Design and testing of the mechanical automatic precision seed metering device for pepper

-

摘要:

辣椒漂浮育苗具有占地面积小、育苗周期短和椒苗品质好的优点,播种环节要求一穴一粒精量播种,通常采用人工点播,存在劳动强度大和播种效率低的问题。针对以上问题,该研究以磁力回位型排种器为基础,设计了一种适于辣椒漂浮育苗的机械式自动精量排种器,并对关键机构进行设计,通过单因素试验获得曲柄直径、曲柄电机工作转速和种量的较优区间,以单粒合格指数、重播指数和漏播指数为指标进行三因素三水平正交试验,建立回归模型,并进行参数优化。试验结果表明,在排种器旋转倾角30°、旋转电机角速度0.07 rad/s(即生产率240盘/h),曲柄直径为30 mm、曲柄电机转速为230 r/min、种量为4千粒时,排种器的播种效果较好,单粒合格指数为91.04%,重播指数为5.21%,漏播指数为3.75%,相比于人工操作磁力回位型排种器,单粒合格指数提升了5.81个百分点,重播指数降低了6.45个百分点,满足辣椒漂浮育苗的播种要求,可为辣椒育苗轻简化生产和小籽粒种子的机械式精量排种器研究提供参考。

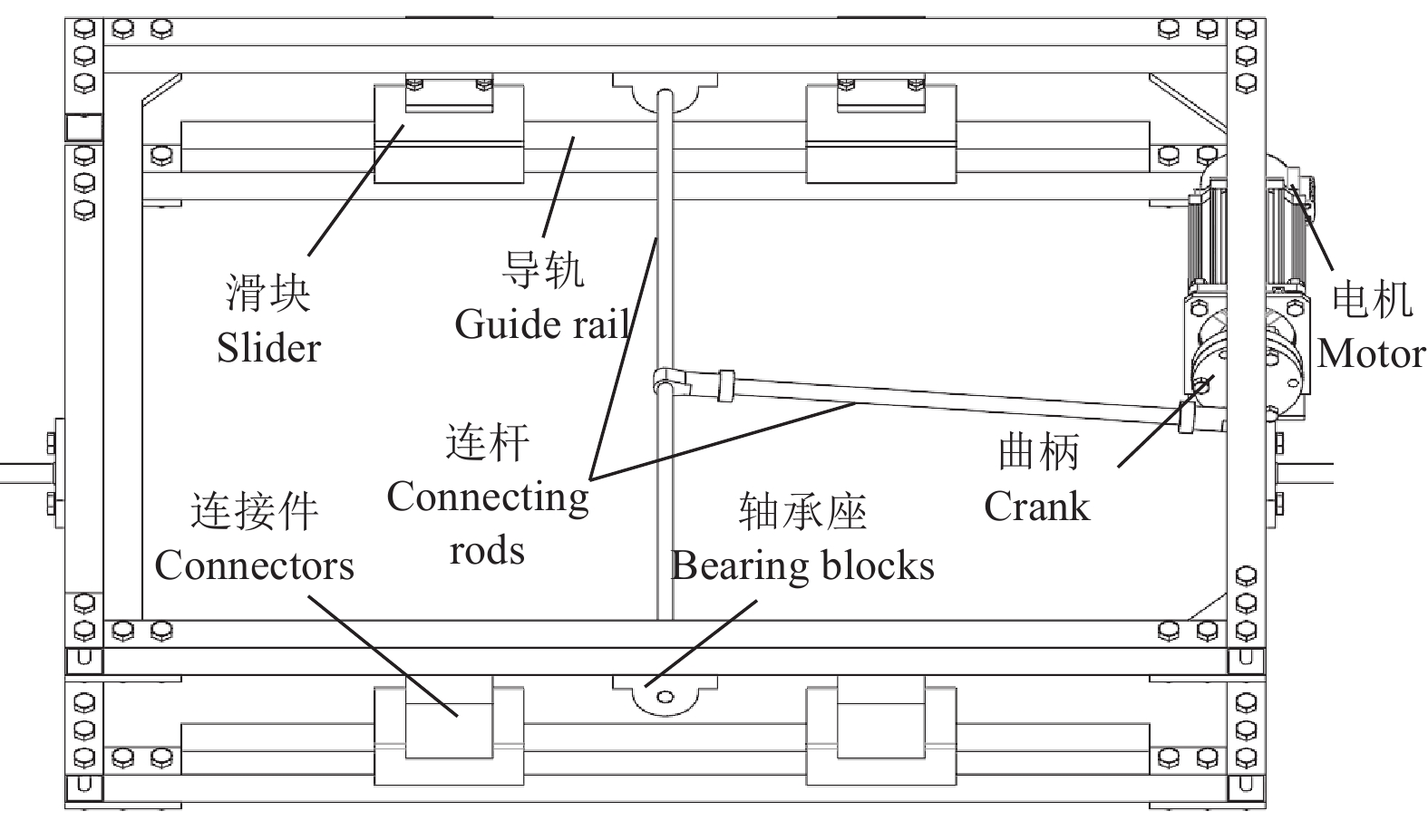

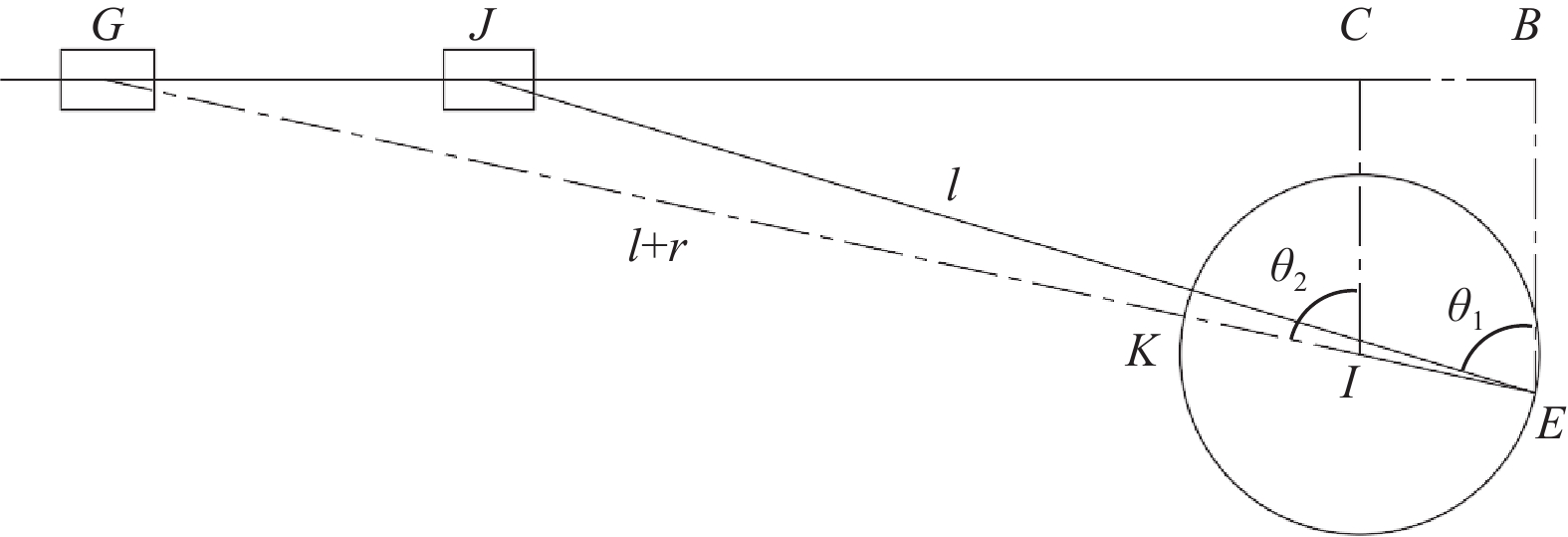

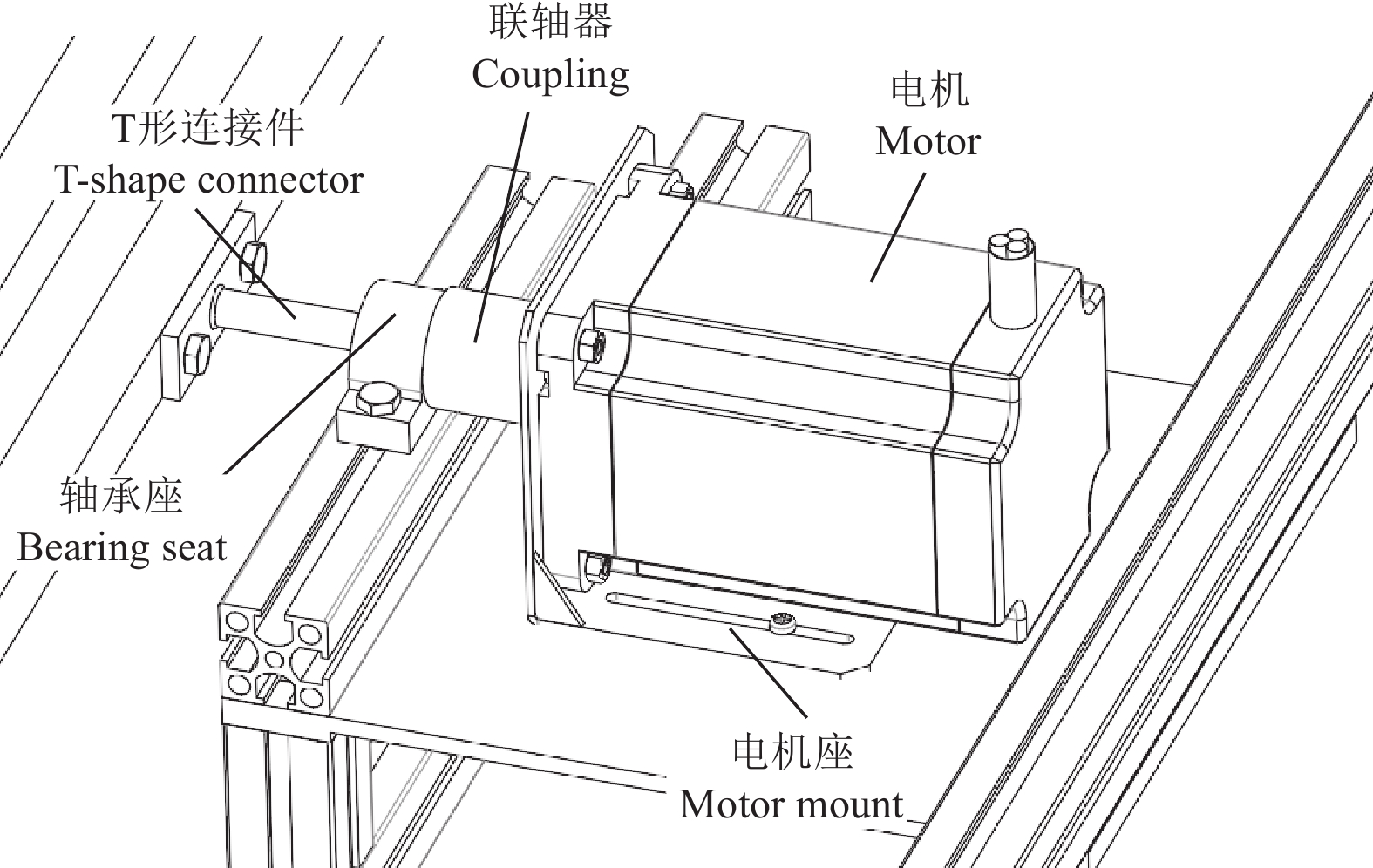

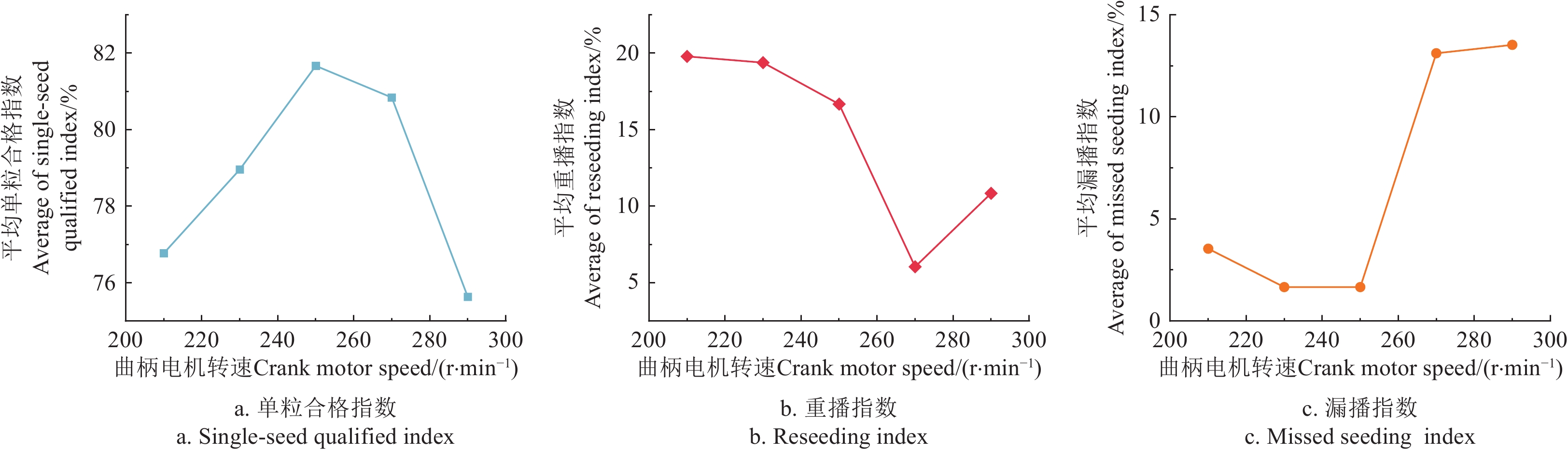

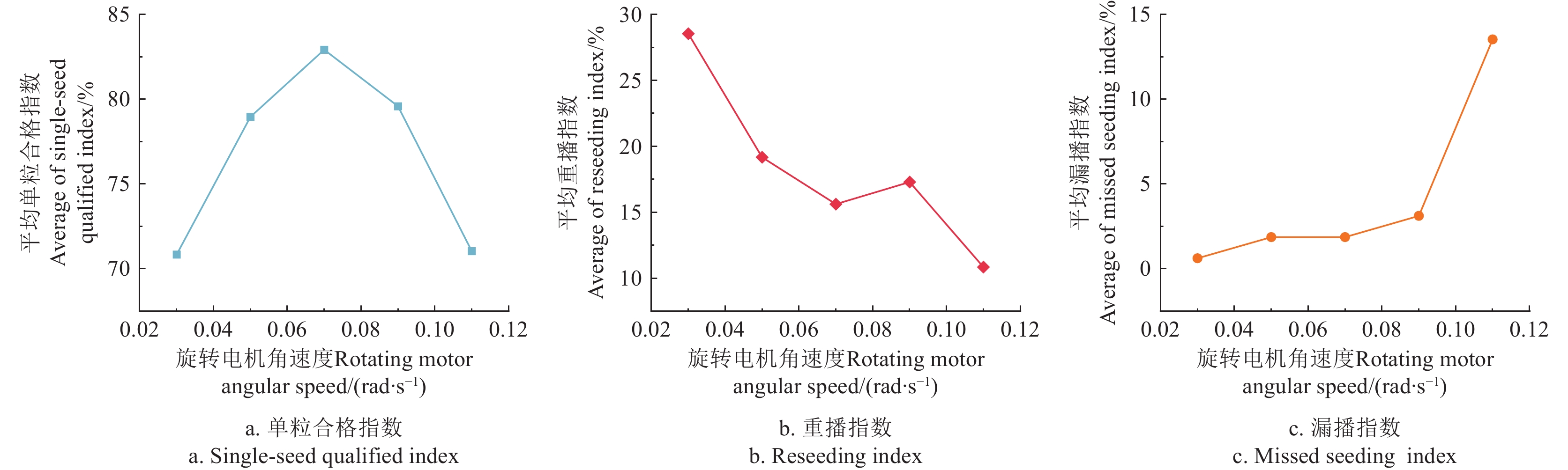

Abstract:Floating seedlings have been widely used in recent years, because of the small footprint, short nursery cycle, and high quality of pepper seedlings. The seeding link of pepper floating seedling is required for one hole and one-grain precision seeding. Among them, manual spot seeding can usually sow with high labor intensity and low seeding efficiency. The high seeding quality is confined to the complex and costly structure of the pneumatic precision seed-metering device. While the mechanical seed-metering device is more suitable for the round or pelletized vegetable seeds, rather than the small pepper seeds. In this study, a low-cost, lightweight, and simplified mechatronic precision seed-metering device was designed for the pepper floating seedlings, according to the magnetic return-type seed-metering device. A series of mechanisms were designed for the reciprocating motion, rotating, and seed dropping. The seed metering device was improved from the filling and discharging of magnetic return-type seed-metering device by means of various mechanisms. The important factors were selected as the diameter of the filling hole and the depth of the seed-dropping hole in the magnetic return-type seed-metering device. The single grain rate was improved for the high quality of sowing. The triaxial dimensions of the pepper seeds were then measured to determine the size of the filling and dropping holes. In reciprocating motion, the crank radius and seed displacement were determined for the minimum radius of the crank. In rotating, the minimum torque of the motor was determined by the center of mass and force analysis. The influencing factors were selected as crank diameter, crank motor speed, rotating motor angular speed, rotation angle, and seed volume in the trial test. One-factor test was carried out to obtain better ranges in the crank diameter, crank motor speed, rotating motor angular speed, rotation angle, and seed volume. Among them, the crank diameter, crank motor speed, and seed volume shared a significant influence on the performance of the seed-metering device. A three-factor and three-level orthogonal test was conducted to establish a regression model, where the crank diameter, crank motor speed, and seed volume were taken as test factors, while the target variables were the single-seed qualified, reseeding, and missed seeding indexes. The bench test was also carried out to verify the model under the optimal combination of parameters. The test results show that the crank diameter of 30 mm, crank motor speed of 230 r/min, and seed volume of 4 000 grains under the rotation angle of 30° and rotating motor angular speed of 0.07 rad/s (i.e., productivity of 240 trays/h). The seed-metering device performed better with a single-seed qualified index of 91.04%, a reseeding index of 5.21%, and a missed seeding index of 3.75%. The seeding performance fully met the industrial requirements of floating seedlings in pepper production and small-seeded seed-metering devices.

-

Keywords:

- agricultural machinery /

- seed metering device /

- pepper /

- floating seedling /

- precision seeding

-

0. 引 言

中国水资源时空分布不均,农业发展很大程度上依赖于灌溉,灌区作为农业灌溉的主体,是农业生产的重要基地,对保障国家粮食安全和社会稳定具有重要作用,对区域可持续发展有着重要影响[1]。在全球气候变化和人类活动的影响下,降水及水资源分布的不均匀性进一步加剧,加之随着经济社会的不断发展,特别是工业化和城镇化进程的加快,水资源供求矛盾日益明显,一些地方挤占农业用水的问题突出,农业用水面临的挑战越来越大[2]。同时,保障粮食安全需要确保粮食播种面积和提升作物单产,要求在水资源配置中充分考虑到农业用水和保障粮食安全的用水需求。因此,在当前水资源日益紧缺的形势下,如何优化种植结构及水资源的时空配置,是保证粮食安全及经济社会可持续发展的关键问题[3-5]。

随着对灌区水资源优化配置研究的不断深入,前人基于不同的优化目标提出了不同的灌区水资源优化配置方法。例如,谌芸等[6]以经济效益为优化目标,针对漳河灌区多水源、多用户的特点建立水资源优化配置模型; LI等[7]以地下水的开采量为优化目标,在都江堰灌区建立了多目标水资源优化配置模型,最大限度地节约了地下水的开采量;王慧等[8]以灌水量和灌水时间为优化对象建立了水资源优化配置模型,提高了灌区经济效益和生态效益。水资源的优化配置能够在一定程度上缓解供需矛盾,但鉴于水资源的多样性和多变性特点,单纯依赖优化配置难以满足复杂多变的水资源需求。在现有农业种植结构下,满足当地粮食生产、经济发展和地区可持续发展的需要,仅靠调节水资源是远远不够的。在此背景下,迫切需要优化调整农业种植结构,提高区域作物水分利用效率及效益[9-11],这已经引发了国内外学者的广泛关注与探索。例如,BIRHANU等[12]利用机会约束线性规划模型,在土地和水资源供应受限的情况下实现产量和效益最大化,对埃塞俄比亚科加灌区主要农作物的种植模式进行了优化;EL-GHOBASHY等[13]通过改变作物种植方式,以获取最大的净效益,提高了土地生产力;王玉宝[14]以黑河为例,综合考虑了生态、经济和社会目标,构建了种植结构多目标优化模型;徐万林等[15]以甘肃省民勤灌区为例,构建了双层结构优化模型,该模型能同时优化作物灌溉制度、种植结构以及灌溉定额,实现了更高效的资源利用;王雷明[16]在河套灌区建立经济、粮食、生态、水资源目标情境下的种植结构优化模型,可有效提高灌区的综合效益;赵丹[17]以黑龙江省为例,基于水土资源匹配分析及脆弱性,探究对农业种植结构的调控策略。前人深入的研究及不同角度的研究方法极大地推动了灌区种植结构调整与水资源合理配置研究[18-21],然而,种植结构调整有较强的地域性、时空性和综合性,现有的种植结构优化理论滞后于生产实践[22-27],农业种植结构调整和水资源合理配置的模型缺乏实用性。

基于此,本文构建了基于种植结构优化的多目标多水源优化配置模型,模型以农业灌溉用水量和经济效益为目标函数,兼顾生态系统的需水要求和农业面源污染约束条件,并将模型应用于河北省漳滏河灌区的实例研究中,探索灌区种植结构优化和水资源配置模式,将有限的地表水资源和地下水资源科学分配给灌区内多种农作物,求解获得不同种植结构优化情景下的水资源优化配置方案,从而缓解邯郸市水资源供需紧张的矛盾,促进粮食安全与水资源高效利用,以期为灌区农业节水和可持续发展提供科学依据。

1. 模型建立与求解

1.1 优化配置模型构建

采用多目标规划方法来构建灌区多目标多水源优化配置模型,模型以农业灌溉缺水量最小和农作物经济效益最大作为目标函数,以生态环境、用水总量、粮食安全、工程条件等为约束条件,通过决策不同计算单元的配水量和不同作物的播种面积来权衡两个目标间的矛盾,进而达到节水增效和生态系统良性循环的目的。

1.1.1 决策变量

模型以不同计算单元的配水量xk,i,t和作物播种面积yi,j作为模型的决策变量,其中i代表不同计算单元;k代表不同水源;j代表不同作物;t代表时间尺度。

1.1.2 目标函数

1)农业灌溉缺水量最小

minW=n∑i=1J∑j=1yi,jmi,j−n∑i=1T∑t=1K∑k=1ηixk,i,t (1) 式中W为农业灌溉缺水量,m3;yi,j为第i单元第j种作物的播种面积,hm2;mi,j为第i单元第j种作物的灌溉定额,m3/hm2;ηi为第i单元的灌溉水利用系数;xk,i,t为第i单元第k种水源第t时段的配水量,m3;n为计算单元的数量;T为时段数;J为作物类型数量。

2)农作物经济效益最大

灌区的经济效益是农作物的净产值,其值等于总产值与总成本的差值,总成本包括物质与服务费用、人工成本和土地成本,其中物质与服务费用包括种子费、化肥费、农药费、农膜费、水费、燃料费以及其他费用等。

maxF=n∑i=1J∑j=1yi,jai,j(bi,j−ci,j+di,j) (2) 式中F为灌区农作物的净产值,元;ai,j为第i单元第j种作物单位面积的产量,kg/hm2;bi,j为第i单元第j种作物的售价,元/kg;ci,j为第i单元第j种作物的总成本,元/kg;di,j为第i单元第j种作物的政府补贴,元/kg。

1.1.3 约束条件

1)生态需水约束

为保障灌区的可持续发展,考虑经济效益的同时满足生态需水要求,改善灌区内部的生态环境,灌区需保留一定的生态环境用水以维持生态环境不再退化、生态系统功能正常运行。

n∑i=1T∑t=1K∑k=1xk,i,t≥Qmin (3) 式中Qmin为最小生态需水量,m3。

2)农业面源污染约束

为实现生态系统的良性循环,改善水环境质量,农药和化肥在农业生产过程中应当低于生态型灌区中所规定施用强度的最大限额。

\sum _{j=1}^{J}\frac{{y}_{i,j}{h}_{j}}{{S}_{i}}\le H (4) \sum _{j=1}^{J}\frac{{y}_{i,j}{r}_{j}}{{S}_{i}}\le R (5) 式中hj为不同作物单位播种面积化肥施用量,kg/hm2;Si为不同计算单元种植结构调整前农作物的总耕地面积,hm2;H为单位作物播种面积化肥施用强度,kg/hm2;rj为不同作物单位播种面积农药施用量,kg/hm2;R为单位作物播种面积农药施用强度,kg/hm2。

3)可供水量约束

\sum _{i=1}^{n}\sum _{t=1}^{T}\sum _{k=1}^{K}{x}_{k,i,t}\le {Q}_{k} (6) 式中Qk为灌区不同水源的可供水量,m3。

4)用水总量控制约束

种植结构调整后的各水源用水量不能超过各水源用水总量控制目标。

\sum _{i=1}^{n}\sum _{t=1}^{T}\sum _{k=1}^{K}{x}_{k,i,t}\le {W}_{k} (7) 式中Wk为不同水源用水总量控制目标,m3。

5)耕地面积约束

种植结构调整后各计算单元不同种植制度下总播种面积不高于各计算单元种植结构调整前农作物的总耕地面积。

\sum _{j=1}^{J}{y}_{i,j}\le {S}_{i} (8) 6)粮食安全约束

灌区内作物产量应不低于灌区所需承担的粮食生产安全红线。

\sum _{i=1}^{n}\sum _{t=1}^{T}\sum _{k=1}^{K}{x}_{k,i,t}{a}_{i,j}\le P (9) 式中P为粮食安全红线,kg。

7)水库水量平衡约束

{V}_{t+1}={V}_{t}-\left(\sum _{i=1}^{n}\sum _{t=1}^{T}\sum _{k=1}^{K}{x}_{k,i,t}\right)+{e}_{t}-{f}_{t}-{g}_{t} (10) 式中Vt、Vt+1分别为第t、t+1时段水库的蓄水量,m3;et为第t时段水库的入库流量,m3;ft为第t时段水库的渗漏量,m3;gt为第t时段水库的蒸发量,m3。

8)水库库容约束

{V}_{\rm{min}t}\le {V}_{t}\le {V}_{{\rm{max}}t} (11) 式中Vmin t、Vmax t分别是水库第t时段的最小、最大库容,m3。

9)渠道输水能力约束

从渠首引水后在渠道中输送的水量要控制在渠道允许的最大流量范围之内,保证渠道不淤不冲。

\sum _{i=1}^{n}\sum _{t=1}^{T}\sum _{k=1}^{K}{x}_{k,i,t}\le {Q}_{\max k,t} (12) 式中Qmaxk,t为第k种水源输水渠道第t时段的最大输水能力,m3。

10)非负约束

模型涉及的所有变量和参数包括计算单元配水量、农作物播种面积、作物需水量、灌溉水利用系数、水库蓄水量、水库取水许可量、水库渗漏量、水库蒸发量、最低蓄水量、最高蓄水量、渠道最大输水能力、生态需水量等均为非负值。

1.2 模型求解

首先,根据种植结构调整需求构建多目标数学优化模型,然后采用自主改进的基于精英策略并协遗传算法(NSGAⅡ-S)对优化模型进行求解,该算法是在NSGA-Ⅱ遗传算法的基础上,通过引入精英策略和协同进化的遗传算法。精英策略可保留每一代中的最优个体,避免丢失有价值的遗传信息;协同进化确保不同个体之间的协同优化,进一步增强多目标优化的效果。与传统遗传算法相比具有更好的适用性,在收敛速度和全局搜索能力上有所改进,求解过程更加快捷方便[28-29],可以精准定量表示水资源变化情况,为水资源动态变化下的水资源适应性开发利用提供科学依据[30]。NSGAⅡ-S的求解利用Matlab R2019b通过GUI方式调用自带的Linprog函数进行编程计算,NSGAⅡ-S算法的原理及求解过程如图1所示。

2. 实例研究

2.1 研究区概况

漳滏河灌区位于河北省邯郸市中部(36˚13΄~36˚53΄N,114˚13΄~115˚16΄E),是河北省最大的灌区(图2),素有“冀南粮仓”“冀南棉海”之称[31]。灌区地处半湿润半干旱区,呈西南高、东北低的地形趋势,属北温带大陆性季风气候,年均耗水量700 mm以上,而年均降水量只有580 mm,水资源难以存续。灌区主要水源地为水库水、外调水和地下水,水库水包括东武仕水库和岳城水库,外调水包括引黄水和引江水,按照地表水源地的不同,整个灌区被划分为滏阳河分灌区和民有渠分灌区,总控制面积为3.48×105 hm2,其中耕地面积占比75%,农田灌溉用水量巨大[32]。

长期以来,灌区形成了冬小麦-夏玉米一年两熟的主要粮食生产种植制度。2022年,灌区的种植结构以冬小麦、夏玉米、棉花、果树、蔬菜、花生、大豆以及苜蓿作为典型作物,作物种植面积分别为23.23、23.23、6.54、1.77、0.40、0.27、3.03、0.33 hm2。其中,以高耗水低效益的冬小麦、夏玉米为主的粮食作物播种面积占灌区农作物播种面积的71.41%,棉花、果树和蔬菜等经济作物占28.59%[33]。在冬小麦生育期,降水和地表水难以满足冬小麦的用水需求,因此抽取地下水补充灌溉成为保障粮食稳产、高产的关键。长期高强度的农业生产已经引发了地下水位下降、河道断流、地面沉降等一系列生态环境问题[34],已成为生态文明建设的突出短板[35],进一步加剧了华北平原的水资源危机[36-37]。

为严格地下水管理与保护,2019年邯郸市水利局制定了《邯郸市地下水超采综合治理实施意见》,要求以节水压采目标为导向,科学合理控制水资源开发程度,提高水资源利用效率,优先利用外调水和地表水,适当压减依靠地下水灌溉的冬小麦播种面积[38],减少取用地下水总量,加快促进农业种植结构调整,进一步提高农业种植效益。地下水压采目标的实现是要在一定程度上减少冬小麦播种面积和耗水,而粮食安全的保障又需要稳定其产量。

根据灌区资料和计算需要,结合地形地貌、灌区内供水系统和灌溉水源的不同[39],将2个节制闸之间控制的区域作为一个计算单元,共设置了17个计算单元,其中,滏阳河分区共有7个(F01~F07)计算单元,由东武仕水库供水;民有分区共有10个(M01~M10)计算单元,由岳城水库供水;引江水的供水单元为F01~F07、M01~M10,引黄水的供水单元包括M07和M10(图3)。

2.2 模型参数

灌区作物种植结构和播种面积数据由美国国家航空航天局(National Aeronautics and Space Administration,NASA)网站(https://ladsweb.modaps.eosdis.nasa.gov/search/)提供的MODIS数据解译得出;农作物的灌溉定额数据来自《河北省地方标准:农业用水定额(DB13/T5449.1-2021)》[40];农作物的产量、产值、利润、成本数据来自2022年《全国农产品成本收益资料汇编》的河北省农业费用及用工情况[41];不同水源的可供水量和用水总量控制目标取自《漳滏河灌区水资源论证报告》,其中东武仕水库、岳城水库、引黄水和引江水以及地下水的用水总量红线分别为1.60×108、2.36×108、1.12×108、3.52×108、2.71×108 m3;东武仕水库和岳城水库的最大最小库容和各渠道的输水能力取自《漳滏河灌区水土资源平衡分析报告》[42],优化配置模型的主要输入参数及变量如表1所示。

表 1 优化配置模型主要输入参数Table 1. The main input parameters of the optimal configuration model符号

Symbol输入参数

Input parameter单位

Unit数值

Value符号

Symbol输入参数

Input parameter单位

Unit数值

ValueQ1 东武仕水库可供水量 108 m3 1.60 e1 东武仕水库入库流量 104 m3 3 000 Q2 岳城水库可供水量 108 m3 2.36 e2 岳城水库入库流量 104 m3 15 000 Q3 引黄水可供水量 108 m3 1.12 f1 东武仕水库渗漏量 104 m3 484.50 Q4 引江水可供水量 108 m3 3.52 f2 岳城水库渗漏量 104 m3 3 900 Q5 地下水可供水量 108 m3 2.71 g1 东武仕水库蒸发量 104 m3 48 W1 东武仕水库取水许可 108 m3 2.10 g2 岳城水库蒸发量 104 m3 390 W2 岳城水库取水许可 108 m3 2.36 Qmax1 滏阳河干渠输水能力 104 m3 9 072 W4 地下水用水总量红线 109 m3 1.17 Qmax2 民有总干输水能力 104 m3 18144 V1 max 东武仕水库最大库容 108 m3 1.62 Qmax3 民有一干输水能力 104 m3 10368 V1 min 东武仕水库最小库容 108 m3 0.08 Qmax4 民有二干输水能力 104 m3 4665.60 V2 max 岳城水库最大库容 108 m3 13.00 Qmax5 民有三干输水能力 104 m3 2592 V2 min 岳城水库最小库容 108 m3 0.50 H 单位面积化肥施用强度 kg·hm-2 850 η 灌溉水利用系数 - 0.62(滏阳河)

0.64(民有)R 单位面积农药施用强度 kg·hm-2 30 2.3 情景方案设置

邯郸市提出推进农业种植结构调整行动,在地下水严重超采区将主要依靠抽取地下水灌溉的冬小麦播种面积适当压减,扩大低耗水作物和耐旱作物的播种面积,种植雨热同季的玉米、油料豆科和苜蓿,减少地下水用量。本研究以2022年漳滏河灌区种植结构作为现状情景(CS1),在此基础上,针对漳滏河灌区适宜的作物熟制、作物种类、种植制度、灌溉方式以及河北省邯郸市提出的农业种植结构调整实施方案又设置了7种情景,分别为CS2(种植结构保持现状,灌溉方式采取管灌或喷灌)、CS3(削减冬小麦的种植面积,种植苜蓿,灌溉方式采取渠道防渗)、CS4(削减冬小麦的种植面积,种植苜蓿,灌溉方式采取管灌或喷灌)、CS5(削减冬小麦和夏玉米的种植面积,种植花生、大豆、苜蓿,灌溉方式采取渠道防渗)、CS6(削减冬小麦和夏玉米的种植面积,种植花生、大豆、苜蓿,灌溉方式采取管灌或喷灌)、CS7(削减冬小麦、夏玉米和蔬菜的种植面积,种植花生、大豆、苜蓿,灌溉方式采取渠道防渗)、CS8(削减冬小麦、夏玉米和蔬菜的种植面积,种植花生、大豆、苜蓿,灌溉方式采取管灌或喷灌);其中苜蓿为旱作雨养型作物,不进行灌溉。8种不同情景设置如表2所示。研究分析8种不同情景下作物种植结构优化前后水资源配置、农作物播种面积和经济效益变化情况。

表 2 情景设置Table 2. Scenario setting序号

No.作物类型Crop type 符号

Symbol冬小麦

Winter wheat夏玉米

Summer maize蔬菜

Vegetables花生

Peanuts大豆

Soybean苜蓿

Alfalfa棉花

Cotton果树

Fruit trees1 N-CA N-CA N-CA N-CA N-CA N-N N-CA N-CA CS1 2 N-PS N-PS N-PS N-PS N-PS N-N N-PS N-PS CS2 3 R-CA N-CA N-CA N-CA N-CA I-N N-CA N-CA CS3 4 R-PS N-PS N-PS N-PS N-PS I-N N-PS N-PS CS4 5 R-CA R-CA N-CA I-CA I-CA I-N N-CA N-CA CS5 6 R-PS R-PS N-PS I-PS I-PS I-N N-PS N-PS CS6 7 R-CA R-CA R-CA I-CA I-CA I-N N-CA N-CA CS7 8 R-PS R-PS R-PS I-PS I-PS I-N N-PS N-PS CS8 注:N代表不进行任何干预;CA代表渠道防渗;PS代表管灌或者喷灌;R代表压减种植面积;I代表增加种植面积。 Note: N represents no intervention; CA represents channel anti-seepage; PS represents pipe irrigation or spray irrigation; R represents the reduction of planting area; I represents an increase in planting area. 3. 结果与分析

3.1 不同情景优化方案水资源配置结果

通过模型对灌区各水源及各计算单元进行水资源优化配置,得到不同情景下的水资源配置情况,详见表3。可以看出水库配水量(岳城和东武仕水库总量)高于其他水源的配水量,水库水、引黄水和引江水均达到用水总量控制目标(表1),但仍难以满足灌区用水需求,需额外抽取地下水进行灌溉,不同情景中灌区配水总量最多的是CS1(11.27×108 m3),最少的是CS4(8.66×108 m3)。

表 3 不同情景水资源优化配置Table 3. Optimal allocation of water resources in different scenarios情景

Scenario配水量Allocation water/108 m3 水库水

Reservoir引黄水

Yellow River water引江水

River water地下水开采量

Groundwater exploration配水总量

Allocation waterCS1 3.96 1.12 3.52 2.67 11.27 CS2 3.96 1.12 3.52 0.55 9.15 CS3 3.96 1.12 3.52 0.67 9.27 CS4 3.96 1.12 3.52 0.06 8.66 CS5 3.96 1.12 3.52 0.84 9.44 CS6 3.96 1.12 3.52 0.21 8.81 CS7 3.96 1.12 3.52 0.78 9.38 CS8 3.96 1.12 3.52 0.15 8.75 为了进一步分析各情景的时空配水情况,需要对不同情景按照不同水源、不同单元进行统计分析。图4为不同情景多水源不同月份配水量统计图,可以看出不同情景的配水量主要集中在3月、5月、7月以及11月,其中水库水、引黄水和地下水的配水量在不同月份呈现出明显的差异;水库水的配水量比例相对稳定,在春季和夏季相对较高;引黄水的配水量主要集中在用水高峰期的冬小麦和夏玉米的生育期,在冬季,由于黄河冰期,水量减少,则更多地使用水库水;地下水的配水量相对较为稳定,在各月份都有所使用,但在夏季也出现了明显的增减。

图5为不同情景计算单元配水量分布图,总体上滏阳河分区(F01~F07)的总配水量低于民有分区(M01~M10),滏阳河分区的各计算单元间的配水量较为均匀,而民有分区的各计算单元间的配水量变化明显。靠近水源的计算单元配置的水量较为均衡,水量变化不明显;而远离水源的计算单元,特别是M05、M07、M10、F07,由于上游用水量和渠道输水能力的限制,其配水量有着明显的变化。

图6为不同情景各计算单元不同水源的配水量,民有分区各单元不同水源的配水量明显多于滏阳河分区,各灌溉分区上游的配水量明显多于下游的配水量。种植结构优化前,滏阳河分区的各计算单元(F01~F07)及民有分区的上游计算单元(M01~M06)主要使用水库水和地下水,民有分区的下游M08和M09计算单元以地下水为主,下游M07和M10计算单元则主要使用引黄水和地下水。种植结构优化后,滏阳河分区的各计算单元(F01~F07)及民有分区的上游计算单元(M01~M06)以水库水为主,辅以地下水;水库水可以供给灌溉分区的下游计算单元,民有分区的下游M08和M09计算单元以水库水为主,下游M07和M10计算单元则主要使用引黄水,地下水用于补充灌溉。种植结构优化后,各计算单元地下水开采量明显减少,有效缓解灌区用水紧张情况,对于实施地下水压采政策和协调水粮矛盾具有一定的指导意义。

3.2 基于节水效果和经济效益的种植结构优化

通过模型进行种植结构优化以及地表水和地下水联合调度后,明显节约了农业灌溉用水量,减少了地下水开采量。计算出不同情景灌区水资源优化配置结果如表4所示,与种植结构优化前(CS1)相比,采取节水措施前,冬小麦播种面积压减17.70%(CS3),地下水压采比例为16.42%,灌区的经济效益增加了26.41%;冬小麦、夏玉米播种面积分别压减13.19%、22.60%(CS5),地下水压采比例为14.77%,灌区的经济效益增加了20.89%;冬小麦、夏玉米、蔬菜播种面积分别压减10.88%、22.60%、39.35%(CS7),地下水压采比例为15.41%,灌区的经济效益增加了20.54%;对比采取节水灌溉方式前后,CS2、CS4、CS6、CS8的配水量分别减少了18.83%、6.68%、6.75%、6.70%,由此可得出,种植结构优化前,由于作物种植模式粗放单一,节水灌溉方式可以节约大量农业用水,提高水资源利用效率;经过种植结构优化后,节水灌溉方式对其节水作用明显减弱。随着种植结构的不断优化和节水灌溉技术的不断进步,灌区农业生产将更加高效和可持续。

表 4 不同情景作物种植面积和经济效益Table 4. Crop planting area and economic benefit under different scenarios作物类型

Crop type种植面积

Planting area/104 hm2压减比例

Reduction ratio/%经济效益

Economic benefit/108元CS1

(CS2)CS3

(CS4)CS5

(CS6)CS7

(CS8)CS1

(CS2)CS3

(CS4)CS5

(CS6)CS7

(CS8)CS1

(CS2)CS3

(CS4)CS5

(CS6)CS7

(CS8)冬小麦

Winter wheat12.79 10.61 11.11 11.40 0 0 13.19 10.88 4.37 3.62 3.79 3.89 夏玉米

Summer maize12.79 12.79 9.90 9.90 0 0 22.60 22.60 6.78 6.78 5.25 5.25 蔬菜

Vegetables1.49 1.49 1.49 0.91 0 0 0 39.35 0.86 0.86 0.86 0.52 花生

Peanuts0 0 2.89 2.89 0 0 0 0 0 0 2.41 2.41 苜蓿

Alfalfa0 2.19 1.69 1.39 0 0 0 0 0 4.60 3.54 2.92 棉花

Cotton2.58 2.58 2.58 2.58 0 0 0 0 0.81 0.81 0.81 0.81 果树

Fruit trees1.05 1.05 1.05 1.05 0 0 0 0 1.75 1.75 1.75 1.75 总计Total 30.71 30.71 30.71 30.12 0 0 0 1.92 14.57 18.41 17.61 17.56 3.3 经济效益分析

不同情景种植结构如图7所示,CS3和CS4压减F01、M01、M07、M09的冬小麦种植面积,改种苜蓿;CS5和CS6压减F01、M01、M07的冬小麦种植面积和M10、F02-F07的夏玉米种植面积,分别种植苜蓿和花生;CS7和CS8压减F01、M01、M03的冬小麦种植面积、F01和F03~M10的蔬菜种植面积和M10、F02~F07的夏玉米种植面积,分别种植苜蓿和花生。

综上,压减高耗水低效益作物的播种面积,增加低耗水高效益作物的播种面积,灌区的经济效益会有明显增加,但是在保障粮食安全和地下水压采的前提下,进一步压减作物面积,其经济效益并不会增加。通过优化后的配水方案和相应的种植结构可知,CS4是最佳的种植结构优化方案,在保证配水总量最小的同时,具有更高的经济效益,也符合灌区的实际效益情况。由于河北省对苜蓿为主的旱作雨养作物补贴较高,因此,将主要依靠抽取地下水灌溉的冬小麦播种面积适当压减,种植苜蓿,变灌溉农业为旱作雨养农业,可以极大地减少地下水开采量,增加灌区经济效益。

4. 结 论

为科学优化灌区水资源配置,以河北省邯郸市漳滏河灌区为研究对象,构建了综合考虑农业灌溉用水量、经济效益的多目标多水源优化配置模型,获得不同情景下的水资源优化配置方案。结论如下:

1)应用模型进行种植结构优化后,各情景配水总量均有所减少,不同情景配水量减少比例为17.71%~23.20%;对比采取节水灌溉方式后的配水量减少比例为6.70%~18.83%。适当压减主要依靠抽取地下水灌溉的冬小麦的播种面积,变灌溉农业为旱作雨养农业,可以极大地减少地下水用量,与种植结构优化前相比,优化后不同情景地下水压采比例为14.77%~23.05%。

2)不同情景的配水量大部分集中在冬小麦和夏玉米的生育期,水库水配水量比例相对稳定,引黄水配水量主要集中在用水高峰期的夏季,在冬季则更多地使用水库水和引江水。滏阳河分区的总配水量低于民有分区,滏阳河分区的各计算单元间的配水量较为均匀,民有分区的各计算单元间的配水量变化明显。

3)压减高耗水低效益作物的播种面积,增加低耗水高效益作物的播种面积,可以明显增加灌区经济效益,不同情景经济效益增加比例为20.54%~26.41%。通过模型优化后的配水方案和相应的种植结构可知,最佳的种植结构优化方案为CS4(削减冬小麦的种植面积,种植苜蓿,灌溉方式采取管灌或喷灌),该方案冬小麦播种面积压减17.10%,地下水开采量减少了16.42%,灌区的经济效益增加了26.41%,在保证配水总量最小的同时,具有更高的经济效益。

本研究所构建的灌区多目标多水源优化配置模型综合考虑了灌区农业灌溉用水量和经济效益,探索了灌区种植结构优化和水资源配置的新模式。此外,通过灌区模型概化厘清了各计算单元的供水关系,充分发挥了灌区水资源的合理调配,为灌区的水资源规划与管理提供了决策依据。由于灌区不同水源的水价差异会对模型的配置结果产生影响,因此,在未来的研究中,应核算灌区不同水源的用水价格,以期获得更为准确的结果。

-

图 6 曲柄滑块机构平面图

注:I为曲柄圆心,E、K为曲柄与连杆的连接点,G为曲柄滑块向左运动的极限位置,J为曲柄滑块向右运动的极限位置,C为I在承载层的投影点,B为E在承载层的投影点;EJ、KG为连杆; l 为连杆长度,mm; r 为曲柄半径,mm; θ1为ED与 EB 的夹角,(°); θ2为 IG 与 IC 的夹角,(°)。

Figure 6. Plan view of crank-slider mechanism

Note: I is the center of the crank circle, E and K are the connection points of the crank and the connecting rod, G is the limit position of the crank slider moving to the left, J is the limit position of the crank slider moving to the right, C is the projection point of I on the bearing layer, and B is the projection point of E on the bearing layer; IE and IK are the crank radius, and EJ and KG are the connecting rods; l is the length of connecting rod, mm; r is the size of crank radius, mm; θ1 is the angle between ED and EB, (°); θ2 is the angle between IG and IC, (°).

图 8 排种器质心位置关系

注:S为质心,Q为转动轴,U为质心与转动轴的连线与重力作用线重合点,V为质心与转动轴的连线与重力作用线垂直点。

Figure 8. Relationship between center-of-mass positions

Note: S is the center of mass, Q is the axis of rotation, U is the point where the line between the center of mass and the axis of rotation coincides with the line of action of gravity, and V is the point where the line between the center of mass and the axis of rotation is perpendicular to the line of action of gravity.

表 1 兴蔬皱辣2号辣椒种子物理参数测定结果

Table 1 Determination of physical parameters of Xingshuzhoula No.2 pepper seeds

P1/mm P 2/mm P 3/mm P 4/mm P 5/mm P 6/(°) 4.13 3.46 0.73 4.62 3.34 26.4 注:P 1为平均长度;P 2为平均宽度;P 3为平均厚度;P 4为最大长度;P 5为最小长度;P 6为滑动摩擦角。 Note: P1 is the average length; P2 is the average width; P3 is the average thickness; P4 is the maximum length; P5 is the minimum length; P6 is the sliding friction angle. 表 2 多因素试验因素水平编码表

Table 2 Multi-factor test code table

水平

Level曲柄直径

Crank diameter/mm种量

Seed amount/

千粒曲柄电机转速

Crank motor speed/

( r∙min−1)-1 28 3 230 0 30 4 250 1 32 5 270 表 3 试验方案与结果

Table 3 Trial protocol and results

试验号

Test No.X1 X2 X3 Y1/% Y2/% Y3/% 1 0 1 1 80.63 9.58 9.79 2 -1 0 -1 85.63 4.79 9.58 3 1 -1 0 41.46 4.58 53.96 4 0 -1 1 5.21 1.04 93.75 5 0 1 -1 81.67 5.83 12.50 6 0 -1 -1 84.58 3.13 12.29 7 0 0 0 83.96 5.83 10.21 8 -1 1 0 82.50 10.42 7.08 9 0 0 0 78.33 4.38 17.29 10 0 0 0 86.04 4.79 9.17 11 1 1 0 69.38 8.75 21.88 12 1 0 -1 79.79 5.21 15.00 13 -1 -1 0 77.50 7.29 15.21 14 1 0 1 18.33 5.21 76.46 15 -1 0 1 44.38 9.17 46.45 16 0 0 0 76.88 5.21 17.91 17 0 0 0 84.17 6.04 9.79 注:X1、X2、X3分别为曲柄直径、种量、曲柄电机转速的水平值;Y1为单粒合格指数,%;Y2为重播指数,%和Y3为漏播指数,%。下同。 Note: X1, X2 ,X3 are the level values of crank diameter, seed amount, crank motor speed respectively; Y1 is the single-seed qualified index , %; Y2 is the reseeding index, %; Y3 is the missed seeding index, %. The same below. 表 4 单粒合格指数方差分析表

Table 4 Analysis of variance of the rate of single-seed qualified index

来源

Source平方和

Sum of squares自由度

Degree of

freedom均方

Mean

squareF P 模型 Model 9711.67 9 1079.07 20.99 0.0003** X1 821.14 1 821.14 15.97 0.0052** X2 1389.44 1 1389.44 27.03 0.0013** X3 4191.62 1 4191.62 81.54 <0.0001** X1 X2 131.33 1 131.33 2.55 0.1540 X1 X3 102.11 1 102.11 1.99 0.2016 X2 X3 1533.90 1 1533.90 29.84 0.0009** X12 427.65 1 427.65 8.32 0.0235* X22 70.37 1 70.37 1.37 0.2803 X32 917.98 1 917.98 17.86 0.003** 残差 Residual 359.84 7 51.41 失拟项 Lack of fit 295.36 3 9845.00 6.11 0.0565 误差 Pure error 64.48 4 16.12 合计 Cor total 10071.51 16 注:*表示显著(0.01 ≤ P < 0.05),**表示极显著(P< 0.01),下同。 Note:*represents significant difference (0.01 ≤ P < 0.05), ** represents extremely significant difference (P< 0.01). The same below. 表 5 重播指数方差分析表

Table 5 Analysis of variance of the rate of reseeding index

来源

Source平方和

Sum of

squares自由度

Degree of

freedom均方

Mean

squareF P 模型 Model 89.05 9 9.89 14.18 0.0010* X1 7.84 1 7.84 11.24 0.0122* X2 42.97 1 42.97 61.58 0.0001** X3 4.56 1 4.56 6.54 0.0377* X1 X2 0.27 1 0.27 0.39 0.5533 X1 X3 4.80 1 4.80 6.87 0.0343* X2 X3 8.53 1 8.53 12.22 0.0101* X12 14.49 1 14.49 20.77 0.0026** X22 1.81 1 1.81 2.59 0.1516 X32 4.30 1 4.30 6.16 0.0421* 残差 Residual 4.88 7 0.6977 失拟项 Lack of fit 2.95 3 0.9845 2.04 0.2509 误差 Pure error 1.93 4 0.4827 合计 Cor total 93.93 16 表 6 漏播指数方差分析表

Table 6 Analysis of variance of the rate of missed seeding index

来源

Source平方和

Sum of squares自由度

Degree of

freedom均方

Mean

squareF P 模型 Model 10385.93 9 1153.99 20.14 0.0003** X1 989.68 1 989.68 17.27 0.0043** X2 1920.76 1 1920.76 33.52 0.0007** X3 3919.67 1 3919.67 68.40 <0.0001** X1 X2 143.40 1 143.40 2.50 0.1577 X1 X3 151.17 1 151.17 2.64 0.1484 X2 X3 1771.15 1 1771.15 30.91 0.0009** X12 284.79 1 284.79 4.97 0.0610 X22 49.66 1 49.6 0.87 0.3829 X32 1047.69 1 1047.69 18.28 0.0037** 残差 Residual 401.12 7 57.30 失拟项 Lack of fit 325.93 3 108.64 5.78 0.0616 误差 Pure error 75.19 4 18.80 合计 Cor total 11436.99 16 20.14 -

[1] 乔立娟,赵帮宏,宗义湘,等. 我国辣椒产业发展现状、趋势及对策[J]. 中国蔬菜,2023(11):9-15. QIAO Lijuan, ZHAO Banghong, ZONG Yixiang, et al. Development current situation, tendency, and countermeasure for China’s pepper industry[J]. China Vegetables, 2023(11): 9-15. (in Chinese with English abstract)

[2] 袁小伟,杨双平,金若成,等. 双螺旋对辊式辣椒收获装置的设计与试验[J]. 农业工程学报,2021,37(15):1-9. YUAN Xiaowei, YANG Shuangping, JIN Ruocheng, et al. Design and experiment of double helix pair roller pepper harvesting device[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(15): 1-9. (in Chinese with English abstract)

[3] 侯加林,张二鹏,张康博,等. 基于DEM-MFBD的辣椒移栽机取投苗装置设计与试验[J]. 农业机械学报,2023,54(12):446-457,87. HOU Jialin, ZHANG Erpeng, ZHANG Kangbo, et al. Optimization design and test of seedling picking and throwing device of plug seeding transplanter based on DEM-MFBD[J]. Transactions of the Chinese Society for Agricultural Machinery, 2023, 54(12): 446-457, 87. (in Chinese with English abstract)

[4] 秦庆雨,李宇宇,李文虎,等. 不同干燥方式下叶蛋白-辣椒素微胶囊理化特性研究[J]. 农业机械学报,2022,53(2):378-385. QIN Qingyu, LI Yuyu, LI Wenhu, et al. Effects of different drying methods on properties of leaf protein-capsaicin microcapsules[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(2): 378-385. (in Chinese with English abstract)

[5] 韩长杰,肖立强,徐阳,等. 辣椒穴盘苗自动移栽机设计与试验[J]. 农业工程学报,2021,37(4):20-29. HAN Changjie, XIAO Liqiang, XU Yang, et al. Design and experiment of the automatic transplanter for chili plug seedlings[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(4): 20-29. (in Chinese with English abstract)

[6] 宋磊,李嵘,焦义涛,等. 基于ResNeXt单目深度估计的幼苗植株高度测量方法[J]. 农业工程学报,2022,38(3):155-163. SONG Lei, LI Rong, JIAO Yitao, et al. Method for measuring seedling height based on ResNeXt monocular depth estimation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022, 38(6): 155-163. (in Chinese with English abstract)

[7] WANG Y S, ZHANG L A, HUANG X M, et al. Design of and experiment with seedling selection system for automatic transplanter for vegetable plug seedlings[J]. Agronomy, 2021, 11(10): 2031. doi: 10.3390/agronomy11102031

[8] MA G X, CHEN X, LIU Y, et al. Effects of compound biochar substrate coupled with water and nitrogen on the growth of cucumber plug seedlings[J]. Agronomy, 2022, 12(11): 2855. doi: 10.3390/agronomy12112855

[9] 张静,龙新华,韩长杰,等. 机械驱动式辣椒穴盘苗自动取投苗系统设计与试验[J]. 农业工程学报,2021,37(5):20-30. ZHANG Jing, LONG Xinhua, HAN Changjie, et al. Design and experiments of mechanically-driven automatic taking and throwing system for chili plug seedlings[J]. Journal of Changjiang Vegetables[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(5): 20-30. (in Chinese with English abstract)

[10] 袁艺,陶婧,汪骞,等. 辣椒漂浮育苗营养液筛选与优化研究[J]. 西南农业学报,2017,30(9):2085-2090. YUAN Yi, TAO Jing, WANG Qian, et al. Screening and optimization of nutrient solution for pepper floating seedling[J]. Southwest China Journal of Agricultural Sciences, 2017, 30(9): 2085-2090. (in Chinese with English abstract)

[11] 徐达,闫航,胡佳未,等. 育苗基质配比及育苗方式对辣椒成苗的影响[J]. 江西农业大学学报,2023,45(6):1370-1384. XU Da, YAN Hang, HU Jiawei, et al. Effect of seedling substrate ratio and seedling raising method on pepper seedling[J]. Acta Agriculturae Universitatis Jiangxiensis, 2023, 45(6): 1370-1384. (in Chinese with English abstract)

[12] 王秀,刘蒙滋,翟长远,等. 蔬菜移栽夹茎式取苗装置设计与试验[J]. 农业机械学报,2023,54(9):122-132. WANG Xiu, LIU Mengzi, ZHAI Changyan, et al. Design and experiment of vegetable transplanting clip stem seedling device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2023, 54(9): 122-132. (in Chinese with English abstract)

[13] 王文新,高杏龙,屠美英,等. 蔬菜水浮育苗技术及其应用效果[J]. 江苏农业科学,2012,40(4):179−180. [14] 王燕玲,任朝辉,周安韦,等. 贵州省辣椒漂浮育苗技术[J]. 辣椒杂志,2023,21(2):38-39,43. [15] GAIKWAD B, SIROHI N. Design of a low-cost pneumatic seeder for nursery plug trays[J]. Biosystems Engineering, 2007, 99(3): 322−329.

[16] 张欢,罗昕,马亚朋,等. 气吹供种盘吸式排种器排种性能试验研究[J]. 机械设计与制造,2017(5):92-95. ZHANG Huan, LUO Xin, Ma Yapeng, et al. Experiment study on performance of air-blowing conveying seeds plate of suction seed metering device[J]. Machinery Design & Manufacture, 2017(5): 92-95. (in Chinese with English abstract)

[17] 赵永满,侯晓晓,姜有忠,等. 气吹悬浮供种的气吸滚筒式排种器设计与试验[J]. 农机化研究,2019,41(2):114-118. ZHAO Yongman, HOU Xiaoxiao, JIANG Youzhong, et al. Design and experiment of seed metering device with roller of air-suction by airborne seeding[J]. Journal of Agricultural Mechanization Research, 2019, 41(2): 114-118. (in Chinese with English abstract)

[18] 姜有忠,侯晓晓,赵永满,等. 气吹投种的气吸滚筒式排种器设计与试验[J]. 甘肃农业大学学报,2019,54(2):211-218. JIANG Youzhong, HOU Xiaoxiao, ZHAO Yongman, et al. Design and experiment of air suction drum precision metering device for air blowing and seeding[J]. Journal of Gansu Agricultural University, 2019, 54(2): 211-218. (in Chinese with English abstract)

[19] 梅玉茹,谢方平,王修善,等. 番茄气吸滚筒式排种器的优化设计与试验[J]. 湖南农业大学学报(自然科学版),2022,38(6):730-736. MEI Yuru, XIE Fangping, Wang Xiushan, et al. Optimization design and experiment of tomato pneumatic roller type seed-metering device[J]. Journal of Hunan Agricultural University(Natural Sciences), 2022, 38(6): 730-736. (in Chinese with English abstract)

[20] 张明华,姜有聪,何思禹,等. 蔬菜气吸轮式精量排种器设计与试验[J]. 农业工程学报,2023,39(7):98-109. doi: 10.11975/j.issn.1002-6819.202211138 ZHANG Minghua, JIANG Youcong, HE Siyu, et al. Design and experiment of the air suction wheel precision seed metering device for vegeables[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2023, 39(7): 98-109. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.202211138

[21] 杨昌敏,易文裕,邱云桥,等. 育苗精量播种机研究现状及发展分析[J]. 中国农机化学报,2022,43(4):183-188. YANG Changmin, YI Wenyu, QIU Yunqiao, et al. Research status and development analysis of seed-raising precision seeder[J]. Journal of Chinese Agricultural Mechanization, 2022, 43(4): 183-188. (in Chinese with English abstract)

[22] 贾雅丽. 精量排种器对比及发展现状分析[J]. 农业技术与装备,2022(5):38-40. JIA Yali. Comparison and Development Status Analysis of Precision Seed Metering Device[J]. Agricultural Technology & Equipment, 2022(5): 38-40. (in Chinese with English abstract)

[23] 张学军,程金鹏,史增录,等. 摆动夹取式玉米精量排种器设计与试验[J]. 农业机械学报,2023,54(4):38-50. ZHANG Xuejun, CHENG Jinpeng, SHI Zenglu, et al. Simulation and experiment of seed taking performance of swing-clamp type maize precision seed-metering device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2023, 54(4): 38-50. (in Chinese with English abstract)

[24] 高丽萍,施彬彬,廖庆喜,等. 正负气压组合油菜精量排种器锥孔盘排种性能[J]. 农业工程学报,2022,38(6):22-33. CHEN Tao, YI Shujuan, LI Yifei, et al. Experimental study on the material characteristics of northern millet[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022, 38(6): 22-33. (in Chinese with English abstract)

[25] 李海艳,朴万寿,刘晔. 磁力回位型育苗播种器:CN205510779U[P]. 2016-08-31. [26] 钟江,张宪,蒋建福. 农业机械质心测量方法研究[J]. 农业机械,2010(S2):116-119. [27] 李凯,周璟成. 基于图像分析的质心和转动惯量测量方法[J]. 力学与实践,2021,43(5):771-775. LI Kai, ZHOU Jingcheng. Center of mass and moment of inertia measurement method based n image analysis[J]. Mechanics in Engineering, 2021, 43(5): 771-775. (in Chinese with English abstract)

[28] 祁兵,张东兴,刘全威,等. 集排式精量排种器清种装置设计与性能试验[J]. 农业工程学报,2015,31(1):20-27. QI Bing, ZHANG Dongxing, LIU Quanwei, et al. Design and experiment of cleaning performance in a centralized pneumatic metering device for maize[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(1): 20-27. (in Chinese with English abstract)

[29] 谢方平,刘敏章,杨米米,等. 袋装缓控释肥有序排肥装置设计[J]. 农业工程学报,2019,35(16):40-49. XIE Fangping, LIU Minzhang, YANG Mimi, et al. Design of ordered fertilizer device for bagged slow-release fertilizer[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2019, 35(16): 40-49. (in Chinese with English abstract)

下载:

下载: