Blind fault separation of RV reducers using time-frequency ridge extraction and improved sparse component analysis

-

摘要:

针对农业机器人的核心传动部件旋转矢量(rotate vector,RV)减速器的故障特征提取问题,该研究提出一种基于时频图像脊线提取与改进稀疏分量分析相结合的RV减速器复合故障盲提取方法。首先利用提出的时频图像脊线提取(ridge extraction from time-frequency images,RETF)方法同步截取机械臂恒速时段的观测振动信号,然后利用提出的sinC函数改进形态滤波(sinC-morphological filtering,SMF)算法、密度峰值聚类(density peak clustering,DPC)算法和正交匹配追踪(orthogonal matching pursuit,OMP)算法相结合的盲源分离方法(SMF-DPC-OMP)实现平稳信号复合故障的分离提取。以sinC函数作为新的结构元素构造平均组合形态滤波器,对恒速时段的振动信号进行形态滤波处理,以提升信号的冲击特性以及稀疏性;利用DPC估计稀疏信号的混合矩阵,构建传感矩阵,并结合OMP在频域完成分离源信号重构,最后对重构的时域信号进行快速傅里叶变换完成故障识别。试验台采集的RV减速器的太阳轮和行星轮磨损复合故障信号的分析结果显示,该算法能有效实现RV减速器复合故障的盲分离。RETE算法能够在变转速工况导致时频图较为模糊的情况下,识别出RV减速器的运动状态;SMF-DPC-OMP算法能够在故障源数目未知的情况下,有效完成复合故障的盲分离。与已有方法相比,SMF-DPC-OMP方法能够节省约75%的时间成本,频谱更为简洁,能够抑制精细侧频和干扰分量,适用于关节型农业机器人RV减速器复合故障盲分离,对生产实际中的故障特征提取具有一定的参考意义。

Abstract:The rotary vector (RV) reducer is one of the most important transmission components inside the joints of robots. The high precision motion control of the robot can be realized in the normal operation and service life of agricultural robots. However, the complex structure of the RV reducer cannot fully meet the variable conditions in actual work and the harsh working environment. Mechanical, cracks, and pitting faults can often occur at the same time or successively in actual operation, due to lubrication, manufacturing errors, and unreasonable forces. The signals collected by the sensor are also the mutual coupling of multiple fault sources. Therefore, it is necessary to explore the composite fault diagnosis of the RV reducer. In this study, a blind fault separation was proposed from the compound signals of the RV reducer using time-frequency image ridge extraction and improved sparse component analysis. The fault feature of the RV reducer was then extracted from the core transmission component of agricultural robots. The composite fault diagnosis of the RV reducer was finally realized with the unknown number of fault sources under the reciprocating motion of the joint arm and the time-varying speed of the agricultural robot. Firstly, the ridge extraction from time-frequency images (RETF) was used to synchronously intercept the vibration signals of the manipulator in the constant speed period. Then, the blind source separation (SMF-DPC-OMP) was combined with the sinC function to improve morphological filtering (SMF), density peak clustering (DPC), and orthogonal matching pursuit (OMP), in order to separate and extract the composite faults of stationary signals. The sinC function was taken as a new structural element to construct the average combined morphological filter. The vibration signal in the constant speed period was subjected to morphological filtering for better impact characteristics and sparsity of the signal. The DPC was used to estimate the mixing matrix of sparse signals, and then the sensing matrix was constructed. The separation source signal was reconstructed to combine with the OMP algorithm in the frequency domain. Finally, the reconstructed time-domain signal was subjected to the fast Fourier transform for fault identification. The test bench was utilized to collect the composite fault signals of the sun gear and planetary gear wear of the RV reducer. The results show that the blind separation was effectively realized on the composite faults of the RV reducer. The RETE was used to identify the motion state of the RV reducer, when the time-frequency diagram was blurred, due to the variable speed condition. The SMF-DPC-OMP effectively completed the blind separation of composite faults when the number of fault sources was unknown. The SMF-DPC-OMP saved about 75% of the running time cost than before. A more concise spectrum was achieved to better suppress the fine side frequency and interference components. It is suitable for the composite fault diagnosis of the RV reducer in the articulated industrial robot. The finding can provide a strong reference for the fault feature extraction in the actual production.

-

Keywords:

- robots /

- fault diagnosis /

- RV reducer /

- ridge extraction /

- density peak clustering /

- orthogonal matching pursuit /

- composite fault

-

0. 引 言

随着农业装备不断向现代化、智能化和规模化发展[1],工业机器人的应用范围扩展至农业装备领域是必然趋势。旋转矢量(rotate vector,RV)减速器具有体积小、传动比范围大、质量轻、精度保持稳定、效率高等特点,农业机械经常需要大比例减速的情况,常选用RV减速器[2]。RV减速器作为农业机器人及农业机械的核心传动部件,其健康状况直接决定了传动精度、可靠性、生产效率和农机寿命。然而,由于RV减速器结构复杂,且在实际工作中工况多变,作业环境恶劣,随时发生故障[3]。RV减速器故障严重时会导致生产停滞,造成巨大的经济损失。因此,研究农业机器人RV减速器的故障诊断方法,及早发现并处理故障,缩短维护时间,对保障机器人安全运行、提高企业生产效率和经济效益具有重大意义。

振动信号能够有效反映部件的健康状态,在故障诊断中得到广泛应用[4]。近年来,许多学者对此开展了研究,提出了神经网络[5]、深度学习[6]、时频分析[7]、盲反卷积[8]等方法。汪久根等[9]采用残差网络提高了RV减速器不同故障的分类准确率。YIN等[10]开发了一种基于知识和数据双驱动的传输网络用于RV减速器故障诊断。彭鹏等[11]提出了一种抗干扰的 RV 减速器故障识别卷积神经网络模型。韩特等[12]在深度特征嵌入空间下构建特征图,通过标签传播算法生成伪标签,利用信息熵评估健康状态概率的分布。上述关于RV减速器的故障诊断精度较高,主要采用神经网络、深度学习、机械学习等算法,但是此类算法的实现需要大量不同类型的数据支撑。而基于时域、频域或时频域的分析方法能够在少量数据的支撑下完成故障诊断。XIE等[13]提出了一种基于电流信号的瞬时频率趋势图与参数自适应变分模态分解算法相结合的RV减速器故障诊断方法,实现了RV减速器太阳轮故障特征提取。GUO等[14]将计算阶跟踪和同步平均相结合识别了RV减速器行星齿轮齿根裂纹故障。雷亚国等[15]利用脊线提取完成RV减速器振动信号的平稳数据截取,有效提取了RV减速器行星轮的故障信息。由于RV减速器因润滑、制造误差和不合理受力会引起各种机械故障,使得实际运行中裂纹、点蚀等故障往往同时或先后出现,传感器采集的信号往往是多个故障源相互耦合的结果,使故障诊断变得非常困难。文献[13-15]提出的故障诊断方法适于单一故障诊断,对RV减速器复合故障检测能力下降甚至失效。因此,如何在复合故障相互耦合以及往复运动、时变转速工况下,精确分离提取耦合故障特征是RV减速器故障诊断领域亟待攻克的难题。盲源分离(blind source separation,BSS)技术可以在传输通道未知的情况下,从混合信号中把多个信号源分离出来。独立成分分析(independent component analysis,ICA) [16]和稀疏分量分析(sparse component analysis,SCA) [17] 是常用的以信号处理技术求解BSS问题。ICA算法的前提是源信号是统计独立的,且每个独立分量必须符合非高斯分布。而现代机械设备难以满足统计独立性的假设,但SCA方法的稀疏性假设相对容易满足。

SCA算法中,聚类方法是混合矩阵估计的首选。WANG等[18]提出了一种两阶段的聚类算法,从而提高了混合矩阵的估计精度。NORSALINA等[19]引入自适应时频阈值提高混合矩阵估计的精度。DING等[20]利用同步压缩S变换估计含谐波传输阻抗的混合矩阵。密度峰值聚类算法(density peak clustering,DPC)考虑局部密度和相对距离绘制决策图,快速识别簇中心并完成聚类。 DPC具有唯一输入参数,无需先验知识和迭代[21]。在解决振动源数目估计方面有一定的潜力。SCA算法还包括了源信号的恢复,主流方法有两类:一是通过优化逼近L0范数的函数恢复源信号。BU等[22]使用光滑的连续函数来近似L0范数。ZHANG等[23]用复三角函数逼近L0范数。但是上述方法具有源信号射入方向越近恢复精度越低。二是压缩感知(compressed sensing,CS)重构算法[24],该方法使用L1范数优化取代L0范数优化恢复源信号,避免了L0范数优化的NP-Hard问题。正交匹配追踪算法(orthogonal matching pursuit,OMP)克服匹配追踪算法的缺陷,在算法迭代过程中,残差能够与已经选择的原子正交,保证相同索引不会被重复选择,迭代过程在有限的次数内收敛[25],在重构信号算法的研究中发挥了重要作用。

结合上述分析,本文提出一种基于时频图像脊线提取与改进稀疏分量分析相结合的RV减速器复合故障盲提取方法,旨在实现往复运动、时变转速、故障源数目未知工况下的RV减速器复合故障诊断。首先使用时频图像脊线提取(ridge extraction from time-frequency images,RETF)从时频图中提取脊线,完成对平稳信号的同步截取,然后利用sinC函数改进形态滤波(sinC-morphological filtering,SMF)、DPC和OPM相结合的盲源分离方法(SMF-DPC-OMP)实现平稳信号复合故障的分离提取,采用SMF对观测信号进行滤波降噪处理,在提高信噪比的同时突出信号的冲击分量,并对滤波后的信号进行密度峰值聚类处理,得到聚类中心,构建传感矩阵;接着将滤波后的信号转换到频域以满足SCA的稀疏性要求;最后利用OMP算法在频域重构源信号,在提高计算速度和适应性的同时,实现复合故障特征的提取。

1. 盲分离的数学模型

盲源分离是指在源信号和信号传输通道均未知的情况下,仅依赖传感器拾取的观测信号恢复和估计源信号的技术[26]。含噪声SCA的数学模型为

{{\boldsymbol{X}}_{m \times t}} = {{\boldsymbol{A}}_{m \times n}}{{\boldsymbol{S}}_{n \times t}} + {{\boldsymbol{V}}_{m \times t}} (1) 式中 {\boldsymbol{X}} 为观测矩阵,即采集到的振动信号; {\boldsymbol{A}} 为混合矩阵; {\boldsymbol{S}} 是具有稀疏性的未知源信号; {\boldsymbol{V}} 为噪声或其他随机干扰成分; m 为传感器数量; n 为源信号数量; t 为观测时间,s。

2. 基于时频图像的脊线提取

短时傅里叶变换(short-time fourier transform,STFT)是有效捕获时变频率的方法之一,其定义为[27]

Q\left( {t,f} \right) = \int\limits_R {x\left( \tau \right){h_\sigma }\left( {\tau - t} \right){{\text{e}}^{ - {j}_0 2{\text{π }}f\tau }}{\text{d}}\tau } (2) 式中x\left( \tau \right) 为多分量信号;Q\left( {t,f} \right)是信号的时频表达(time frequency representation,TFR);{h_\sigma }\left( {\tau - t} \right)是长度为\tau 的高斯窗;R为实数集;t为时间;f为频率;j表示复数。

从TFR中提取时频脊线估计瞬时频率(instantaneous frequency,IF)是完全非参数的,并且能适应不同的情况。有效的脊线提取方法是寻找TFR的最大位置[27],其定义如下:

\overline {{D}} (t) = \mathop {\arg \max }\limits_{f \in J} \left| {Q(t,f)} \right|,{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} t = {t_0}, \ldots ,{t_{N - 1}} (3) 式中 \overline {{D}} (t) 表示得到的脊线,是理论 {{D}}(t) 的估计, J 是频率的集合,N 为信号截止时间。RETF算法的具体实现步骤如下:

1)初始化参数,并创建一个预存矩阵{{\boldsymbol{K}}_i};

2)对时域信号x\left( t \right)进行STFT变换,得到其时频分布Q\left( {t,f} \right);

3)寻找并标记最大能量点\left[ \begin{gathered} {t_0} \\ {f_0} \\ \end{gathered} \right],将该点存储为{\boldsymbol{K}}矩阵的第一列;

4)使Q\left( {{t_0},f} \right)在最大值点{t_0}附近时刻归0,即Q\left( {{t_0},f} \right) = 0,f \in \left[ {{f_0} - \Delta f,{f_0} + \Delta f} \right],其中\Delta f为滤波带宽惩罚参数,控制滤波带宽;

5)在Q\left( {{t_0},f} \right)的邻域内寻找下一个最大能量点 \left[ \begin{gathered} t_{0}' \\ f_{0}' \\ \end{gathered} \right] = \ {\mathrm{\max}} _{\left( {{t_\alpha },{f_\alpha }} \right)}Q\left( {t,f} \right) 。 {t_\alpha } \in \left[ {{t_0} - 1,{t_0} + 1} \right] ,{f_\alpha } \in \left[ {f_0} -F,{f_0} + F \right],H为选定的窗参数,控制迭代中 \overline {{D}} (t) 增量的平滑程度,H越小, \overline {{D}} (t) 增量越平滑;

6)将 \left[ \begin{gathered} t_0' \\ f_0' \\ \end{gathered} \right] 存储为{\boldsymbol{K}}矩阵的下一列;

7)使Q\left( {t_0',f} \right)在最大值点t_0'附近时刻归0,即Q\left( {t_0',f} \right) = 0,f \in \left[ {{f_0} - \Delta f,{f_0} + \Delta f} \right];

8)如果时间指标{t_\alpha }和频率指标{f_\alpha }未达到TFR矩阵的边界,返回步骤5);否则返回步骤1),并创建一个新的预存矩阵{{\boldsymbol{K}}_{i + 1}};

9)当剩余TFR能量小于阈值\varepsilon 时停止算法(每一个预存矩阵,即是一条时频脊线)。

3. 基于SMF-DPC-OMP的盲源分离

3.1 基于\sin C函数的改进形态滤波降噪

3.1.1 构建\sin C结构元素

\sin C函数又称辛格函数,定义如下:

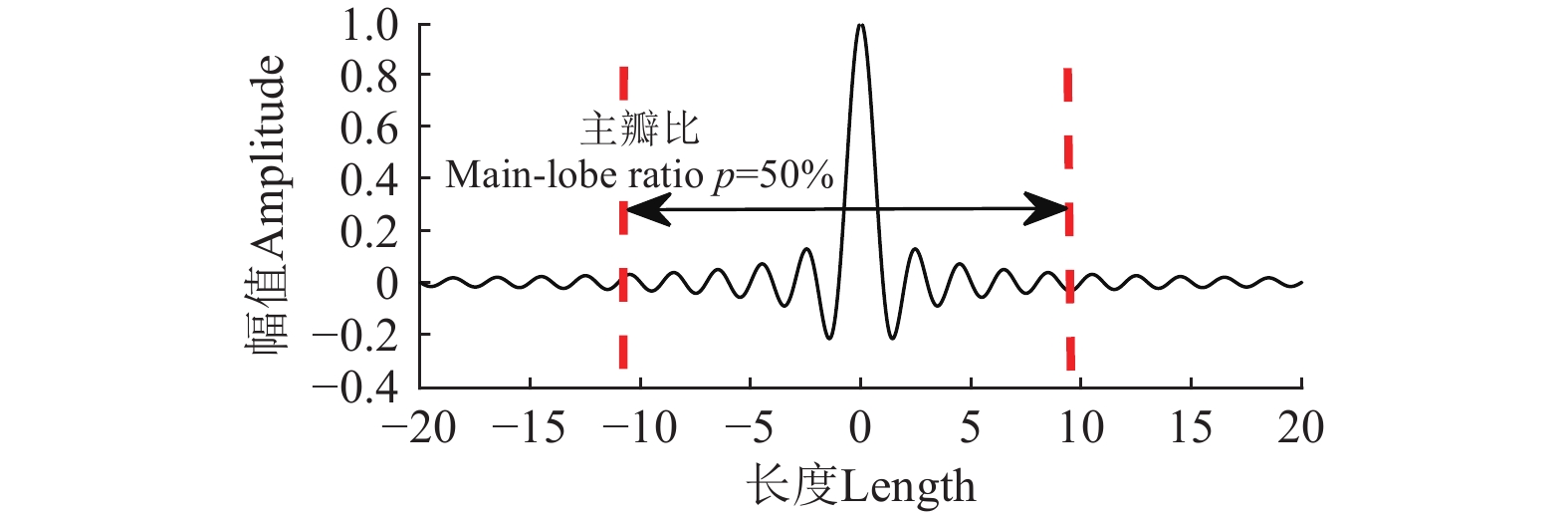

\sin C\left( x \right) = \frac{{\sin \left( {{\text{π}}x} \right)}}{{{\text{π}}x}} (4) 本文选取 \sin C 函数作为结构元素时主要定义长度L和主瓣比p。长度是指整个图像的长度,主瓣比是指从中间截取整个图像的百分比。图1为L = 20、 p = 50\text{%} 的 {\mathrm{sin}} C 结构元素。

3.1.2 构建平均组合滤波器

形态滤波器的构建主要包括结构元素和形态算子。结构元素的选择包括结构元素的形状、长度、高度(振幅)等。在处理一维信号时 ,结构元素的形状一般有线形、三角形、半圆形、正弦等,本文选择 sin C函数作为结构元素 ,结合形态算子腐蚀Θ、膨胀\oplus 、形态开○和形态闭●,构建基于sinC函数的SMF平均组合滤波器。

设原信号f\left( n \right)和结构元素g\left( m \right)为分别定义在F\left( {1,2, \ldots ,n - 1} \right)和G = \left( {1,2, \ldots, m - 1} \right)上的离散函数, N \geqslant M。则f\left( n \right)关于g\left( m \right)的腐蚀运算、膨胀运算、开运算和闭运算[28]分别为

(f\Theta g)(n) = \min[f(n + m) - g(m)] (5) (f \oplus g)(n) = \max [f(n - m) + g(m)] (6) (f \circ g){\kern 1pt} (n) = (f\Theta g \oplus g)(n) (7) (f \bullet g){\kern 1pt} (n) = (f \oplus g\Theta g)(n) (8) 通常使用形态开和形态闭的级联形式去除信号中的正、负噪声。TANG[28]为了去除信号中的正、负噪声,定义了形态闭-开(closing-opening,CO)和开-闭(opening-closing,OC)滤波器:

{\mathrm{CO}}{\kern 1pt} (f(n)) = (f \bullet g \circ g)(n) (9) {\mathrm{OC}}{\kern 1pt} (f(n)) = (f \circ g \bullet g)(n) (10) 为了抑制统计偏倚,本文采用结合OC和CO的平均组合滤波器[28]:

y(n) = [{\mathrm{OC}}(f(n) + {\mathrm{CO}}(f(n)]/2 (11) 3.1.3 基于\sin C的平均组合滤波器效果验证

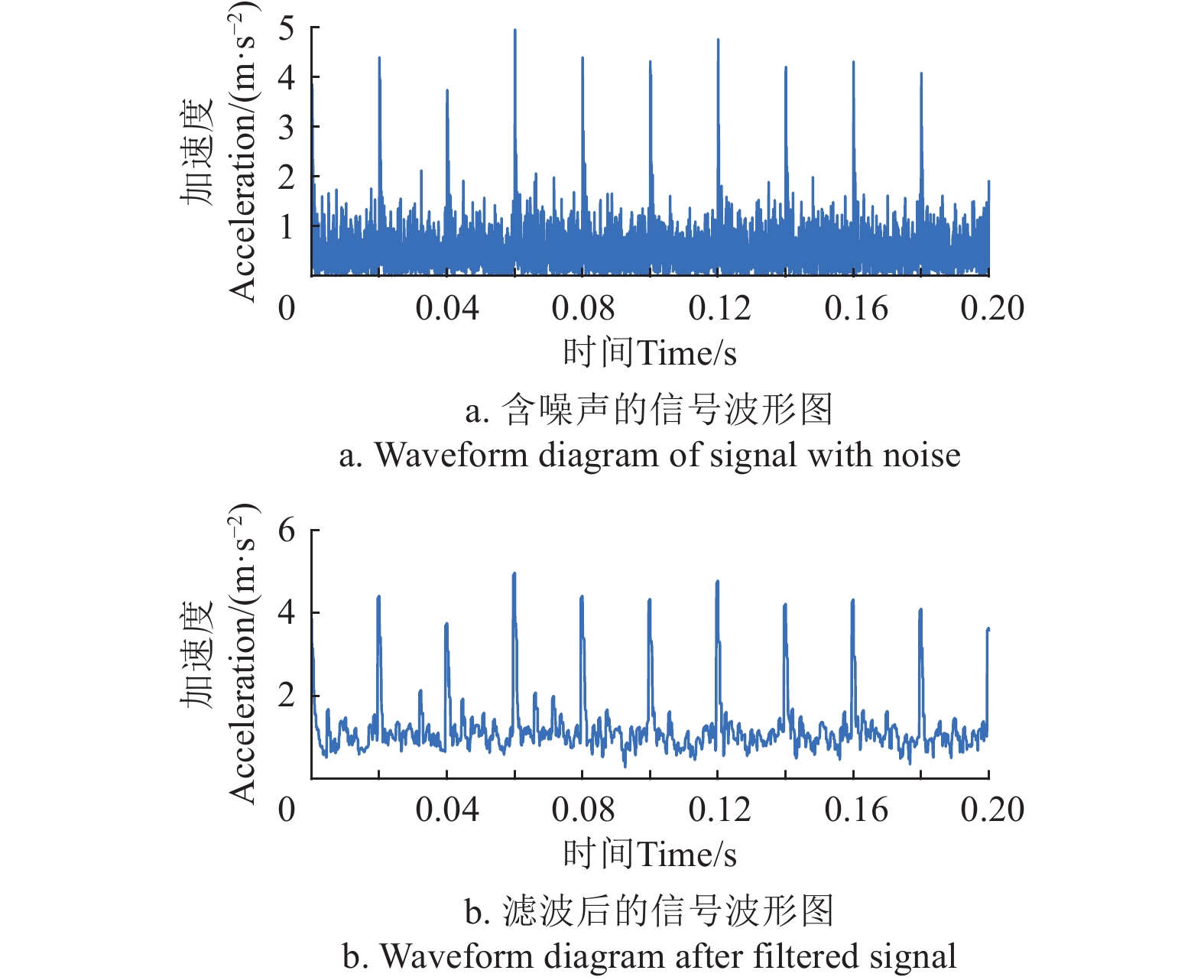

为了验证基于{\mathrm{sin}}\; C 函数的SMF滤波效果,生成模拟轴承外圈故障的仿真信号并添加信噪比(signal-to-noise ratio,SNR)为−3 dB的白噪声。图2为含噪声的仿真信号及滤波后的时域波形图,SMF降噪后的信噪比为0.7 dB,说明SMF较好的滤除干扰噪声,突显了信号的冲击特性。

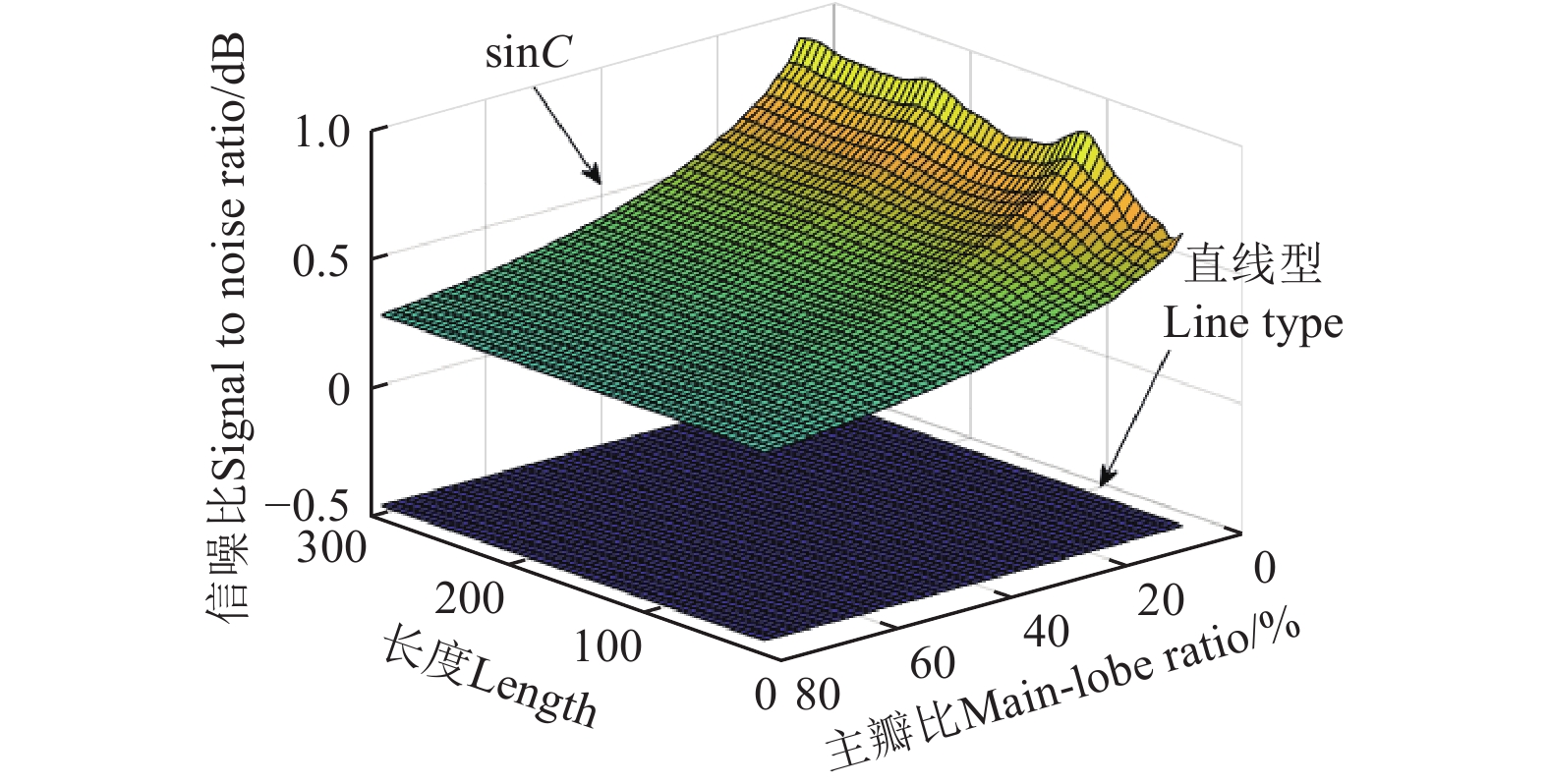

将本文的SMF滤波器与文献[29]中的直线型滤波器(幅值为0,长度为10)进行对比,滤波器参数及滤波效果如图3所示。分析图3可知无论滤波器的参数如何选择,SMF的滤波后的信噪比总是要优于直线型滤波器。

3.2 基于DPC-OMP的盲源分离

3.2.1 DPC理论

DPC算法主要基于2个假设:1)聚类中心周围是低密度的点;2)聚类中心与密度较高的样本点之间的距离较大。设数据集U{{ = }}\left\{ {{u_1},{u_2}, \cdots, {u_R}} \right\}, {u_i}{{ = }}{\left( {{u_{i1}},{u_{i2}}, \cdots, {u_{io}}} \right)^{\mathrm{T}}} ,其中i = 1,2, \cdots ,R,{u_{ij}}表示数据点i的j维属性,j = 1,2, \cdots ,O;R为总体样本数。

1)计算局部密度\rho

对于每个数据点{u_i},i = 1,2, \cdots ,R,局部密度{\rho _i}可以被认为是距离点{u_i}较近的点的数量,{\rho _i}的定义如下[30]:

{\rho _i} = \sum\limits_{j,j \ne i} {\chi \left( {{d_{ij}} - {d_c}} \right)} (12) 式中\chi \left( x \right)为分段函数,x < 0时,\chi \left( x \right){\text{ = }}1,否则\chi \left( x \right){\text{ = 0}};{d_{ij}}表示i和j之间的距离(通常为欧氏距离),{d_c}表示截断距离。

2)计算最近邻距离\delta

每个点的最近邻距离{\delta _i} 为

{\delta _i} = \left\{ \begin{gathered} \mathop {\min \left( {{d_{ij}}} \right)}\limits_{j:{\rho_j} > {\rho_i}} ,{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\rho _i} < \max \left( \rho \right) \\ \mathop {\max \left( {{d_{ij}}} \right)}\limits_j ,{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\rho _i} = \max \left( \rho \right) \\ \end{gathered} \right. (13) 对于密度较低的样本点,计算该样本点与高于其密度的最近样本点之间的距离;而对于密度最高的样本点,则计算该点与最远样本点之间的距离。

3)选取聚类中心 V

聚类中心定义为同时具有高密度{\rho _i}和较大距离{\delta _i}的点{x_i},令{V_i} = {\rho _i}{\delta _i},取 V > \dfrac{2}{N}\displaystyle\sum\limits_{i = 1}^N {{V_i}} 为聚类中心。由于聚类对象为RV故障信号,{V_i}大多为0。为保证不遗漏正确的聚类中心,因此选取大于均值2倍的数据点为聚类中心。

3.2.2 压缩感知重构算法

利用压缩感知重构算法中的OMP算法对源信号进行重构。将 m 个长度为 t 的观测信号表示为 {\boldsymbol{y}} = ({y_{11}}, {y_{12}}, \cdots {y_{1\;t}}, \cdots ,{y_{m1}},{y_{m2}}, \cdots {y_{mt}})^{\mathrm{T}} 。

利用聚类中心 {\boldsymbol{V}}(m \times n) 构造传感矩阵 {\boldsymbol{W}} 。根据压缩感知模型,当混合信号长度为 mt \times 1 ,其传感矩阵 {\boldsymbol{W}} 的长度为 mt \times nt 。利用傅里叶变换正交矩阵 {{\boldsymbol{E}}_{t \times t}} 扩充矩阵 {\boldsymbol{V}} 的元素值,变换关系为 {{\boldsymbol{B}}_{ij}} = {{\boldsymbol{E}}_{t \times t}}{{\boldsymbol{V}}_{ij}} ,具体变换如式(14)所示。

{\boldsymbol{y}} = \left[ \begin{gathered} {{\boldsymbol{{\boldsymbol{B}}}}_{11}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{12}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \cdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{1n}} \\ {{\boldsymbol{B}}_{21}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{21}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \cdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{2n}} \\ {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \vdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \vdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \vdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \vdots \\ {{\boldsymbol{B}}_{m1}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{m2}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \cdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{mn}} \\ \end{gathered} \right]{\boldsymbol{x}} (14) {\boldsymbol{x}} = {({x_{11}},{x_{12}}, \cdots ,{x_{1\;t}}, \cdots ,{x_{n1}},{x_{n2}}, \cdots ,{x_{nt}})^{\mathrm{T}}} 的长度是 (nt \times 1) 。至此,盲源分离的重构模型构建完成。

OMP是一种常用的压缩感知重构算法。首先在每次迭代过程中对所有选定的原子进行Schmidt正交化,以确保每次迭代的结果都是最优解。利用OMP算法进行重构的核心思想是构造频域感知矩阵。具体算法步骤如下:

1)初始化残差 {r_0} ,迭代次数 \ell ,傅立叶正交变换矩阵 {{\boldsymbol{E}}_{t \times t}} ,并根据 {{\boldsymbol{B}}_{ij}} = {{\boldsymbol{E}}_{t \times t}}{{\boldsymbol{V}}_{ij}} 构造传感矩阵 {\boldsymbol{W}}{\kern 1pt} {\kern 1pt} {\text{ = }}{\kern 1pt} {\kern 1pt} {\kern 1pt} \left[ \begin{gathered} {{\boldsymbol{B}}_{11}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{12}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \cdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{1n}} \\ {{\boldsymbol{B}}_{21}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{21}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \cdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{2n}} \\ {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \vdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \vdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \vdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \vdots \\ {{\boldsymbol{B}}_{m1}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{m2}}{\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} \cdots {\kern 1pt} {\kern 1pt} {\kern 1pt} {\kern 1pt} {{\boldsymbol{B}}_{mn}} \\ \end{gathered} \right] ;

2)使用内积法计算传感矩阵 {\boldsymbol{W}} 的列向量与残差{r_i}的投影系数,并记录最大投影系数相对应的位置 {{\boldsymbol{\beta}} _i} ,随后将最大投影系数所对应的传感矩阵 {\boldsymbol{W}} 的列置0;

3)使用最小二乘法计算本次迭代的重构信号的估计值 {x_i} = {({{\boldsymbol{\beta}} _i}^{\mathrm{T}} \cdot {{\boldsymbol{\beta}} _i})^{ - 1}} \cdot {{\boldsymbol{\beta}} _i}^{\mathrm{T}} \cdot {{\boldsymbol{r}}_i} ;

4)更新残差 {r_{i + 1}} = {r_i} - {x_i} ,并重复步骤2),直到迭代结束;

5)使用 {E_{t \times t}} 做逆傅立叶变换得到维数为 (kt \times 1) 的时域信号 x ,并根据聚类中心的维数k,将维数为 (kt \times 1) 的时域信号 x 分割为k个维数为\left( {t \times 1} \right)的时域信号,从而完成信号的盲源分离。

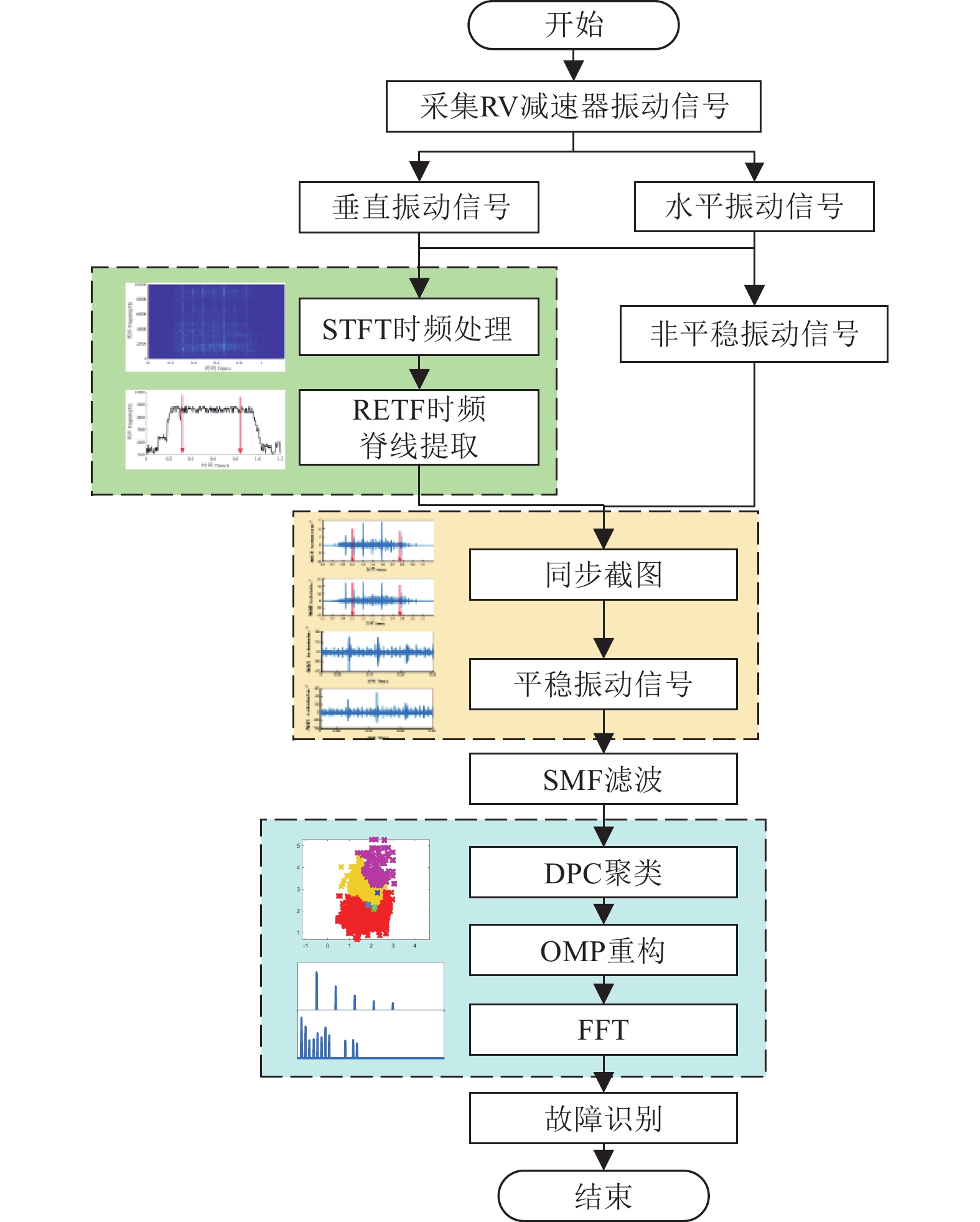

3.3 本文算法总流程

1)平稳阶段截取:提取一组观测信号x\left( t \right)并进行STFT得到其时频表达Q\left( {t,f} \right)。随后提取时频脊线并截取恒速时段信号,获得平稳信号{x_1}\left( t \right);

2)信号预处理:构造基于 \sin C 结构元素的平均组合滤波器,并对平稳信号{x_1}\left( t \right)进行滤波降噪,得到滤波信号{x_2}\left( t \right);

3)估计混合矩阵:对滤波信号{x_2}\left( t \right)进行DPC得到聚类中心,即混合矩阵;

4)源信号重构:利用步骤3)的混合矩阵构造传感矩阵,使用OMP算法在频域重构源信号;

5)故障识别:对重构源信号进行快速傅里叶变换(fast Fourier transform,FFT)处理,根据分离信号频谱中的频率进行故障识别。

本文算法的总体流程图如图4所示。

4. 试验验证

4.1 试验介绍

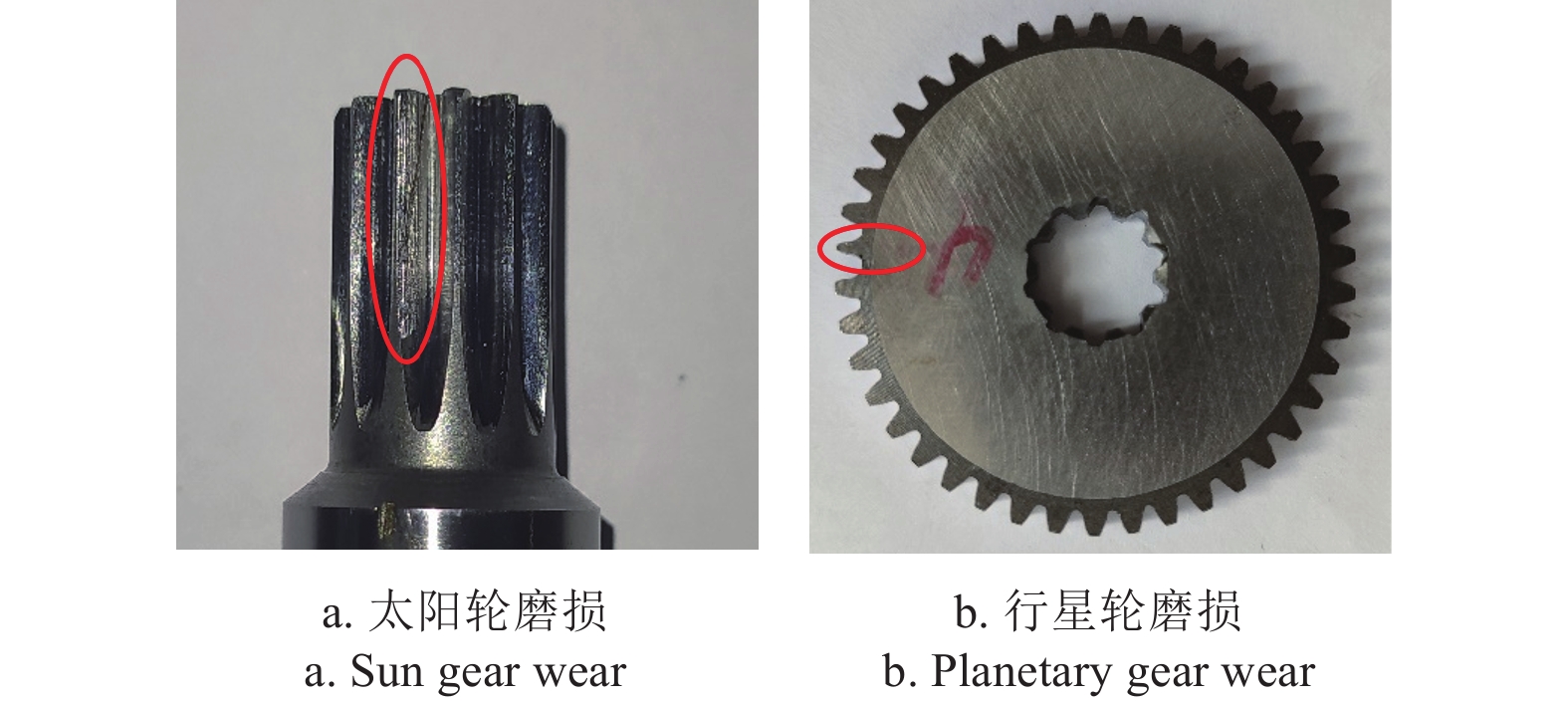

试验信号来自于模拟农业机器人单关节臂往复运动的RV减速器试验台,如图5所示。将2个型号为333B30的PCB加速度传感器相互垂直安装于减速器保持架上拾取信号。水平方向为传感器1,垂直方向为传感器2。其中,试验台基座7上安装减速器保持架4,通过减速器保持架4装RV减速器5,型号为SV-X2MH100C-B2 LN的电机6输出轴通过RV减速器5连接关节臂1。图6为故障齿轮的实物图,图6a为太阳轮磨损图,图6b为行星轮磨损图。

试验选用RV40E型减速器并以针轮固定的方式固定于试验台,减速比121、行星齿轮数目为2,太阳轮齿数{Z_1} = 12,行星轮齿数{Z_2} = 42,摆线轮齿数{Z_3} = 39,针轮齿数{Z_4} = 40。采集系统包括NI-USB9234采集卡与单向加速度传感器,采样频率为25.6 kHz。试验预设摆臂运动范围为0°~90°(单次抬升或下降90°),运行速度为100°/s。RV减速器的各个特征频率计算式见表1。

表 1 RV减速器各零件的工作频率Table 1. Working frequency of each part of RV reducer名称Name 计算公式Calculation formula 电机主轴转速

Motor spindle speed {n_1}/(r·min−1){n_1} = 60f/P 太阳轮转频

Sun gear rotation frequency {f_1}/Hz{f_1} = {n_1}/60 行星轮转频

Planetary gear rotation frequency {f_2}/Hz{f_2} = \dfrac{{{z_1}{z_4}}}{{({z_3} - {z_4})\left( {{z_1} + {z_2}{z_4}} \right)}}{f_1} 一级啮合频率

First stage engagement frequency {f_{1c}}/Hz{f_{1c}} = \dfrac{{{z_1}{z_2}{z_4}}}{{{z_1} + {z_2}{z_4}}}{f_1} 注:P为伺服电机磁极对数,{{\textit{z}}_1}为太阳轮齿数,{{\textit{z}}_2}为行星轮齿数,{{\textit{z}}_3} 为摆线轮齿数,{{\textit{z}}_4} 为针轮齿数。

Note: P is the number of magnetic poles of the servo moto, {{\textit{z}}_1} is the number of solar gear, {{\textit{z}}_2} is the number of planetary gear, {{\textit{z}}_3} is the number of cycloidal gear, and {{\textit{z}}_4} is the number of needle gear.行星轮故障频率{f_p}为行星轮相对于行星架的旋转频率,{f_p} = {f_2} - {f_3};太阳轮故障频率{f_s}为太阳轮相对于行星架的旋转频率,{f_s} = {f_1} + {f_3}。由于摆臂转速=100(°)/s =0.27 Hz,即支撑盘转频{f_3}=0.27 Hz。根据表1及太阳轮故障频率计算式计算可得太阳轮故障频率{f_s}为38.34 Hz,行星轮故障频率{f_p}为10.83 Hz。

4.2 试验信号分析

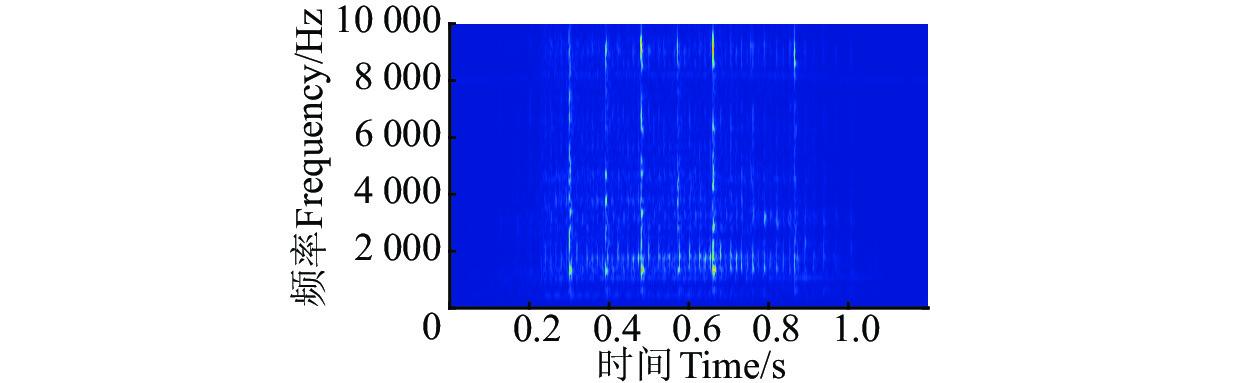

由传感器1和传感器2采集的2组信号都具有相同的运动状态,即同时加速或同时减速。因此本文在平稳阶段选取水平方向传感器1的振动信号用以分析机械臂的运动状态。图7为选取的振动信号进行STFT获得的时频图。可以看出,由于RV减速器的瞬时冲击过大,无法通过时频图区分出机械臂的3种运动状态,即启动加速阶段,恒速运动阶段以及减速停滞阶段。

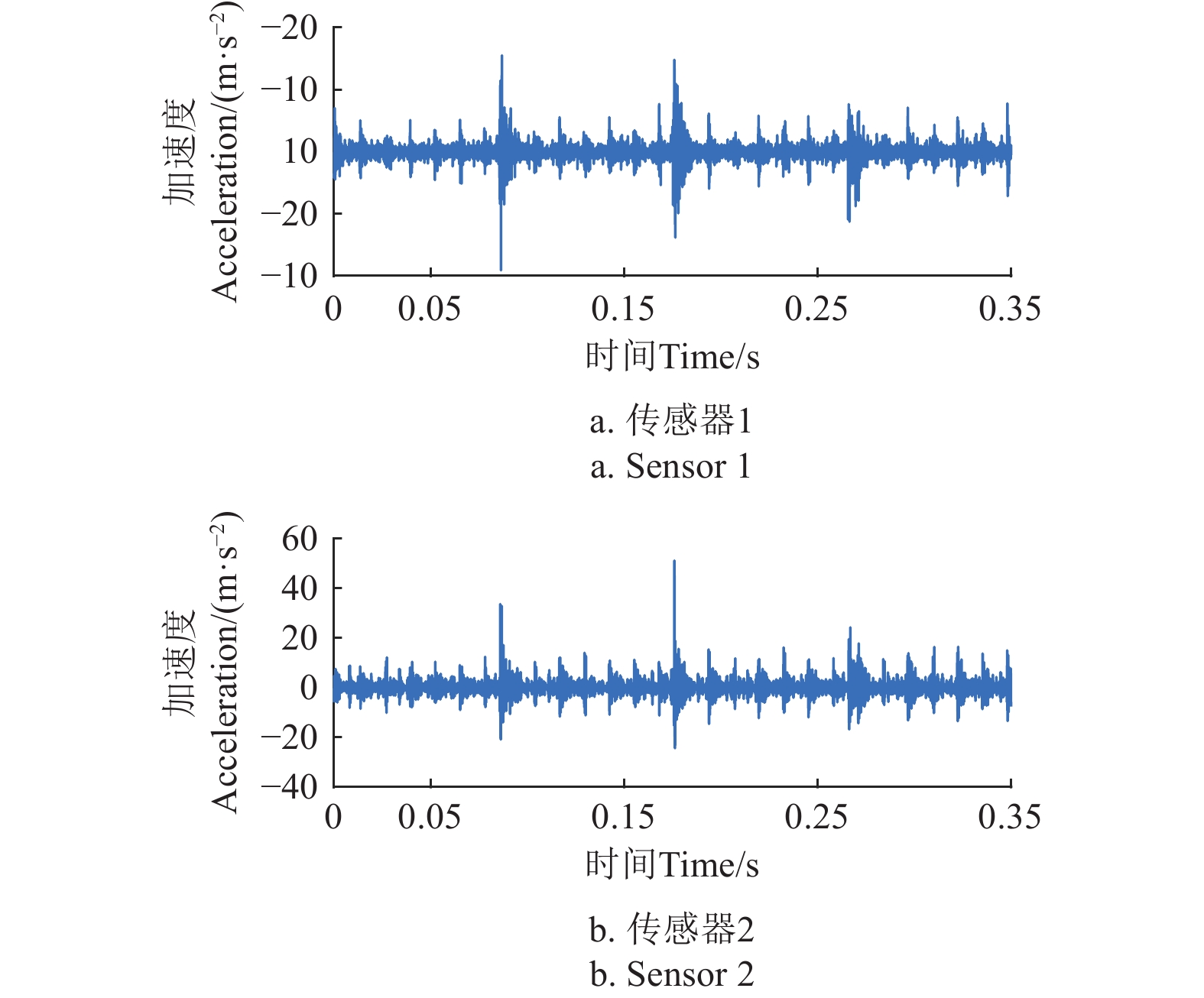

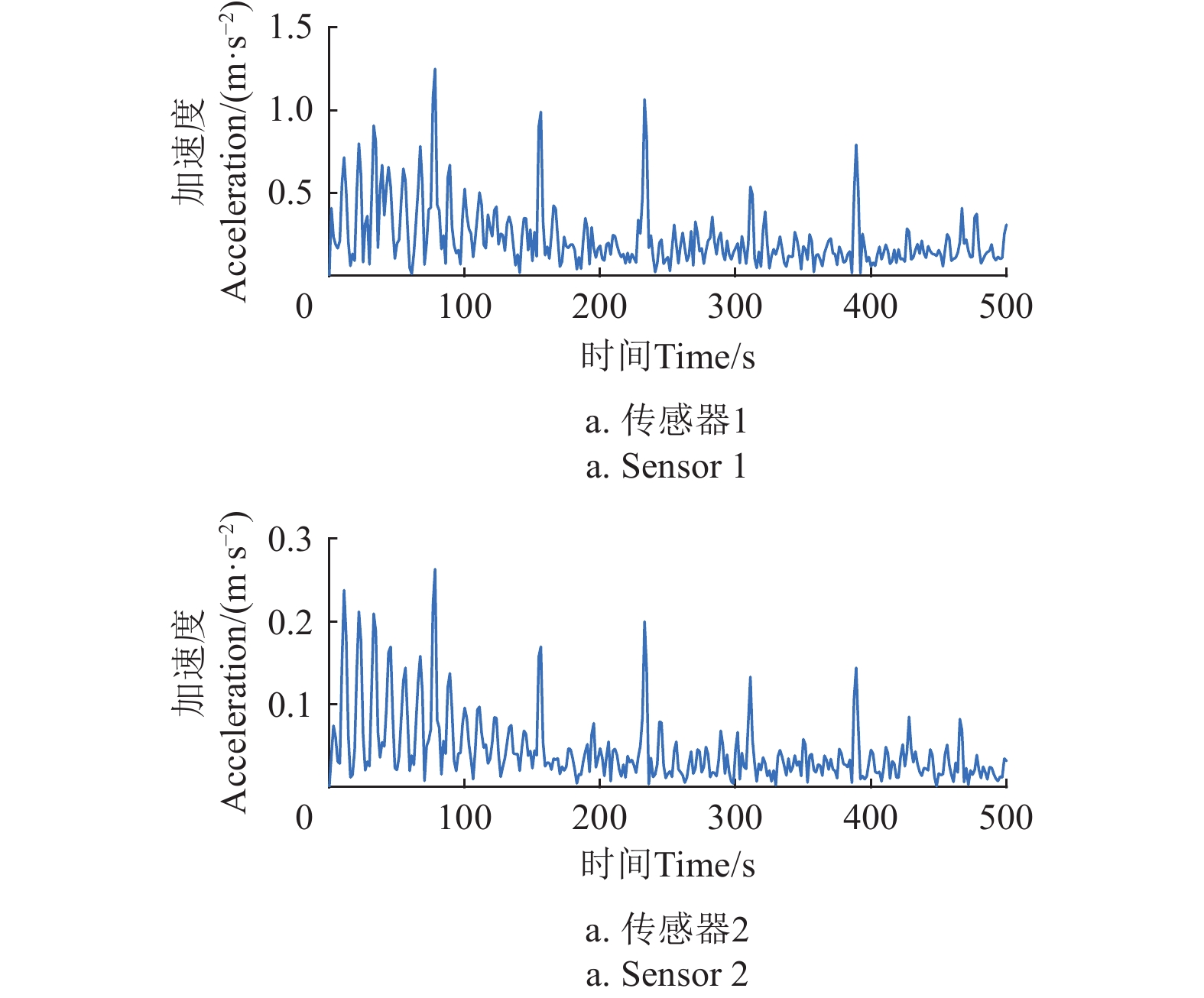

时频图中的脊线对应时频域中能量最大的路径,可以近似看作设备瞬时频率的时频轨迹。对时频图进行脊线提取,结果如图8所示。分析脊线走势能够较为清楚地区分机械臂的不同运行阶段,包括启动加速阶段,平稳运行阶段以及减速停滞阶段(后续分析均为此阶段)。图9a为水平方向传感器1采集信号的时域波形,图9b为垂直方向传感器2采集信号的时域波形。图9时域波形体现了机械臂启动、平稳到停止整个工作过程幅值的变化。依据图8中脊线的平稳阶段区间,在图9中标注同步截取相应时段的时域振动信号(后续分析皆是截取后的振动信号)。

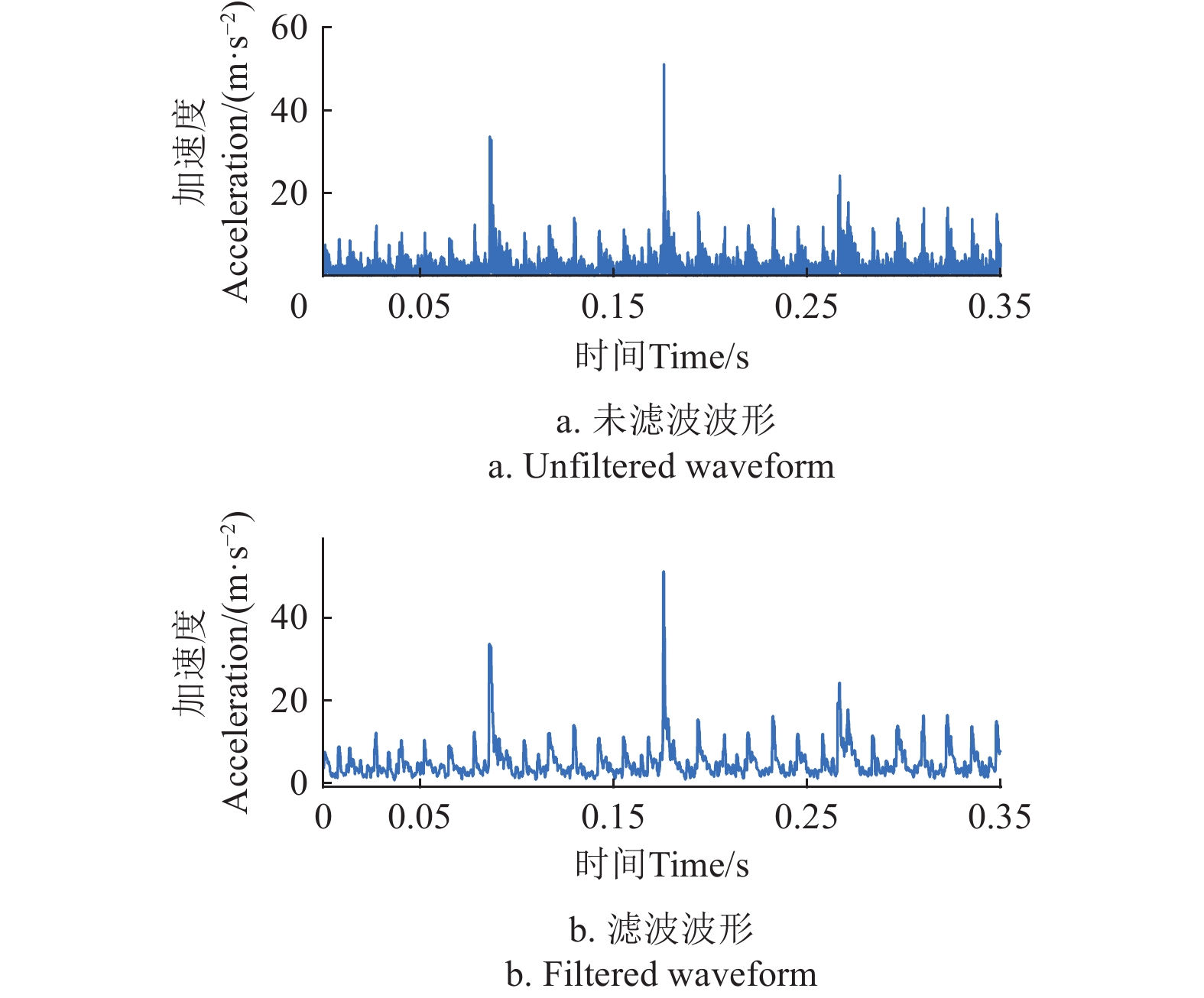

图10a为截取平稳阶段传感器1的信号波形,图10b为截取平稳阶段传感器2信号波形。对图10振动信号进行SMF处理,对图10振动信号进行SMF处理,传感器2的滤波前后的信号波形对比如图11所示,从图11b中能够观测到故障所导致的冲击更加明显。

对滤波后的信号进行包络谱分析,如图12所示,传感器1和传感器2滤波信号的频谱分别如图12a、12b所示。分析图12a、12b发现,太阳轮与行星轮的故障特征频率成分完全混合在一起,故障类型判断困难。

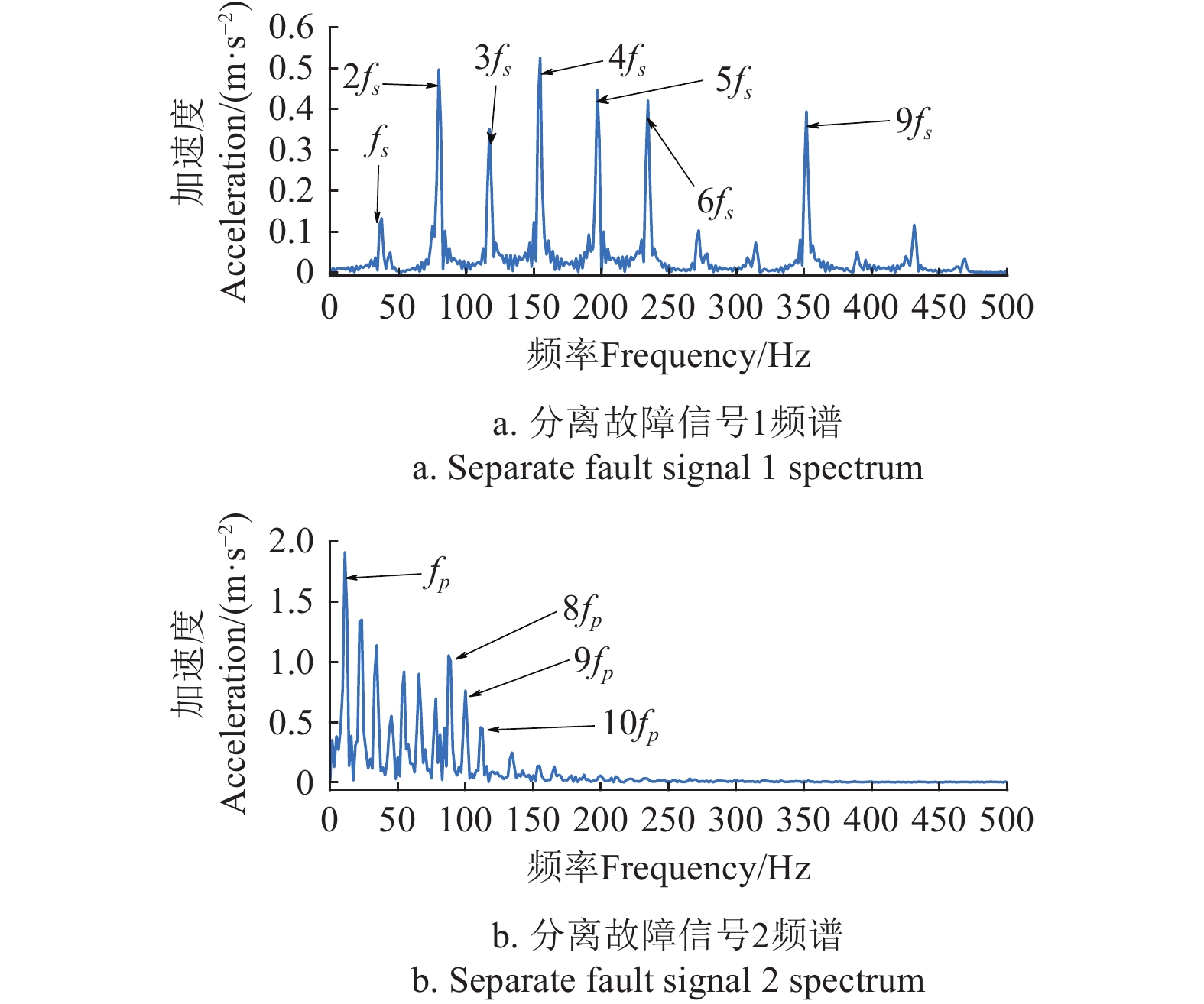

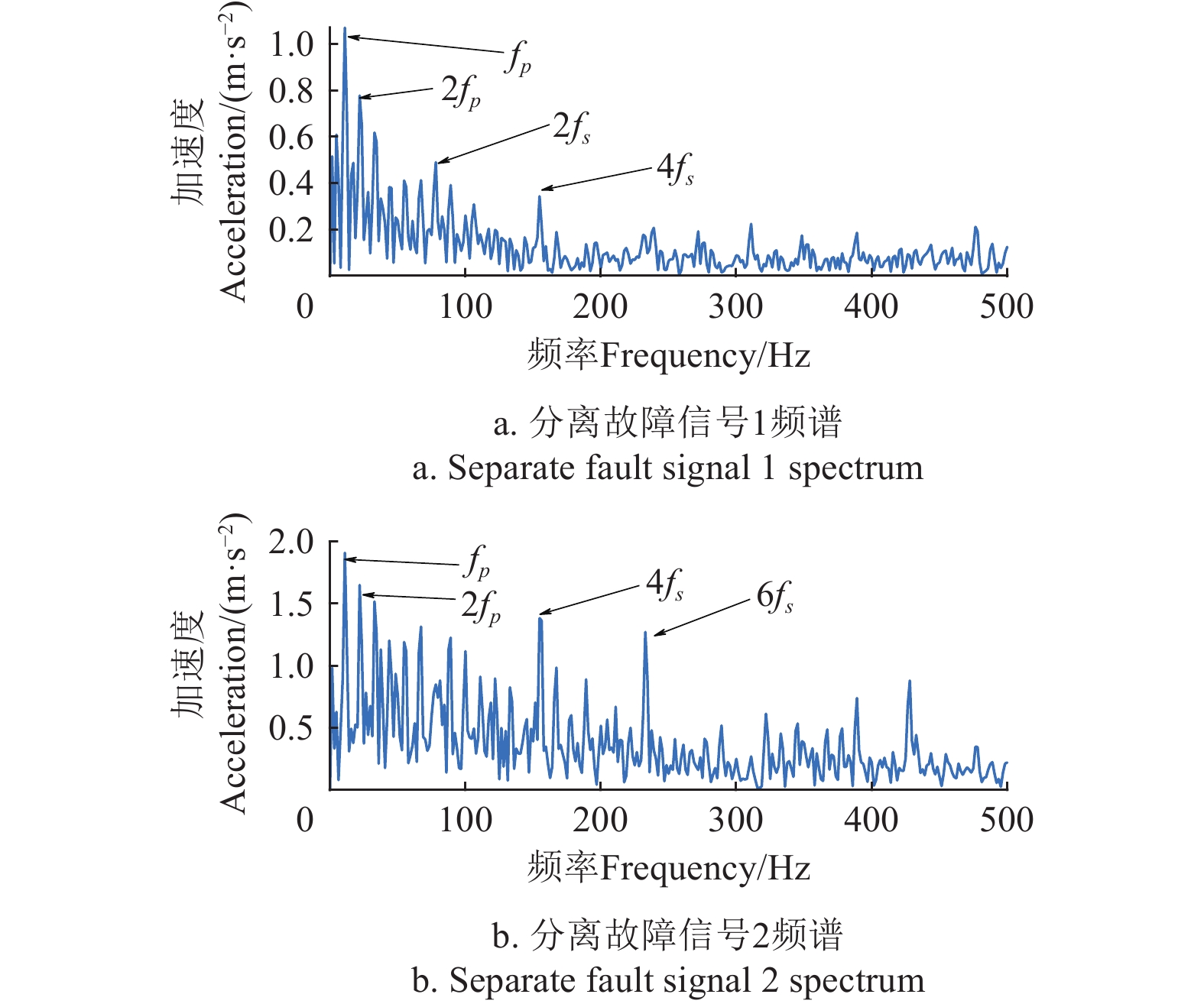

经SMF-DPC-OMP算法处理的频谱如图13所示,图13a的频率谱线集中在37.5 Hz及其倍频,与太阳轮理论计算故障频率38.34 Hz接近,故可推断图13a为太阳轮故障。图13b的频率谱线分布在10.94 Hz及其倍频,与行星轮理论计算故障频率10.83 Hz逼近,故识别其为行星轮故障。相比图12,图13中的频率混合现象已经完全被消除,说明本文方法可实现复合故障的完全分离。采用文献[29]提出的结合形态滤波与稀疏分量分析(MF-SCA)的盲分离算法进行对比进一步验证本文方法的有效性,结果如图14所示,分析可见,图14a、14b均存在太阳轮和行星轮故障特征频率,说明MF-SCA方法无法有效实现RV减速器复合故障的分离。与MF-SCA方法相比,SMF-DPC-OMP算法能够节省约75%的时间运行成本。

5. 结 论

本文结合时频图像脊线提取、\sin C函数改进形态滤波和密度峰值聚类改进的稀疏分量分析各算法的优点,提出一种新的往复运动、变转速工况的RV减速器复合故障盲分离方法。通过RETE算法提取的脊线解决旋转机械变转速的问题,利用SMF-DPC-OMP实现了RV减速器复合故障的分离提取。试验台采集的RV减速器的太阳轮和行星轮磨损复合故障信号的分析结果显示,本文方法能够有效地完成复合故障的盲分离任务,主要结论如下:

1)RETE算法能够在变转速工况导致时频图较为模糊的情况下,识别出RV减速器的运动状态;

2)SMF-DPC-OMP算法能够在故障源数目未知的情况下,有效完成复合故障的盲分离任务;

3)与MF-SCA方法比较,SMF-DPC-OMP算法能够节省约75%的时间运行成本,使得频谱更为简洁,抑制精细侧频和干扰分量。

本文今后的工作将重点放在欠定条件下的故障提取上,或者进一步将该算法推广到旋转机械声信号的故障诊断中。

-

表 1 RV减速器各零件的工作频率

Table 1 Working frequency of each part of RV reducer

名称Name 计算公式Calculation formula 电机主轴转速

Motor spindle speed {n_1}/(r·min−1){n_1} = 60f/P 太阳轮转频

Sun gear rotation frequency {f_1}/Hz{f_1} = {n_1}/60 行星轮转频

Planetary gear rotation frequency {f_2}/Hz{f_2} = \dfrac{{{z_1}{z_4}}}{{({z_3} - {z_4})\left( {{z_1} + {z_2}{z_4}} \right)}}{f_1} 一级啮合频率

First stage engagement frequency {f_{1c}}/Hz{f_{1c}} = \dfrac{{{z_1}{z_2}{z_4}}}{{{z_1} + {z_2}{z_4}}}{f_1} 注:P为伺服电机磁极对数,{{\textit{z}}_1}为太阳轮齿数,{{\textit{z}}_2}为行星轮齿数,{{\textit{z}}_3} 为摆线轮齿数,{{\textit{z}}_4} 为针轮齿数。

Note: P is the number of magnetic poles of the servo moto, {{\textit{z}}_1} is the number of solar gear, {{\textit{z}}_2} is the number of planetary gear, {{\textit{z}}_3} is the number of cycloidal gear, and {{\textit{z}}_4} is the number of needle gear. -

[1] 杨子涵,宋正河. 利用优选状态数的MCMC模拟农机装备负载[J]. 农业工程学报,2021,37(20):15-22. doi: 10.11975/j.issn.1002-6819.2021.20.002 YANG Zihan, SONG Zhenghe. Simulation of agricultural equipment load using MCMC with optimal state number[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2021, 37(20): 15-22. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2021.20.002

[2] 王霖宽,孙首群,孙福佳. 农业机械中的摆线轮齿参数优化设计[J]. 农业装备与车辆工程,2018,56(1):37-41. WANG Linkuan, SUN Shouqun, SUN Fujia. Cycloidal pinwheel reducer parameters optimization design based on MATLAB[J]. Agricultural Equipment & Vehicle Engineering, 2018, 56(1): 37-41. (in Chinese with English abstract)

[3] CHEN L R, CAO J F, WU K, et al. Application of generalized frequency response functions and improved convolutional neural network to fault diagnosis of heavy-duty industrial robot[J]. Robotics and Computer-Integrated Manufacturing, 2022, 73: 102228. doi: 10.1016/j.rcim.2021.102228

[4] 赵小强,郭海科. 多特征融合的滚动轴承故障诊断[J]. 农业工程学报,2023,39(13):80-88. ZHAO Xiaoqiang, GUO Haike. Fault diagnosis of rolling bearings using multi-feature fusion[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2023, 39(13): 80-88. (in Chinese with English abstract)

[5] 施杰,伍星,刘韬. 采用HHT算法与卷积神经网络诊断轴承复合故障[J]. 农业工程学报,2020,36(4):34-43. SHI Jie, WU Xing, LIU Tao. Bearing compound fault diagnosis based on HHT algorithm and convolution neural network[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2020, 36(4): 34-43. (in Chinese with English abstract)

[6] 万安平,杨洁,王景霖,等. 基于深度学习的航空发动机齿轮故障诊断[J]. 振动、测试与诊断,2022,42(6):1062-1067. doi: 10.16450/j.cnki.issn.1004-6801.2022.06.002 WAN Anping, YANG Jie, WANG Jinglin, et al. Progress and prospects in piezoelectric actuation technologies[J]. Journal of Vibration, Measurement and Diagnosis, 2022, 42(6): 1062-1067. (in Chinese with English abstract) doi: 10.16450/j.cnki.issn.1004-6801.2022.06.002

[7] 耿令新,李康,庞靖,等. 基于时频和功率谱密度的移栽机振动特性测试与分析[J]. 农业工程学报,2021,37(11):23-30. GENG Lingxin, LI Kang, PANG Jing, et al. Test and analysis of vibration characteristics of transplanting machine based on time frequency and power spectral density[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2021, 37(11): 23-30. (in Chinese with English abstract)

[8] 刘桂敏,马军,熊新,等. 基于改进 CYCBD 的滚动轴承复合故障自适应诊断方法[J]. 农业工程学报,2022,38(16):98-106. LIU Guimin, MA Jun, XIONG Xin, et al. Adaptive diagnosis method of composite fault for rolling bearings using improved CYCBD[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2022, 38(16): 98-106. (in Chinese with English abstract)

[9] 汪久根,柯梁亮. 基于残差网络的RV减速器故障诊断[J]. 机械工程学报,2019,55(3):73-80. doi: 10.3901/JME.2019.03.073 WANG Jiugen, KE Liangliang. Fault diagnosis of RV reducer based on residual network[J]. Journal of Mechanical Engineering, 2019, 55(3): 73-80. (in Chinese with English abstract) doi: 10.3901/JME.2019.03.073

[10] YIN T, LU N, GUO G, et al. Knowledge and data dual-driven transfer network for industrial robot fault diagnosis[J]. Mechanical Systems and Signal Processing, 2023, 182: 109597. doi: 10.1016/j.ymssp.2022.109597

[11] 彭鹏,柯梁亮,汪久根. 噪声干扰下的RV减速器故障诊断[J]. 机械工程学报,2020,56(1):30-36. doi: 10.3901/JME.2020.01.030 PENG peng, KE Liangliang, WANG Jiugen. Fault diagnosis of RV reducer under noise interference[J]. Journal of Mechanical Engineering, 2020, 56(1): 30-36. (in Chinese with English abstract) doi: 10.3901/JME.2020.01.030

[12] 韩特,李彦夫,雷亚国,等. 融合图标签传播和判别特征增强的工业机器人关键部件半监督故障诊断方法[J]. 机械工程学报,2022,58(17):116-124. doi: 10.3901/JME.2022.17.116 HAN Te, LI Yanfu, LEI Yaguo, et al. Semi-supervised fault diagnosis method for key parts of industrial robots by integrating graph label propagation and discriminative feature enhancement[J]. Journal of Mechanical Engineering, 2022, 58(17): 116-124. (in Chinese with English abstract) doi: 10.3901/JME.2022.17.116

[13] XIE W S, ZHOU J, LIU T, et al Characteristic enhancement of RV reducer under non-stationary condition based on WDT-IF-SS-VMD[J]. Measurement Science and Technology, 2023, 34(10): 105108.

[14] YAN Y H, GUO Y, LIU X Q. Tooth root crack detection of planet gear in RV reducer based on improved compute order tracking and angular domain synchronous averaging[J]. Journal of Physics:Conference Series, 2022, 2184: 012019. doi: 10.1088/1742-6596/2184/1/012019

[15] 雷亚国,何平,乔煜庭,等. 基于平稳工况数据截取的RV减速器故障诊断方法[J]. 电子机械工程,2023,39(4):1-7. doi: 10.19659/j.issn.1008-5300.2023.04.001 LEI Yaguo, HE Ping, QIAO Yuting, et al. A fault diagnosis method for RV reducer based on stationary condition data capturing[J]. Electro-Mechanical Engineering, 2023, 39(4): 1-7. (in Chinese with English abstract) doi: 10.19659/j.issn.1008-5300.2023.04.001

[16] 黄维新,刘敦文. 基于变分模态分解和独立成分分析的矿山微震信号降噪[J]. 振动与冲击,2019,38(4):56-63. doi: 10.13465/j.cnki.jvs.2019.04.010 HUANG Weixin, LIU Dunwen. Mine microseismic signal noise reduction based on variational mode decomposition and independent component analysis[J]. Vibration and Shock, 2019, 38(4): 56-63. (in Chinese with English abstract) doi: 10.13465/j.cnki.jvs.2019.04.010

[17] HAO Y, SONG L, REN B, et al. Step-by-step compound faults diagnosis method for equipment based on majorization-minimization and constraint SCA[J]. IEEE/ASME Transactions on Mechatronics, 2019, 24(6): 2477-2487. doi: 10.1109/TMECH.2019.2951589

[18] WANG J D, CHEN X, ZHAO H Y, et al. An effective two-stage clustering method for mixing matrix estimation in instantaneous underdetermined blind source separation and its application in fault diagnosis[J]. IEEE Access, 2021, 9: 115256-115269. doi: 10.1109/ACCESS.2021.3105538

[19] NORSALINA H, DZATI A R. Sparse component analysis (SCA) based on adaptive time-frequency thresholding for underdetermined blind source separation (UBSS)[J]. Sensors, 2023, 23(2060): 2060.

[20] DING T, CHEN H K, CHEN L, et al. Improved sparse component analysis for multi-point harmonic contribution evaluation under incomplete measurement[J]. IEEE Transactions on Power Delivery, 2022, 37(5): 4019-4031. doi: 10.1109/TPWRD.2022.3142968

[21] 徐晓,丁世飞,丁玲. 密度峰值聚类算法研究进展[J]. 软件学报,2022,33(5):1800-1816. XU Xiao, DING Shifei, DING Ling. Survey on density peaks clustering algorithm[J]. Journal of Software, 2022, 33(5): 1800-1816. (in Chinese with English abstract)

[22] BU H, TAO R, BAI X, et al. Regularized smoothed ℓ0 norm algorithm and its application to CS-based radar imaging[J]. Signal Processing, 2016, 122: 115-122. doi: 10.1016/j.sigpro.2015.11.024

[23] ZHANG C, HAO D, HOU C, et al. A new approach for sparse signal recovery in compressed sensing based on minimizing composite trigonometric function[J]. IEEE Access, 2018, 6: 44894-44904. doi: 10.1109/ACCESS.2018.2855958

[24] WANG H M, YANG S P, LIU Y Q. Compressive sensing reconstruction for rolling bearing vibration signal based on improved iterative soft thresholding algorithm[J]. Measurement, 2023, 210: 112528. doi: 10.1016/j.measurement.2023.112528

[25] 刘素娟,崔程凯,郑丽丽,等. 基于压缩感知的贪婪类重构算法原子识别策略综述[J]. 电子与信息学报,2023,45(1):361-370. LIU Sujuan, CUI Chengkai, ZHENG Lili, et al. A review of atom recognition strategies for greedy class reconstruction algorithms based on compressed sensing[J]. Journal of Electronics & Information Technology, 2023, 45(1): 361-370. (in Chinese with English abstract)

[26] MA S, ZHANG H J, MIAO Z Y. Blind source separation for the analysis sparse model[J]. Neural Computing and Applications 2021, 33(14): 8543-8553.

[27] 赵雅琴,聂雨亭,吴龙文,等. 基于脊路跟踪的变分非线性调频模态分解方法[J]. 浙江大学学报(工学版) ,2020,54(10):1874-1882. ZHAO Yaqin, NIE Yuting, WU Longwen, et al. Multi-component signal separation using variational nonlinear chirp mode decomposition based on ridge tracking[J]. Journal of Zhejiang University (Engineering Science), 2020, 54(10): 1874-1882. (in Chinese with English abstract)

[28] TANG M J, LIAO Y H, HE D, et al. Rolling bearing diagnosis based on an unbiased-autocorrelation morphological filter method[J]. Measurement, 2022, 189: 110617. doi: 10.1016/j.measurement.2021.110617

[29] 李豫川,伍星,迟毅林,等. 基于形态滤波和稀疏分量分析的滚动轴承故障盲分离[J]. 振动与冲击,2011,30(12):170-174. doi: 10.3969/j.issn.1000-3835.2011.12.033 LI Yuchuan, WU Xing, CHI Yilin, et al. Blind fault separation of rolling bearings based on morphological filtering and sparse component analysis[J]. Vibration and Shock, 2011, 30(12): 170-174. (in Chinese with English abstract) doi: 10.3969/j.issn.1000-3835.2011.12.033

[30] WEI X X, PENG M S, HUANG H J, et al. An overview on density peaks clustering[J]. Neurocomputing, 2023, 554: 126633.

-

期刊类型引用(4)

1. 郭俊杰,郭正红. 基于深度置信网络的旋转机械在线故障诊断. 计算机测量与控制. 2025(01): 60-68 .  百度学术

百度学术

2. 刘喜庆,张文豪,潘真真. 基于DAL的工业机器人RV齿轮箱故障识别分析. 现代工业经济和信息化. 2024(09): 217-219 .  百度学术

百度学术

3. 高国泽,郭瑜,赵博涵,王红伟. 基于瞬时角速度信号窄带解调的RV减速器针齿故障检测. 振动与冲击. 2024(22): 155-161+208 .  百度学术

百度学术

4. 孙长胜,曹浩男. 基于VMD和CNN方法的电机传动系统故障诊断研究. 机械管理开发. 2024(12): 75-77 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: