Standardizing the irrigation water sources for emitter anti-clogging test

-

摘要:

滴头的抗物理堵塞性能测试是滴头设计研发和选型应用工作中的重要内容,但该测试程序中统一化、标准化的试验水源研究仍处于探索阶段。针对此问题,该研究将市售石英砂和天然黄河沙作为致堵物质分别开展滴头抗堵塞性能测试,探究采用石英砂配制标准水源的可行性。将两种颗粒筛分为≤0.063 mm、>0.063 ~ 0.075 mm、>0.075 ~ 0.090 mm三个粒径范围,分别设计粒径质量比1:1:1、4:1:1、1:1:4和浓度1.0、2.0、3.0 g/L组合配制试验水源,开展5种滴头的抗堵塞性能测试,采用堵塞偏差评价试验期间两种颗粒条件下滴头平均相对流量的差距,利用堵塞结果区分度评价试验结束时5种滴头堵塞程度之间的差异情况,并从石英砂和黄河沙的粒径组成、外观形貌特征对试验结果进行分析。结果表明:1)黄河沙颗粒圆度高,黏粒含量极低,而石英砂颗粒圆度低、棱角多,黏粒含量高。两者粒径组成和外观形貌上的差异导致相同条件下石英砂的堵塞结果比黄河沙严重,继而导致石英砂的堵塞结果区分度在颗粒浓度低/高时分别呈现出高于/低于黄河沙的结果。2)1.0 g/L或>0.075 ~ 0.090 mm颗粒含量多时,石英砂与黄河沙的堵塞偏差大,3.0 g/L或≤0.063 mm颗粒含量多时,两者堵塞偏差小。3)从单个滴头流量变化特征来看,所有处理下的滴头单次流量降幅均呈现两个集中分布区(100%和20%左右),且黄河沙和石英砂条件下都存在相似的堵塞后流量恢复和流量过载(超过额定流量)的现象,但石英砂的流量过载时的流量平均值和最大值比黄河沙更大(2.0 g/L+1:1:4处理除外)。4)从滴头平均流量的堵塞偏差、单个滴头流量变化特征、堵塞结果区分度3方面综合考虑,当浓度为2.0 g/L、≤0.063 mm、>0.063 ~ 0.075 mm、>0.075 ~ 0.090 mm三个粒径组质量比为1:1:1时,石英砂可以替代黄河沙作为滴头抗堵塞性能测试的标准水源。该研究可为滴头抗物理堵塞性能测试的标准化提供科学依据。

Abstract:Anti-clogging test is one of the most important steps to design the emitter and type selection. However, it is still lacking on the standardized irrigation water in the testing procedures. In this study, a series of emitter clogging tests were carried out with the commercially available quartz sand and natural Yellow River sand as the clogging substances. A comparison was also made on the emitter clogging characteristics of the quartz and natural sand using standard test. Five kinds of emitters clogging performance tests were conducted with prepared the test water: three ranges of particle size (>0.075–0.090 mm, >0.063–0.075 mm, and ≤0.063 mm) and three mixing ratios (1:1:1, 4:1:1, and 1:1:4) at three concentrations (1.0, 2.0, and 3.0 g/L). The distribution of particle size and morphologies of both materials were analyzed at the same time. The results indicate: 1) Yellow River sand particles exhibited the high roundness and low clay content, while the quartz sand particles were characterized by the low roundness, sharp edges, and high clay content. These differences in particle size distribution and morphology led to more severe clogging with the quartz sand, compared with the natural sand. The deviation of clogging (Dc) was used to evaluate the difference between the average relative flow rate of Yellow River sand and quartz sand during the experiment period. And the Dc value was higher at 1.0 g/L or the predominant 0.075–0.090 mm particle fraction. However, the Dc value was the minimum at 3.0 g/L or with a predominance of particles smaller than 0.063 mm. 2) Both quartz sand and Yellow River sand exhibited the similar trends in the decrease of individual emitter flow rates, due to clogging. The drop from normal flow rate to complete clogged (flow rate reduced to 0) was usually completed within 8h. There were also the similar flow rate recovery and flow overload (exceeding the emitter rated flow rate) of clogging emitter in both particles conditions. However, the average and maximum of emitter relative flow rate (the maximum relative flow rate of 150.36%) with quartz sand were much larger, when the overload occurred, compared with Yellow River sand. 3) The clogging differentiation (Dcr) was used to evaluate the differences between the clogging behavior of the five kinds of emitters, indicating the even distribution. The clogging of quartz sand was more serious than that of Yellow River sand under the same conditions. Quartz sand demonstrated the higher Dcr at lower particle concentrations, but the lower Dcr at higher concentrations, compared with the Yellow River sand. 4) A systematic analysis was made to consider the clogging deviation of average emitter flow rate, individual emitter flow rate variation, and differentiation of clogging among five kinds of emitters. It was concluded that the quartz sand can be expected to replace the Yellow River sand as clogging substances, in order to prepare the standardized water for the emitter clogging performance tests, when using 1:1:1 mass ratio mixture of the three particle size ranges (0.075–0.090 mm, 0.063–0.075 mm, and <0.063 mm) at a concentration of 2 g/L. This finding can provide the scientific evidence to standardize the emitter anti-physical clogging tests. A viable approach can be offered to select the quartz sand as the substitute for the natural Yellow River sand, in order to optimize the water source for the emitter test.

-

Keywords:

- emitter /

- anti-clogging ability /

- physical clogging /

- yellow river sand /

- partical size

-

0. 引 言

抗堵塞性能测试是研究滴头堵塞问题中的关键环节,然而针对测试所用的水源目前行业内缺少详细、规范的标准[1]。含沙浑水是滴头抗堵性能测试的常见灌溉水源,早期研究人员根据ISO国际标准草案[2],结合国内实践,常选取当地天然河沙或土壤作为致堵物质,经过清洗、过筛等处理后添加到清水中制成含沙浑水。喻黎明等在研究滴头的堵塞问题时采用的是云南省的红壤土[3-5];牛文全等采用的是渭河漫滩的河床泥沙[6-7];侯鹏等采用的是内蒙古河套灌区的黄河水[8];陶洪飞等使用的是乌鲁木齐市西山的自然黄土作为浑水堵塞物质[9];LI等使用内蒙古磴口县流域的黄河水作为试验水源[10];宋蕾等在研究微灌系统的过滤设备时采用的是人民胜利渠新磁灌渠段的黄河泥沙[11];另外在王新端等的研究中采用的致堵物质为过筛后的风干土壤,但未声明其确切来源[12-13]。可见,在研究滴头堵塞时所用的关键材料——含沙水源存在强烈的地域依赖。这就导致不同地区的滴头堵塞的研究结果之间缺乏可比性,同时其结论的指导意义也被限制。虽然在最新国标对侧翼式滴头的抗泥沙堵塞测试中所用的泥沙做出了粒径级配特征的规范说明[14-15],但不同地区的泥沙性质仍会对测试结果造成不可忽视的影响。

在滴头抗堵塞性能的研究中,相关学者对测试程序和评价方法的标准化进行了探索和尝试。LAVANHOLI 等用4种滴头对目前广泛应用的ISO国际标准草案推荐的堵塞测试方法进行了验证试验[16]。该方法自1974年以来一直由IRSTEA实验室使用,其内容目前正在由国际标准化组织ISO TC23/SC18委员会讨论。结果显示该方法能够较准确地重现其中3种滴头的测试结果,但仍有一种滴头因对堵塞敏感导致3次测试结果间有明显差异。对此LAVANHOLI等建议应当增加滴头样本量,以提高该方法测试结果的可靠性[16]。SOUSA等在此基础上提出了改进的测试程序,并指出对试验用水的特性应当加以严格的定义和要求,以限制由于化学和生物因素造成的干扰,保证试验的可重复性[17]。HAN等针对劣质水提出了一种原位加速测试方法,对比试验周期较长的方法,其方法可大大缩短试验时长,虽堵塞结果相对较轻但两种方法间有较好的相关性[18]。由以上可知,研究人员从不同角度对滴头堵塞测试程序提出了许多改进和规范化的建议,同时这些研究也反映出统一试验用水的重要性。

石英砂由天然石英石经破碎、筛选、水洗、烘干等工艺加工而成,杂质较少、方便易得,堆积密度一般在1.5~1.7 g/cm3。河沙同属于天然砂,主要成分是石英、长石等,其堆积密度与石英砂相似,一般取1.3~1.6 g/cm3。石英砂与河沙在成分、密度等方面比较相似。黄磊等利用天然石英砂代替河沙研究颗粒表面电荷分布和吸附模型,获得良好效果[19]。熔融石英砂与天然砂土的工程物理学性质非常相似[20],在岩土工程领域常利用其为骨料制备透明土模拟天然砂土[21-23]。同时,研究表明引黄灌区滴头内堵塞物质的主要成分为石英,占总堵塞物质的41.8%~56.3%[24]。

基于以上,本研究拟采用市售石英砂、天然黄河沙为致堵物质,配制不同浓度和粒径组成的浑水作为水源开展滴头抗堵塞性能测试。以堵塞偏差、堵塞结果区分度为评价指标,结合单个滴头的流量变化过程,对比分析石英砂、黄河沙下的滴头堵塞规律,并从两种颗粒物的粒径组成、外观形貌特征阐释两者堵塞结果差异的原因,以提出一种能够代替黄河沙的石英砂浑水配制方法,为滴头抗堵塞性能测试中所用水源的标准化提供借鉴。

1. 材料与方法

1.1 试验材料

试验用河沙为黄河下游天然河沙,采于济宁市黄河滩区。石英砂为市售工业制石英砂,生产商河南省邦洁净水公司。将两种致堵物质用标准筛分别进行粒径筛分,分为≤0.063、>0.063 ~ 0.075、>0.075 ~ 0.090 mm三个粒径范围待用。筛分后的颗粒物经激光粒度仪(英国Malvern,Mastersizer

3000 )分析颗粒组成和粒径特征值,同时利用场发射扫描电镜(日本HITACHI,SU8010)对颗粒物进行连续放大观测和拍摄。1.2 试验装置

如图1所示,试验装置包含循环滴灌系统和自动称量系统。滴灌系统包括带搅拌器的水箱、水泵、变频控制、压力传感器、循环供水管道等。其中变频控制器依据压力传感器实时反馈的管道内压力数据,调节水泵转速,控制管道系统供水压力始终在100 kPa左右,以消除试验期间由滴头堵塞造成的管道压力升高所带来的试验误差。5种滴头分别安装在5条直径16 mm、长1.8 m的PE管上(其中1条为内镶4个贴片式滴头的滴灌带)。每条管上等间距(0.5 m)安装4个样本滴头,即为每个处理下每种滴头的4个重复,按水流流动方向依次标记为e1、e2、e3、e4。5种滴头的性能参数如表1所示。自动称量系统包括称量传感器、量杯、数据采集软件等部分。滴灌系统每天灌水1次,每次连续灌水8 h,总灌水时长为40 h。水箱容积约为150 L,在每种水源试验期间需要每天补充配制好的滴灌用水。每次灌水结束清洗水箱和管道系统。

表 1 试验滴头的性能参数Table 1. Performance parameters of tested emitters滴头

Emitter外观

Appearance安装类型

Installation method额定流量

Rated flow/(L·h−1)流量系数

Discharge coefficient流态 指数

Flow index制造偏差

Manufacturing deviation /%E1

内镶贴片式 1 0.86 0.17 2.70 E2

管上式 8 7.40 0.01 2.60 E3

管上式 4 3.43 0.03 5.70 E4

管上式 2 1.79 0.01 1.03. E5

管上式 4 3.50 0.03 1.70 1.3 试验设计

分别用黄河沙、石英砂与自来水混合配制灌溉用水,设置1.0、2.0、3.0 g/L 3种浓度,粒径分为≤0.063、>0.063 ~ 0.075、>0.075 ~ 0.090 mm三个范围,三个粒径范围分别按质量比1:1:1、4:1:1、1:1:4混合,组合后一共形成10个水源处理(表2),对5种滴头展开抗堵塞性能测试。试验结束后在相同条件下对比分析石英砂和黄河沙的堵塞结果。

表 2 10种试验水源处理Table 2. 10 kinds of experimental water treatment水源编号

Water treatment致堵物质

Particulate causing

clog浓度

Concentration/

(g·L−1)粒径质量比

Mass ratio of

particle sizes1 黄河沙 1.0 1:1:1 2 黄河沙 2.0 1:1:1 3 黄河沙 2.0 4:1:1 4 黄河沙 2.0 1:1:4 5 黄河沙 3.0 1:1:1 6 石英砂 1.0 1:1:1 7 石英砂 2.0 1:1:1 8 石英砂 2.0 4:1:1 9 石英砂 2.0 1:1:4 10 石英砂 3.0 1:1:1 注:粒径质量比中的3种粒径分别为≤0.063、>0.063 ~ 0.075、>0.075 ~ 0.090 mm。

Note:The 3 particle sizes are ≤ 0.063, 0.063 ~ 0.075 and 0.075 ~ 0.090 mm for the particle size mass ratio.1.4 分析指标

每种配制的水源进行滴灌试验前,先用清水进行30 min的滴灌,获得滴头的初始流量。之后开始用配制的水源进行滴灌,连续5天每天滴灌8 h,每天在滴灌结束前半小时采集一次每个滴头的出流数据。试验期间共采集6次滴头流量(包含初始流量)。根据每个滴头流量计算以下分析指标。

1)单个滴头相对流量

qr=qq0×100% (1) 式中qr为单个滴头的相对流量,%; q为单个滴头的实际流量,L/h;q0为该滴头初始流量,L/h。

2)滴头平均相对流量

每个处理下的4个样本滴头的相对流量平均值Q为[25]

Q=4∑1qri/4 (2) 式中qri为每个处理下第i个滴头的相对流量,%;i=1, 2,3,4。

3)堵塞偏差

为了评价相同条件下石英砂和黄河沙的堵塞结果之间的差距,计算两者平均相对流量之间的差值作为堵塞偏差(deviation of clogging)。该指标可直观反映石英砂与黄河沙的堵塞结果之间的偏差。

Dc=QS−QY (3) 式中QS和QY分别为相同条件下石英砂和黄河沙的平均相对流量,%;Dc为该条件下石英砂和黄河沙之间的堵塞偏差,可理解为石英砂的平均相对流量比黄河沙高出的百分点。理论上滴头平均相对流量在[0, 100]之间,故Dc的取值范围在[−100, 100]之间,正值表示石英砂平均相对流量大于黄河沙,即堵塞程度比黄河沙轻,负值则相反;同时,该值的绝对值越接近0,表示两种水源的堵塞差异越小。

4)堵塞结果区分度

评价一种水源是否适合做抗堵塞性能测试,还需要考察测试结束时,不同滴头的堵塞程度是否呈现出较大的区分度。若水源颗粒物浓度过高,导致所有滴头都出现严重堵塞,则无法评价滴头之间抗堵塞性能的优劣。因此,本文提出“堵塞结果区分度(differentiation of clogging result)”这一指标来表征多种滴头的最终堵塞结果之间的差异。具体计算过程如下:

参考董爱红等提出的滴头堵塞程度等级划分标准[26],以最终平均相对流量的降幅位于[0, 10]、(10, 25]、(25, 40]、(40, 70]、(70, 100]范围内时分别划定为发生“未堵塞”、“轻微堵塞”、“一般堵塞”、“严重堵塞”、“完全堵塞”。从“未堵塞”至“完全堵塞”分别赋以0、1、2、3、4的分值,根据式(4)计算一种水源条件下堵塞结果的区分度Dcr为

Dcr=RSD (4) 式中R为多种滴头堵塞程度赋分的极差,即R=赋分max−赋分min;进一步的,将滴头按赋分从小到大的顺序排列,计算相邻两滴头赋分之间的差值,形成数列L,SD为数列L的标准差。Dcr值越大,即R越大、同时SD越小,表示滴头堵塞程度之间差别越大、且不同滴头堵塞程度的分布越均匀,也就表示滴头堵塞程度的区分度越好。

2. 结果与分析

2.1 黄河沙、石英砂粒径组成和表面形貌的差异

黄河沙、石英砂筛分为粗(>0.075 ~ 0.090 mm)、中(>0.063 ~ 0.075 mm)、细(≤0.063 mm)颗粒后分别进行了粒径测量和形貌观测,结果分别见表3和图2。表3显示,两种颗粒物的粒径特征的差别主要表现在粗、细两组中。细颗粒组中,石英砂具有更低的砂含量(6.05%)和更高的黏粒含量(32.63%),中值粒径和平均粒径分别为14.1、20.8 μm,低于黄河沙约67%和52%。而粗颗粒组中,石英砂具有更高的砂含量(80.14%)和更低的黏粒含量(0.44%),中值粒径和平均粒径分别为101、111 μm,比黄河沙大约23%和39%。相比之下,两者在>0.063 ~ 0.075 mm(中)粒径组有较为相似的粒径特征。

表 3 筛分后颗粒物粒径组成和粒径特征值Table 3. Size composition and particle size statistical magnitudes粒径筛分

Sectionalization/mm颗粒来源

Source黏粒含量

Clay grain content/%粉砂含量

Silt content/%砂含量

Sand grain content/%中值粒径

Median size/μm平均粒径

Mean size/μm≤ 0.063 黄河沙 4.73 77.84 17.43 42.7 43.5 石英砂 32.63 61.32 6.05 14.1 20.8 >0.063 ~ 0.075 黄河沙 4.49 39.14 56.38 67.0 66.0 石英砂 3.00 54.63 42.37 55.5 60.3 >0.075 ~ 0.090 黄河沙 4.48 22.41 73.11 82.4 80.1 石英砂 0.44 19.42 80.14 101 111 图2展示了3个粒径组的黄河沙、石英砂样品平铺后的放大结果,黄河沙颗粒圆度高、棱角少、大小较为均匀,而石英砂圆度低、棱角多且尖锐,存在不少片状、棒状颗粒,且颗粒大小不均匀。同时,3个粒径组的石英砂颗粒中均混有大量明显小于该组筛分下限的颗粒(图2b),尤其在≤0.063 mm粒径组中,石英砂中存在大量直径小于10 μm和亚微米级的颗粒,相比之下,黄河沙显得十分“干净”(图2a)。

观察≤0.063 mm粒径组的拍摄结果,绝大多数石英砂的颗粒直径明显小于黄河沙,这与表3中石英砂黏粒含量高达32.63%的测量结果一致。同时也造成其中值粒径(14.1 μm)和平均粒径(20.8 μm)不及筛分上限0.063 mm的1/3。>0.075 ~ 0.090 mm粒径组的拍摄结果显示,石英砂的颗粒直径并没有明显大于黄河沙,这与其中值粒径(101 μm)和平均粒径(111 μm)明显超出黄河沙甚至筛分上限0.090 mm的检测结果不符。原因可能是石英砂片状、条状的颗粒形状,影响了以“球形颗粒”假设为理论基础的激光粒度仪的测量结果[27-29]。

2.2 不同水源条件下的堵塞偏差

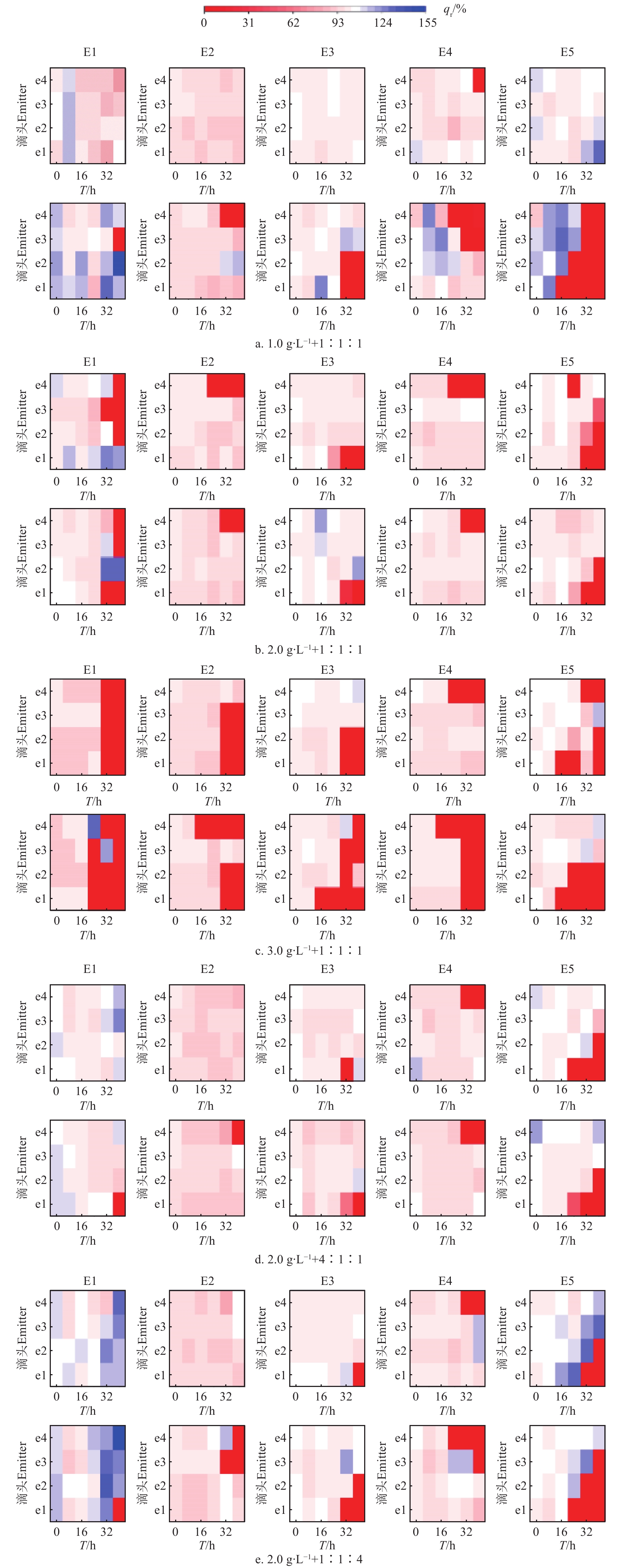

为明确石英砂、黄河沙条件下滴头堵塞过程中的差异,按式(3)计算相同浓度、粒径质量比条件下石英砂和黄河沙灌水系统运行40 h内的堵塞偏差,绘制图3。

可以看到系统运行初期(前16 h内),石英砂、黄河沙之间的堵塞偏差在0附近波动,之后随着时间的增加偏离0的幅度增大,但也有回归。相比2.0 g/L,系统运行后期(16~40 h)1.0、3.0 g/L的偏离幅度更大,最大分别能达到−111.75%(E5)、−70%(E4),并且偏差多为负值。说明这两种浓度条件下,系统运行后期石英砂、黄河沙的堵塞程度相差较大,且对多数滴头而言石英砂的堵塞程度重于黄河沙。另外图3a中E5在第40 h的堵塞偏差Dc为−111.75%,处于[−100, 100]范围之外,是因为此时黄河沙灌水时滴头出现了流量过载即实际流量大于额定流量的现象, QY为111.75%,而相对应的石英砂的QS为0。

在2.0 g/L下对比3种不同粒径组成处理的结果,系统运行后期1:1:4条件下的偏差比其他两者更大,且偏差多数为负值,说明该处理下石英砂的堵塞程度重于黄河沙。1:1:1与4:1:1相比,虽然两者在整个运行期间偏差都较小,但在运行结束时(第40 h),1:1:1条件下5种滴头的偏差值,有4种在0附近,仅有E5偏差较大(22.44%),而4:1:1条件下,仅E4、E5的偏差值在0附近,E1、E2、E3的偏差值分别为−38.88%、−18.27%、−28.83%。就系统运行结束时的结果而言,1:1:1条件下两种颗粒物的堵塞结果更接近。

另外,1:1:1条件下E3、E4在32 h、24 h虽然有较大的正偏差值,但最终分别在40、32 h回归至0左右,这表明对这两种滴头而言石英砂堵塞进程稍晚于黄河沙,但随后堵塞程度又达到了一致。综上可知,2.0 g/L+1:1:1组合时,滴头在石英砂、黄河沙下的平均相对流量变化过程为5组试验中最一致的。

2.3 不同水源条件下的单个滴头流量变化特征

为了对比石英砂和黄河沙条件下单个滴头的堵塞发展进程和位置特征,图4展示了所有滴头在试验期间的相对流量变化过程。从图中可以看出在第3~5天许多色块突然变为标尺中代表0的红色,表明滴头堵塞在滴灌运行一天的8 h内完成,一次灌溉期间的流量下降幅度非常大。从图中还可以看到所有水源处理中都出现了滴头大幅超过额定流量的现象(本文中简称为流量过载),且该现象在试验期间全程都有发生,最高达到额定流量的150%左右,对流量的影响不可忽视。在此对试验期间所有滴头每天的流量下降幅度和流量过载现象进行统计分析。由于灌溉水中含有一定浓度的颗粒物,同时考虑设备运行的稳定性和测量误差,故在流量下降分析中统计所有大于10%的相对流量降幅,在流量过载现象分析中统计大于110%的滴头相对流量。

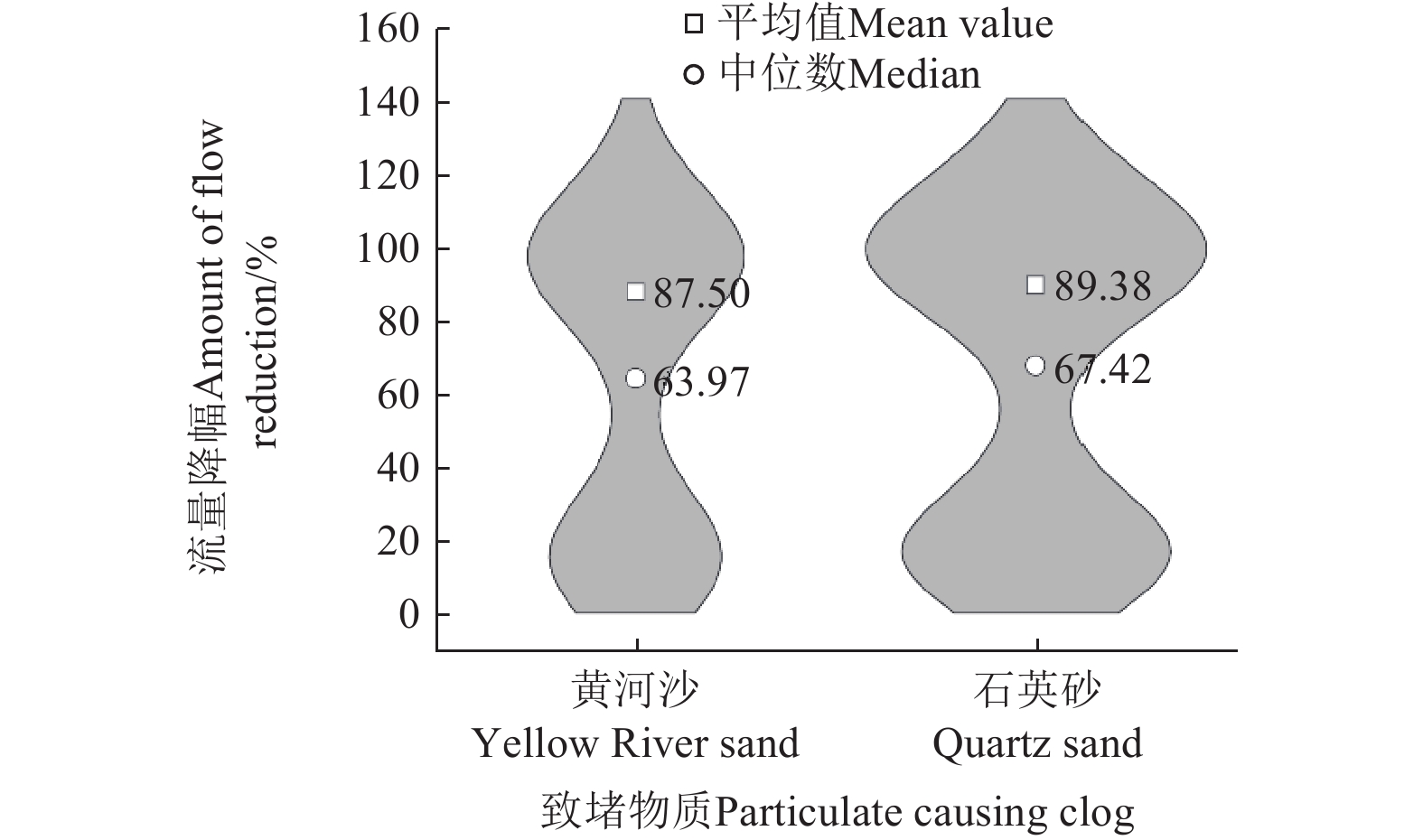

图5显示,石英砂比黄河沙的提琴图更宽,这是由于两者大于10%的相对流量降幅分别有55、86例,即石英砂的数据样本更多(因其堵塞滴头多)。两者的流量降幅数据均表现为双峰分布,且100%对应的峰值比20%对应的峰值更宽,这表明两种颗粒条件下大部分降幅集中在100%左右,多数出现在第4~6天内(图4),与滴灌运行后期出现大量滴头突然堵塞的现象一致;另一部分降幅集中在20%左右,多数出现在试验运行前2~4天内,与前期流量正在波动状态中出现的小幅下降的现象一致。另外,两种颗粒条件下,滴头每天流量降幅的平均值(87.50%和89.38%)和中位数(63.97%和67.42%)相差非常小,分别为2.10个百分点和5.12个百分点。从单个滴头流量变化这一角度,黄河沙和石英砂条件下滴头在8 h内的降幅具有较为一致的变化规律。

滴头出流超过额定流量(即流量过载)的现象的统计结果见表4。对比1.0 g/L、2.0 g/L、3.0 g/L下该现象出现的次数可知,颗粒物浓度越高,流量过载现象出现的次数越少;但粒径对此的影响更大,在粗颗粒更多时,黄河沙和石英砂条件下分别出现了21次、19次流量过载现象,比其他条件下明显增多(1.0 g/L石英砂除外)。对比黄河沙和石英砂条件下流量过载现象中滴头相对流量的平均值和最大值,发现除2.0 g/L+4:1:1处理外,石英砂条件下的平均值和最大值均大于黄河沙。

表 4 不同水源条件下滴头相对流量大于110%的统计分析Table 4. Statistical analysis of the relative flow rate greater than 110% of emitters under different irrigation water统计指标

Statistical index1.0 g·L−1+1:1:1 2.0 g·L−1+1:1:1 3.0 g·L−1+1:1:1 2.0 g·L−1+4:1:1 2.0 g·L−1+1:1:4 黄河沙

Yellow River

sand石英砂

Quartz sand黄河沙

Yellow River

sand石英砂

Quartz sand黄河沙

Yellow River

sand石英砂

Quartz sand黄河沙

Yellow River

sand石英砂

Quartz sand黄河沙

Yellow River sand石英砂

Quartz sand出现次数

Number of times7 32 5 5 2 3 7 6 21 19 平均Mean/% 116.42 120.10 117.6 123.15 113.75 120.83 115.44 113.78 119.04 121.37 最大值Maximum/% 131.05 146.44 129.13 131.02 115.08 130.17 127.00 120.01 133.52 150.36 另外,从图4中也看到,黄河沙2.0 g/L+1:1:1中E5e4、3.0 g/L+1:1:1中E5e1和石英砂3.0 g/L+1:1:1中E1e3及E3e2都出现堵塞后流量恢复的现象。从单个滴头的堵塞过程来看,由于试验中的石英砂和黄河沙颗粒成分、粒径、理化性质比较接近,在试验中引发的都属于物理堵塞,因此滴头堵塞过程中存在相似的流量波动特性和堵塞物冲淤交替的现象[30-31]。

观察5组黄河沙、石英砂的对比处理,2.0 g/L+1:1:1(图4b)条件下,滴头的堵塞程度和位置差异最小,在E2、E3、E4中表现出了几乎一致的堵塞位置特征和发展进程,同时在E1、E5中仅有个别滴头堵塞不一致。而其他组处理,在堵塞程度和堵塞位置上均存在较大的差异。因此从单个滴头堵塞特征上看,2.0 g/L+1:1:1组合条件下石英砂与黄河沙的堵塞结果更一致。

2.4 不同水源条件下的堵塞程度和堵塞区分度

所有水源条件下5种滴头的堵塞区分度Dcr值如表5所示。在1.0 g/L时,黄河沙的5种滴头堵塞结果总体轻微,但石英砂的堵塞结果较重,且在不同滴头之间出现较大差别,Dcr值为4.90也表明了堵塞在不同滴头之间具有较大的差异。可见低浓度下石英砂仍然能获得较重的堵塞结果,且区分度较高。在2.0 g/L时,黄河沙、石英砂的Dcr值3.13、6.00相应地比1.0 g/L时均有明显提高,且5种滴头的堵塞程度从“轻微堵塞”至“完全堵塞”有比较均匀的分布。而在3.0 g/L时,黄河沙、石英砂的堵塞结果多数为“严重堵塞”和“完全堵塞”,对应的Dcr值分别为3.46、2.00,表明该浓度条件下,滴头堵塞结果均比较严重,堵塞区分度均不高。观察另外两种水源条件,黄河沙、石英砂的Dcr值处于中等水平,在2.83~3.46之间。原因在于细颗粒多时(4:1:1),除E5外其他滴头的堵塞程度差别不大,多数处于“未堵塞”、“轻微堵塞”级别;而粗颗粒多时(1:1:4),石英砂条件下除E1外其他4种滴头堵塞程度均较高,处于“严重堵塞”、“完全堵塞”级别,差别亦不够大,黄河沙条件下所有滴头处在“一般堵塞”级别以下,所以区分度Dcr值处在中等水平。

表 5 不同水源下5种滴头的堵塞程度和堵塞区分度DcrTable 5. Clogging degree Dcr of five kinds of emitters under different irrigation water滴头

Emitter1.0 g·L−1+1:1:1 2.0 g·L−1+1:1:1 3.0 g·L−1+1:1:1 2.0 g·L−1+4:1:1 2.0 g·L−1+1:1:4 黄河沙

Yellow River

sand石英砂

Quartz sand黄河沙

Yellow River

sand石英砂

Quartz sand黄河沙

Yellow River

sand石英砂

Quartz sand黄河沙

Yellow River

sand石英砂

Quartz sand黄河沙

Yellow River

sand石英砂

Quartz sandE1 未 未 完全 完全 完全 完全 未 轻微 未 未 E2 未 一般 一般 一般 完全 完全 未 一般 未 严重 E3 未 严重 一般 轻微 严重 完全 未 轻微 一般 严重 E4 轻微 严重 轻微 一般 一般 完全 一般 轻微 轻微 严重 E5 未 完全 完全 严重 严重 严重 严重 严重 一般 完全 Dcr 2.00 4.90 3.13 6.00 3.46 2.00 3.13 3.46 3.46 2.83 表5显示,多数处理下多数滴头的石英砂堵塞程度比黄河沙重,说明其更易引发滴头堵塞,故其在低浓度、细颗粒多时仍能获得较高的区分度;也正因如此,在高浓度、粗颗粒多时,由于其堵塞过于严重,区分度反而比黄河沙低。对比两种颗粒物,黄河沙在3.0 g/L+1:1:1、2.0 g/L+1:1:4条件下获得了最高的区分度,Dcr值为3.46;石英砂在2.0 g/L+1:1:1条件下获得了所有处理的最高的区分度,Dcr值为6.00。

3. 讨 论

黄河沙和石英砂的粒径、形貌特征影响滴头堵塞结果。整体而言,相同浓度和粒径组成条件下,石英砂的堵塞程度较黄河沙严重。这是由于试验所用石英砂是一种机制砂,主要通过机械破碎获得,颗粒圆度低、棱角尖锐[32]。如图2b中所示3个粒径分组中均有大量颗粒具有尖锐的棱角(<90°),且有较多颗粒为片状、棒状。显然,圆度更高的河沙颗粒更容易随水流运动,而圆度低的机制石英砂更容易因颗粒间的相互交错咬合而引起拱桥效应[33],继而快速形成堆积体堵塞滴头流道。同时,机制砂在生产过程中伴随产生了大量粉粒(石英粉)[34],如图2b中所示,石英砂中存在大量粒径小于10 μm和亚微米级的颗粒。10 μm以下的颗粒通常称为超细颗粒[35],这种颗粒的比表面积非常大,其强大的吸附作用能够吸附水中杂质,颗粒之间也极易发生团聚[36-37],同时也容易粘附在管道和流道内壁面上[38],引发滴头堵塞。基于以上两点,机制石英砂比河沙更易引发滴头堵塞,因此在相同的运行条件下,石英砂比黄河沙的堵塞结果更严重。

颗粒浓度影响黄河沙和石英砂堵塞结果之间的差距。试验中,颗粒直径的上限为0.090 mm,而滴头流道的尺寸一般为1 mm左右[31]。由于长期冲刷、风化作用黄河沙颗粒圆度较高,因此在低浓度条件下,黄河沙颗粒能够较容易地通过滴头流道,故最终堵塞程度较轻。有研究表明,黄河水滴灌系统中,进入灌水器内部的泥沙99%以上可以排出体外[8]。而石英砂由于拱桥效应、吸附作用等仍然能引起较重的堵塞结果。因此,低浓度时,两者间的差距被放大。如图4a中所示,黄河沙条件下仅有1个滴头(E4e4)完全堵塞,而石英砂条件下有10个滴头。而颗粒浓度高时,浓度的影响超过了颗粒形状带来的影响,两者的堵塞结果都非常严重,因此两者之间的差距反而缩小。如表5中3.0 g/L+1:1:1条件下,除E4滴头在黄河沙和石英砂下分属“一般”堵塞、“完全”堵塞,差别较大外,其他4种滴头堵塞程度都在“严重”堵塞和“完全”堵塞级别,差别很小,且E1、E2、E5滴头的堵塞程度在两种颗粒条件下完全一致。

相同浓度下(2.0 g/L)不同粒径组成之间比较,1:1:4条件下,由于大量粗颗粒的拱桥效应,石英砂堵塞较黄河沙严重(图4e),堵塞偏差较大且多为负值(图3e)。1:1:1和4:1:1条件下,系统运行全程石英砂和黄河沙的堵塞偏差均较小,即两者的堵塞过程较为一致(图3b、3d),且4:1:1条件下的堵塞结果更为轻微(图4d和表5),可见细颗粒的团聚、粘附作用可以引发堵塞,但在本试验条件下(周期短、物理堵塞为主)作用有限,相比而言,粗颗粒的拱桥效应在短周期的抗堵塞试验中对堵塞的影响更大。

压力补偿式滴头的堵塞并不总是表现为流量降低,也可能表现为流量升高[39]。PINTO等对压力补偿式滴头开展堵塞试验时也出现了这一问题,单个滴头相对流量最高达到额定流量的182%,统计结果表明在0~500 μm粒径范围内,粒径越大,流量过载现象出现的次数越少,同时指出该现象的原因是颗粒物聚集在滴头的弹性膜片和出水口之间影响了弹性膜片的正常形变[40]。本试验中,大量滴头在灌溉期间出现流量大幅超过额定流量(流量过载)的现象,统计结果表明颗粒物浓度、粒径、性状对流量过载现象出现的次数、幅度的影响各不相同(表4)。0~0.090 mm粒径范围内粗颗粒较多的处理(2.0 g/L+4:1:1)其流量过载次数更多,与PINTO等的研究结果相反[40]。这可能是由于两个试验选择的粒径范围相差较大。相较于黄河沙,石英砂更严重的流量过载现象可能是由于其不规则的形状和尖锐的棱角导致弹性垫片的形变量更大所致。

综上可知,尽管经过了粒径筛分,石英砂和黄河沙在颗粒外观形貌、粒径组成上仍然存在不同,导致两者在不同滴头上开展的抗堵塞性能测试结果呈现出不同程度的差异;同时,试验用水的颗粒浓度、粒径组成对石英砂和黄河沙堵塞差异的大小也有影响。但是,由于两者在物理、化学性质上相似,在灌水期间单个滴头流量降幅统计特征、堵塞位置和流量过载现象3方面仍出现了较高的一致性。综合本试验结果,以滴头平均流量的堵塞偏差最小、单个流量变化特征最接近、堵塞区分度最高为标准,可选择2.0 g/L浓度、≤0.063、>0.063 ~ 0.075、>0.075 ~ 0.090 mm三个粒径组质量比为1:1:1这一组合处理,作为石英砂可以替代黄河沙开展滴头抗堵塞性能测试的标准水源配制方法。本研究探讨了滴头抗堵塞性能测试中的试验水源标准化的必要性,以及利用石英砂代替天然河沙作为致堵物质的可行性。虽然提出了石英砂能够替代黄河沙的浑水配制方法,但是由于本研究的局限性,在两者在致堵过程和堵塞机理方面仍需要进一步的试验和分析。

4. 结 论

为研究滴头抗堵塞性能测试中石英砂代替天然河沙的可行性,试验对市售石英砂和黄河沙进行了粒径特征测量和外观形貌的放大观测。将两者筛分为粗、中、细颗粒后再按不同比例进行混合,以浓度和粒径组成为变量共设置了10种滴灌水源,对5种滴头展开40 h的抗堵塞性能测试。得到结论如下:

1)黄河沙颗粒圆度高,黏粒含量极低,而石英砂颗粒圆度低、棱角多,黏粒含量高。两者粒径组成和外观形貌上的差异导致相同条件下石英砂的堵塞结果比黄河沙严重。

2)颗粒浓度和粒径组成影响黄河沙和石英砂堵塞结果之间的差距。颗粒浓度低或粗颗粒多时,两者之间的差距大,颗粒浓度高或细颗粒多时,两者之间的差距小。

3)由于石英砂比黄河沙更容易引起堵塞,因此在颗粒浓度低或细颗粒多时,石英砂的堵塞区分度比黄河沙更高,而颗粒浓度高或粗颗粒多时,石英砂的堵塞区分度反而比黄河沙低。

4)黄河沙和石英砂的物理堵塞的一般过程和典型出流特征一致,两者都经历流量波动阶段和下降阶段;单个滴头均存在冲淤交替、流量过载等现象。从滴头平均流量的堵塞偏差、单个流量变化特征、堵塞区分度3方面综合考虑,当浓度为2.0 g/L、≤0.063、>0.063 ~ 0.075、>0.075 ~ 0.090 mm三个粒径组质量比为1:1:1时,石英砂可以替代黄河沙作为滴头抗堵塞性能测试的标准水源。

-

表 1 试验滴头的性能参数

Table 1 Performance parameters of tested emitters

滴头

Emitter外观

Appearance安装类型

Installation method额定流量

Rated flow/(L·h−1)流量系数

Discharge coefficient流态 指数

Flow index制造偏差

Manufacturing deviation /%E1

内镶贴片式 1 0.86 0.17 2.70 E2

管上式 8 7.40 0.01 2.60 E3

管上式 4 3.43 0.03 5.70 E4

管上式 2 1.79 0.01 1.03. E5

管上式 4 3.50 0.03 1.70 表 2 10种试验水源处理

Table 2 10 kinds of experimental water treatment

水源编号

Water treatment致堵物质

Particulate causing

clog浓度

Concentration/

(g·L−1)粒径质量比

Mass ratio of

particle sizes1 黄河沙 1.0 1:1:1 2 黄河沙 2.0 1:1:1 3 黄河沙 2.0 4:1:1 4 黄河沙 2.0 1:1:4 5 黄河沙 3.0 1:1:1 6 石英砂 1.0 1:1:1 7 石英砂 2.0 1:1:1 8 石英砂 2.0 4:1:1 9 石英砂 2.0 1:1:4 10 石英砂 3.0 1:1:1 注:粒径质量比中的3种粒径分别为≤0.063、>0.063 ~ 0.075、>0.075 ~ 0.090 mm。

Note:The 3 particle sizes are ≤ 0.063, 0.063 ~ 0.075 and 0.075 ~ 0.090 mm for the particle size mass ratio.表 3 筛分后颗粒物粒径组成和粒径特征值

Table 3 Size composition and particle size statistical magnitudes

粒径筛分

Sectionalization/mm颗粒来源

Source黏粒含量

Clay grain content/%粉砂含量

Silt content/%砂含量

Sand grain content/%中值粒径

Median size/μm平均粒径

Mean size/μm≤ 0.063 黄河沙 4.73 77.84 17.43 42.7 43.5 石英砂 32.63 61.32 6.05 14.1 20.8 >0.063 ~ 0.075 黄河沙 4.49 39.14 56.38 67.0 66.0 石英砂 3.00 54.63 42.37 55.5 60.3 >0.075 ~ 0.090 黄河沙 4.48 22.41 73.11 82.4 80.1 石英砂 0.44 19.42 80.14 101 111 表 4 不同水源条件下滴头相对流量大于110%的统计分析

Table 4 Statistical analysis of the relative flow rate greater than 110% of emitters under different irrigation water

统计指标

Statistical index1.0 g·L−1+1:1:1 2.0 g·L−1+1:1:1 3.0 g·L−1+1:1:1 2.0 g·L−1+4:1:1 2.0 g·L−1+1:1:4 黄河沙

Yellow River

sand石英砂

Quartz sand黄河沙

Yellow River

sand石英砂

Quartz sand黄河沙

Yellow River

sand石英砂

Quartz sand黄河沙

Yellow River

sand石英砂

Quartz sand黄河沙

Yellow River sand石英砂

Quartz sand出现次数

Number of times7 32 5 5 2 3 7 6 21 19 平均Mean/% 116.42 120.10 117.6 123.15 113.75 120.83 115.44 113.78 119.04 121.37 最大值Maximum/% 131.05 146.44 129.13 131.02 115.08 130.17 127.00 120.01 133.52 150.36 表 5 不同水源下5种滴头的堵塞程度和堵塞区分度Dcr

Table 5 Clogging degree Dcr of five kinds of emitters under different irrigation water

滴头

Emitter1.0 g·L−1+1:1:1 2.0 g·L−1+1:1:1 3.0 g·L−1+1:1:1 2.0 g·L−1+4:1:1 2.0 g·L−1+1:1:4 黄河沙

Yellow River

sand石英砂

Quartz sand黄河沙

Yellow River

sand石英砂

Quartz sand黄河沙

Yellow River

sand石英砂

Quartz sand黄河沙

Yellow River

sand石英砂

Quartz sand黄河沙

Yellow River

sand石英砂

Quartz sandE1 未 未 完全 完全 完全 完全 未 轻微 未 未 E2 未 一般 一般 一般 完全 完全 未 一般 未 严重 E3 未 严重 一般 轻微 严重 完全 未 轻微 一般 严重 E4 轻微 严重 轻微 一般 一般 完全 一般 轻微 轻微 严重 E5 未 完全 完全 严重 严重 严重 严重 严重 一般 完全 Dcr 2.00 4.90 3.13 6.00 3.46 2.00 3.13 3.46 3.46 2.83 -

[1] 中华人民共和国国家质量监督检验检疫总局,中国国家标准化管理委员会. 塑料节水灌溉器材 第3部分:内镶式滴灌管及滴灌带: GB/T 19812.3-2017[S]. 北京:中国标准出版社,2017. [2] Subcommittee SC 18, Irrigation and drainage equipment and systems. Clogging test methods for emitters:ISO/TC 23/SC l8/WG5 N4[S]. Geneva: International Organization for Standardization, 2003.

[3] 喻黎明,曹丽,李娜,等. 额定流量与毛管位置对纽扣式滴头堵塞的影响及机理分析[J]. 农业工程学报,2023,39(20):123-131. doi: 10.11975/j.issn.1002-6819.202307109 YU Liming, CAO Li, LI Na, et al. Effects of rated flow rate and lateral position on the clogging of buttontype emitter and its mechanism analysis[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2023, 39(20): 123-131. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.202307109

[4] 喻黎明,池晓清,刘柯涵,等. 正弦波动态水压提升迷宫流道滴头抗堵塞性能[J]. 农业工程学报,2022,38(8):79-87. doi: 10.11975/j.issn.1002-6819.2022.08.010 YU Liming, CHI Xiaoqing, LIU Kehan, et al. Anti-clogging performance of labyrinth emitters improved by sinusoidal wave dynamic water pressure[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022, 38(8): 79-87. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2022.08.010

[5] 余杨,许文其,宋时雨,等. 红壤粒径肥料浓度和灌溉方式对不同灌水器堵塞的影响[J]. 农业工程学报,2018,34(15):92-99. doi: 10.11975/j.issn.1002-6819.2018.15.012 YU Yang, XU Wenqi, SONG Shiyu, et al. Influence of red loam particles, fertilizer concentration and irrigation method on clogging of different irrigation emitters[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(15): 92-99. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2018.15.012

[6] 牛文全,赵雪,王照熙,等. 含沙水磁化处理减缓滴头堵塞机理研究[J]. 农业机械学报,2022,53(3):346-356. doi: 10.6041/j.issn.1000-1298.2022.03.037 NIU Wenquan, ZHAO Xue, WANG Zhaoxi, et al. Mechanism of magnetization treatment of sandy water to relieve clogging of dripper[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(3): 346-356. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2022.03.037

[7] 牛文全,张二信,吕畅,等. 不同加气和粒径条件下浑水滴灌滴头堵塞特性研究[J]. 农业机械学报,2021,52(11):144-152,169. doi: 10.6041/j.issn.1000-1298.2021.11.015 NIU Wenquan, ZHANG Erxin, LV Chang, et al. Clogging characteristics of muddy drip irrigation dripper under different aeration and particle size conditions[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(11): 144-152,169. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2021.11.015

[8] 侯鹏,肖洋,吴乃阳,等. 黄河水滴灌系统灌水器结构-泥沙淤积-堵塞行为的相关关系研究[J]. 水利学报,2020,51(11):1372-1382. HOU Peng, XIAO Yang, WU Naiyang, et al. Cascade relationship between the emitter structure-sedimentation-clogging behavior in drip irrigation systems with Yellow River water[J]. Journal of Hydraulic Engineering. 2020, 51(11): 1372-1382. (in Chinese with English abstract)

[9] 陶洪飞,陶娟琴,周良,等. 不同因素对内镶贴片式滴灌带抗堵塞性能指标的试验研究[J]. 灌溉排水学报,2022,41(12):44-51,58. TAO Hongfei, TAO Juanqin, ZHOU Liang, et al. The effect of different factors on clogging of inlay patch drip irrigation belt[J]. Journal of Irrigation and Drainage, 2022, 41(12): 44-51,58. (in Chinese with English abstract)

[10] LI Q, SONG P, ZHOU B, et al. Mechanism of intermittent fluctuated water pressure on emitter clogging substances formation in drip irrigation system utilizing high sediment water[J]. Agricultural Water Management, 2019, 215: 16-24. doi: 10.1016/j.agwat.2019.01.010

[11] 宋蕾,蔡九茂,翟国亮,等. 微灌砂石过滤器滤层泥沙的沉积与迁移特征[J]. 农业工程学报,2023,39(4):76-83. SONG Lei, CAI Jiumao, ZHAI Guoliang, et al. Sediment deposition and migration feature in the filter layer of micro-irrigation sand filter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2023, 39(4): 76-83. (in Chinese with English abstract)

[12] 王新端,白丹,宋立勋,等. 基于流量对泥沙沉积敏感度的滴灌灌水器水力性能动态评价[J]. 农业工程学报,2018,34(15):85-91. doi: 10.11975/j.issn.1002-6819.2018.15.011 WANG Xinduan, BAI Dan, SONG Lixun, et al. Dynamic response evaluation of hydraulic performance based on sediment deposition sensitivity to flow rate of dripper emitter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(15): 85-91. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2018.15.011

[13] JIN B B, WANG X K, HUANG S, et al. Effects of high-frequency pressure pulse generated by a jet tee on the clogging of labyrinth emitter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(22): 165-171.

[14] 中华人民共和国国家质量监督检验检疫总局,中国国家标准化管理委员会. 塑料节水灌溉器材 第1部分:单翼迷宫式滴灌带:GB/T 19812.1-2017[S]. 北京: 中国标准出版社,2017. [15] 中华人民共和国国家质量监督检验检疫总局,中国国家标准化管理委员会. 塑料节水灌溉器材 第2部分:压力补偿式滴头及滴灌管: GB/T 19812.2-2017[S]. 北京: 中国标准出版社,2017. [16] LAVANHOLI R, OLIVEIRA F C, CAMARGO A P, et al. Methodology to evaluate dripper sensitivity to clogging due to solid particles: An assessment[J]. The Scientific World Journal, 2018, 2018(1): 7697458.

[17] SOUSA D J, LAVANHOLI R, Araujo A C S, et al. Evaluating sensitivity to clogging by solid particles in irrigation emitters: Assessment of a laboratory protocol[J]. Journal of Irrigation and Drainage Engineering, 2020, 146(11): 04020033. doi: 10.1061/(ASCE)IR.1943-4774.0001509

[18] HAN S, LI Y, ZHOU B, et al. An in-situ accelerated experimental testing method for drip irrigation emitter clogging with inferior water[J]. Agricultural Water Management, 2019, 212: 136-154. doi: 10.1016/j.agwat.2018.08.024

[19] 黄磊,方红卫,王靖宇,等. 天然石英砂的表面络合模型研究[J]. 环境科学学报,2014,34(5):1141-1149. HUANG Lei, FANG Hongwei, WANG Jingyu, et al. Surface complexation model for quartz sand particles[J]. Acta Scientiae Circumstantiae, 2014, 34(5): 1141-1149. (in Chinese with English abstract)

[20] EZZEIN F M, BATHURST R J. A transparent sand for geotechnical laboratory modeling[J]. Geotechnical Testing Journal, 2011, 34(6): 590-601. doi: 10.1520/GTJ103808

[21] DING X H, ZHOU W, LU X, et al. Physical simulation test of soil-rock mixture from synthetic transparent soil[J]. Journal of Central South University, 2018, 25(12): 3085-3097. doi: 10.1007/s11771-018-3976-4

[22] GANIYU A A, RASHID A S A, OSMAN M H. Utilisation of transparent synthetic soil surrogates in geotechnical physical models: A review[J]. Journal of Rock Mechanics and Geotechnical Engineering, 2016, 8(4): 568-576. doi: 10.1016/j.jrmge.2015.11.009

[23] YUAN B, XIONG L, ZHAI L, et al. Transparent synthetic soil and its application in modeling of soil-structure interaction using optical system[J]. Frontiers in Earth Science, 2019, 7: 276. doi: 10.3389/feart.2019.00276

[24] SHEN Y, PUIG-BARGUÉS J, LI M, et al. Physical, chemical and biological emitter clogging behaviors in drip irrigation systems using high-sediment loaded water[J]. Agricultural Water Management, 2022, 270: 107738. doi: 10.1016/j.agwat.2022.107738

[25] CHEN H, LIU Y, CHEN J, et al. The clogging rules of ceramic emitter in irrigation using saline water with different EC[J]. Agronomy, 2019, 9(8): 436. doi: 10.3390/agronomy9080436

[26] 董爱红,张文倩,张二信,等. 滴头堵塞程度分级和评价及堵塞风险预测方法[J]. 农业工程学报,2022,38(5):56-64. doi: 10.11975/j.issn.1002-6819.2022.05.007 DONG Aihong, ZHANG Wenqian, ZHANG Erxin, et al. Classification and evaluation of emitter clogging degree and prediction method of emitter clogging risk[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022, 38(5): 56-64. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2022.05.007

[27] 张福根,刘辉. 微粉粒度测量中形貌因素的影响[J]. 金刚石与磨料磨具工程,2013,33(1):75-78, 82. ZHANG Fugen, LIU Hui. Influence of particle shape on the results of particle size measurement[J]. Diamond & Abrasives Engineering, 2013, 33(1): 75-78, 82. (in Chinese with English abstract)

[28] MATHAES R, WINTER G, ENGERT J, et al. Application of different analytical methods for the characterization of non-spherical micro-and nanoparticles[J]. International Journal of Pharmaceutics, 2013, 453(2): 620-629. doi: 10.1016/j.ijpharm.2013.05.046

[29] MATSUYAMA T, YAMAMOTO H. Particle shape and laser diffraction: A discussion of the particle shape problem[J]. Journal of Dispersion Science and Technology, 2005, 25(4): 409-416. doi: 10.1081/DIS-200025692

[30] 刘璐,牛文全,BOB Zhou. 细小泥沙粒径对迷宫流道灌水器堵塞的影响[J]. 农业工程学报,2012,28(1):87-93. doi: 10.3969/j.issn.1002-6819.2012.01.017 LIU Lu, NIU Wenquan, BOB Zhou. Influence of sediment particle size on clogging performance of labyrinth path emitters[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(1): 87-93. (in Chinese with English abstract) doi: 10.3969/j.issn.1002-6819.2012.01.017

[31] 刘燕芳. 硬水滴灌灌水器堵塞特性和机理研究[D]. 杨凌:西北农林科技大学,2018. LIU Yanfang. Characteristics and Mechanism of Emitter Clogging in Drip Irrigation with Hard Water[D]. Yangling: Northwest A&F University, 2018. (in Chinese with English abstract)

[32] 马成昊,朱长歧,瞿茹,等. 中国南海珊瑚砂的多尺度颗粒形貌特征分析[J]. 岩土力学,2023,44(S1):117-126. MA Chenghao, ZHU Changqi, QU Ru, et al. Multi-scale particle morphology analysis of coral sand in South China Sea[J]. Rock and Soil Mechanics, 2023, 44(S1): 117-126. (in Chinese with English abstract)

[33] RABINOVICH Y, ESAYANUR M, JOHANSON K, et al. The flow behavior of the liquid/powder mixture, theory and experiment. I. The effect of the capillary force (bridging rupture)[J]. Powder Technology, 2010, 204(2/3): 173-179. doi: 10.1016/j.powtec.2010.07.035

[34] 李育彪,雷绍民,魏桢伦,等. 高纯石英砂制备技术与原理[M]. 北京:科学出版社,2023. [35] 李懿江,夏文成,牛晨凯,等. 超细石英粉对煤颗粒浮选行为的影响及机理研究[J]. 中国矿业大学学报,2019,48(5):1020-1028. LI Yijiang, XIA Wencheng, NIU Chenkai, et al. Effect of super-fine quartz powder on the flotation behavior of coal particle and its mechanism[J]. Journal of China University of Mining & Technology, 2019, 48(5): 1020-1028. (in Chinese with English abstract)

[36] 刘振海,张展华,袁语欣,等. 矿物超细颗粒的形成机制、结构特征及其环境行为和效应[J]. 环境科学,2024,45(4):2171-2184. LIU Zhenhai, ZHANG Zhanhua, YUAN Yuxin, et al. Formation mechanism, structural characteristics of ultrafine mineral particles, and their environmental effects[J]. Environmental Science, 2024, 45(4): 2171-2184. (in Chinese with English abstract)

[37] YEAP S P. Permanent agglomerates in powdered nanoparticles: Formation and future prospects[J]. Powder Technology, 2018, 323: 51-59. doi: 10.1016/j.powtec.2017.09.042

[38] 刘霞,魏正英,王立朋,等. 采用能量平衡黏附理论的灌水器泥沙-壁面黏附特性研究[J]. 西安交通大学学报,2011,45(10):115-121. LIU Xia, WEI Zhengying, WANG Lipeng, et al. Particle-wall adhesion behavior in labyrinth emitter obeying energy balanced adhesion theory[J]. Journal of Xi'an Jiaotong University, 2011, 45(10): 115-121. (in Chinese with English abstract).

[39] El Bouhali M, OUARRICHE H, BOUISFI F, et al. Experimental study on clogging of three different types of emitters with similar properties[J]. World Water Policy, 2023, 9(4): 737-745. doi: 10.1002/wwp2.12152

[40] PINTO M F, MOLLE B, ALVES D G, et al. Flow rate dynamics of pressure-compensating drippers under clogging effect[J]. Revista Brasileira de Engenharia Agrícola e Ambiental, 2017, 21(5): 304-309.

下载:

下载: