Optimization of the production process and quality evaluation of mulberry-purple potato compound freeze-dried fruit blocks

-

摘要:

传统冻干产品加工工艺技术含量低,产品配方、营养和口味单一,市场同质化现象严重,日渐无法满足消费者的需求。为增加市面上复合型果蔬冻干产品的多样性,丰富冻干产品的口感和营养价值,该研究以桑葚和紫薯为主要原料,采用真空冷冻干燥技术,使用Box-behnken结合综合评分法,探究了果胶、阿拉伯胶、麦芽糊精、果葡糖浆和柠檬酸添加量对桑葚-紫薯复合冻干果块综合评分的影响。结果表明,最佳制备工艺为:果胶添加量0.20%、麦芽糊精添加量8.00%、阿拉伯胶添加量0.20%、果葡糖浆添加量4.00%和柠檬酸添加量0.24%,综合评分为0.87分。工艺优化后的产品总体感官可接受度8.90分,比未添加辅料的复合冻干果块显著(P<0.05)提高了25.35%。同时,所得复合冻干果块具有良好的品质,其脆度、总黄酮含量、总花青素含量及铁离子还原能力分别显著(P<0.05)提高了80.53%、23.10%、11.36%和39.95%。研究结果可以为复合型冻干果蔬产品的发展提供一定的理论依据。

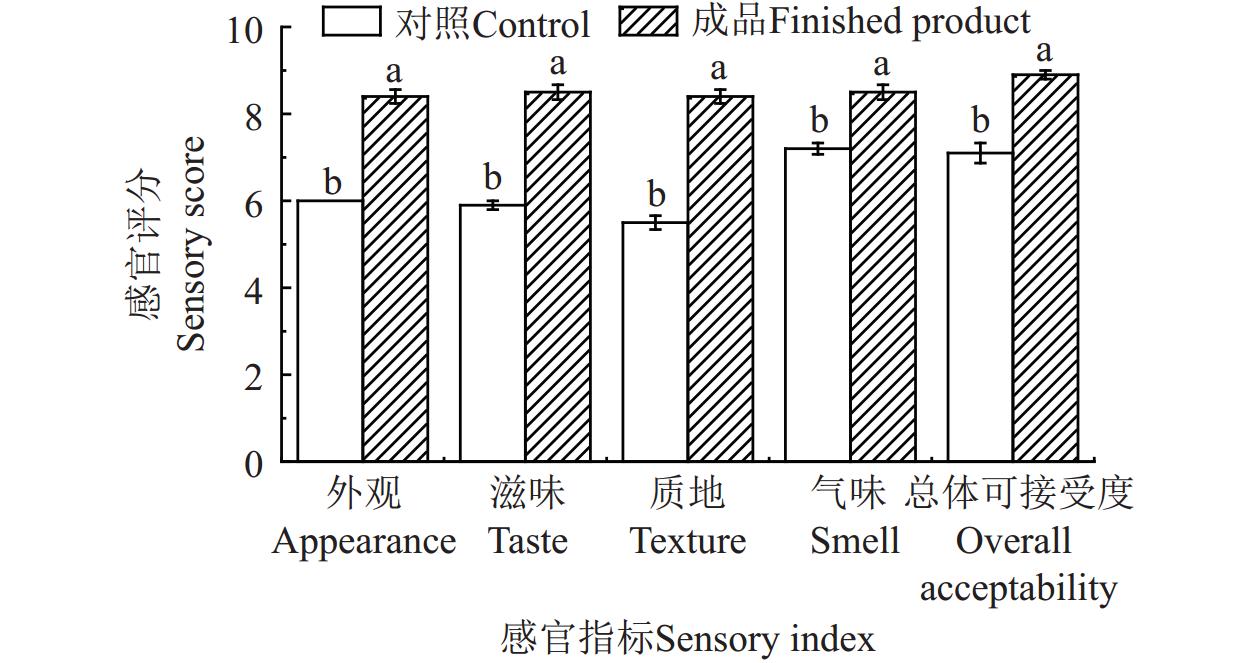

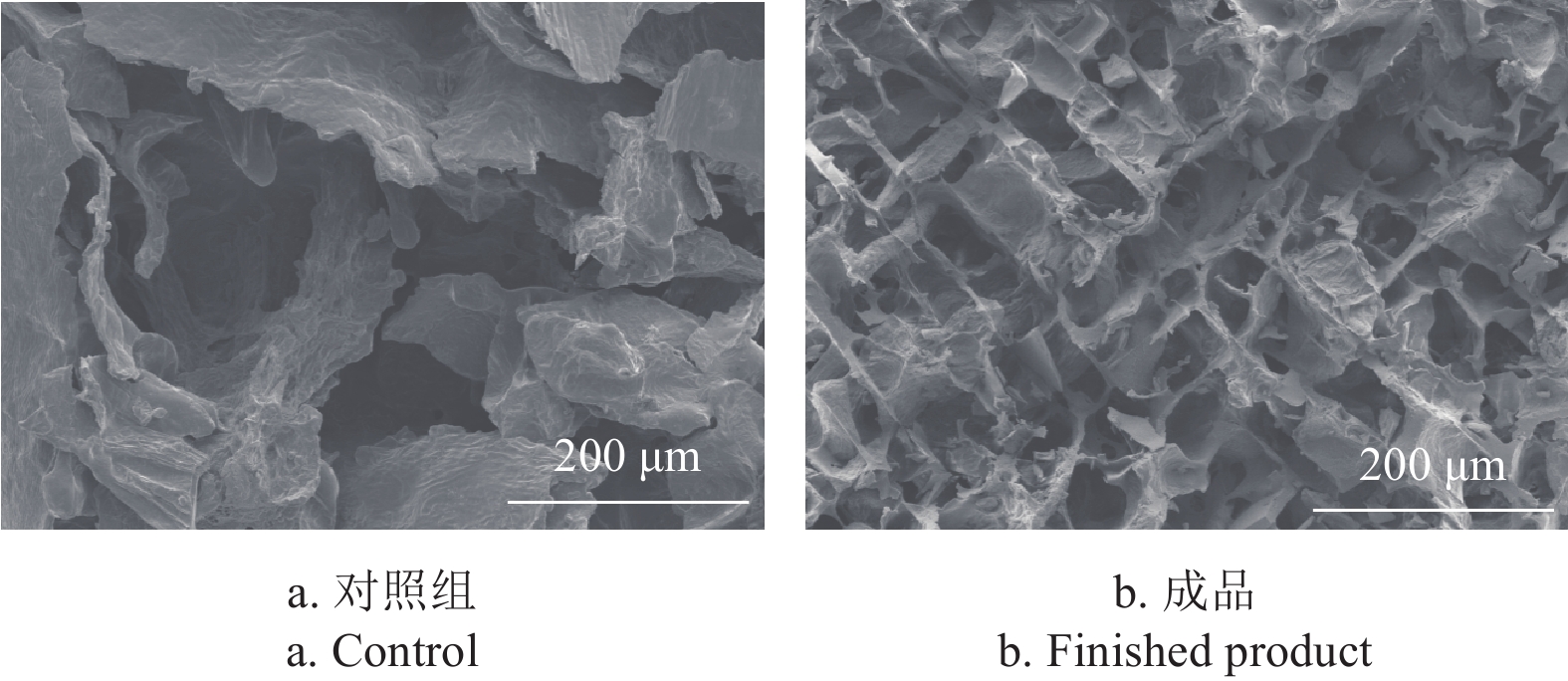

Abstract:Lyophilized products have been limited to the formula options of a single product. It is also lacking in diversity in nutrition and taste. Alternatively, both mulberry and purple potato have been renowned for their sweet taste and rich content of anthocyanins and bioactive compounds. Specifically, the high starch content of purple potatoes can contribute significantly to the texture, color, nutrition, flavor, and overall quality of food products. In this study, the mulberry and purple potato were combined to increase the diversity of compound freeze-dried fruit and vegetable products on the market. The taste and nutritional value of freeze-dried products were also improved under the unique combination. Firstly, the mulberry and purple potato were mixed at a ratio of 3:7. The compound freeze-dried fruit block was prepared by vacuum freeze-drying. Furthermore, an initial single-factor test was conducted to determine the optimal quantities of five additives: pectin, maltodextrin, gum arabic, fructose syrup, and citric acid, in order to ensure the high quality, excellent taste, and robust nutrition of the mulberry and purple potato compound freeze-dried fruit block. A composite scoring system was established with the influencing factors, such as color difference, hardness, brittleness, and hygroscopic property. The composite score was optimized to enhance the quality of the compound freeze-dried fruit block. Consequently, the experimental factors were narrowed down to the specific ranges: pectin supplementation (0.15%, 0.20%, and 0.25%), maltodextrin supplementation (7.00%, 8.00%, and 9.00%), fructose syrup supplementation (3.00%, 4.00%, and 5.00%), and citric acid supplementation (0.15%, 0.20%, and 0.25%). Subsequently, a response surface optimization test was conducted with the composite score as the key response value. The results indicated that the optimal combination of parameters was obtained to prepare the compound freeze-dried fruit block: 0.20% pectin, 8.00% maltodextrin, 4.00% fructose syrup, 0.24% citric acid, and 0.20% gum arabic. This optimal formula was achieved in a composite score of 0.87. The sensory evaluation demonstrated that the overall sensory acceptability of products scored 8.90 points, which was 25.35% higher than that of the control group. The finished product also shared a significantly higher level of market appeal and consumer acceptance. In addition, the optimal products then exhibited remarkable improvements in the various qualities. Specifically, the fracturability was enhanced by 80.53%. The microstructure of the product was much smoother, denser, and more organized. In the contents of bioactive ingredients, the ascorbic acid, total phenol, total flavone, and total anthocyanin increased by 2.91%, 3.53%, 23.10%, and 11.36%, respectively. The antioxidant capacities were measured using DPPH, ABTS, and FRAP tests, which were elevated by 26.92%, 11.27%, and 39.95%, respectively. A higher quality was obtained than before. In summary, supplementary materials were added to effectively enhance the product quality of the compound freeze-dried fruit block. The findings enriched the taste and nutritional value of these products, particularly in the diversity of compound freeze-dried fruit and vegetable products on the market. The novel insights were then offered to develop the freeze-dried products.

-

Keywords:

- drying /

- process design /

- optimization /

- mulberry /

- purple potato /

- compound freeze-dried fruit block

-

0. 引 言

东北地区苏打盐碱地是中国盐碱地的主要集中区,对盐碱土壤进行改良研究与实践,使之适宜农作物的生长发育,对提高粮食安全具有重要意义[1-2]。针对东北苏打盐碱地特征,课题组设计了一种具有叶脉状内通道的深松铲[3],可以实现自润减阻配合改良液层施,进而达到改良东北地区苏打盐碱土的目的。目前多孔分布管广泛应用于给排水、滴喷灌等领域[4]。为研究其出流特性,国内外众多学者开展了大量分析研究[5]。不同学者针对不同情况下对多孔管内流体分布的计算方程进行推导, RAVIKUMAR等[6]建立了分析方程来确定压力的变化系数,推导出计算流量变化系数的简单解析方程,用于求解数值问题中的流量变异系数;CHELLAM等[7]研究了具有1道和2道可渗透壁的均匀多孔管内不可压缩层流的特性,建立了四阶微分方程并得到了所有壁面雷诺数的解;刘文华等[8]结合水力学分析理论,对坡度、压力水头、孔距、管长4个参数对沿程压力分布的影响规律开展研究;杜涛等[9]建立多孔管出流控制体模型并对达西-韦斯巴赫公式进行完善,得出了多孔管沿程水头损失的计算公式;一些学者通过物理试验方法对多孔管的液体出流进行了相应研究,王亚朦等[10]根据达西-韦斯巴赫公式,结合理论分析与试验的方法,对不同坡度下多孔分布管内流体压力分布规律开展研究;鞠学良等[11]根据微灌毛管水力解析模型,提出了考虑适宜布置形式的均匀坡微灌毛管设计方案以提高灌水均匀度;杨宝中等[12]结合单孔出流试验结果,对多孔管土中出流计算公式进行分析研究,为多孔管地下灌溉提供参考;随着计算流体动力学的发展,数值模拟技术已成为研究单相流和结构优化的重要工具,钱卫忠等[13]使用有限元分析的方法分析多孔管孔径、管长、水压等因素对多孔管出流速度和流量的影响,并得到影响多孔管出流速度及出流量影响显著的因素;王鹏辉[14]提出了基于CFD的“流场分析设计方法”并对喷淋装置几何结构进行了设计优化;韩圆圆[15]通过数值模拟的方法分析了T型三通管内的气液流动特性及相分布规律。

综上,关于多孔管出流速度及出流量的研究多与水利灌溉工程相关,目前未见将其与深松部件结合的相关研究。针对叶脉状内通道的流场分布规律及影响因素不明确的问题,本文拟采用基于计算流体动力学的仿真方法结合物理试验对其进行研究。首先利用仿真的方法,开展单因素试验,优选出影响内通道分支出口流速的因素水平范围值,其次开展Box-Behnken试验,建立各影响因素与分支出口流速之间的二阶回归模型,进而得到最优参数组合。按最优参数组合条件对叶脉状内通道进行设计加工后进行相应的物理试验,得出物理试验值。通过仿真与物理试验结果的对比,检验叶脉状内通道结构优化设计的效果,从而达到对叶脉状内通道优化设计的目的,为利用叶脉状内通道多分支出口管结构在东北地区苏打盐碱地进行深松及化学改良耦合技术提供理论基础。

1. 数值计算模型与计算方法

1.1 数值计算模型

以课题组自研的叶脉状内通道自润滑减阻深松铲的内部结构——叶脉状内通道多分支出口管为研究对象。其深松铲结构由铲柄、弧形铲刃、凿型铲尖及叶脉状多分支出口内通道组成。深松铲铲体长度为1200 mm,其中铲柄长500 mm,弧形铲刃长600 mm,铲尖长100 mm,铲刃横截面为等腰三角形且刃口角度为42°。叶脉状内通道与深松铲铲柄及弧形铲刃的总长度尺寸一致,由主通道直管部分及弧形叶脉状多分支出口管两部分构成,其总长度为1100 mm,主通道直径10 mm,直管部分长度500 mm,弧形叶脉状多分支出口管部分是半径550 mm的圆弧,其长度为600 mm。其中每组分支出口由两个在主通道X轴线上呈42°夹角对称分布的分支出口组成,同时每组分支出口在Y轴上以相同间距在叶脉状内通道多分支出口弧形管段上均匀分布。其叶脉状内通道深松铲及内通道多分支出口管结构如图1。

![]() 图 1 叶脉状内通道深松铲与叶脉状内通道多分支出口管结构图1.主通道 2.深松铲体 3.深松铲刃口夹角42° 4.直管部分 5.弧形管部分 6.末端分支出口 7.分支出口夹角42° 8.首端分支出口 9.主通道入口Figure 1. Structure diagram of deep loosening shovel and a porous pipe flow channel model in leaf vein shaped inner channel1.Main channel 2.Deep loosening shovel body 3. Deep loosening shovel blade angle 42° 4. Straight pipe section 5. Curved tube section 6. End branch outlet 7. Branch outlet angle 42° 8. The head branch outlet 9. Main channel entrance

图 1 叶脉状内通道深松铲与叶脉状内通道多分支出口管结构图1.主通道 2.深松铲体 3.深松铲刃口夹角42° 4.直管部分 5.弧形管部分 6.末端分支出口 7.分支出口夹角42° 8.首端分支出口 9.主通道入口Figure 1. Structure diagram of deep loosening shovel and a porous pipe flow channel model in leaf vein shaped inner channel1.Main channel 2.Deep loosening shovel body 3. Deep loosening shovel blade angle 42° 4. Straight pipe section 5. Curved tube section 6. End branch outlet 7. Branch outlet angle 42° 8. The head branch outlet 9. Main channel entrance1.2 数值模型网格划分

数值模拟计算中选取的叶脉状内通道多孔管的流体计算流域为主通道入口至叶脉状多分支出口处。采用ICEM中的O-Block技术进行流体计算域网格划分[16],可获得较规整的结构网格和较好的边界层网格。计算域采用适应度较强的非结构四面体网格进行划分,算法采用补丁适形法,采用美国机械工程协会(American Society of Mechanical Engineers,ASME)推荐的网格收敛指数 GCI 进行网格离散误差的估计,对网格进行无关性验证[17-19]。最终确定选取中等网格,此时的模型网格总数为198353个,节点总数为43799个,并检查网格问题与质量,结果显示平均网格质量、偏度和纵横比分别为0.837、0.228、1.85, 所生成网格的质量较高,符合本文计算要求。

1.3 数值计算方法及试验设计

1.3.1 数值计算方法

图2为多孔管计算域网格。液体入口位于直管部分顶端,出口位于弧形管部分上的各分支出口上,其余位置均密闭,壁面处设置为无滑移壁面,计算流体使用不可压缩的液态水,进口边界选择流速入口边界条件,对于出口边界条件,采用压力出口边界条件压力值为0,参考压力为标准大气压[20]。采用k-ε湍流模型,依靠计算流体力学求解软件Fluent进行求解[21-24]。在多孔管设置中给定主通道入口流速,经过软件模拟可得到多孔管在该主通道入口流速下达到稳定状态时的内通道各分支出口流速。

1.3.2 试验设计

文章中所讨论的叶脉状内通道分支多孔管,目的是在深松过程中,利用分支出口流出的液体改良剂在铲刃面上形成液膜达到自润滑减阻目的,同时利用流出的改良剂对盐碱地进行化学改良。这就需要每组分支出口的流速要达到一定要求,同时每组分支出口的流量也要达到一定要求,通过大量田间试验发现,叶脉状内通道的结构参数(孔径、孔间距、孔数)及运行参数(主通道入口流速)对分支出口的出流速度及液膜的形成起到决定性作用。因此本文选择分支出口的孔径、孔间距、孔数及主通道入口流速为研究因素。其中孔径即为分支出口的直径,孔间距即为相邻两组分支出口的距离,孔数即为分支出口的组数,主通道入口流速即为改良剂流入主通道的速度。

结合实际工况及多次预试验发现,分支出口6 mm以下的孔径所流出的液体在深松过程中不能够形成将整个深松铲铲面完全覆盖的液膜,即不能保证流量要求,因此选择6 mm以上的孔径进行讨论。分支出口孔间距距离太小及孔数过少则达不到分层减阻及化学改良液层施时所需效果,同时分支出口孔间距距离太大及孔数过多则使最末端分支出口流量太小。在确保各组分支出口的表面积流速大于1 m/s以及所流出的液体能够使铲刃面形成液膜的前提下,初步确定叶脉状内通道分支出口孔径、孔间距、孔数和主通道入口流速4个因素的水平取值范围,进而开展单因素仿真模拟试验,对因素水平进行初步优选,以确定各因素最佳工作水平范围,具体因素水平见表1。研究单因素对各组分支出口流速的影响时,其他因素取中间水平值。

表 1 叶脉状内通道多孔管数值模拟参数Table 1. Numerical simulation parameters of leaf vein shaped inner channel porous tube水平

Factors分支出口孔径

Branch outlet

aperture D/mm分支出口孔间距

Branch outlet

hole spacing

A/mm孔数

Hole number

B主通道入口流速

Main channel

inlet velocity

C/(m·s−1)1 6 80 3 3 2 7 90 4 4 3 8 100 5 5 4 9 110 6 6 5 10 120 7 7 内通道分支出口截面上的最大流速即为表面积最大流速,内通道分支出口截面上的平均流速即为平均流速,两种流速表达的含义不同。距主通道入口最近的一组分支出口即为首端出口,距主通道入口最远的一组分支出口即为末端出口;主通道入口流速在沿程上经过首端或末端分支出口的分流而减少的值即为首端或末端出口分流损失;主通道入口流速在沿程上经过各分支出口的分流而减少的值与主通道入口流速的比值即为流速的分流损失率,以此来量化表征主通道入口流速经过各分支出口被分流的多少,进而分析不同影响因素水平对流速的影响大小。即:首端出口分流损失等于主通道入口流速减去首端分支出口流速;末端出口分流损失等于主通道入口流速减去末端分支出口流速;首末端出口分流损失等于首端分支出口流速减去末端分支出口流速;首端出口分流损失率等于首端出口分流损失与主通道入口流速的比值;末端出口分流损失率等于末端出口分流损失与主通道入口流速的比值;首末端出口分流损失率等于首末端出口分流损失与首端分支出口流速的比值。

2. 结果与分析

2.1 叶脉状内通道多分支出口管沿程流速变化规律

图3为叶脉状内通道主通道流速剖面图。由图3发现叶脉状主通道上沿程流速变化趋势为先逐渐增大后逐渐减小。以叶脉状内通道多分支出口管主通道直径10 mm、内通道分支出口孔径6 mm、孔间距100 mm、孔数5、主通道入口端流速5 m/s时为例,叶脉状主通道上最大流速值为5.736 m/s,最小流速为0。沿程流速从入口处开始逐渐增加直至首组分支出口处上端达到沿程流速最大值,经过首端分支出口下端后开始逐渐减小,在达到末端分支出口后沿程流速逐渐减小至最小值。出现主通道内部沿程流速先逐渐增大后逐渐减小的原因,可能是在射流和惯性重力及离心力的影响作用下,在主通道内部产生沿程流速加速现象,使主通道内部沿程流速先逐渐增大到流速最大值[25];随后液体经过首组内通道分支出口后压力减小,液体开始逐级分流,沿程流速开始逐渐减小。

2.2 单因素试验结果

通过对初步确定的影响叶脉状内通道分支出口流速的因素进行单因素试验,根据试验数据分析各因素对分支出口流速的影响情况,进一步确定参数范围,试验结果如图4所示。

![]() 图 4 各因素下的内通道分支出口平均流速注:B1为首端分支出口;B2为第二分支出口;B3为第三分支出口;B4为第四分支出口;B6为第六分支出口;B5和B7为末端分支出口。Figure 4. Average flow velocity at the outlet of internal channel branches under various factorsNote:B1is the head branch outlet; B2 is the second branch outlet; B3 is the third branch outlet; B4 is the fourth branch outlet; B6 is the sixth branch outlet; B5 and B7 are the end branch outlet.

图 4 各因素下的内通道分支出口平均流速注:B1为首端分支出口;B2为第二分支出口;B3为第三分支出口;B4为第四分支出口;B6为第六分支出口;B5和B7为末端分支出口。Figure 4. Average flow velocity at the outlet of internal channel branches under various factorsNote:B1is the head branch outlet; B2 is the second branch outlet; B3 is the third branch outlet; B4 is the fourth branch outlet; B6 is the sixth branch outlet; B5 and B7 are the end branch outlet.2.2.1 分支出口孔径对流速的影响

根据图4a可知,随着内通道分支出口孔径的增加,同一分支出口下的流速逐渐减小,同一孔径下的各分支出口流速逐渐减小。当孔径由6 mm增加到10 mm时,表面积最大流速的首端出口分流损失率、末端出口分流损失率及首末端出口分流损失率均逐渐增加,当孔径为6 mm时,表面积最大流速的三种分流损失率分别为4.43%、38.52%和35.67%,均为最小。同时随着孔径的增加内通道分支出口平均流速的首端出口分流损失率、末端出口分流损失率及首末端出口分流损失率同样均逐渐增加,当孔径为6 mm时,平均流速的三种分流损失率分别为67.14%、58.32%和−26.83%,均为最小。孔径由6 mm增加到10 mm时,内通道分支出口表面积最大流速首端出口减小1.567 m/s,末端出口减小1.878 m/s;平均流速首端出口减小0.657 m/s,末端出口减小1.475 m/s。根据结果数据发现在主通道入口流速统一的情况下,内通道分支出口孔径越小,相邻两分支出口的出流速度差值变化越小,随着分支出口孔径的增加,同一孔径下相邻两分支出口出流速度差值逐渐增加,进而使各个分支出口平均流速减小。在孔径为6 mm时液体出流速度最快,因此液体流量也最大,能够达到自润滑减阻的目的。因此优选出叶脉状内通道多孔管模型内通道分支出口孔径为6 mm。

2.2.2 分支出口孔间距对流速的影响

根据图4b可知在内通道分支出口孔间距增加的情况下,内通道分支出口首端出口流速逐渐增大,末端出口流速逐渐减小,这是因为分支出口流速随着孔间距的增加在第二、三分支出口之后降幅开始加剧。同一孔间距下各分支出口流速整体上逐渐减小,只有当孔间距为80 mm时各分支出口流速先增加后减小。当孔间距为80 mm时,首端出口分流损失率同其他孔间距相比最大为26.30%;末端出口分流损失率及首末端出口分流损失率同其他孔间距相比最小,分别为60.22%和46.02%。当孔间距为120 mm时,首端出口分流损失率同比最小为15.46%;末端出口分流损失率及首末端出口分流损失率同其他孔间距相比最大,分别为68.58%和62.83%。同时随着孔间距的增加内通道分支出口平均流速的首端出口分流损失率、末端出口分流损失率及首末端出口分流损失率变化同表面积最大流速变化趋势一样。孔间距由80 mm增加到120 mm时,内通道分支出口表面积最大流速首端出口增加0.542 m/s,末端出口减小0.418 m/s;平均流速首端出口增加0.268 m/s,末端出口减小0.285 m/s。在主通道入口流速统一的情况下,内通道分支出口孔间距越小对各分支出口的首端出口出流速度影响变化较大,反而对末端出口出流速度影响变化较小,当孔间距由90 mm增加到110 mm时流速变化不大,这是叶脉状内通道分支出口这一结构造成的,但在对因素水平讨论优选的过程中是有必要的,因为在实际工作环境中分支出口的位置关系到改良剂液体对深松铲减阻的部位,以及利用叶脉状内通道这一结构进行化学改良过程中,达到化学改良剂分层施用这一目的。因此考虑综合实际试验因素,优选出叶脉状内通道多孔管模型内通道分支出口孔间距90、100、110 mm进行Box-Behnken仿真试验,进一步探究孔间距及其它因素水平交互下对分支出口流速的影响。

2.2.3 分支出口孔数对流速的影响

根据图4c可知在内通道分支出口孔数增加的情况下,内通道分支出口首末端流速均逐渐减小,同一孔数下各分支出口流速整体上是逐渐减小的,只有当孔数为3时各分支出口流速逐渐增加。孔数由3增加到7时,内通道分支出口表面积最大流速的首端出口分流损失率、末端出口分流损失率及首末端出口分流损失率均先增加后减小,当孔数为3时,三种分流损失率均为最小,分别为10.23%、21.49%和12.54%。当孔数为7时,此时首端出口分流损失率不是最大,分别为24.20%、67.44%和57.05%。同时随着孔数的增加内通道分支出口平均流速的首端出口分流损失率、末端出口分流损失率及首末端出口分流损失率变化同表面积最大流速变化趋势一样。孔数由3增加到7时,内通道分支出口表面积最大流速首端出口减少0.698 m/s,末端出口减小2.298 m/s;平均流速首端出口增加0.455 m/s,末端出口减小1.663 m/s。在主通道入口流速统一的情况下,内通道分支出口孔数越少对各分支孔的首末两端组出流速度影响变化越小,通过试验数据可以得出孔数在4~6时对流速影响变化幅度适中,同时为了考虑综合实际试验因素,优选出叶脉状内通道多孔管模型内通道分支出口孔数4、5、6进行Box-Behnken仿真试验,进一步探究孔数对分支出口流速的影响。

2.2.4 主通道入口流速对流速的影响

根据图4 d可知在内通道主通道入口流速增加的情况下,内通道各分支出口的流速是逐渐增大的,同一主通道入口流速下各分支出口流速先增加后逐渐减小。主通道入口流速由3 m/s增加到7 m/s时,内通道分支出口表面积最大流速的首端出口分流损失率逐渐增加,末端出口分流损失率逐渐减少,当主通道入口流速为3 m/s时,首端出口分流损失率同比最小为14.83%;末端出口分流损失率及首末端出口分流损失率同比最大为82.74%和79.74%。当主通道入口流速为7 m/s时,首端出口分流损失率同比最大为26.03%;末端出口分流损失率及首末端出口分流损失率同比最小为54.53%和38.53%。同时随着主通道入口流速的增加内通道分支出口平均流速的首端出口分流损失率先减少后增加,末端出口分流损失率及首末端出口分流损失率均减少。当主通道入口流速为7 m/s时,首端出口分流损失率为78.58%,末端出口分流损失率及首末端出口分流损失率74.38%和−19.58%,均为最小。在其他因素不变的情况下,主通道入口流速为5、6、7 m/s时首端出口分流损失率、末端出口分流损失率及首末端出口分流损失率均为中间值,因此优选出叶脉状内通道多孔管模型内通道分支出口主通道入口流速为5、6、7 m/s进行Box-Behnken仿真试验,进一步探究主通道入口流速对分支出口流速的影响。

3. Box-Behnken仿真试验

基于单因素仿真试验中优选出的各因素范围,设计二次回归正交试验,建立叶脉状内通道分支出口平均流速回归模型,以得到最优参数组合[26]。内通道分支出口孔径在单因素试验中已经优选出最优值为6 mm,其他因素水平如表2所示,Box-Behnken试验设计及结果如表3所示。

表 2 因素水平表Table 2. The factor level table水平

Level分支出口孔间距

Branch outlet

hole spacing

A/mm分支出口孔数

Holes number of branch

outlet B主通道入口流速

Main channel

inlet velocity

C/(m·s−1)−1 90 4 5 0 100 5 6 1 110 6 7 表 3 Box-Behnken试验设计及结果Table 3. Box Behnken experimental design and results序号No. X1 X2 X3 出口流速Outlet velocity/(m·s−1) 1 −1 −1 0 6.069 2 1 −1 0 5.896 3 −1 1 0 5.483 4 1 1 0 5.889 5 −1 0 −1 4.713 6 1 0 −1 4.961 7 −1 0 1 6.456 8 1 0 1 6.806 9 0 −1 −1 4.903 10 0 1 −1 4.769 11 0 −1 1 7.263 12 0 1 1 6.334 13 0 0 0 5.621 14 0 0 0 5.685 15 0 0 0 5.679 16 0 0 0 5.558 17 0 0 0 5.681 注:X1、X2、X3分别为分支出口孔间距、分支出口孔数、主通道入口流速的水平值。 Note: X1, X2, X3 are the levels of branch outlet hole spacing, branch outlet hole number, main channel inlet velocity respectively. Box-Behnken试验方差分析结果如表4所示,由表4的分析结果可知,X2、X3和X2X3对平均流速影响极其显著, X1、X1X2和X 22对平均流速影响显著;X1X3、X12和X32对平均流速影响不显著。模型的P<0.0001,说明回归模型高度显著;模型失拟项P>0.05,说明模型失拟性不显著,回归模型拟合程度高。回归方程决定系数R2=0.9911,校正决定系数R2=0.9796,与1非常接近,且变异系数CV=1.75%。根据统计学上F值越大、表明该因素对结果的影响越大[27-28],通过F值大小,可以判定各因素对平均流速影响的重要性,试验因素对平均流速影响从大到小为主通道入口流速、内通道分支出口孔数、内通道分支出口孔间距;综上表示该回归模型极其显著,能够可靠和真实的反映真实情况,可用于进一步的目标平均流速的预测分析。

表 4 Box-Behnken试验方差分析Table 4. Variance analysis of Box Behnken experiment方差源

Variance

source均方

Mean

square自由度

Degree of

freedom平方和

Sum of

squareF值

F-valueP值

P-value模型Model 7.830 9 0.870 86.21 <0.0001** X1 0.086 1 0.086 8.55 0.0222* X2 0.343 1 0.343 33.96 0.0006** X3 7.060 1 7.060 698.99 <0.0001** X1X2 0.084 1 0.084 8.30 0.0236* X1X3 0.003 1 0.003 0.26 0.6273 X2X3 0.158 1 0.158 15.65 0.0055** X1² 0.012 1 0.012 1.18 0.3141 X2² 0.078 1 0.078 7.75 0.0271* X3² 0.006 1 0.006 0.54 0.4849 残差

Residual0.071 7 0.010 失拟项

Lack of fit0.059 3 0.020 6.39 0.0525 纯误差

Pure error0.012 4 0.003 总和Sum 7.900 16 注: **表明影响极显著(P<0.01),*表明影响显著(P<0.05)。 Note: ** indicates that the impact is extremely significant (P<0.01), and * indicates that the impact is significant (P<0.05). 通过Design–Expert 11.0对Box-Behnken试验结果进行多元回归拟合,得到仿真试验出口流速二阶回归方程:

V=5.64+0.104X1−0.207X2+0.939X3+0.145X1X2+0.026X1X3−0.199X2X3+0.053X21+0.136X22+0.036X23 (1) 在Design–Expert 11.0软件的优化模块中,以分支出口平均流速最大值为优化目标值,将二阶回归方程式(1)中的不显著项剔除后进行优化求解,求解出最优参数组合为内通道分支出口孔间距110 mm、内通道分支出口孔数4、主通道入口流速7 m/s。

为验证仿真优化参数的可靠性,在最优参数条件下进行3次Fluent仿真模拟,得到分支出口平均流速为3.262、3.255、3.275 m/s,其平均值为3.264 m/s。

4. 试验验证

根据数值模拟选定的最优参数组合,加工出用于验证试验的叶脉状内通道多孔管,主通道入口端通过软管、阀门、流量计、变径接头与增压泵相连接构成试验通路,各分支出口由软管及量杯进行承接构成泄放通路,主通道入口流速通过控制流量计算获得,液体流动示意图及实际装置见图5。

![]() 图 5 叶脉状内通道多分支出口流动示意图及试验装置图1.叶脉状内通道深松铲 2.深松铲卡钳 3.流量计 4.变径接头 5.水箱 6.机架 7.软管 8.量杯 9.分支出口Figure 5. Schematic diagram and experimental setup diagram of multi branch outlet flow in leaf vein like internal channels1.Vein shaped inner channel deep loosening shovel 2. Deep loosening shovel caliper 3. Flowmeter 4. Reducer union 5. Water tank 6. Frame 7. Hose 8. Counting cup 9. Branch outlet

图 5 叶脉状内通道多分支出口流动示意图及试验装置图1.叶脉状内通道深松铲 2.深松铲卡钳 3.流量计 4.变径接头 5.水箱 6.机架 7.软管 8.量杯 9.分支出口Figure 5. Schematic diagram and experimental setup diagram of multi branch outlet flow in leaf vein like internal channels1.Vein shaped inner channel deep loosening shovel 2. Deep loosening shovel caliper 3. Flowmeter 4. Reducer union 5. Water tank 6. Frame 7. Hose 8. Counting cup 9. Branch outlet因无法直接测定各分支出口流速,利用图5中量杯,通过软管与深松铲分支出口进行密闭连接,当深松铲达到稳定工作水平状态时,测量出单位时间内各个分支出口所流出液体量Q,根据液体流量计算式(2)计算各分支出口的平均流速[29-31]。

Q=SV (2) 式中Q为分支出口流量,L/min;S为分支出口面积,cm2;V为分支出口平均流速,m/s。

在最优参数组合下,经过3次重复物理试验计算出内通道分支出口平均流速值为2.988、3.102、2.824 m/s,其平均值为2.971 m/s。与仿真值平均误差为8.97%,验证了数值模拟的可靠性,同时检验了叶脉状内通道结构优化设计的效果。分析各分支出口的平均流速小于数值模拟,造成该数据异常的原因可能是实际多分支开孔处不平整,增加了叶脉状内通道多分支出口处的压力损失;另外,实际管路开孔直径的精度有限,而分支孔管出流量对孔径的变化较为敏感,孔径的变化都会对管的流量造成一定的影响。

5. 结 论

1)通过数值仿真分析得到叶脉状内通道多孔管主通道上的沿程流速变化规律为先增大后减小。沿程流速从入口处开始逐渐增加直至首端分支出口处上端达到沿程流速最大值,经过首端分支出口下端后开始逐渐减小,在达到最末组出口端后沿程流速逐渐减小至最小值。

2)采用单因素仿真分析对4个因素进行初步优选,以流速最大为前提,优选出内通道分支出口孔径为6 mm、孔间距为90、100、110 mm、孔数为4、5、6、主通道入口流速为5、6、7 m/s。

3)利用Design–Expert 11.0对仿真数据进行分析,求解得到最优参数组合为内通道分支出口孔间距为110 mm、孔数为4、主通道入口流速为7 m/s。对流速影响因素大小依次为主通道入口流速、内通道分支出口孔数、内通道分支出口孔间距。

4)在最优参数组合下进行仿真与物理试验,内通道分支出口平均流速分别为3.264 m/s和2.971 m/s,误差为8.97%。

-

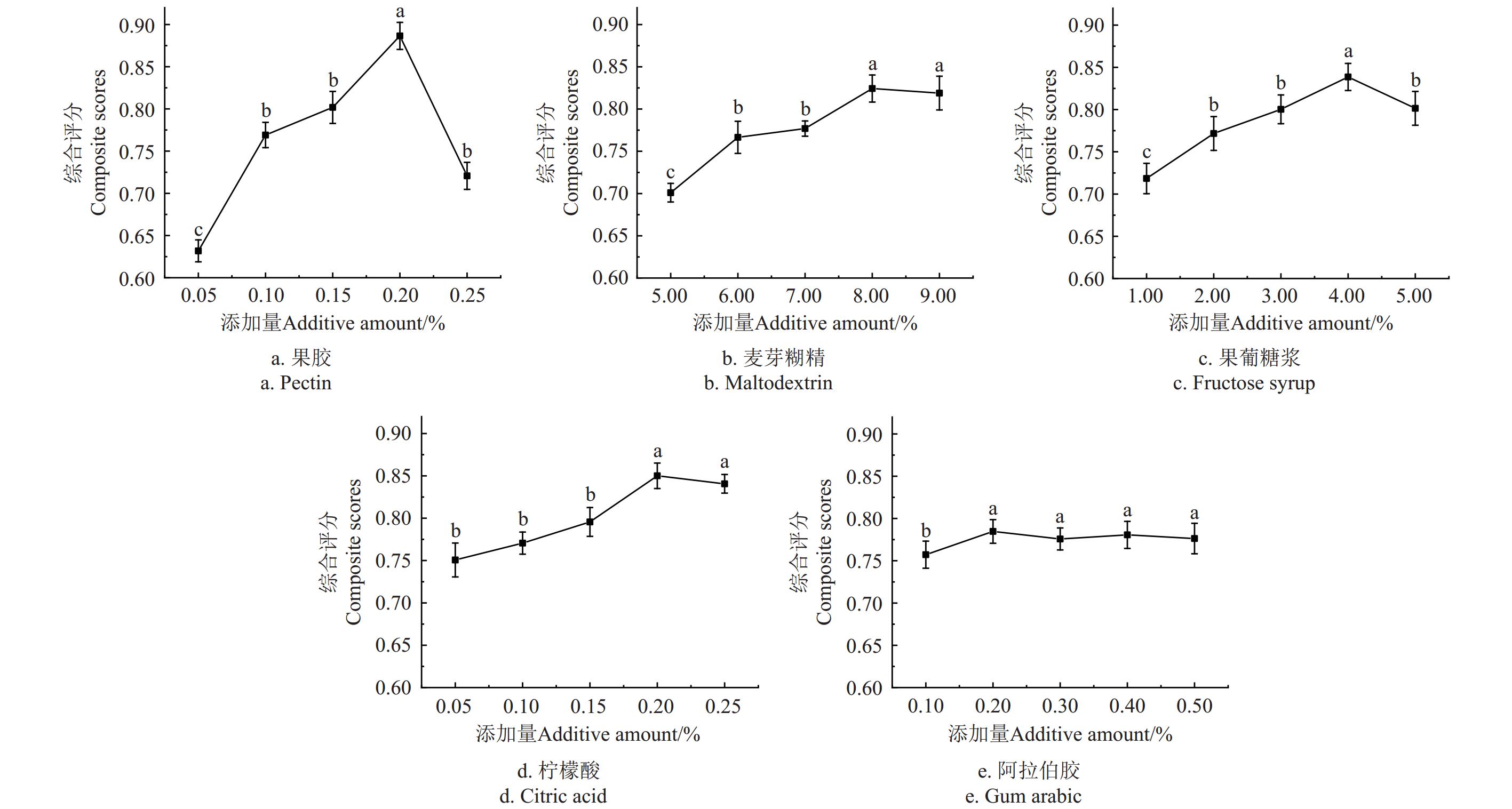

图 1 不同辅料添加量对复合冻干果块综合评分的影响

注:固定因素水平为:果胶添加量为0.15%,麦芽糊精添加量为7.00%,果葡糖浆添加量为3.00%,柠檬酸添加量为0.15%,阿拉伯胶添加量为0.30%。不同字母表示差异显著(P < 0.05),下同。

Figure 1. Effects of different excipients addition on the composite score of compound freeze-dried fruit block

Note: The fixed factor levels were: pectin addition 0.15%, maltodextrin addition 7.00%, fructose syrup addition 3.00%, citric acid addition 0.15%, and gum arabic addition 0.30%. Different letters indicate significant differences(P < 0.05), the same below.

表 1 单因素试验指标与权重值

Table 1 Indicators and weighting values for single-factor tests

因素

Factors添加量

Additive amount/

%标准化 Standardisation 色差值

Chromatic

aberration

value ΔE吸湿率

Hygroscopic/

%硬度

Hardness/

(N·cm2)脆度

Fracturability/

(N·cm2)综合评分

Composite

scoresA 0.05 0.68 0.64 1.00 0.44 0.63 0.10 0.75 0.85 0.86 0.71 0.77 0.15 0.75 0.62 0.70 0.96 0.80 0.20 0.86 0.83 0.71 1.00 0.80 0.25 0.81 0.65 0.82 0.66 0.72 B 5.00 0.73 0.80 0.83 0.58 0.70 6.00 0.76 0.86 0.85 0.69 0.77 7.00 0.80 0.87 0.79 0.72 0.78 8.00 0.82 0.93 0.77 0.80 0.82 9.00 0.89 0.92 0.74 0.77 0.82 C 1.00 0.65 0.90 0.90 0.59 0.72 2.00 0.75 0.86 0.86 0.70 0.77 3.00 0.75 1.00 0.84 0.72 0.80 4.00 0.73 0.94 0.70 0.91 0.84 5.00 0.73 0.84 0.61 0.91 0.80 D 0.05 0.75 0.83 0.78 0.70 0.75 0.10 0.76 0.85 0.86 0.70 0.77 0.15 0.83 0.87 0.80 0.74 0.80 0.20 0.97 0.91 0.83 0.77 0.85 0.25 1.00 0.88 0.79 0.76 0.84 E 0.10 0.75 0.83 0.83 0.69 0.76 0.20 0.75 0.85 0.85 0.74 0.78 0.30 0.62 0.92 0.74 0.81 0.78 0.40 0.66 0.92 0.69 0.82 0.78 0.50 0.66 0.80 0.66 0.88 0.78 熵权

Entropy weight0.22 0.19 0.18 0.41 注:A、B、C、D和E分别为果胶、麦芽糊精、果葡糖浆、柠檬酸和阿拉伯胶,下同。 Note: A, B, C, D and E are respectively pectin, maltodextrin, fructose syrup, citric acid and gum arabic, the same below. 表 2 响应面试验因素水平表

Table 2 Response surface test factors and levels

因素Factors 水平Levels -1 0 1 A 0.15 0.20 0.25 B 7.00 8.00 9.00 C 3.00 4.00 5.00 D 0.15 0.20 0.25 表 3 感官评分表

Table 3 Sensory scoring scale

感官指标

Sensory index评价标准

Evaluation criteria评分范围

Scoring range外观

Appearance色泽鲜艳、组织均一、脆度好 7~9 色泽较鲜艳、组织较均匀、脆度一般 4~6 色泽暗淡、组织不均匀、脆度差 1~3 滋味

Taste口感细腻、酸甜适中、果味浓烈 7~9 口感较细腻、酸/甜味偏重、果味一般 4~6 口感粗糙,酸甜味及果味不明显 1~3 质地

Texture硬度适中、酥脆度高、易咀嚼 7~9 偏硬、酥脆度一般、较易咀嚼 4~6 硬、酥脆度差、不易咀嚼 1~3 气味

Smell具有强烈的果香、无异味 7~9 具有果香、轻微异味 4~6 无果香、异味较重 1~3 总体可接受度

Overall acceptability非常接受 7~9 一般接受 4~6 不接受 1~3 表 4 响应面试验设计与结果

Table 4 Response surface methodology design and test results

试验编号

Test No.A B C D 综合评分

Composite scores1 -1 -1 0 0 0.73 2 1 -1 0 0 0.70 3 -1 1 0 0 0.74 4 1 1 0 0 0.72 5 0 0 -1 -1 0.78 6 0 0 -1 1 0.79 7 0 0 1 -1 0.79 8 0 0 1 1 0.79 9 -1 0 -1 0 0.64 10 1 0 -1 0 0.61 11 -1 0 1 0 0.69 12 1 0 1 0 0.64 13 0 -1 0 -1 0.80 14 0 1 0 -1 0.80 15 0 -1 0 1 0.80 16 0 1 0 1 0.82 17 -1 0 0 -1 0.78 18 1 0 0 -1 0.77 19 -1 0 0 1 0.78 20 1 0 0 1 0.77 21 0 -1 -1 0 0.74 22 0 1 -1 0 0.75 23 0 -1 1 0 0.76 24 0 1 1 0 0.76 25 0 0 0 0 0.93 26 0 0 0 0 0.87 27 0 0 0 0 0.87 28 0 0 0 0 0.86 29 0 0 0 0 0.85 表 5 单指标回归方程方差分析

Table 5 Analysis of variance of single-index regression equations

方差来源

Source of variance平方和

Sum of squares自由度

Degree of freedom均方

Mean squareF 值

F valueP 值

P value模型 Model 0.132 9 14 0.009 5 11.650 0 <0.000 1 A 0.001 6 1 0.001 6 2.010 0 0.177 8 B 0.000 3 1 0.000 3 0.324 9 0.577 7 C 0.000 1 1 0.000 1 0.128 3 0.725 5 D 0.001 1 1 0.001 1 1.400 0 0.255 8 AB 0 1 0 0.022 0 0.884 2 AC 0 1 0 0.003 6 0.953 3 AD 0.000 1 1 0.000 1 0.092 1 0.766 0 BC 0.000 1 1 0.000 1 0.072 7 0.791 4 BD 0 1 0 0.005 4 0.942 2 CD 0 1 0 0.000 6 0.981 1 A2 0.086 5 1 0.086 5 106.110 0 <0.000 1 B2 0.013 0 1 0.013 0 15.980 0 0.001 3 C2 0 1 0 0.032 4 0.859 7 D2 0.056 8 1 0.056 8 69.650 0 <0.000 1 残差 Residual 0.011 4 14 0.000 8 失拟项 Lack of fit 0.007 8 10 0.000 8 0.872 1 0.610 5 纯误差 Pure error 0.003 6 4 0.000 9 总计 Total 0.144 3 28 系数 Coefficient R2=0.920 9 R2adj=0.841 8 注:P < 0.001表示差异极显著。 Note: P < 0.001 indicates a highly significant difference. 表 6 复合冻干果块色泽和质地评价

Table 6 Evaluation of colour and texture of compound freeze-dried fruit block

样品

Sample色泽参数 Color parameters 质构参数 Texture parameters 亮度

Brightness L红绿值

Red/Green value a黄蓝值

Yellow/Blue value b色差值

Chromatic aberration value ΔE硬度

Hardness/(N·cm−2)脆度

Fracturability/(N·cm−2)初始样品Initial sample 25.09 ± 0.01b 6.87 ± 0.15c 0.79 ± 0.03a - - - 对照组Control 24.94 ± 0.28b 18.19 ± 0.18b -1.25 ± 0.03b 11.51 ± 0.28b 13.88 ± 0.32b 13.63 ± 0.44b 成品

Finished product37.46 ± 0.27a 20.07 ± 0.13a -4.15 ± 0.11c 18.75 ± 0.35a 22.92 ± 0.51a 24.61 ± 0.53a 注:同列不同字母表示差异显著(P < 0.05),下同。 Note: Different letters in the same column indicate significant differences(P < 0.05), the same below. 表 7 复合冻干果块生物活性化合物评价

Table 7 Evaluation of bioactive compounds of compound freeze-dried fruit block

(g·kg−1) 样品

Sample抗坏血酸

Ascorbic acid总酚

Total phenol总黄酮

Total flavonoid总花青素

Total anthocyanin对照组

Control5.16 ± 0.05a 11.05 ± 0.07b 3.29 ± 0.02b 0.88 ± 0.02b 成品

Finished product5.31 ± 0.03a 11.44 ± 0.11a 4.05 ± 0.03a 0.98 ± 0.01a 表 8 复合冻干果块抗氧化能力评价

Table 8 Evaluation of the antioxidant capacity of compound freeze-dried fruit block

(g·kg−1) 样品

SampleDPPH ABTS FRAP 对照组

Control1.04 ± 0.01b 4.26 ± 0.03b 29.79 ± 0.12b 成品

Finished product1.32 ± 0.02a 4.74 ± 0.04a 41.69 ± 0.17a 注:DPPH、ABTS和FRAP分别为2, 2-二苯基-1-苦基肼基自由基清除能力、2,2'-联氮-双-3-乙基苯并噻唑啉-6-磺酸自由基清除能力和铁离子还原能力。 Note: DPPH, ABTS, and FRAP represent 2,2-Diphenyl-1-picrylhydrazyl radical scavenging ability, 2,2'-Azino-bis(3-ethylbenzothiazoline-6-sulphonic acid) radical scavenging ability, and ferric reducing antioxidant power, respectively. -

[1] 贺付亮,郭永彩,高潮,等. 基于视觉显著性和脉冲耦合神经网络的成熟桑葚图像分割[J]. 农业工程学报,2017,33(6):148-155. HE Fuliang, GUO Yongcai, GAO Chao, et al. Image segmentation of ripe mulberries based on visual saliency and pulse coupled neural network[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(6): 148-155. (in Chinese with English abstract)

[2] 蒋希芝,徐磊,张蓓,等. 基于生物酶法的酰基化桑椹花青素的制备与特性[J]. 农业工程学报,2021,37(3):294-301. JIANG Xizhi, XU Lei, ZHANG Bei, et al. Preparation and characterization of acylated mulberry anthocyanins using biological enzyme method[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(3): 294-301. (in Chinese with English abstract)

[3] ALAM M K. A comprehensive review of sweet potato (Ipomoea batatas [L. ] Lam): Revisiting the associated health benefits[J]. Trends in Food Science & Technology, 2021, 115: 512-529.

[4] MENG M, SUN Y, QI Y L, et al. Structural characterization and induction of tumor cell apoptosis of polysaccharide from purple sweet potato (Ipomoea batatas (L.) Lam)[J]. International Journal of Biological Macromolecules, 2023, 235: 123799. doi: 10.1016/j.ijbiomac.2023.123799

[5] 胡泽茜,李洋,崔琢玉,等. 冷链物流环境下时间温度指示器的制备与应用[J]. 农业工程学报,2023,39(22):246-257. HU Zexi, LI Yang, CUI Zhuoyu, et al. Preparation and application of time temperature indicator in cold chain logistics[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2023, 39(22): 246-257. (in Chinese with English abstract)

[6] 陈丽潇,王晓梅,李靓靓,等. 紫薯营养与加工研究进展[J]. 农产品加工,2023(20):74-77,82. CHEN Lixiao, WANG Xiaomei, LI Liangliang, et al. Research progress on nutrition and processing of purple potato[J]. Farm Products Processing, 2023(20): 74-77, 82. (in Chinese with English abstract)

[7] 吴小华,马渊博,宁旭丹,等. 西洋参分段式热风干燥动力学模型构建[J]. 农业工程学报,2020,36(5):318-324. WU Xiaohua, MA Yuanbo, NING Xudan, et al. Construction of staged hot-air drying dynamic model for American ginseng[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(5): 318-324. (in Chinese with English abstract)

[8] 代建武,周厚彬,黄杰,等. 不同干燥方式对红托竹荪干燥特性和品质的影响[J]. 农业工程学报,2024,40(6):90-100. DAI Jianwu, ZHOU Houbin, HUANG Jie, et al. Effects of different drying technologies on the drying characteristics and quality of Dictyophora rubrovolvata[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2024, 40(6): 90-100. (in Chinese with English abstract)

[9] LI X , ZHOU Y, DONG H , et al. Effects of ultrasonication and freeze-thaw pretreatments on the vacuum freeze-drying process and quality characteristics of apricot(Prunus armeniaca L. cv. Diaoganxing)[J]. Food Chemistry: X, 2024, 22: 101357. doi: 10.1016/j.fochx.2024.101357

[10] 王海鸥,谢焕雄,陈守江,等. 不同干燥方式对柠檬片干燥特性及品质的影响[J]. 农业工程学报,2017,33(14):292-299. WANG Haiou, XIE Huanxiong, CHEN Shoujiang, et al. Effect of different drying methods on drying characteristics and qualities of lemon slices[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(14): 292-299. (in Chinese with English abstract)

[11] 谢焕雄,胡志超,王海鸥,等. 真空冷冻干燥对柠檬挥发性风味化合物保留的影响[J]. 农业工程学报,2018,34(22):282-290. XIE Huanxiong, HU Zhichao, WANG Haiou, et al. Effect of vacuum freeze-drying methods on retention of volatile flavor compounds of lemon[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(22): 282-290. (in Chinese with English abstract)

[12] 欧阳锐,江贻洁,王志辉,等. 一款真空冷冻干燥胡萝卜黄花梨果蔬脆的研制[J]. 食品工业,2020,41(3):133-137. OUYANG Rui, JIANG Yijie, WANG Zhihui, et al. Development of a carrot and yellow pear composite crisp by vacuum freeze drying technology[J]. The Food Industry, 2020, 41(3): 133-137. (in Chinese with English abstract)

[13] 杨惠莲. 苹果-甘薯复合脆片原辅料配方优化及品质研究[D]. 沈阳:沈阳农业大学,2020. YANG Huilian. Study on the Optimization of Raw and Auxiliary Materials and Quality Analysis of Apple-sweet Potato Re-structured Chips[D]. Shenyang: Shenyang Agricultural University, 2020. (in Chinese with English abstract)

[14] 候春辉. 再造型胡萝卜复合脆片加工工艺及品质研究[D]. 天津:天津科技大学,2018. HOU Chunhui. Studied on Processing Technology and Quality Analysis of Restructured Carrot Chips[D]. Tianjin: Tianjin University of Science and Technology, 2018. (in Chinese with English abstract)

[15] 遇艳萍,罗华丽,刘鹏莉,等. 真空冷冻干燥苹果复合果蔬块的工艺研究[J]. 中国果菜,2023,43(4):7-12. YU Yanping, LUO Huali, LIU Pengli, et al. Research on the process of producing apple chunks compounded with other fruitsand vegetables by vacuum freeze-drying technology[J]. china fruit and vegetable, 2023, 43(4): 7-12. (in Chinese with English abstract)

[16] 刘竞妍,张可,王桂华. 综合评价中数据标准化方法比较研究[J]. 数字技术与应用,2018,36(6):84-85. LIU Jingyan, ZHANG Ke, WANG Guihua. Comparative study on data standardization methods in comprehensive evaluation[J]. Digital Technology & Application, 2018, 36(6): 84-85. (in Chinese with English abstract)

[17] 张兆芳,王耀鹏,宋治荣,等. 正交设计结合熵权法优选扶正屏风颗粒成型工艺[J]. 亚太传统医药,2023,19(11):76-79. ZHANG Zhaofang, WANG Yaopeng, SONG Zhirong, et al. Optimization of forming process of fuzheng pingfeng granules by orthogona design combined with entropy weight method[J]. Asia-Pacific Traditional Medicine, 2023, 19(11): 76-79. (in Chinese with English abstract)

[18] 中华人民共和国国家质量监督检验检疫总局. 感官分析方法学总论:GB/T 10220-2012 [S]. 北京:中国标准出版社,2012. [19] 朱新茹,肖书书,金敏凤,等. 基于九点快感标度和“恰好”检验对3种市售粳米样品的年轻消费者偏好研究[J]. 上海师范大学学报(自然科学版),2021,50(2):170-180. ZHU Xinru, XIAO Shushu, JIN Minfeng, et al. Evaluation of young consumer preference in three commercial Japonica rice varieties via hedonic and Just-About-Right tests[J]. Journal of Shanghai Normal University(Natural Sciences), 2021, 50(2): 170-180. (in Chinese with English abstract)

[20] 中华人民共和国国家卫生和计划生育委员会. 食品安全国家标准食品中水分的测定:GB5009. 3-2016 [S]. 北京:中国标准出版社,2016. [21] 王吉强,邓利珍,裴昱鹏,等. 成熟度对冬枣真空脉动干燥动力学及产品品质的影响[J]. 农业工程学报,2021,37(23):273-279. WANG Jiqiang, DENG Lizhen, PEI Yupeng, et al. Effects of maturity on pulsed vacuum drying kinetics and product quality of winter jujube[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(23): 273-279. (in Chinese with English abstract)

[22] JIANG N, LIU C Q, LI D J, et al. Evaluation of freeze drying combined with microwave vacuum drying for functional okra snacks: Antioxidant properties, sensory quality, and energy consumption[J]. LWT-Food Science and Technology, 2017, 82: 216-226.

[23] 王海鸥,扶庆权,陈守江,等. 不同组合冷冻干燥方法对水蜜桃脆片品质的影响[J]. 食品与发酵工业,2018,44(7):173-178. WANG Haiou, FU Qingquan, CHEN Shoujiang, et al. Effect of different combined freeze-drying methods on the qualities of peach crisp[J]. Food and Fermentation Industries, 2018, 44(7): 173-178. (in Chinese with English abstract)

[24] 马有川,毕金峰,易建勇,等. 预干燥方式和水分转换点对真空冷冻联合干燥苹果脆片品质的影响[J]. 中国食品学报,2021,21(9):110-120. MA Youchuan, BI Jinfeng, YI Jianyong, et al. Effects of pre-drying methods and moisture conversion point on the quality of freeze dried apple chips[J]. Journal of Chinese Institute of Food Science and Technology, 2021, 21(9): 110-120. (in Chinese with English abstract)

[25] 廖雅萱,程少波,张伟达,等. 骏枣变温干燥工艺优化及品质评价[J]. 农业工程学报,2023,39(6):237-246. LIAO Yaxuan, CHENG Shaobo, ZHANG Weida, et al. Optimization of the variable temperature drying process and quality evaluation of Junzao jujube[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2023, 39(6): 237-246. (in Chinese with English abstract)

[26] KUMAR D, LADANIYA M S, GURJAR M, et al. Impact of drying methods on natural antioxidants, phenols, and flavanones of immature dropped Citrus sinensis L. Osbeck fruits[J]. Scientific Reports, 2022, 12(1): 6684. doi: 10.1038/s41598-022-10661-7

[27] 王心,闫璟圆,张倩,等. 甜菜果胶对小麦淀粉老化的影响[J]. 中国食品学报,2023,23(7):169-176. WANG Xin, YAN Jingyuan, ZHANG Qian, et al. Effect of sugar beet pectin on the retrogradation of wheat starch[J]. Journal of Chinese Institute of Food Science and Technology, 2023, 23(7): 169-176. (in Chinese with English abstract)

[28] BROXTERMAN S E, SCHOLS H A. Interactions between pectin and cellulose in primary plant cell walls[J]. Carbohydrate Polymers, 2018, 192: 263-272. doi: 10.1016/j.carbpol.2018.03.070

[29] 宋翔宇. 浆果脆片孔隙及质构特性研究[D]. 哈尔滨,东北农业大学,2013. SONG Xiangyu. Research on Porosity and Texture Characterics of Berry Chips[D]. Harbin, Northeast Agricultural University, 2013. (in Chinese with English abstract)

[30] ROLANDELLI G, RODRIGUEZ S D, BUERA M P. Modulation of the retrogradation kinetics of sweet potato starch by the addition of pectin, guar gum, and gallic acid[J]. Food Hydrocolloids, 2024, 146: 109211. doi: 10.1016/j.foodhyd.2023.109211

[31] MOSQUERA L H, MORAGA G, MARTINEZ-NAVARRETE N. Critical water activity and critical water content of freeze-dried strawberry powder as affected by maltodextrin and arabic gum[J]. Food Research International, 2012, 47: 201-206. doi: 10.1016/j.foodres.2011.05.019

[32] POURMOHAMMADI K, ABEDI E, HASHEMI S M B, et al. Effects of sucrose, isomalt, and maltodextrin on microstructural, thermal, pasting, and textural properties of wheat and cassava starch gel[J]. International Journal of Biological Macromolecules, 2018, 120: 1935-1943. doi: 10.1016/j.ijbiomac.2018.09.172

[33] VAN DER SMAN R G M. Phase field simulations of ice crystal growth in sugar solutions[J]. International Journal of Heat and Mass Transfer, 2016, 95: 153-161. doi: 10.1016/j.ijheatmasstransfer.2015.11.089

[34] ARENDSE W, JIDEANI V. Storage stability and consumer acceptability of dried apple: impact of citric acid, potassium sorbate and moringa oleifera leaf extract powder[J]. Foods, 2022, 11: 984. doi: 10.3390/foods11070984

[35] ABD-ELHADY M. Effect of citric acid, calcium lactate and low temperature pre-freezing treatment on the quality of frozen strawberry[J]. Annals of Agricultural Sciences, 2014, 59(1): 69-75. doi: 10.1016/j.aoas.2014.06.010

[36] 苏伟娟. 阿拉伯胶对玉米淀粉功能性影响的研究及其应用[D]. 广州:仲恺农业工程学院,2017. SU weijuan. Study on the Effects of Gum Arabic on the Properties of Corn Starch and its Applications[D]. Guangzhou: Zhongkai University of Agriculture and Engineering, 2017. (in Chinese with English abstract)

[37] CAO X H, ZHANG M, MUJUMADAR A S, et al. Effects of ultrasonic pretreatments on quality, energy consumption and sterilization of barley grass in freeze drying[J]. Ultrasonics Sonochemistry, 2018, 40: 333-340. doi: 10.1016/j.ultsonch.2017.06.014

[38] CAO Y, XIA Q L, ANIYA, et al. Copigmentation effect of flavonols on anthocyanins in black mulberry juice and their interaction mechanism investigation[J]. Food Chemistry, 2023, 399: 133927. doi: 10.1016/j.foodchem.2022.133927

[39] 胡冰冰,刘淼,曹赓,等. 酸处理对烤马铃薯条品质的影响[J]. 中国粮油学报,2023,38(11):180-187. HU Bingbing, LIU Miao, CAO Geng, et al. Effects of acid treatment on quality of baking potato strips[J]. Journal of the Chinese Cereals and Oils Association, 2023, 38(11): 180-187. (in Chinese with English abstract)

[40] LAHAYE M, FALOURD X, LAILLET B, et al. Cellulose, pectin and water in cell walls determine apple flesh viscoelastic mechanical properties[J]. Carbohydrate Polymers, 2020, 232: 115768. doi: 10.1016/j.carbpol.2019.115768

[41] SILVA-ESPINOZA M A, CAMACHO M D M, MARTINEZ-NAVARRETE N. Use of different biopolymers as carriers for purposes of obtaining a freeze-dried orange snack[J]. LWT-Food Science and Technology, 2020, 127: 109415. doi: 10.1016/j.lwt.2020.109415

[42] YUAN L, LAO F, SHI X, et al. Effects of cold plasma, high hydrostatic pressure, ultrasound, and high-pressure carbon dioxide pretreatments on the quality characteristics of vacuum freeze-dried jujube slices[J]. Ultrasonics Sonochemistry, 2022, 90: 106219. doi: 10.1016/j.ultsonch.2022.106219

[43] DE LA CRUZ-MOLINA A V, AYALA ZAVALA J F, BERNAL MERCADO A T, et al. Maltodextrin encapsulation improves thermal and pH stability of green tea extract catechins[J]. Journal of Food Processing and Preservation, 2021, 45: e15729.

[44] PAN L H, CHEN L P, WU C L, et al. Microencapsulation of blueberry anthocyanins by spray drying with soy protein isolates/high methyl pectin combination: Physicochemical properties, release behavior in vitro and storage stability[J]. Food Chemistry, 2022, 395: 133626. doi: 10.1016/j.foodchem.2022.133626

[45] QI K X, CAO S B, LI C. Possible interaction between pectin and gluten alters the starch digestibility and texture of wheat bread[J]. International Journal of Biological Macromolecules, 2024, 269(1): 131907.

下载:

下载: