而水溶性也呈现出不断下降的趋势,同样是因为在整个共混膜中体系中PVA的占比随着WBPU的不断加入而越来越小,使得降低了共混膜的亲水性能,水分子由膜的内层逐渐向表面扩散[38]。

3. 结 论

1)一定含量L(D)的加入在一定程度上能够提升L(D)/PVA共混膜的拉伸强度,且在L(D)含量为15%时拉伸强度从42.07 MPa增加到46.53 MPa,提高了10.60%;并且L(D)的加入能够显著的改善共混膜吸收紫外光辐射的能力,且透明度较好。同时L(D)的加入改善了共混膜整体的耐水性。综合考虑,L(D)加入量为15%时,共混膜整体性能最佳。

2)在WBPU的加入下,L(D)/WBPU/PVA共混膜整体的抗紫外能力和耐水性都得到进一步的增强。但是在力学性能上,由于WBPU能够削弱L(D)和 PVA分子间作用力,拉伸强度上则有一定程度的下降。因此,综合考虑下7:3比例下的共混膜性能最佳。

3)在该试验研究和过程分析中,经过液化后的L(D)和WBPU都对PVA膜的性能产生了一定影响,尤其是在抗紫外性能和耐水性能上表现出了优异的提升效果。L(D)/WBPU/PVA共混膜可用作良好的紫外屏蔽材料和防水材料,可应用于特殊包装和地膜等,同时为L(D)/WBPU/PVA共混膜制备的合理性提供了理论依据,并对其在农用膜的应用有一定的参考意义。

-

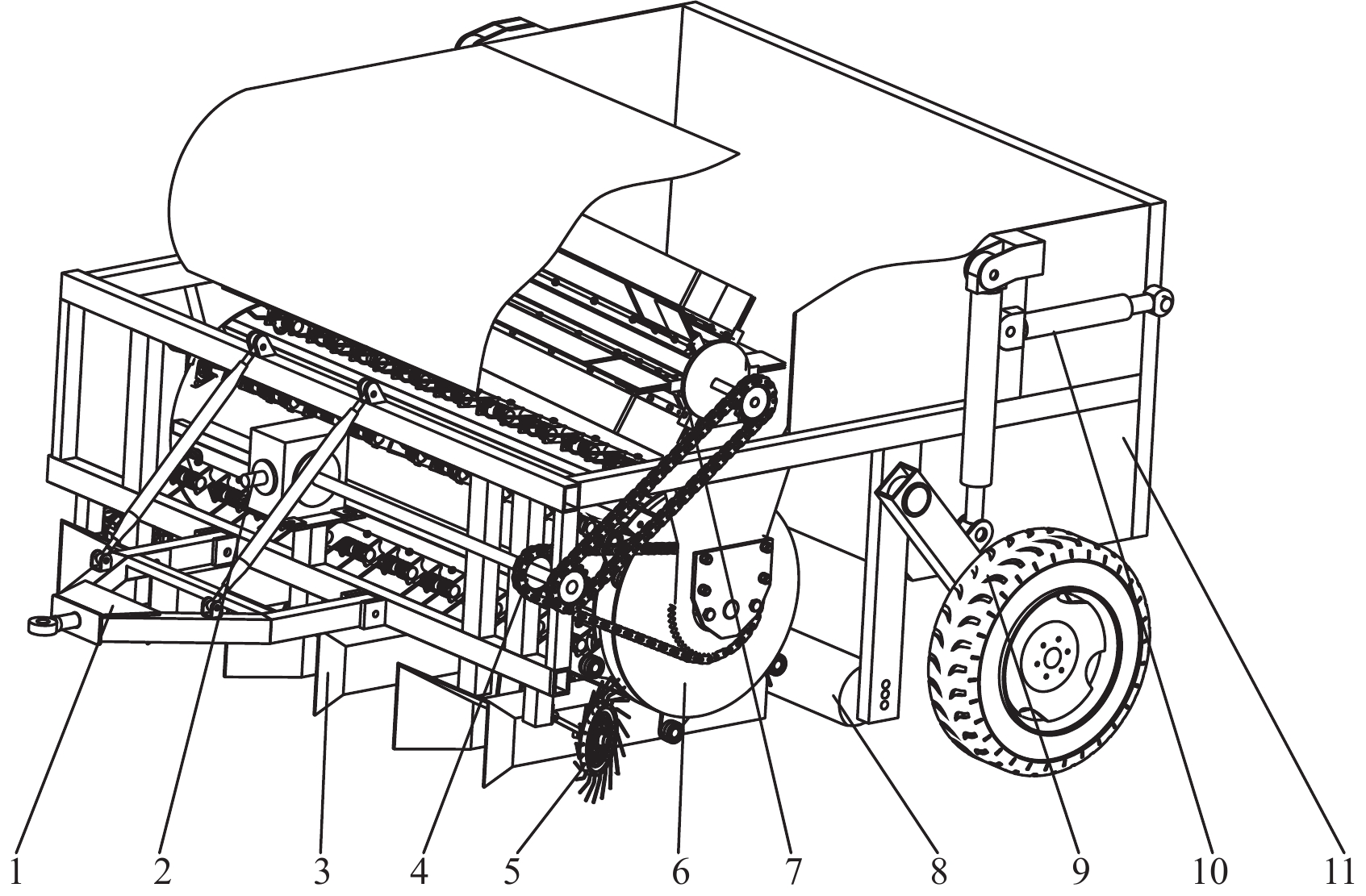

图 1 压秆式棉田地膜回收机结构示意图

1.牵引架 2.减速箱 3.束秆盒 4.链传动系统 5.边膜起出机构 6.导向式地膜捡拾滚筒 7.气力式脱膜机构 8.限深辊 9.行走轮 10.液压油缸 11.集膜箱

Figure 1. Structure diagram of stalk pressing type cotton field mulch film collector

1.Traction frame 2.Reducer casing 3.Binding stalk box 4.Chain transmission system 5.Edge film lifting mechanism 6.Guided mulch film picking roller 7.Pneumatic film removal mechanism 8.Depth limiting roller 9.Walking wheel 10. Hydraulic cylinder 11. Film collecting box

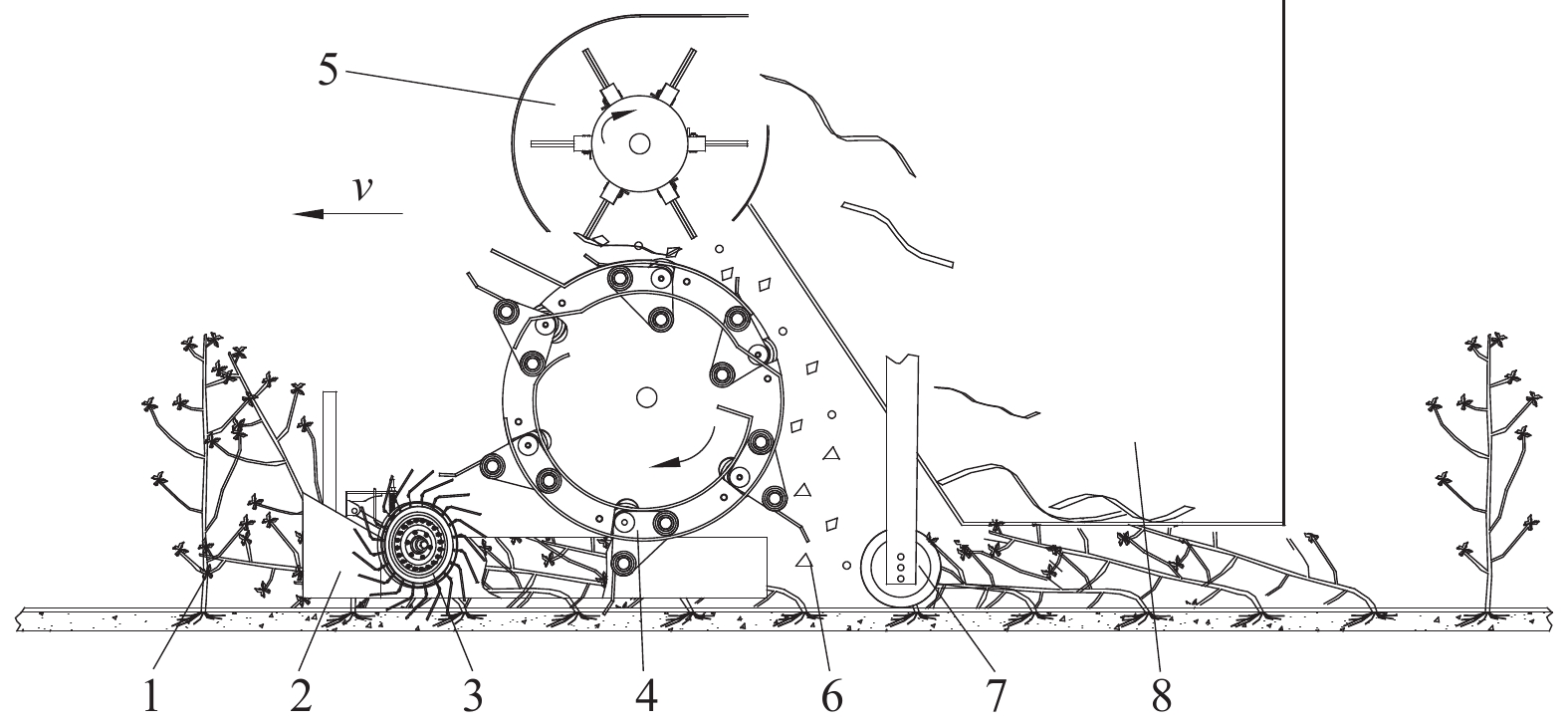

图 2 工作原理示意图

Figure 2. Diagram of working principle

1.棉秆 2.束秆盒 3.边膜起出机构 4.拾膜滚筒 5.脱膜机构 6.杂质 7.限深辊 8.集膜箱 1.Cotton stalk 2.Binding stalk box 3.Edge film lifting mechanism 4.Film picking roller 5.Film removing mechanism 6.Impurity 7.Depth limiting roller 8.Film collecting box注:v为机具前进速度,m·s−1。Note: v is the machine advance velocity, m·s−1.

图 3 束秆盒设计分析

注:φ为束秆盒前端倾角,(°);h1为束秆盒前端高度,mm;h2为束秆盒后端矩形管高度,mm;b1为束秆盒前端宽度,mm;b2为束秆盒后端矩形管宽度,mm;l1为束秆盒前端长度,mm;l2为束秆盒整体长度,mm。L为棉秆整株长度,mm;h3为束秆盒下端距离地面高度,mm;θ为棉秆变形倾角,(°)。

Figure 3. Design analysis of binding stalk box

Note: φ is the front angle of the binding stalk box, (°); h1 is the front height of the binding stalk box, mm ; h2 is the height of the rectangular tube at the back end of the binding stalk box, mm ; b1 is the front width of the binding stalk box, mm ; b2 is the width of the rectangular tube at the back end of the binding stalk box, mm ; l1 is the length of the front end of the binding stalk box, mm ; l2 is the overall length of the binding stalk box, mm. L is the whole plant length of cotton stalk, mm ; h3 is the height from the lower end of the binding stalk box to the ground, mm ; θ is the deformation angle of cotton stalk , (°).

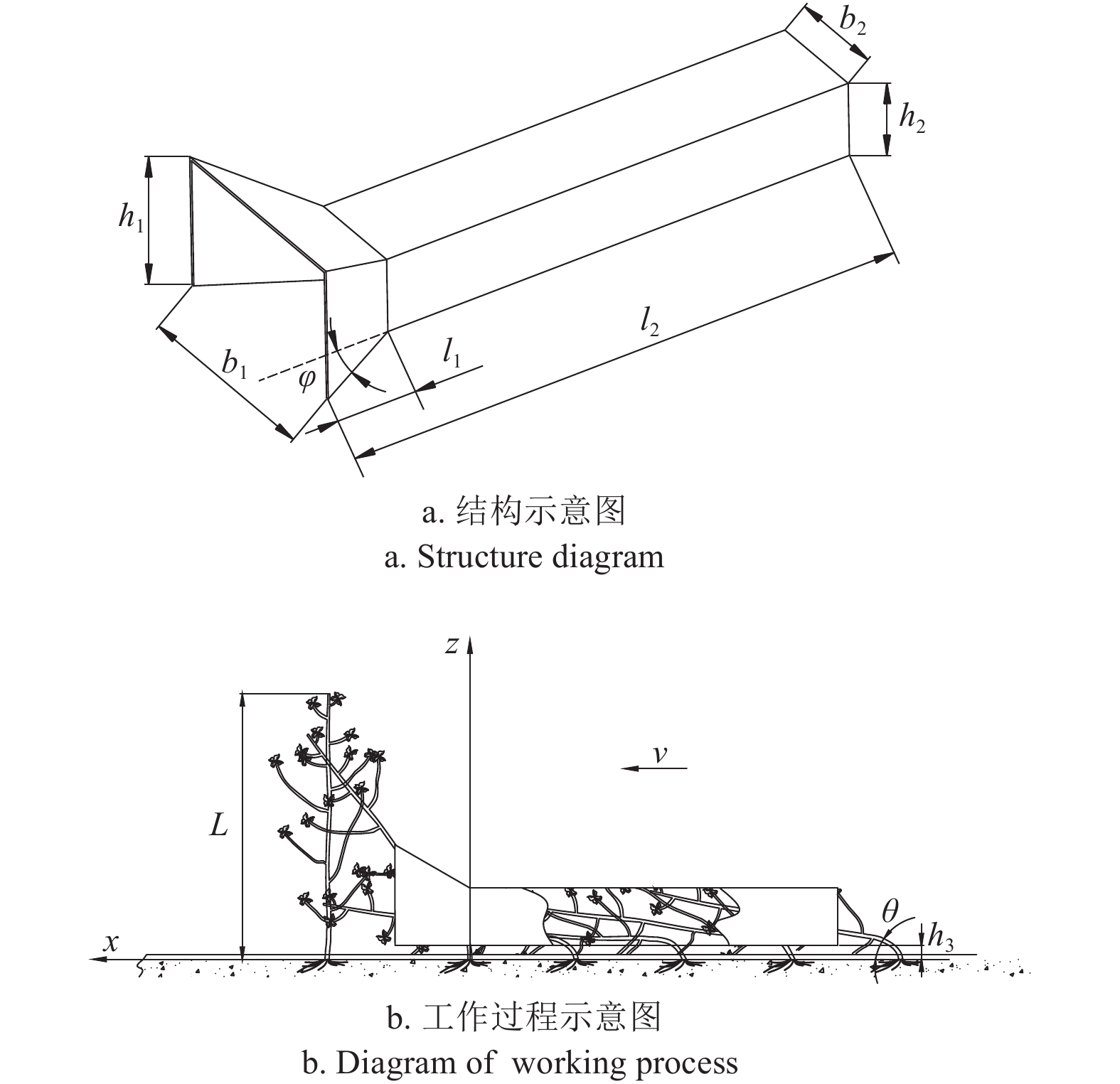

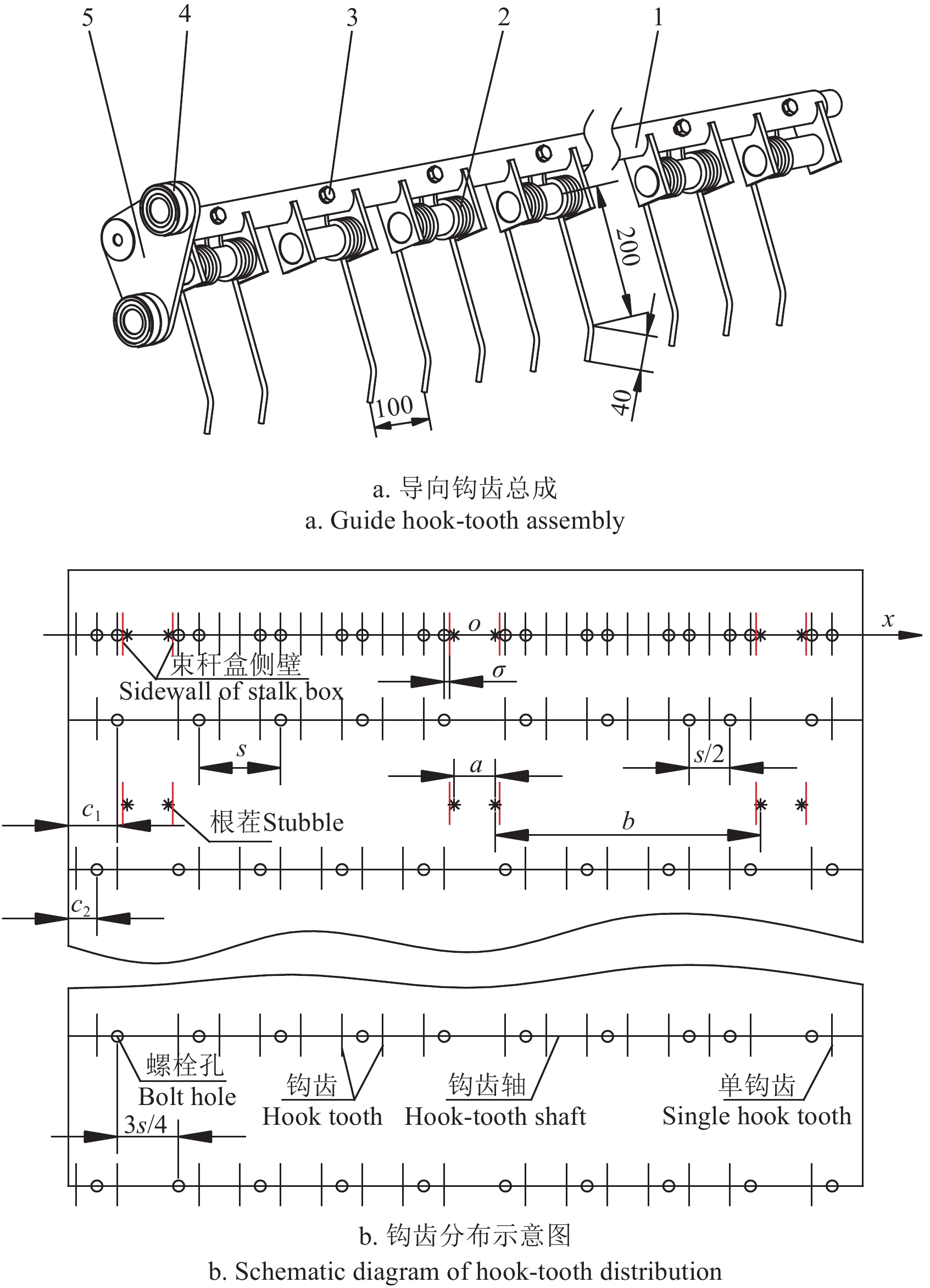

图 5 导向钩齿总成结构及分布示意图

1.导向板 2.滚子 3.螺纹紧固件 4.钩齿 5.钩齿安装轴1.Guide plate 2.Roller 3.Threaded fastener 4.Hook tooth 5.Hook-tooth shaft 注:s为同排齿齿间中心距,mm;σ为拾膜钩齿和与束秆盒侧壁间的距离,mm;a为棉花种植窄行间距, mm;b为棉花种植宽行间距,mm;c1、c2为钩齿安装孔与滚筒边缘的距离,mm。Note: s is the center distance between teeth in the same row, mm; σ is the distance between the pick-up hook teeth and the side wall of the stalk box, mm; a is cotton planting narrow spacing, mm; b is cotton planting wide spacing, mm; c1, c2 are the distance between the hook-tooth mounting hole and the edge of the cylinder, mm.

Figure 5. Structure and distribution diagram of guide hook-tooth assembly

图 6 滚子中心运动轨迹

注:A、B为滚子中心点;C为钩齿末端点;O为钩齿回转运动中心点;ω1为拾膜滚筒旋转角速度,rad·s−1;ε0为滑道初始摆角,(°);R为钩齿轴回转半径,mm;ω1t为拾膜滚筒旋转弧度,rad;ε为滑道摆角增加量,(°);s1为滚子中心A的位移量,mm;r0为基圆半径,mm;rr为滚子半径,mm;δ1卸膜工位角,(°);δ2回程工位角,(°);δ3拾膜工位角,(°);δ4输送工位角,(°)。

Figure 6. Movement path of roller center

Note : A, B is the center point of the roller; C is the end point of the hook-tooth; O is the center point of the rotary motion of the hook-tooth; ω1 is the rotation angular velocity of the film pickup roller, rad·s−1; ε0 is the initial swing angle of the slide, (°); R is the rotation radius of hook-tooth shaft, mm; ω1t is the arc of rotation of the pickup roller, rad; ε is the increase in the swing angle of the slide, (°); s1 is the displacement of roller center A, mm; r0 is the base circle radius, mm; rr is the roller radius, mm; δ1 is unloading angle, (°) ; δ2 is return station angle (°); δ3 is film picking station angle, (°); δ4 is conveying position angle, (°).

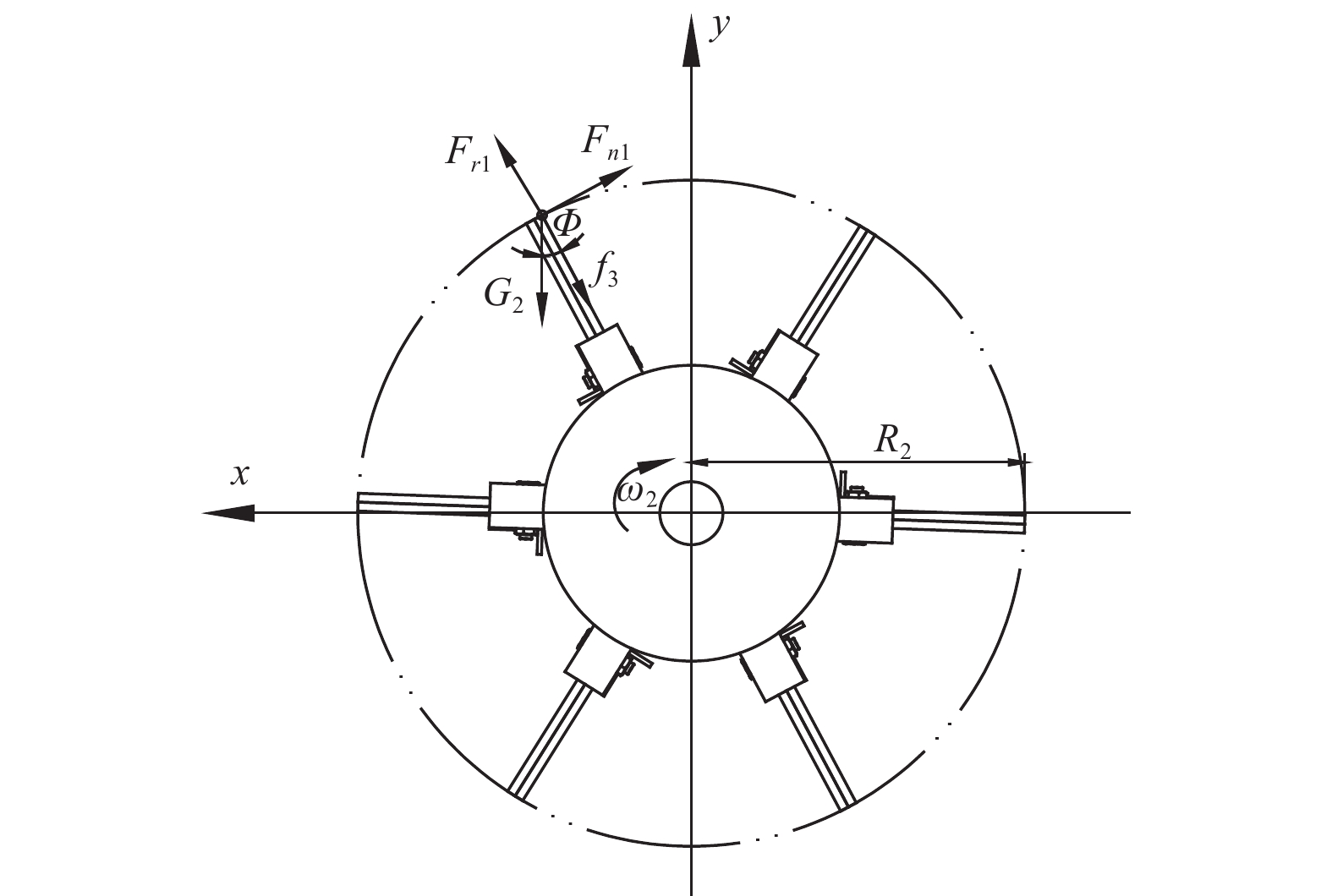

图 9 脱膜叶片上地膜受力分析

注:ω2为脱膜叶轮旋转角速度,rad·s−1;Fr1为地膜受到的离心力,N;Fn1为脱膜叶片对地膜的支持力,N;G2为地膜物料受到的重力,N;Φ为脱膜叶片与地膜重力G2方向的夹角,(°);R2为脱膜叶轮的回转半径,mm;f3为脱膜叶片对地膜的摩擦力,N。

Figure 9. Force analysis of mulch film on defilmed blade

Note : ω2 is the rotation angular velocity of the defilmed impeller, rad·s−1; Fr1 is the centrifugal force on the mulch film, N; Fn1 is the support force of the defilmed blade to the mulch film, N; G2 is the gravity of mulch film material, N; Φ is the angle between the defilmed blade and the mulch film gravity in the G2 direction, (°); R2 is the radius of gyration of the defilmed impeller, mm; f3 is the friction of defilmed blade to mulch film, N.

图 10 钩齿齿端运动轨迹

注:ω1为拾膜滚筒旋转角速度,rad·s−1;O为钩齿入土时的回转中心;R1为捡拾阶段钩齿齿端回转半径,mm;α为拾膜钩齿入土初始相位角,(°)。

Figure 10. Motion trajectory of hook tooth end

Note : ω1 is the rotation angular velocity of the film pickup roller, rad·s−1; O is the rotation center when hook-tooth is buried; R1 is the rotation radius of hook-tooth end in picking stage, mm; α is the initial phase angle of the pickup hook-tooth into the soil, (°).

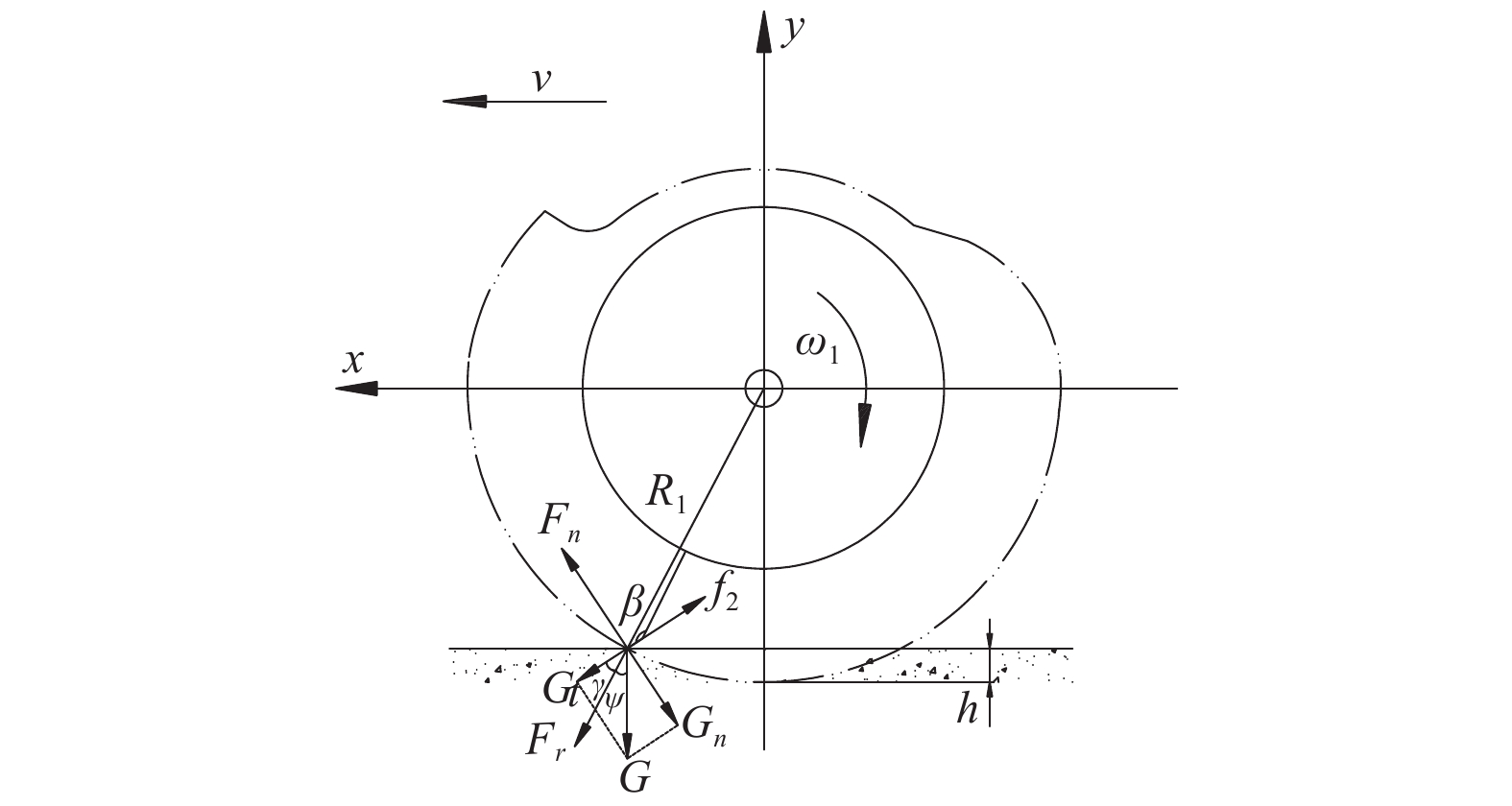

图 11 地膜受力分析示意图

注:G为地膜重力,N;Gn为地膜重力在钩齿方向的法向分力,N;Gt为地膜重力在钩齿方向的切向分力,N;Fn为拾膜钩齿对地膜的支持力,N;Fr为地膜受到的离心力,N;f2为钩齿对地膜的摩擦力,N;β为拾膜钩齿折弯角,(°);ψ为地膜受到的离心力Fr与重力G之间的夹角,(°);γ为地膜受到的离心力Fr与Gt之间的夹角,(°);h为拾膜钩齿入土深度,mm。

Figure 11. Force analysis diagram of mulch film

Note : G is mulch film gravity, N; Gn is the normal component of the mulch film gravity in the direction of the hook-tooth, N; Gt is the tangential component of the mulch film gravity in the direction of the hook-tooth, N; Fn is the supporting force of spring-tooth to mulch film, N; Fr is the centrifugal force on the mulch film, N; f2 is the friction force of hook tooth to mulch film, N; β is the bending angle of pickup hook-tooth, (°) ; ψ is the angle between the centrifugal force Fr on the mulch film and the gravity G, (°) ; γ is the angle between the centrifugal force Fr and Gt on the mulch film, (°) ; h is the depth of pickup hook-tooth, mm.

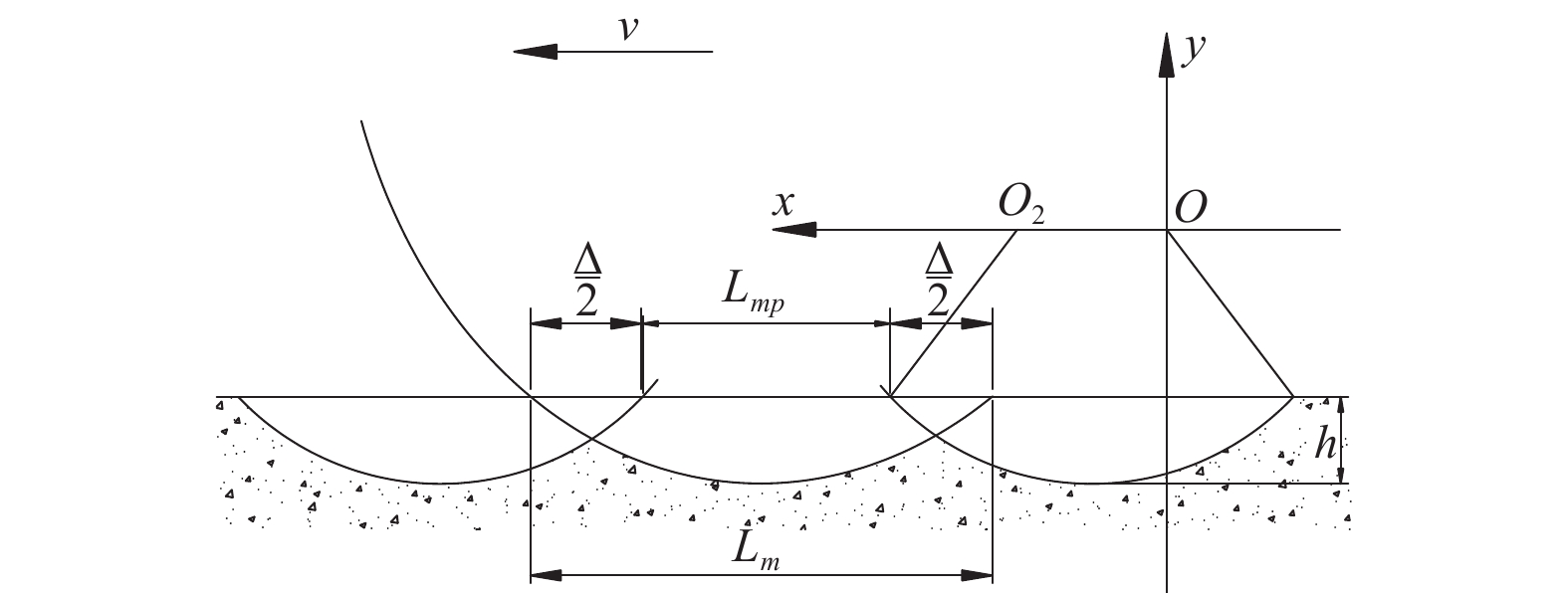

图 12 相邻拾膜钩齿齿端运动轨迹

注:Δ为相邻钩齿绝对轨迹曲线的重叠量;mm;Lmp钩齿的有效划土长度,mm;Lm为钩齿划土长度,mm。

Figure 12. Motion trajectory of adjacent pick-up hook-tooth end

Note : Δ is the overlap of absolute trajectory curves of adjacent hook-tooth, mm; Lmp is the effective cutting length of hook-tooth, mm; Lm is the cutting length of the hook-tooth, mm.

表 1 机具主要参数

Table 1 Main parameters of device

参数Parameters 值Value 机具尺寸Complete machine size/(mm×mm×mm) 3730×3230×1725 配套动力Matched power/kW 60~95 工作幅宽Working width/mm 2150 作业深度Working depth/mm 10~80 机具前进速度Machine forward speed/( km·h−1) 3~8 连接方式Connection method 牵引式 表 2 试验因素和水平

Table 2 Test factors and levels

编码

Levels机具前进速度

Machine advancing

velocity x1/(km·h-1)钩齿入土深度

Depth of hook-

tooth into soil x2/mm拾膜滚筒转速

Rotate speed of film

pickup roller x3/(r·min-1)−1 4 20 45 0 5 40 60 1 6 60 75 表 3 试验方案及结果

Table 3 Test plan and result

试验序号

Test No.X1 X2 X3 拾膜率

Film pickup rate Y1/%含膜率

Film content rate Y2/%1 0 −1 −1 84.0 10.2 2 1 1 0 85.4 13.2 3 1 0 1 84.3 12.8 4 0 0 0 86.2 14.6 5 0 0 0 86.4 14.7 6 1 −1 0 83.9 11.6 7 0 0 0 86.6 14.5 8 1 0 −1 84.1 10.9 9 0 1 −1 84.9 12.9 10 −1 1 0 83.5 12.7 11 0 1 1 85.8 13.4 12 0 0 0 86.1 14.8 13 0 0 0 86.5 14.5 14 0 −1 1 85.3 13.9 15 −1 0 1 84.2 13.1 16 −1 −1 0 83.5 12.4 17 −1 0 −1 82.9 11.5 注:X1、X2、X3分别为x1、x2、x3的水平值。 Note: X1, X2 and X3 are the level values of x1, x2 and x3. 表 4 回归模型方差分析

Table 4 Regression model analysis of variance

指标

Index方差来源

Source of variance平方和

Sum of squares自由度

Degree of freedom均方

Mean squareF P 显著性

Significant拾膜率

Film

pickup

rate Y1模型 22.91 9 2.55 49.56 <0.000 1 ** X1 1.62 1 1.62 31.54 0.000 8 ** X2 1.05 1 1.05 20.47 0.002 7 ** X3 1.71 1 1.71 33.32 0.000 7 ** X1X2 0.56 1 0.56 10.95 0.013 0 * X1X3 0.30 1 0.30 5.89 0.045 6 * X2X3 0.04 1 0.04 0.78 0.406 8 X12 12.24 1 12.24 238.33 <0.000 1 ** X22 1.42 1 1.42 27.58 0.001 2 ** X32 2.56 1 2.56 49.88 0.000 2 ** 残差 0.36 7 0.051 失拟 0.19 3 0.063 1.45 0.353 0 误差 0.17 4 0.043 总和 23.26 16 含膜率

Film

content

rate Y2模型 30.96 9 3.44 129.79 <0.000 1 ** X1 0.18 1 0.18 6.79 0.035 1 * X2 2.10 1 2.10 79.29 <0.000 1 ** X3 7.41 1 7.41 279.67 <0.000 1 ** X1X2 0.42 1 0.42 15.94 0.005 2 ** X1X3 0.023 1 0.023 0.85 0.387 5 X2X3 2.56 1 2.56 96.60 <0.000 1 ** X12 7.50 1 7.50 283.17 <0.000 1 ** X22 2.76 1 2.76 104.25 <0.000 1 ** X32 6.16 1 6.16 232.63 <0.000 1 ** 残差 0.19 7 0.027 失拟 0.12 3 0.039 2.30 0.218 7 误差 0.068 4 0.017 总和 31.14 16 注:P<0.05(显著*);P<0.01(极其显著**)。 Note: P<0.05(significant,*); P<0.01(highly significant, **). 表 5 试验验证结果

Table 5 Experiment verification results

试验序号Test No. Y1/% Y2/% 1 86.7 14.6 2 86.9 15.1 3 86.8 14.9 平均值Average value 86.8 14.9 -

[1] 胡灿,王旭峰,陈学庚,等. 新疆农田残膜污染现状及防控策略[J]. 农业工程学报,2019,35(24):223-234. doi: 10.11975/j.issn.1002-6819.2019.24.027 HU Can, WANG Xufeng, CHEN Xuegeng, et al. Current situation and control strategies of residual film pollution in Xinjiang[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(24): 223-234. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2019.24.027

[2] 严昌荣,刘恩科,舒帆,等. 我国地膜覆盖和残留污染特点与防控技术[J]. 农业资源与环境学报,2014,31(2):95-102. doi: 10.13254/j.jare.2013.0223 YAN Changrong, LIU Enke, SHU Fan, et al. Review of agricultural plastic mulching and its residual pollution and prevention measures in China[J]. Journal of Agricultural Resources and Environment, 2014, 31(2): 95-102. (in Chinese with English abstract) doi: 10.13254/j.jare.2013.0223

[3] 白云龙,李晓龙,张胜,等. 内蒙古地膜残留污染现状及残膜回收利用对策研究[J]. 中国土壤与肥料,2015(6):139-145. doi: 10.11838/sfsc.2015.06.20150923 BAI Yunlong, LI Xiaolong, ZHANG Sheng, et al. Study on the current situation of plastic film residue pollution and the countermeasures for the recovery and utilization of residual film in Inner Mongolia[J]. Soil and Fertilizer Sciences in China, 2015(6): 139-145. (in Chinese with English abstract) doi: 10.11838/sfsc.2015.06.20150923

[4] 梁荣庆,陈学庚,张炳成,等. 新疆棉田残膜回收方式及资源化再利用现状问题与对策[J]. 农业工程学报,2019,35(16):1-13. doi: 10.11975/j.issn.1002-6819.2019.16.001 LIANG Rongqing, CHEN Xuegeng, ZHANG Bingcheng, et al. Problems and countermeasures of recycling methods and resource reuse of residual film in cotton fields of Xinjiang[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(16): 1-13. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2019.16.001

[5] 严昌荣,梅旭荣,何文清,等. 农用地膜残留污染的现状与防治[J]. 农业工程学报,2006,22(11):269-272. doi: 10.3321/j.issn:1002-6819.2006.11.055 YAN Changrong, MEI Xurong, HE Wenqing, et al. Present situation of residue pollution of mulching plastic film and controlling measures[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2006, 22(11): 269-272. (in Chinese with English abstract) doi: 10.3321/j.issn:1002-6819.2006.11.055

[6] XIE J H, TANG W, ZHANG X J, et al. Mechanical properties tests and analysis of plastic mulching film residue[J]. International Agricultural Engineering Journal, 2018, 27(4): 130-135.

[7] 刘艳霞. 中国农村地膜残留污染现状及治理对策思考[D]. 杨凌:西北农林科技大学,2014,43. LIU Yanxia . Reflections on the Pollution Status and Control Countermeasures of Plastic Film Residuals in Chinese Rural Areas[D]. Yangling: Northwest A&F University, 2014, 43. (in Chinese with English abstract)

[8] 段文献,王吉奎,李阳,等. 夹指链式残膜回收装置的设计及试验[J]. 农业工程学报,2016,32(19):35-42. doi: 10.11975/j.issn.1002-6819.2016.19.005 DUAN Wenxian, WANG Jikui, LI Yang, et al. Design and test of clamping finger-chain type device for recycling agricultural plastic film[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(19): 35-42. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2016.19.005

[9] 木拉提·马吾开,郭瑞. 中国机械化残膜回收存在问题及发展对策[J]. 儋州:世界热带农业信息,2021(3):43. doi: 10.3969/j.issn.1009-1726.2021.03.024 [10] 由佳翰,陈学庚,张本华,等. 4JSM-2000型棉秆粉碎与残膜回收联合作业机的设计与试验[J]. 农业工程学报,2017,33(10):10-16. doi: 10.11975/j.issn.1002-6819.2017.10.002 YOU Jiahan, CHEN Xuegeng, ZHANG Benhua, et al. Design and experiment of 4JSM-2000 type combined operation machine for cotton stalk chopping and residual plastic film collecting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(10): 10-16. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2017.10.002

[11] 谢建华,侯书林,付宇,等. 残膜回收机弹齿式拾膜机构运动分析与试验[J]. 农业机械学报,2013,44(S1):94-99. XIE Jianhua, HOU Shulin, FU Yu, et al. Motion analysis and experiment on spring-tooth mulching plastic film collector[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(S1): 94-99. (in Chinese with English abstract)

[12] 赵岩,陈学庚,温浩军,等. 农田残膜污染治理技术研究现状与展望[J]. 农业机械学报,2017,48(6):1-14. doi: 10.6041/j.issn.1000-1298.2017.06.001 ZHAO Yan, CHEN Xuegeng, WEN Haojun, et al. Research status and prospect of control technology for residual plastic film pollution in farmland[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(6): 1-14. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2017.06.001

[13] 孙兴冻,陈玉龙,罗昕,等. 针对秋后立秆模式的残膜回收机的设计[J]. 农机化研究,2015,37(9):73-76. doi: 10.3969/j.issn.1003-188X.2015.09.017 SUN Xingdong, CHEN Yulong, LUO Xin, et al. Design and research of plastic film residue collector used on vertical stem after autumn[J]. Journal of Agricultural Mechanization Research, 2015, 37(9): 73-76. (in Chinese with English abstract) doi: 10.3969/j.issn.1003-188X.2015.09.017

[14] 任萍,胡斌,罗昕. 1MSF-2型立秆式地膜回收机的研制[J]. 农机化研究,2016,38(9):136-140. doi: 10.3969/j.issn.1003-188X.2016.09.027 REN Ping, HU Bin, LUO Xin, et al. Research on manufacturing the 1MSF-2 plastic flim recycling machine[J]. Journal of Agricultural Mechanization Research, 2016, 38(9): 136-140. (in Chinese with English abstract) doi: 10.3969/j.issn.1003-188X.2016.09.027

[15] 鲁兵,王旭峰,胡灿,等. 立秆式搂膜机搂膜齿的设计与有限元分析[J]. 农机化研究,2017,39(10):63-66,71. doi: 10.13427/j.cnki.njyi.2017.10.013 LU Bing, WANG Xufeng, HU Can, et al. Design and finite element analysis of cuddle plastic film tooth for plastic film residue collector used on vertical cotton stem[J]. Journal of Agricultural Mechanization Research, 2017, 39(10): 63-66,71. (in Chinese with English abstract) doi: 10.13427/j.cnki.njyi.2017.10.013

[16] 由佳翰,张本华,温浩军,等. 铲齿组合式残膜捡拾装置设计与试验优化[J]. 农业机械学报,2017,48(11):97-104. doi: 10.6041/j.issn.1000-1298.2017.11.012 YOU Jiahan, ZHANG Benhua, WEN Haojun, et al. Design and test optimization on spade and tine combined residual plastic film device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(11): 97-104. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2017.11.012

[17] 田辛亮,赵岩,陈学庚,等. 4JSM-2000A型棉秆粉碎及搂膜联合作业机的研制[J]. 农业工程学报,2018,34(10):25-35. doi: 10.11975/j.issn.1002-6819.2018.10.003 TIAN Xinliang, ZHAO Yan, CHEN Xuegeng, et al. Development of 4JSM-2000A type combined operation machine for cotton stalk chopping and residual plastic film collecting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(10): 25-35. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2018.10.003

[18] 张恒恒,王香茹,胡莉婷,等. 不同机采棉种植模式和种植密度对棉田土壤水热效应及产量的影响[J]. 农业工程学,2020,36(23):39-47. ZHANG Hengheng, WANG Xiangru, HU Liting, et al. Effects of different machine-harvested cotton planting patterns and planting densities on soil hydrothermal conditions and cotton yield[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(23): 39-47. (in Chinese with English abstract)

[19] 杨明韶,杜健民. 草业工程机械学:草业工程机械学[M]. 北京:中国农业大学出版社,2013,386. [20] 张佳喜,郜周明,蔡佳麟,等. 横轴对辊式棉秆起拔装置设计与试验[J]. 农业工程学报,2021,37(7):43-52. doi: 10.11975/j.issn.1002-6819.2021.07.006 ZHANG Jiaxi, GAO Zhouming, CAI Jialin, et al. Design and experiments of cotton stalk pulling machine with horizontal-counter rollers[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(7): 43-52. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2021.07.006

[21] 温浩军,牛琪,纪超. 地膜机械化技术现状及分析[J]. 中国农业大学学报,2017,22(3):145-153. WEN Haojun, NIU Qi, JI Chao. Current status of and analysis on the mechanical technology of plastic film[J]. Journal of China Agricultural University, 2017, 22(3): 145-153. (in Chinese with English abstract)

[22] 曹肆林,谢建华,杨豫新,等. 侧排式棉秸秆还田及残地膜回收联合作业机的设计与试验[J/OL]. 吉林大学学报(工学版):1-14 CAO Silin, XIE Jianhua, YANG Yuxin, et al. Design and experiment of side row cotton straw returning and residual film recovery combined machine [J/OL]. Journal of Jilin University(Engineering and Technology Edition): 1-14. [2022-11-13] (in Chinese with English abstract)

[23] 刘旋峰,石鑫,郭兆峰,等. 滚筒式残膜回收机的性能试验研究[J]. 农业工程学报,2017,33(16):26-31. doi: 10.11975/j.issn.1002-6819.2017.16.004 LIU Xuanfeng, SHI Xin, GUO Zhaofeng, et al. Performance test on roller type residual film recycling machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(16): 26-31. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2017.16.004

[24] 中国农业机械化科学研究院. 农业机械设计手册. [M]. 北京:中国农业科学技术出版社,2007,1885. [25] 赵海军. 残膜捡拾滚筒的运动学和动力学研究[D]. 乌鲁木齐:新疆农业大学,2005,70. ZHAO Haijun. Study on Kinematics and Dynamics of Roller for Collecting Plastic Film Residue[D]. Urumqi: Xinjiang Agricultural University, 2015, 70. (in Chinese with English abstract)

[26] 许涛,沈永哲,高连兴,等. 基于两段收获的弹齿式花生捡拾机构研究[J]. 农业机械学报,2016,47(3):90-97,111. XU Tao, SHEN Yongzhe, GAO Lianxing, et al. Spring-finger peanut pickup mechanism based on two-stage harvest[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(3): 90-97,111. (in Chinese with English abstract)

[27] 李斌,王吉奎,胡凯,等. 残膜回收机顺向脱膜机理分析与试验[J]. 农业工程学报,2012,28(21):23-28. LI Bin, WANG Jikui, HU Kai, et al. Analysis and test of forward film removing mechanism for polythene film collector[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(21): 23-28. (in Chinese with English abstract)

[28] 靳伟,张学军,丁幼春,等. 基于EDEM-Fluent的残膜与杂质悬浮分离仿真与试验[J]. 农业机械学报,2022,53(4):89-98. JIN Wei, ZHANG Xuejun, DING Youchun, et al. Experiment on suspension separation of residual film and impurity based on EDEM-Fluent coupling[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(4): 89-98. (in Chinese with English abstract)

[29] 杨伦,谢一华. 气力输送工程[M]. 北京:机械工业出版社,2006,416. [30] 谢建华,唐炜,曹肆林,等. 齿链复合式残膜回收机设计与试验[J]. 农业工程学报,2020,36(1):11-19. doi: 10.11975/j.issn.1002-6819.2020.01.002 XIE Jianhua, TANG Wei, CAO Silin, et al. Design and experiment of tooth chain compound type residual plastic film collector[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(1): 11-19. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2020.01.002

[31] 谢建华,杨豫新,曹肆林,等. 导向链耙式地表残膜回收机设计与试验[J]. 农业工程学报,2020,36(22):76-86. doi: 10.11975/j.issn.1002-6819.2020.22.009 XIE Jianhua, YANG Yuxin, CAO Silin, et al. Design and experiments of rake type surface residual film recycling machine with guide chain[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(22): 76-86. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2020.22.009

[32] 郁志宏,淮守成,王文明. 基于弹齿轨迹的滚筒式牧草捡拾器遗漏率及工作参数优化[J]. 农业工程学报,2018,34(4):37-43. YU Zhihong, HUAI Shoucheng, WANG Wenming. Leakage rate and optimization of working parameters for cylinder pickup collector based on spring-finger trajectory[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(4): 37-43. (in Chinese with English abstract)

下载:

下载: