Design and experiment of the maize sowing robot chassis with front and rear dual drive and dual steering

-

摘要:

在无人化、智能化农机装备快速发展背景下,结合玉米根茬地玉米种植模式和实际需求,该研究提出了一种基于无线遥控技术的前后双驱双转向玉米播种机器人底盘,可搭载玉米播种作业部件实现无人化玉米播种。结合实际作业场景特点和玉米种植要求,确定了底盘整体结构与布局,并对车架、驱动转向系统、拱形调平机构和控制系统等关键部件进行了设计。基于ANSYS对车架进行静态和动态特性分析,结果表明车架结构设计合理,不会产生共振,在匀速满载弯曲和匀速满载扭转工况条件下,结构强度均能满足田间播种作业的设计要求。通过理论分析和样机试验相结合的方法,验证了玉米播种机器人底盘的各项工作性能,结果表明,底盘采用前后轮同步转向方式时转弯半径最小,田间最大行驶速度为1.461 m/s,直线行驶平均偏移率为4.42%;底盘能平稳地通过8°~15°斜坡和6~15 cm的凸起和凹陷障碍,具备良好的复杂地形通过性能;在不同试验条件下进行播种,底盘的播深合格率均大于86%,无重播漏播,行距最大偏差不大于4 cm,符合玉米精密播种作业要求。

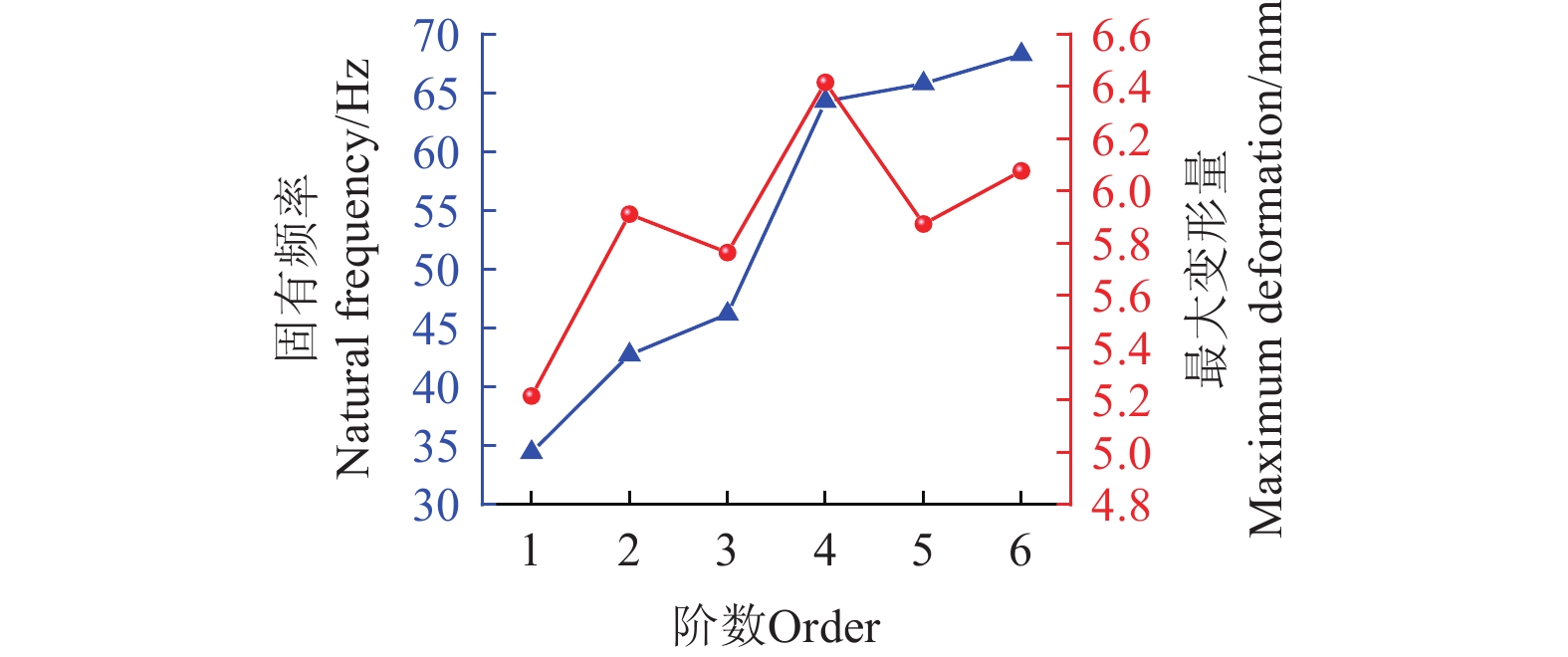

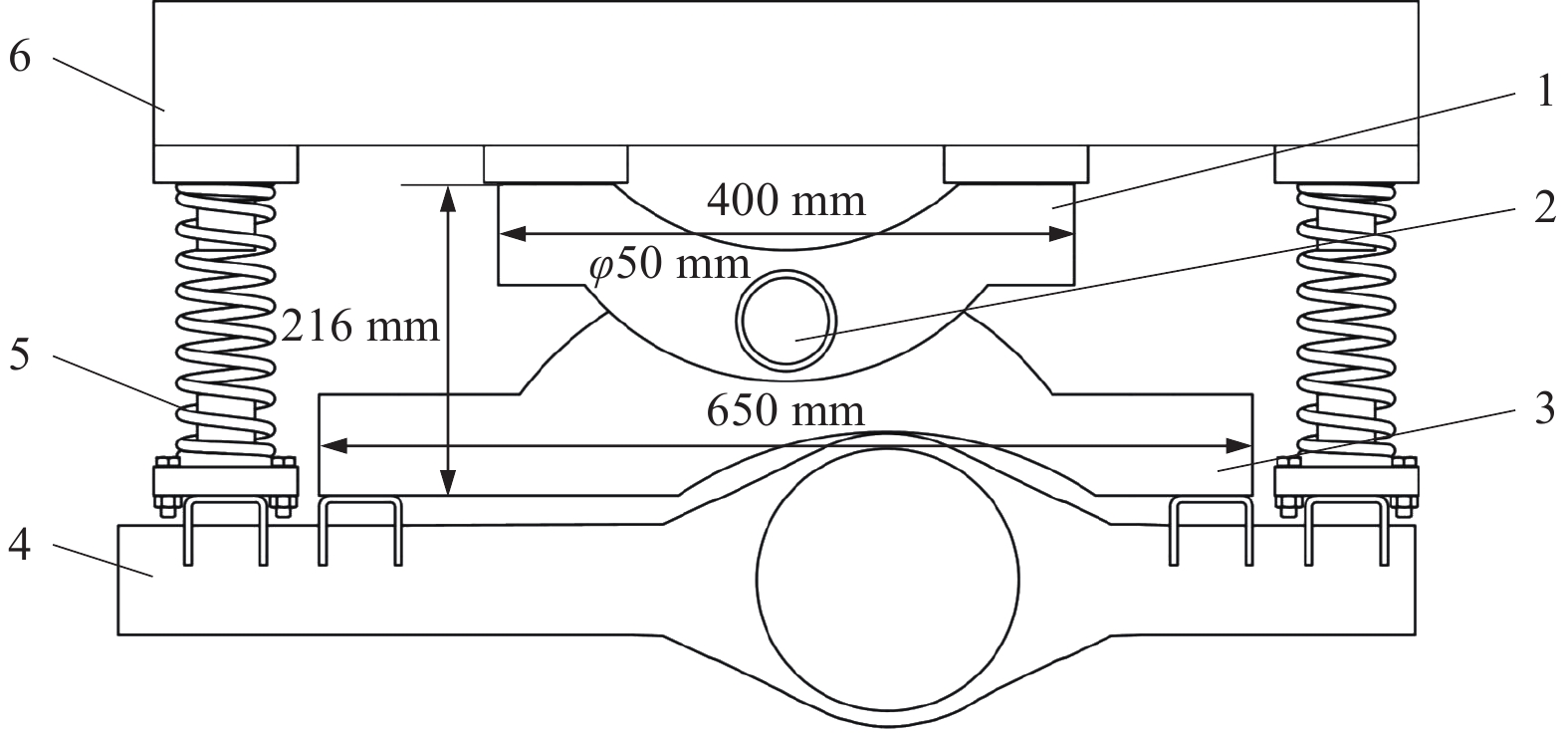

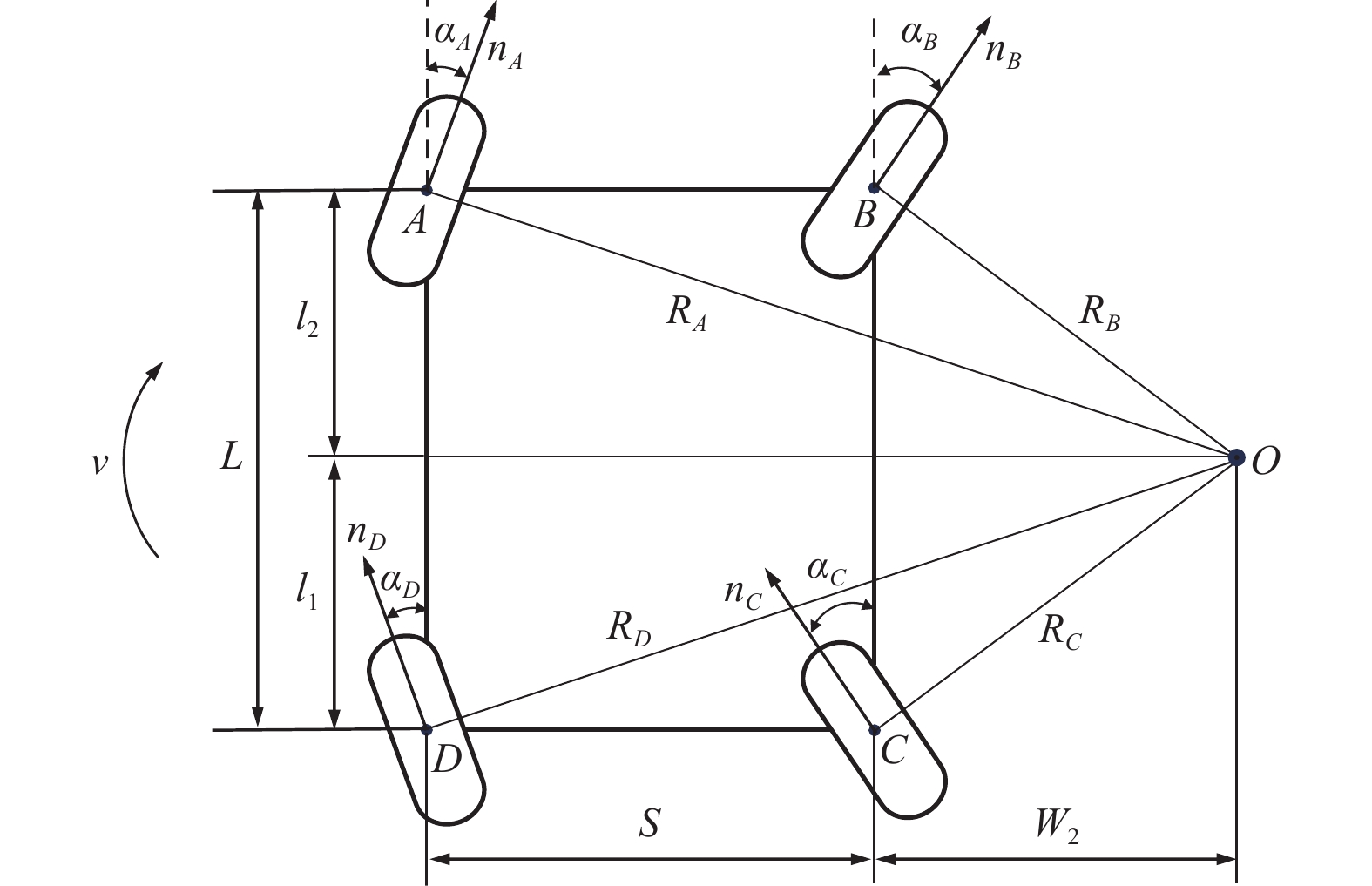

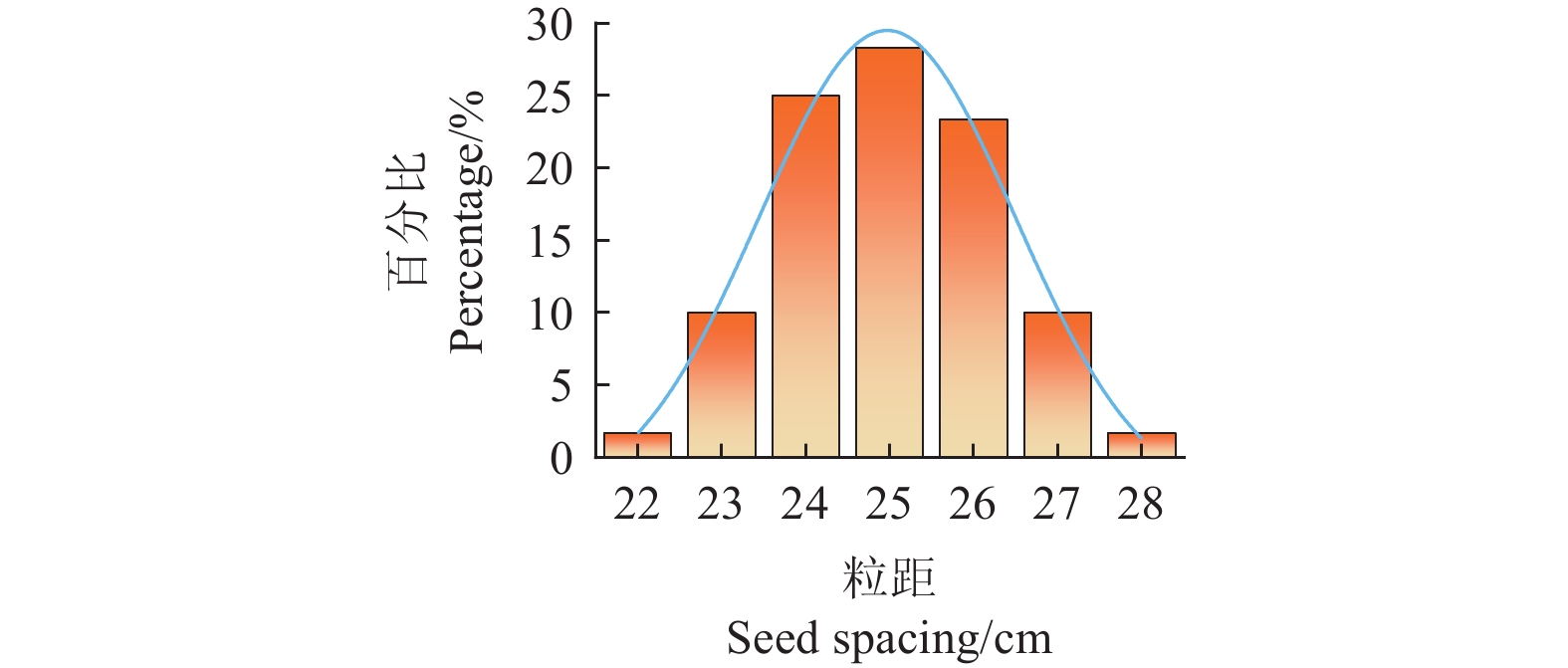

Abstract:This study aims to promote the intelligent development of field crop sowing for low labor intensity. A front and rear dual-drive and dual-steering robot chassis was designed for maize sowing using a wireless remote control system. Some components were equipped to realize the unmanned maize sowing. The overall structure and layout of the chassis were also determined to fully meet the requirements of maize sowing in the maize stubble fields. The key components were designed as well, such as the frame, drive steering system, arch leveling mechanism, and control system. According to theoretical calculation, two AC asynchronous motors of 2.2 kW were used to provide the driving force for the chassis. A column-type electric power steering was used to obtain the front and rear wheel steering. A wire-controlled brake was used for the remote braking during sowing. The vehicle control system was constructed with the VCU (vehicle control unit) as the core controller. Radio signals were also transmitted between the remote control and VCU. CAN bus communication was adopted between VCU and the rest subsystems. The static and modal analysis was performed on the frame using the finite element method, in order to verify the structural design and material strength of the frame. As such, the maximum equivalent stress of the frame was 98.2 MPa at the constant speed under full load bending. The maximum deformation was 1.84 mm. In terms of full load torsion, the maximum equivalent stress of the frame was 106.65 MPa at the constant speed, and the maximum deformation was 2.05 mm. The stress at each position of the frame was less than the standard stress of the material. The constrained modal analysis showed that the first-order natural frequency of the frame was 34.442 Hz, and the maximum deformation was 6.415 9 mm. While the vibration frequencies caused by terrain undulations and ditching were generally less than 20 and 10 Hz, respectively. Therefore, the influence of resonance on the performance of the sowing components was effectively avoided after optimization. The finite element simulation showed that the structural strength of the frame fully met the requirements of maize sowing, indicating a reasonable design. The synchronous reverse steering of the front and rear wheels was adopted to reduce the turning radius for the high efficiency of the chassis. Theoretical analysis showed that the smallest turning radius of the chassis was achieved when the front and rear wheels were rotated in opposite on the same side that deflect by the same angle. Specifically, the turning radius values of the inner and outer wheels were 3.44 and 4.65 m, respectively. Once the chassis was traveling on a slope, the force analysis showed that the maximum overturning angles for the uphill and downhill slopes were 69° and 67.7°, respectively, while the lateral overturning angle and the lateral slip angle were 58.3° and 33.8°, respectively. The performance test of the prototype showed that the chassis safely and stably went through 8°-15° slopes and overcame 6-15 cm obstacles.It infers that the chassis shared the better performance of climbing stability and obstacle crossing. The maize planting was successfully realized under various complex surfaces. The better driving performance of the chassis was achieved with the average driving speeds of 1.461 m/s on corn stubble fields, with an average straight-line deviation rate of 4.42%. The qualified rate of the sowing depth was greater than 86% in the chassis of the maize sowing robot under different test conditions. Nevertheless, the qualified rate of sowing depth decreased slightly with the increase in the operating speed. There was a relatively small variation in the standard deviation and the coefficient of variation of sowing depth. The better stability of the chassis was achieved in the sowing depth under different speeds and soil compaction. The average spacing of qualified seed was 24.32 cm, and the coefficient of variation of seed spacing was 5.1%. There was no re-seeding or missed sowing. The field vibration and excitation shared no influence on the working performance of the seed meter. The average row spacing was 69.3 cm, while the standard and maximum deviation of row spacing were 2.27 and no more than 4 cm, respectively. The chassis can be expected to achieve uniform row spacing during sowing.

-

Keywords:

- sowing robot /

- maize sowing /

- chassis /

- finite element analysis /

- performance test

-

0. 引 言

土地资源具有非再生的属性,其数量结构、空间分布的变化会对区域经济发展和环境质量产生不同程度的影响。对区域土地使用进行优化配置是有效提升土地资源应用效率的途径之一,即在兼顾土地的生态与经济两者效益的情况下,对土地进行数量结构和空间布局的优化,来实现土地资源的可持续利用[1-3]。黄河中上游地区是中国重要的生态屏障和经济地带,近年来面临诸多资源短缺、环境退化和生态破坏问题[4-5],社会经济与农牧业可持续发展均受到严重的影响,如何理清区域开发与保护关系,在发展与保护之间寻求平衡点是该区域当前研究的关键命题[6-7],而土地使用优化配置是寻求经济与生态平衡点的重要途径之一。此外黄河中上游地区作为典型的生态脆弱区,存在土地资源匮乏、土地使用结构欠合理等问题,在该地区进行土地使用优化配置研究可为极具迫切性的现实问题提供解决思路和建议。

国内外学者常用的土地优化配置方法包括模型法、综合法和多情景分析法[8-11]。土地使用数量结构的预测模型有马尔科夫(Markov)[12-13]、灰色线性规划(gray forecast model,GM)[14]、系统动力学(system dynamics,SD)[15-16]、多目标规划(multi-objective programming, MOP)[17-19]等。其中Markov模型、GM模型往往忽略驱动因子的影响,仅从数理统计的角度出发研究未来土地数量结构;SD模型虽然考虑了多个驱动因子与土地使用的相互作用,但模型构建过程过于繁杂,在解决土地优化配置的时适配度并不高。相比之下,MOP模型不仅构建相对简单,可以较为快速地推断出土地使用优化配置方案,而且兼具SD模型的正反馈特征和目标函数多维性的突破,这意味着MOP模型不仅能够考虑到不同因素之间的相互作用,还能够同时优化经济效益和生态效益。此外,遗传算法被广泛认为是解决多目标优化问题最适用的方法之一[20],其全局优化的特性能够高效地解决土地使用数量结构的优化配置问题。

空间格局预测模型有Patch-Logistic(CA)模型[21]、多智能体(ABM/MAS)模型[22-23]、Fore-SCE模型[24]、CLUE-S模型[25-26]、FLUS模型[27]等。上述模型在景观动态变化模拟策略和转化规则挖掘策略两个方面都存在一定的不足。在精细尺度下较难模拟不同类型土地斑块的演变,也不能实现特定模拟时段内土地使用变化机理的分析,而2021年中国地质大学提出的PLUS模型结合了TAS和PAS的优势并克服了其缺点[28],集成了基于多类型随机种子机制的CA模型和基于土地扩张分析的规则挖掘方法,实现了土地扩张时驱动因子及其贡献率的挖掘,并实现更准确的地类斑块级演变预测。

将数量结构预测模型和空间格局预测模型进行结合组成土地优化配置复合模型,可以从比例结构和空间分布双重层面对区域土地使用进行复合调控,提升综合效益。而探究两者间互馈机制,揭示各组成要素的互动路径,可以提升土地利用合理性。因此,本文以均衡黄河中上游地区经济发展与生态保护两者关系为目标,设置4种发展情景,首先基于MOP模型,利用多目标遗传算法,分析研究区多情景(生态保护、经济发展优先、生态-经济均衡)下的土地使用数量结构,其次,引入人口、植被指数等15个驱动因子,利用PLUS模型中的CARS工具对多情景下的土地使用优化格局进行空间落位。最后,讨论土地数量结构与空间布局的实时互馈路径,佐证土地复合优化方案的有效性。以期为黄河中上游区土地规划、土地资源可持续开发提供方法借鉴和决策参考。

1. 研究区概况与数据来源

1.1 研究区概况

黄河中上游地区(图1)包括青、川、甘、宁、内蒙古、陕、晋、豫8个省区、46市。区域内常住总人口7930万人,国土面积108.90万km2。

该区域地貌类型复杂,横跨青藏、黄土、内蒙古三大高原,属于生态安全高度威胁区[5-7];范围内用地大多位于山地高原,山地面积约占2/3,地形起伏度大,建设用地约束性强;且大多土地位于黄土高原范围内,沟壑密度较高(约为35 km/km2),用地破碎化明显;区域内总降雨少,年均降雨量(375 mm)低于全国水平,且分布差异大,主要集中在7—8月,处于干旱半干旱地区;区域水资源总量(744亿m3,占全国的2%,占长江流域的7.7%)短缺,干流径流量较小,平均径流量397.75亿m3,仅为长江干流的 4.1%,整个区域受水资源约束大。同时,黄河中上游地区处于中国“两屏三带”生态安全格局的重点位置,是国家重要的生态屏障[5]。

1.2 数据来源及处理

本文涉及数据包括土地使用数据、人口经济数据、可达性数据及自然条件数据(表1)。其中土地使用数据来源于武汉大学团队中国土地覆被及动态数据集,年份为2000—2020年,共获取2期土地数据。应用GIS中重分类工具,将流域的土地使用从二级分类整合为一级分类,包括耕地、林地、草地、水域、建设用地和未利用地6类;限制转换数据来源于国家保护区平台和中国生态系统评估与生态安全格局数据库;人口经济数据包括流域人口和GDP公里网格数据集,来源于全球变化科学研究数据出版系统;铁路等数据来源于Open Street Map;土壤等数据来源于国家青藏高原科学数据中心;高程、坡度和坡向数据来自于地理空间数据云平台。收集各类数据的空间分辨率尺度包括30 m、300 m和1 km,通过GIS栅格处理中重采样工具对栅格像元进行改变,统一分辨率为300 m。

表 1 数据来源Table 1. Data Sources类型

Variety数据名称

Data name年份

Year分辨率

Resolution/m数据来源

Data sources土地使用数据 土地使用数据 2010、2020 30 (https://doi.org/10.5281/zenodo.4417810) 限制转换区域数据 国家自然保护区 2020 30 保护区平台(http://www.papc.cn/html/folder/13100752-1.htm) 高度敏感区[28] 2020 1000 中国生态系统评估与生态安全格局数据库http://www.ecosystem.csdb.cn/ 人口经济数据 人口 2020 1000 https://landscan.ornl.gov/ GDP 2020 1000 全球变化科学研究数据出版系统http://www.geodoi.ac.cn/WebCn/doi.aspx?Id=125 可达性数据 到铁路距离 2020 300 Open Street Map

https://www.openstreetmap.org/

ArcGIS欧氏距离分析到快速路距离 2020 300 到主干道距离 2020 300 到次干道距离 2020 300 到城市中心距离 2020 300 自然环境因素 土壤类型 2000 300 国家青藏高原科学数据中心http://data.tpdc.ac.cn/zh-hans/ 到河流距离 2020 300 Open Street Maphttps://www.openstreetmap.org/ NDVI 2020 300 https://search.earthdata.nasa.gov/search 年平均温度 2000—

20201000 WorldClimhttps://worldclim.org/data/index.html 年平均降雨 2000—

20201000 高程 / 300 地理空间数据云http://www.gscloud.cn/sources/accessdata/310?pid=1 坡度 / 300 坡向 / 300 2. 研究方法

2.1 研究思路

本文耦合多目标模型和PLUS模型对黄河流域中上游地区进行土地使用优化配置,研究思路(图2)包括土地使用结构优化和土地使用布局优化两个模块。土地使用结构优化模块是基于不同的发展目标,设置4种发展情景。首先构建以生态保护、经济发展优先、经济-生态均衡3种情景为目标函数,以土地总面积、耕地保有量、生态环境保护等为约束条件的多目标优化模型,得到前3种情景下的土地使用结构数据。其次,利用Markov Chain与多期土地使用数据,预测得到惯性发展情景下的土地使用结构数据;土地使用布局优化模块是利用PLUS模型进行4种发展情景的土地空间落位,即土地使用空间优化布局。

2.2 MOP模型

MOP即为多目标规划模型,多被用于土地使用优化相关研究,通常包含目标函数、决策变量、约束条件3个部分。该模型旨在多个具有相同约束条件优化的目标当中寻找合适的变量,帮助决策者在多个目标之间找到最佳平衡点,以支持土地使用规划和决策的制定。

1)目标函数和决策变量

F1(x)=max (1) {F}_{2}\left(x\right)={\max}_{\sum _{j=1}^{n}{d}_{j}{x}_{j}} (2) {{\mathrm{s}}}{.}{{\mathrm{t}}}{.}=\left\{\begin{array}{c}\sum _{j=1}^{n}{a}_{ij}{x}_{j}=\left(\ge \text{,}\le \right){b}_{j}\text{,}(i=1\text{,}2\text{,}\cdots \text{,}m)\\ {x}_{j}\ge 0\text{,}(j=1\text{,}2\text{,}\cdots \text{,}n)\end{array}\right. (3) 式中F1表示研究区的经济效益(万元),F2则为生态效益(万元); {x}_{j} 表示第j类土地使用面积(j=1,2,…,6),其中x表示决策变量,即土地使用面积(km2),j为用地类型索引,包括6种不同的土地使用类型,即x1耕地,x2园地,x3林地,x4草地,x5建设用地,x6其他用地;cj为各类土地使用类型的经济效益系数(万元/km2);dj为各类土地使用类型的生态价值系数(万元/km2);约束条件s.t.中,aij为第i个约束条件中第j个变量对应的系数;bj为约束值。

2010—2020逐年经济效益系数是通过计算2010—2020年研究区各个县(旗)的不同土地使用类型对应的产值与其面积之比(农业产值/耕地面积、林业产值/林地面积、牧草业产值/草地面积、渔业产值/湿地面积、二产+三产产值/建设用地面积),而未利用地的经济效益可以忽略,接着引入GM(1,1)灰色预测模型来测算目标年份2030年研究区的经济效益系数cj(表2)。

表 2 土地使用类型对应的经济效益系数cj、生态价值系数djTable 2. Economic benefit coefficient(cj) and ecological value coefficient(dj) corresponding to land use type万元·km−2 项目

Item耕地

Cultivated land x1林地

Wood

land x2草地

Grass

x3水域

Water

x4建设用地

Construction land x5未利用地

Bare

x6cj 5.58 34.32 4.41 1509.78 10182.27 0.00 dj 1118.96 5482.01 4086.01 144744.07 0.00 1898.33 同时采用中国生态系统服务价值当量因子表[7]来估算生态系统服务价值系数dj,并应用修正系数[8-9]进行验证(表2),具体步骤为:以2010—2020年黄河中上游地区平均粮食单产5517.67 kg/km2作为基准,取2002—2010年国家退耕还林补助标准1.4元/kg为粮食单价[10],设定全国粮食平均单价是一个纯自然生态系统(无人力投入)所产生的经济价值量的7倍[10]。

2)发展情景设定

基于经济与生态效益相均衡的目标原则,同时考虑到黄河流域的区域特殊性和生态脆弱性,本文以2030年为目标年,设定惯性发展、生态保护、经济发展、生态-经济均衡4种发展情景,并在参考现有文献[11]的基础上,采取德尔菲法[19]且综合专家意见确定了4种情景下生态和经济效益各自所占权重比例。其中惯性情景下各类用地应顺应自然演变规律,对其生态和经济效益目标不设权重;经济优先情景下应以经济建设为目标,提高区域土地使用强度,优化土地使用结构,提升土地使用效能,从而有效推动城镇化进程。该情景下生态和经济效益目标所占权重比为1:4;生态保护情景下应以生态文明建设为目标,关注山、湖、林、田、草地的保护,防止建设用地和城市边界的无限扩张,该情景下生态和经济效益目标所占权重比为4:1;均衡情景下应关注生态保护和社会经济的协调发展,在不侵占生态保护用地的情况下大力促进经济建设,该情景下生态和经济效益目标所占权重比为1:1。

3)约束条件

依据黄河中上游地区各县(旗)的相关规划文本、惯性情景下的2030年土地使用需求数据(基于Markov Chain预测),并结合灰色预测模型对研究期内土地使用的变化状况来制定多目标模型的约束条件(表3)。

表 3 约束条件设置Table 3. Constraint setting约束类型

Constraint type约束条件

Constraint condition说明Illustrate 土地总面积T T=781480 各类土地面积xi的总和应等于黄河中上游地区的总面积781480 km2 决策变量非负约束 xi≥0,i=1,2,3,4,5,6 各决策变量应为非负值 耕地保有量x1 188984≥x1≥169808 x1不应低于2020年现状耕地面积,最大不应超出惯性发展情景下的x1需求数据上调10%的量[10] 林地规模x2 108947≥x2≥94970 x2最小不应低于2020年现状规模;最大不应超出惯性发展情景下的x2需求数据上调10%的量 草地面积x3 461158≥x3≥452026 x3的增减受到降雨量和人类活动双重影响,且x3占比面积最大,其增减幅度不应超过惯性发展情景下x3需求数据±1%的量[19] 水域面积x4 6510≥x4≥5166 x4最小不应低于2020年现状规模;最大不应超出惯性发展情景下的x4需求数据上调10%的量 建设用地规模x5 23484≥x5≥18739 x5最小不应低于2020年现状规模;最大不应超出惯性发展情景下的x5需求数据上调10%的量 未利用地规模x6 28192≥x6≥24095 x6最小不应低于惯性发展情景下的x6需求数据下调10%的量,最大不应超出2020年现状规模 生态环境保护 x2≥101302

x4≥5840仅针对生态保护情景,x2、x4最小不应低于:取2005—2020年内每5a为间隔,共4期数据为基础,应用灰色模型预测的2030年x2、x4面积[10] 注:面积单位为km2。

Note: The area unit is km2.2.3 PLUS模型

PLUS模型是在FLUS模型的基础上构建的一种新的改进的CA模型,其耦合了一种新的用地扩张分析策略和基于多类随机斑块种子的CA模型,一方面可以更好地挖掘各类土地使用变化的诱因,另一方面也可以更好地模拟多类土地使用斑块级的变化。

1)土地扩张分析策略

土地扩张分析策略(land expansion analysis strategy, LEAS)不仅能避免多地类分析时的复杂计算,而且可以在一定时间段内分析土地使用变化机理。其将各地类转换规则的挖掘转化成一个二元分类问题,探索各地类扩张与多驱动因子关系、获取各地类发展概率及驱动因子贡献率。本文从自然、社会经济维度选取了GDP、人口等15个驱动因子。

2)土地演化模拟

土地演化模拟是对多种地类斑块演化进行模拟,采用基于阈值下降的多类型随机斑块种子机制。模型参数设置如下:

①用地需求:用地需求表示模拟年份不同土地使用类型的栅格数量,主要包括两种模拟方法分别为线性回归法和马尔科夫链法。本研究运用马尔科夫链法预测2030年惯性情景下各土地使用类型的栅格数量,其计算结果如表4所示。

表 4 各情景下各地类斑块2030年土地需求面积预测Table 4. Prediction of land demand area for various types of patches in various scenarios by 2030km2 情景

Scenarios耕地

Cultivated land林地

Forest草地

Grass水域

Water建设用地

Construction land未利用地

Bare惯性发展 171804 99043 456593 5918 21350 26772 生态保护 171318 103025 454437 6011 20366 26324 经济优先 172603 97972 455711 6011 21672 27543 均衡发展 172613 97879 455734 6011 21640 27572 ②领域权重:邻域权重参数代表着不同用地类型的扩张强度,反映了各地类在空间驱动因子影响下的扩张能力,本文基于前人经验,依据研究时段各地类斑块总面积变化量设定,计算式如下:

X_i=\frac{\Delta T_{Ai}-\Delta T_{Amin}}{\Delta T_{Amax}-\Delta T_{Amin}} (4) 式中Xi某一地类i的邻域权重参数,TA为用地面积,∆TAi为研究时段内该地类TA的变化量,∆TAmax、∆TAmin分别为研究时段内TA的最大、最小变化量。表5为邻域权重参数表。

表 5 邻域权重参数表Table 5. Neighborhood weight parameters table项目Item 耕地Cultivated land 林地Forest 草地Grass 水域Water 建设用地Construction land 未利用地Bare ∆TAi -43699 75236 -78558 7448 47788 -8215 权重 0.29 1.29 0.01 0.72 1.06 0.59 ③转移矩阵:转移矩阵表示不同土地使用类型之间的转换规则,主要依靠历史土地使用数据和经验设定。具体规则为:当一种土地使用类型不能转换为另一种土地使用类型时,其矩阵中对应值为0,反之则为1(图3)。

④模型精度验证:本文使用Kappa系数评估模型模拟准确性,计算式如下:

\mathrm{K}\mathrm{a}\mathrm{p}\mathrm{p}\mathrm{a}=\frac{{P}_{0}-{P}_{c}}{{P}_{p}-{P}_{c}} (5) 式中P0为模拟正确的栅格占比,Pp为理想状态下模拟正确比例,Pc为随机状态下模拟正确比例。Kappa值判断标准为:当Kappa系数值分别介于0~0.2、>0.2~0.4、>0.4~0.6、>0.6~0.8和>0.8~1之间时,其模拟效果分别判定为低、较差、中等、较高和高。

3. 结果与分析

3.1 PLUS模型各参数运行结果

3.1.1 驱动因子及其贡献率

根据驱动因子的选取原则[25],本研究选取了15个能作用于土地使用变化的驱动因子(图4)。包括:人口、植被指数(NDVI)、GDP、到铁路的距离、到高速公路的距离、到主干道的距离、至次干道距离、到市中心的距离、土壤类型、到河流的距离、年平均气温、年平均降雨量、DEM、坡度、坡向。按照PLUS模型测度要求对驱动因子进行了标准化处理,且要求各驱动因子栅格数据的单元格大小和数目均保持一致。

2010—2020年黄河中上游地区各类用地扩张因子均方根误差RMSE均低于0.14,效果较好。如图5所示,土地与驱动因子之间的连线越粗,即表示该驱动因子对于该类土地演化预测的贡献度越高。

从综合角度而言,贡献度最高的几项因子为DEM、植被指数、GDP、年平均气温。其中对耕地扩张影响度最高的驱动因子是DEM,对林地扩张影响度最高的是植被指数,对草地扩张影响度最高的是年平均气温,对建设用地扩张影响度最高的是DEM和人口。

3.1.2 土地使用时空变化

通过分析可知,2010—2020年黄河中上游地区地类变化中,草地(−6408.81 km2) 、林地(6771.24 km2)、建设用地(4300.92 km2) 与耕地(−3932.91 km2)总量变化依次最多,草地、耕地、林地、未利用地依次向其他类用地转换最多(图6),其中草地转换为耕地、未利用地的面积较多,占比分别为5.05%和1.51%;耕地向草地、林地转出最多,占比分别为13.39%和0.82%;林地向草地、耕地转出最多,占比分别为8.25%和1.64%。

3.1.3 模型精度验证

本文以2010年的土地使用数据为基础,通过PLUS模拟得到2020年的土地使用情形,将其与2020年的真实的土地使用格局进行对比验证(图7),得知各类用地中水域的模拟精度最高,草地模拟精度最低。运行PLUS验证其Kappa系数为0.86,总体精度为91.04%,则可知模型的各项参数设置合理,模拟精度比较高。

3.2 研究区土地使用数量结构方案

运用PLUS软件中马尔科夫链模型测算惯性发展情景下的2030年研究区的土地使用结构方案,运用多目标遗传算法测算得到余下3种情景下的土地使用结构方案(表6)。4种情景下各类土地的比例结构存在较大差异,水域、建设用地和林地相较于2020年现状用地变化比例较大,因此对于生态效益和经济效益具有直接显著的影响。

表 6 黄河中上游地区多种模拟情景下土地使用面积及变化比例的对比分析Table 6. Comparative analysis of land use area and change proportion under various simulation scenarios情景

Scenarios项目

Item耕地

Cultivated land林地

Forest草地

Grass水域

Water建设用地

Construction land未利用地

Bare现状current 面积/km2 169808.40 94970.34 464603.85 5166.45 18739.17 28192.68 惯性发展

Inertial development面积/km2 171804.23 99043.01 456592.83 5918.34 21349.98 26772.49 变化比例/% 1.18 4.29 -1.72 14.55 13.93 -5.04 生态保护

Ecological protection面积/km2 171318.20 103025.12 454436.52 6011.01 20366.02 26324.00 变化比例/% 0.89 8.48 -2.19 16.36 8.68 -6.63 经济优先

Economic priority面积/km2 172603.00 97972.00 455711.00 6011.00 21672.02 27543.00 变化比例/% 1.65 3.16 -1.91 16.35 15.65 -2.31 均衡发展

Balanced development面积/km2 172613.20 97879.11 455733.52 6011.01 21640.00 27572.00 变化比例/% 1.65 3.06 -1.91 16.35 15.48 -2.20 如表6所示,惯性发展情景下,2030年黄河中上游区域的耕地、林地、水域和建设用地面积呈现增长趋势,草地和未利用地面积呈现减少趋势,其中水域和建设用地的增长比例最高,达到14.55%和13.93%,未利用地的面积减少比例最高达到5.04%。黄河中上游地区属于生态脆弱区,生态类用地的增加有利于研究区的生态建设与保护,同时经济类用地的增加,有利于经济水平的提高。多目标模型设置的三类情景下,经济优先情景下的建设用地面积增加的比例最高,达到2932.85 km2(15.65%),生态优先情景下的林地和水域面积增加比例最高,分别为8054.78 km2(8.48%)和844.56 km2(16.36%)。该用地变化的趋势符合情景设置的初衷。

3.3 研究区土地使用空间分布格局

研究通过PLUS模型对2030年4种情景下的黄河中上游地区土地使用空间格局进行空间落位(图8)。建设用地在惯性发展、经济优先和均衡发展3种情景下的空间格局变化幅度明显,扩张发生的位置大多处在研究区的西北部,在生态情景下的空间格局变化幅度较小,仅增长了1626.87 km2。草地在生态情景下的空间格局变化幅度较大,呈现增长趋势,主要分布在研究区中部和南部,草地在其他3种情景下的空间格局变化幅度较小(图9)。水域在4种情景下的空间格局变化幅度是6类用地中最小的,而耕地、未利用地、林地的格局形态有着较大幅度变化,其中未利用地变化始终保持减少趋势。

1)惯性发展情景下,各类用地变化面积从大到小依次为草地、林地、建设用地、耕地、未利用地、水域,草地变化幅度最大。各区域用地面积均发生了不同程度的增长和收缩,差异主要分布在研究区北部,其中内蒙古收缩最为明显。林地主要在南部、中部出现增长,其中山西、陕西、甘肃和青海省的增长较多。建设用地和耕地面积扩张主要位于北部和中部,其中大多处在内蒙古、宁夏、甘肃和山西范围内。各区域未利用地均有不同程度的减少。水域受到保护,极少向其他土地类型转换。

2)生态保护情景下,各类用地变化面积从大到小依次为草地、林地、未利用地、建设用地、耕地、水域,耕地和水域的空间分布格局无明显的变化,仅有少量增长和消退。建设用地在研究区的东南部出现增长,主要位于山西、陕西和河南省范围内。生态类用地即草地和林地大量在研究区北部的内蒙古、陕西、青海和甘肃范围内发生大幅扩张,林地在青海省南部、四川省范围内增幅最多。

3)经济优先情景下,各类用地变化面积从大到小依次为草地、建设用地、林地、耕地、未利用地、水域,经济类用地即建设用地和耕地扩张明显,尤其是研究区北部的内蒙古增长最多。草地和未利用地在大部分区域(研究区南部、东部)发生了收缩和消退,草地大多向耕地和林地进行了转换,同时在少数地区出现少许增长现象。

4)生态-经济均衡发展情景下,各类用地变化面积从大到小依次为草地、林地、建设用地、耕地、水域、未利用地,草地在研究区北部、中部发生了扩张,包括内蒙古、甘肃省范围,在研究区西部、南部发生少量收缩,尤其是青海省和陕西省。建设用地在研究区北部(内蒙古省范围)扩张幅度较大,且主要延展方式为边缘式和填充式。耕地和林地在研究区内大致均匀扩张,主要由草地类型转换而来。

上述结果表明,生态-经济均衡情景下的各类土地空间分布的格局更加合理,其中建设用地布局最为紧凑;耕地有向四周蔓延的趋势,表现为边缘式扩张;林地和水域更侧重填充式和飞地式扩张,主要填充的类型是原有的草地和未利用地,从而实现更高的生态价值。

3.4 研究区土地使用方案效益分析

本研究通过MATLAB2021b中的MUGA模块进行迭代运算,直到算法运行满足停止准则,搜索到的Pareto非劣解前端大体呈曲线分布(图10),可以得到2030年4种情景下研究区的经济效益值与生态效益值(表7)。

表 7 多情景下经济、生态效益对比分析Table 7. Comparative analysis of economic and ecological benefits under multiple scenarios项目

Item惯性发展

Inertial development生态保护

Ecological protection经济优先

Economic priority均衡发展

Blanced develpntat经济效益/×108元 11999.82 11745.89 13181.04 12223.88 生态效益/×108元 7166.68 7606.28 7092.92 7257.12 经济效益变化比例/% 2.16 0.00 12.22 4.07 生态效益变化比例/% 1.04 7.24 0.00 2.32 注:经济效益变化比例是以生态保护情景为基准计算,生态效益变化比例是以经济优先情景为基准计算。

Note: The proportion of economic benefits change is calculated based on the ecological protection scenario, while the proportion of ecological benefits change is calculated based on the economic priority scenario.由表7可知,经济优先情景下研究区的经济效益显著,预测2030年达到13181.04亿元,但生态效益不佳且为最低,仅有7092.92亿元,综合效益20 273.96亿元该情景不利于生态文明建设。在生态保护情景下,经济效益仅为11745.89亿元,而生态效益达到了4种情景下最高,为7606.28亿元,该情景对经济发展不利。上述两种情景均可能导致区域发展失衡,不利于两者协调发展。此外,惯性发展情景下生态与经济效益相对平衡,但其综合效益(19166.50亿元)不及均衡发展情景(19481.00亿元),且与生态保护情景相比均衡发展情景下的经济效益增幅达到4.07%(大于惯性情景的2.16%);与经济优先情景相比,其生态效益增幅达到2.32%(大于惯性情景的1.04%)。即生态-经济均衡情景所提出的土地使用方案能够支持区域发展效益最大化,有利于促进地区可持续发展。

4. 讨 论

4.1 土地利用结构与布局的互馈机制

从数量结构、空间布局方面调控土地利用一直是土地复合优化配置的核心[28],阐明两者互馈路径是黄河中上游区高质量发展的关键,也是建立两者紧密耦合关系的基础(图11)。土地空间布局是数量结构的平面体现,数量结构则反映空间布局的三维构成。土地总量和各类型的分配状况受到多个因素影响,城市化不断推进有效提升了土地盈利的能力,拔高地价的同时对建设用地的需求显著增强。该场景下经济优先发展,但会引起土地结构中建设用地比例过高,耕地等生态用地减少,此时基本农田保护、生态红线保障政策出台,保护林、草、耕地,促进土地良性流转,实现土地格局的优化,进而回馈经济、推进新型城镇化建设,则土地结构与布局的第一条互馈路径完成闭环,该组互馈关系反映经济蓬勃发展,但生态要素受到制约;土地格局破碎、斑块细碎度高会制约经济发展,造成产业结构失衡、绿地萎缩、环境污染加重,需践行退耕还林等生态保护政策去优化土地空间布局。则形成第二条互馈路径。该路径重视生态保护,关注经济发展较少;人口变化意味着需要更多(少)住房等经济建设用地,引起土地需求的调整或结构失衡,此时将未利用地作为弹性空间进行管制,可优化土地结构、平衡生态关系,达到土地与人口匹配的状态,再结合城市规划的刚性管制指标,可以实现数量结构与空间格局复合优化的局面,则使第三条互馈路径闭环。该组互馈关系平衡了经济与生态的关系。三组互馈路径的作用过程能有效佐证均衡发展情景优于生态或经济单一保护情景。

4.2 研究区土地复合优化的建议

黄河中上游地区是典型的生态脆弱区,当前出现了土地利用总量和分配比例相对失调、经济和生态发展亟需平衡、土地空间分布不尽合理等问题,迫切需要对土地可持续发展提供参考建议。本文设置的4种情景方案,可以了解未来不同情景下土地数量结构与空间布局的状态。惯性情景下草地和未利用地大幅降低,建设用地相应增大,与主流规划要求不符,远期应对建筑用地的快速扩张进行遏制。生态保护和经济优先情景基本显露了区域未来土地利用的潜在矛盾,不符合高质量发展的要求。均衡情景既能有效约束建设用地的增长,又能使生态用地的变化维持在合理范围,在未来建设中,建议依照该情景下的土地数量结构与空间布局的复合优化方案进行土地规划。

相较于普遍应用的CLUE-S模型、FLUS[21,27,29-30],本文应用的PLUS模型构建了一个灵活的处理多类土地使用斑块变化的机制,可以更精确地模拟黄河中上游地区土地使用空间分布情况。同时以往研究在PLUS模型的参数设置的调试过程中,对于限制转换区的设置比较单一[31-32],多以自然保护区为主,而本文立足于生态脆弱区的地域特点,在生态保护情景下的将高脆弱区作为限制转换区域,增强了模拟过程的科学性。存在不足是受制于收集到的规划文本数据有限,在多目标模型约束条件构建过程中以惯性情景下的土地使用数据、2020年现状数据作为参照对演变趋势做出边界控制,导致了少量主观判断的引入。在后续研究中应不断补充约束条件,扩充数据来源,使土地优化配置更加客观。

5. 结 论

本文构建了黄河中上游地区生态保护、经济优先和生态-经济均衡多目标土地使用优化模型,并引用遗传算法求解,得到3种情景的土地使用结构优化配置的方案,从而对该区域内的土地使用结构进行优化,再应用PLUS模型中的CARS板块,模拟2030年黄河中上游地区空间格局的优化配置。主要结论如下:

1)得到一组使综合效益达到较优水平的Pareto非劣解方案。利用多目标遗传算法对生态保护、经济优先与生态-经济均衡3项不同目标的土地使用结构优化配置问题进行求解,得到了一组Pareto非劣解方案。该结果从一定程度上为决策人预案提供多种选择方案,并通过与空间落位模型PLUS相结合,实现对权衡不同发展目标的土地使用结构及格局分布的情景模拟。

2)4种发展情景下,土地使用比例结构存在较大差异。与2020年现状相比,耕地在经济优先情景下、林地在惯性发展情景下、草地和未利用地在生态保护情景下、水域和建设用地在均衡发展情景下的变化是最大的。

3)4种情景中的生态-经济均衡情景提供的优化配置方案更为合理。从土地使用比例结构、空间格局和总体效益3个角度进行模拟比较,得知均衡情景的总体优于另外3种情景。该方案可为黄河中上游地区未来的生态保护、经济建设和土地优化配置提供参考建议。

-

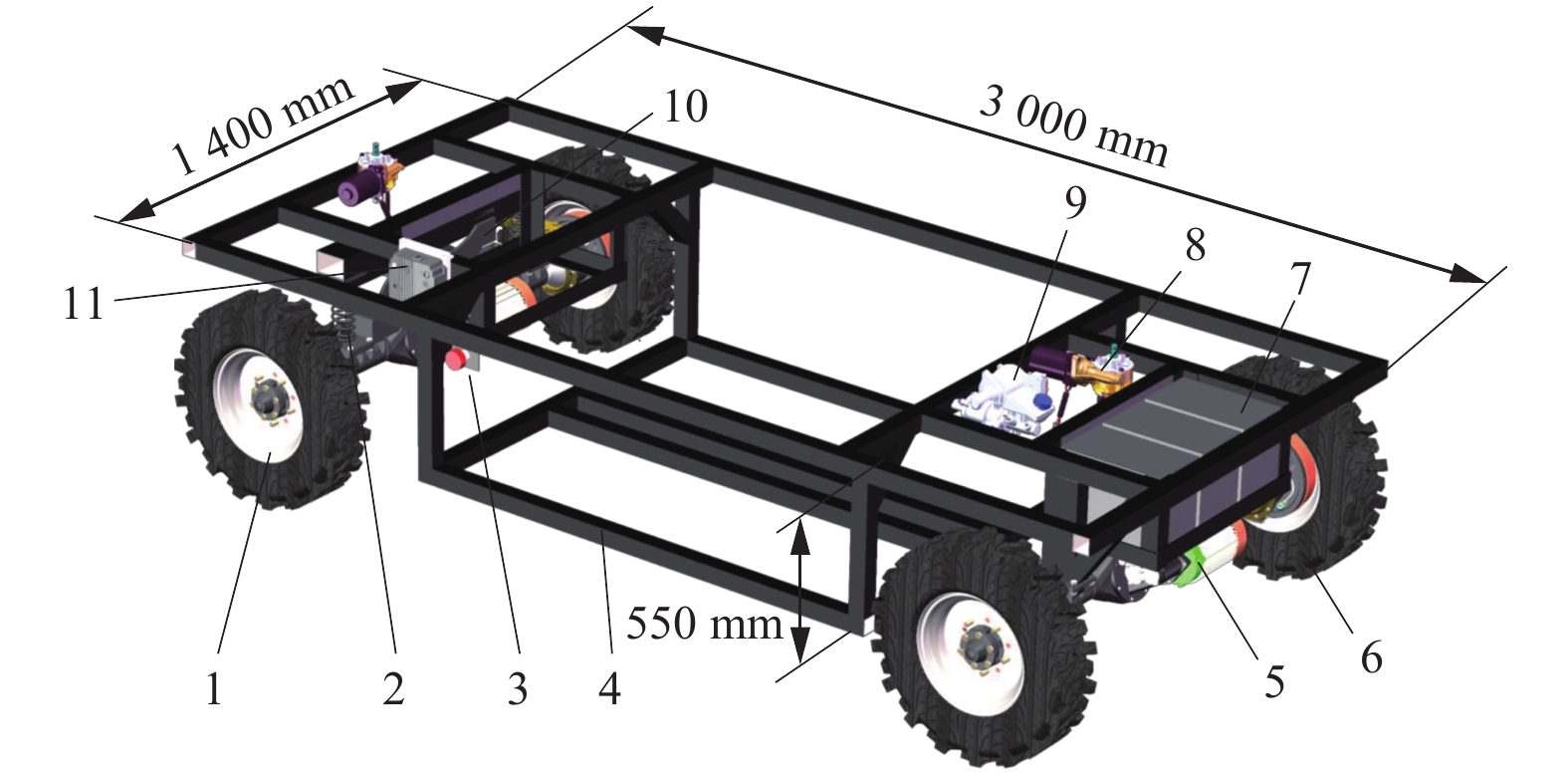

图 1 玉米播种机器人整体结构

1. 底盘 2. 播深调控系统 3. 种肥垂直分层播施装置 4. 电驱播种单元 5. 覆土镇压轮 6.外壳 7. 行距调控系统 8. 种肥箱

Figure 1. Overall structure of maize sowing robot

1. Chassis 2. Seeding depth control system 3. Seed and fertilizer vertical layering device 4. Electric driven seeding unit 5. Soil covering and pressing wheel 6. Shell 7. Row spacing adjustment system 8. Seed and fertilizer box

图 2 玉米播种机器人底盘结构

1. 前桥 2. 减振弹簧 3. 总开关 4. 车架 5. 驱动电机 6. 后桥 7. 电池组 8. 电动助力转向器 9. 线控制动器 10. 拱形调平机构 11. 整车控制器

Figure 2. Structure of maize sowing robot chassis

1. Front axle 2. Damping spring 3. Switch 4. Frame 5. Drive motor 6. Rear axle 7. Battery pack 8. Electric steering actuator 9. Electronic brake actuator 10. Arch leveling mechanism 11. Vehicle controller

图 7 底盘转向运动学模型

注:O为转向瞬心,A,B,C,D为车轮中心点,M1为底盘运动方向,S为轮距,m;W2为内侧车轮中心到O点的水平距离,m; L为轴距,m;l1和l2分别为后轮和前轮到O点的距离,m;αi(i=A,B,C,D)表示车轮的转向角,(°);ni(i=A,B,C,D)表示车轮的转速,r·min−1;Ri(i=A,B,C,D)表示车轮的转弯半径,m。

Figure 7. Chassis steering kinematics model

Note: O refers to instantaneous center of steering, A, B, C, D refers to the center points of the wheels, M1 refers to the direction of chassis movement, S refers to the wheel center distance, m; W2 refers to the distance from inner wheel instantaneous center to O, m; L refers to the wheelbase, m; l1 and l2 refers to the distance from the rear and front wheels to O, m; αi (i=A, B, C, D) refers to the steering angle of the wheel, (°); ni (i=A, B, C, D) refers to the rotational speed of wheel, r·min−1; Ri (i=A, B, C, D) refers to steering radius of wheel, m.

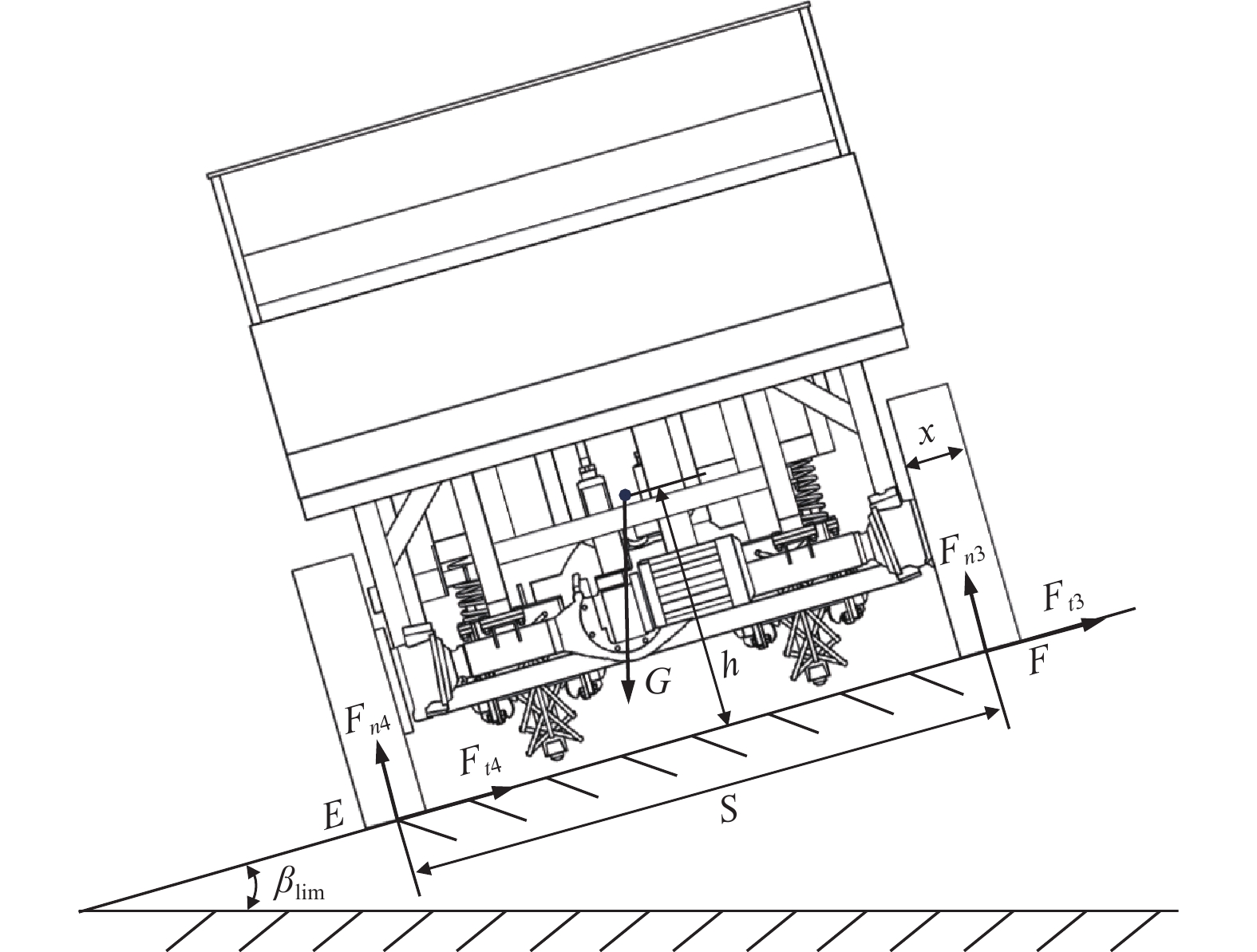

图 8 玉米播种机器人底盘纵向稳定性分析

注:Ft1、Ft2分别为地面对前、后轮的切向作用力,N;Fn1、Fn2分别为地面对前轮的法向作用力,N;G为底盘自身重力,N;h为重心到地面垂直高度,mm;L1为重心到后桥轴心的距离,mm;αlim为底盘极限倾翻角,(°)。

Figure 8. Analysis of longitudinal stability of maize sowing robot chassis

Note: Ft1, Ft2 refers to the tangential force of the front and rear wheel by ground, respectively, N; Fn1, Fn2 refers to the normal force of the front and rear wheel by ground, respectively, N; G refers to the gravity of the chassis, N; h refers to the vertical height from the center of gravity to the ground, mm; L refers to the wheelbase of the chassis, mm; L1 refers to the distance from the center of gravity to the rear axle, mm; αlim refers to the maximum overturning angle of the chassis, (°).

图 9 玉米播种机器人底盘横向稳定性分析

注:Ft3、Ft4分别为地面对上、下侧轮的切向作用力,N;Fn3、Fn4分别为地面对上、下侧轮的法向作用力,N;S为车轮中心距离,mm;x为车轮宽度,mm;βlim为底盘横向极限倾翻角,(°)。

Figure 9. Analysis of lateral stability of maize sowing robot chassis

Note: Ft3, Ft4 refers to the tangential force of the upper and lower wheel by ground, respectively, N; Fn3, Fn4 refers to the normal force of the upper and lower wheel by ground, respectively, N; S refers to the tire center distance, mm; x refers to the tire width, mm; βlim refers to the lateral maximum overturning angle of the chassis, (°).

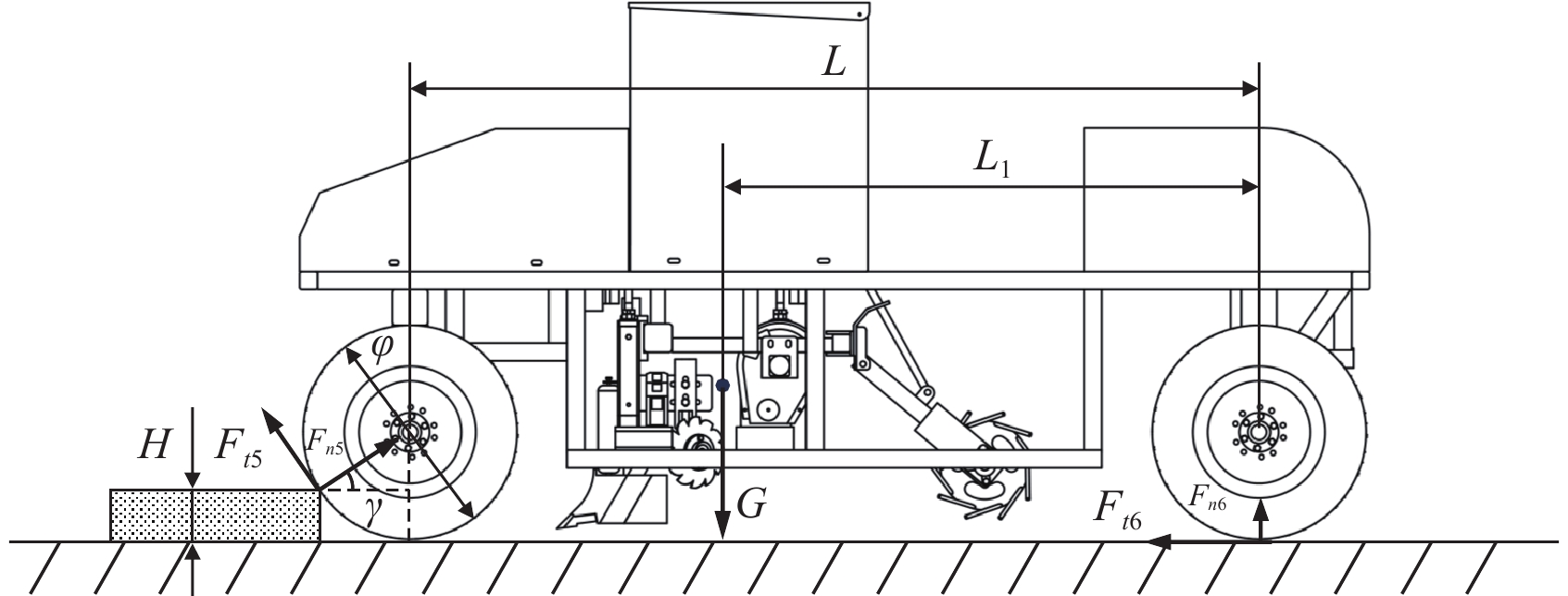

图 10 玉米播种机器人底盘越障受力分析

注:Ft5、Ft6分别为障碍对前、后轮的切向作用力,N;Fn5、Fn6分别为障碍对前、后轮的法向作用力,N;H为障碍高度,mm;φ为车轮直径,mm;γ为前轮与障碍的夹角,(°)。

Figure 10. Force analysis of maize sowing robot chassis for crossing obstacles

Note: Ft5, Ft6 refers to the tangential force of the front and rear wheel by obstacle, respectively, N; Fn5, Fn6 refers to the normal force of the front and rear wheel by obstacle, respectively, N; H refers to the height of the obstacle, mm; φ refers to the tire diameter, mm; γ refers to the angle between the front wheel and the obstacle, (°).

表 1 玉米播种机器人底盘主要技术参数

Table 1 Main technical parameters of maize sowing robot chassis

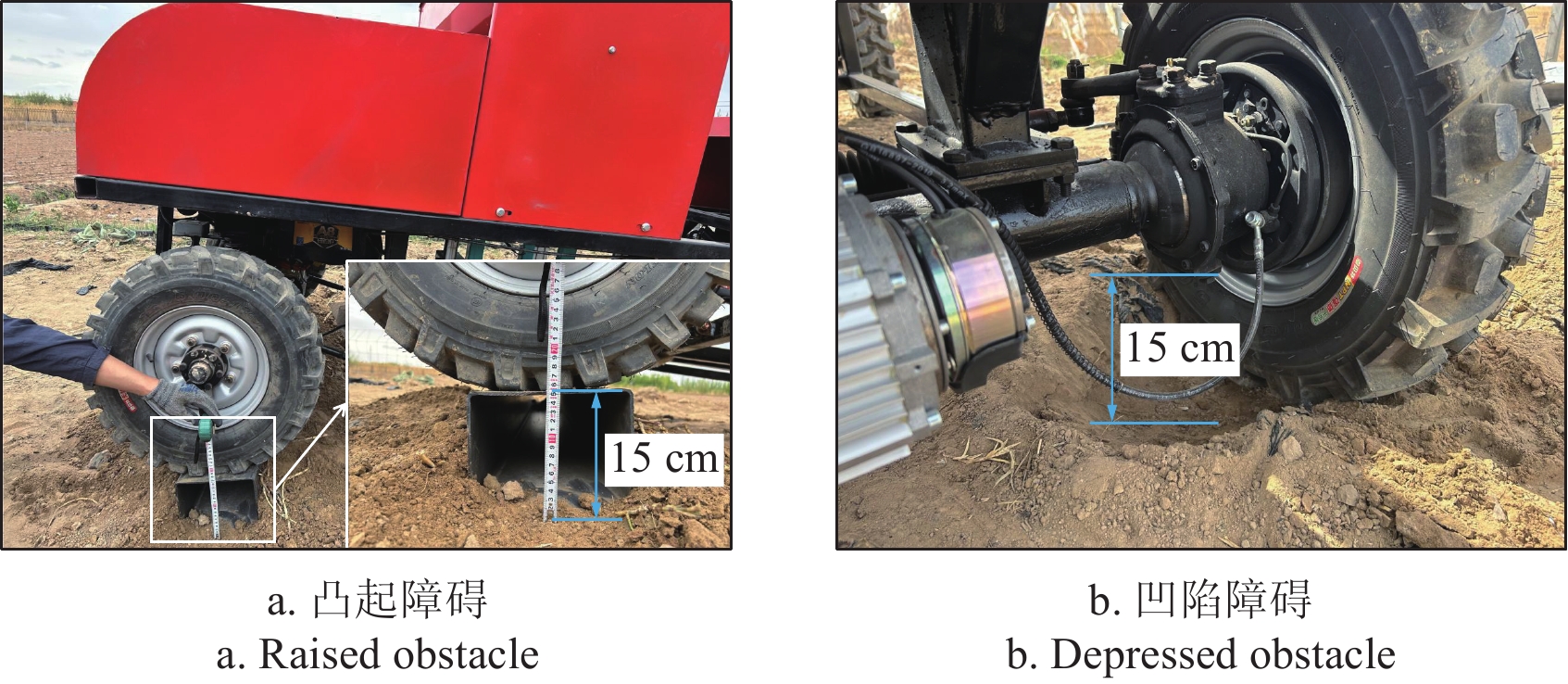

参数Parameters 数值Values 长×宽×高Length×width×height/mm×mm×mm 3000 ×1500 ×752驱动电机功率Drive motor power/kW 2.2 承载质量Load bearing/kg 900 轴距Wheelbase/mm 2380 最小离地间隙Minimum ground clearance/mm 200 最大行驶速度Maximum driving speed/(km·h−1) 7.2 外侧轮转弯半径Turning radius/m 4.65 最大遥控距离Maximum remote control distance/m 400 表 2 越障性能试验结果

Table 2 Test results of obstacle crossing performance

障碍类型

Obstacle type高度/深度

Height or depth/mm通过情况

Pass status凸起障碍

Raised obstacle60 平稳通过 90 平稳通过 120 平稳通过 150 平稳通过 凹陷障碍

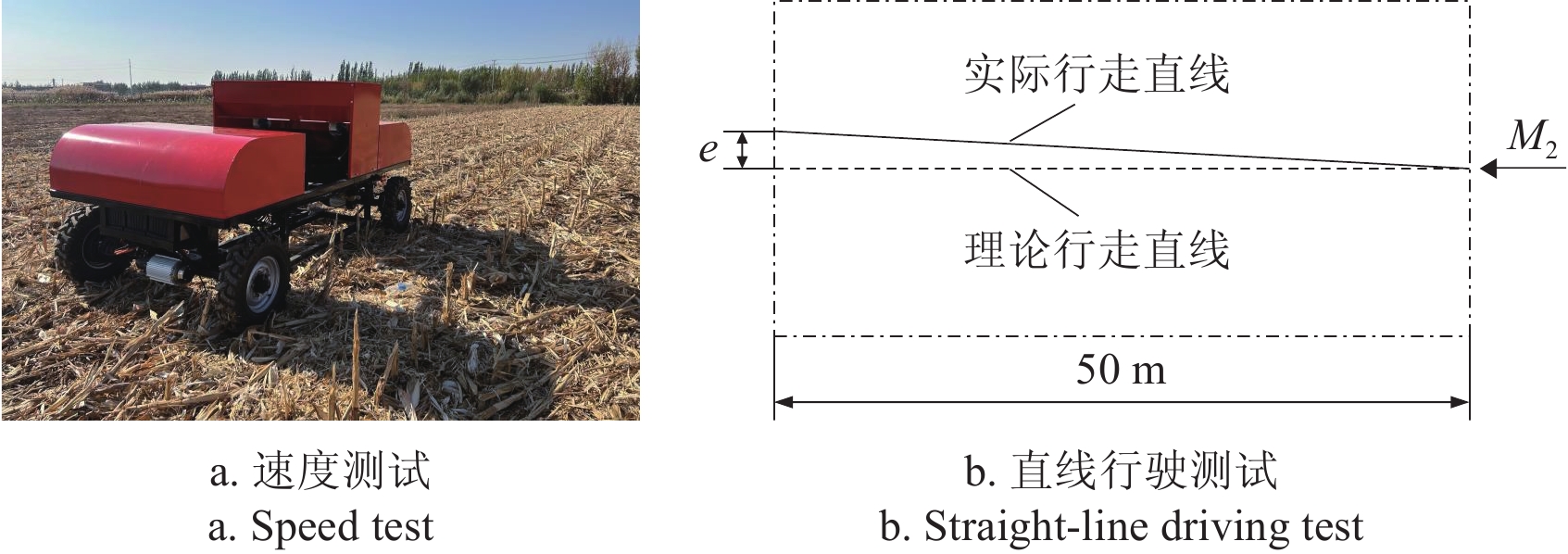

Depressed obstacle60 平稳通过 90 平稳通过 120 平稳通过 150 通过,车轮打滑,车身抖动 表 3 根茬地速度测试试验结果

Table 3 Results of speed test in stubble field

编号No. 时间Time/s 速度Velocity/(m·s−1) 1 27.03 1.480 2 27.30 1.465 3 27.53 1.453 4 27.43 1.458 5 27.60 1.449 表 4 直线行驶偏移率试验结果

Table 4 Test results of straight-line driving deviation rate

编号No. 偏移量Deviation/m 偏移率Deviation rate/% 1 2.23 4.46 2 2.33 4.66 3 2.07 4.14 表 5 不同速度和耕作条件的播深试验结果

Table 5 Test results of sowing depth under different speed and tillage

评价指标

Evaluation indicators免耕

No tillage旋耕

Rotary tillage1.0 m·s−1 1.4 m·s−1 1.0 m·s−1 1.4 m·s−1 播深合格率

Sowing depth qualified rate/%93.3 86.7 92.9 88.9 播深平均值

Average sowing depth/mm48.87 48.13 51.60 52.80 播深标准差

Standard deviation of sowing depth/mm5.50 5.62 6.06 5.60 播深变异系数

Coefficient of variation of sowing depth/%11.26 11.67 11.74 10.60 表 6 行距测量结果

Table 6 Test results of line spacing measurement

测量位置

Test location第1行

Row 1第2行

Row 2第3行

Row 3第4行

Row 4第5行

Row 5第6行

Row 6始端Beginning 67.5 67.5 68.0 74.0 70.0 − 中间Middle 70.0 69.0 67.0 70.0 73.5 − 末端End 70.0 68.0 66.0 68.0 71.0 − -

[1] 国家统计局[EB/OL]. [2024-03-31] https://data.stats.gov.cn/easyquery.htm?cn=C01. [2] 崔爱民,张久刚,张虎,等. 我国玉米生产现状及发展变革[J]. 中国农业科技导报,2020,22(7):10-19. CUI Aimin, ZHANG Jiugang, ZHANG Hu, et al. Method for recognition of grape disease based on support vector machine Preliminary exploration on current situation and development of maize production in China[J]. Journal of Agricultural Science and Technology, 2020, 22(7): 10-19. (in Chinese with English abstract)

[3] 杨光友,倪博文,李江,等. 水田作业农业机器人平台设计[J]. 农机化研究,2021,43(7):51-57. doi: 10.3969/j.issn.1003-188X.2021.07.009 YANG Guangyou, NI Bowen, LI Jiang, et al. Design of agricultural robot platform for paddy field operation[J]. Journal of Agricultural Mechanization Research, 2021, 43(7): 51-57. (in Chinese with English abstract) doi: 10.3969/j.issn.1003-188X.2021.07.009

[4] 李道亮,李震. 无人农场系统分析与发展展望[J]. 农业机械学报,2020,51(7):1-12. doi: 10.6041/j.issn.1000-1298.2020.07.001 LI Daoliang, LI Zhen. System analysis and development prospect of unmanned farming[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(7): 1-12. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2020.07.001

[5] 翟长远,杨硕,王秀,等. 农机装备智能测控技术研究现状与展望[J]. 农业机械学报,2022,53(4):1-20. doi: 10.6041/j.issn.1000-1298.2022.04.001 ZHAI Changyuan, YANG Shuo, WANG Xiu, et al. Status and prospect of intelligent measurement and control technology for agricultural equipment[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(4): 1-20. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2022.04.001

[6] 崔志超,管春松,陈永生,等. 温室用小型多功能电动履带式作业平台[J]. 农业工程学报,2019,35(9):48-57. doi: 10.11975/j.issn.1002-6819.2019.09.006 CUI Zhichao, GUAN Chunsong, CHEN Yongsheng, et al. Design of small multi-functional electric crawler platform for greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(9): 48-57. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2019.09.006

[7] 刘成良,贡亮,苑进,等. 农业机器人关键技术研究现状与发展趋势[J]. 农业机械学报,2022,53(7):1-22,55. doi: 10.6041/j.issn.1000-1298.2022.07.001 LIU Chengliang, GONG Liang, YUAN Jin, et al. Current status and development trends of agricultural robots[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(7): 1-22, 55. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2022.07.001

[8] LIN H, DONG S, LIU Z, et al. Study and experiment on a wheat precision seeding robot[J]. Journal of Robotics, 2015, 2015(1): 696301.

[9] XU Q, LI H, WANG Q, et al. Wheel Deflection control of agricultural vehicles with four-wheel independent omnidirectional steering[J]. Actuators, 2021, 10(12): 334. doi: 10.3390/act10120334

[10] 李鹏,劳彩莲,杨瀚,等. 基于移动机器人平台的玉米植株三维信息采集系统[J]. 农业机械学报,2019,50(S1):15-21. LI Peng, LAO Cailian, YANG Han, et al. Maize plant 3D information acquisition system based on mobile robot platform[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(S1): 15-21. (in Chinese with English abstract)

[11] 权龙哲,张景禹,姜伟,等. 基于玉米根系保护的株间除草机器人系统设计与试验[J]. 农业机械学报,2021,52(12):115-123. doi: 10.6041/j.issn.1000-1298.2021.12.012 QUAN Longzhe, ZHANG Jingyu, JIANG Wei, et al. Development and experiment of intra-row weeding robot system based on protection of maize root system[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(12): 115-123. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2021.12.012

[12] GREEN O, SCHMIDT T, PIETRZKOWSKI R P, et al. Commercial autonomous agricultural platform-kongskilde robotti[C]// Proceedings of the Second International Conference on Robotics, Associated High-Technologies and Equipment for Agriculture and Forestry-RHEA 2014: New trends in mobile robotics, perception and actuation for agriculture and forestry. Madrid, Spain, 2014: 351-356.

[13] AGROINTELLI [EB/OL]. [2024-03-31] https://agrointelli.com/robotti/lr/.

[14] GRIMSTAD L, FROM P J, et al. Thorvald II - a modular and re-configurable agricultural robot[J]. IFAC-Papers On Line, 2017, 50(1): 4588-4593. doi: 10.1016/j.ifacol.2017.08.1005

[15] 徐琪蒙,李洪文,何进,等. 小麦播种自走式农用移动平台设计与试验[J]. 农业工程学报,2021,37(14):1-11. doi: 10.11975/j.issn.1002-6819.2021.14.001 XU Qimeng, LI Hongwen, HE Jin, et al. Design and experiment of the self-propelled agricultural mobile platform for wheat seeding[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(14): 1-11. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2021.14.001

[16] 徐圣林,朱立成,韩振浩,等. 作物表型信息获取机器人底盘设计与试验[J]. 农业机械学报,2023,54(S2):388-399. XU Shenglin, ZHU Licheng, HAN Zhenhao, et al. Design and experiment of robot chassis for obtaining crop phenotype information[J]. Transactions of the Chinese Society for Agricultural Machinery, 2023, 54(S2): 388-399. (in Chinese with English abstract)

[17] 李善军,陈辉龙,彭际博,等. 丘陵山地果园全液压遥控式履带动力底盘设计与试验[J]. 农业机械学报,2024,55(2):119-127,201. doi: 10.6041/j.issn.1000-1298.2024.02.011 LI Shanjun, CHEN Huilong, PENG Jibo, et al. Design and test of hydraulic remote control crawler power chassis for hilly and mountainous orchards[J]. Transactions of the Chinese Society for Agricultural Machinery, 2024, 55(2): 119-127,201. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2024.02.011

[18] 王德成,赵彦瑞,尤泳,等. 履带自走式缓坡地王草收获机底盘设计与试验[J]. 农业机械学报,2023,54(9):178-187. doi: 10.6041/j.issn.1000-1298.2023.09.017 WANG Decheng, ZHAO Yanrui, YOU Yong, et al. Design and experiment of self-propelled tracked chassis of king grass harvester for gentle sloping fields[J]. Transactions of the Chinese Society for Agricultural Machinery, 2023, 54(9): 178-187. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2023.09.017

[19] 郝朝会,杨学军,刘立晶,等. 果园多功能动力底盘设计与试验[J]. 农业机械学报,2018,49(12):66-73,92. doi: 10.6041/j.issn.1000-1298.2018.12.008 HAO Zhaohui, YANG Xuejun, LIU Lijing, et al. Design and experiment of multifunctional dynamic chassis for orchard[J]. Transactions of the Chinese Society of Agricultural Machinery, 2018, 49(12): 66-73,92. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2018.12.008

[20] 吉志勇. 电动物流车车架结构设计及性能分析[D]. 太原:太原理工大学,2019. JI Zhiyong. Structural Design and Performance Analysis of Electric Logistics Vehicle Frame[D]. Taiyuan: Taiyuan University of Technology, 2019. (in Chinese with English abstract)

[21] 刘双喜,徐春保,张宏建,等. 果园开沟施肥机机架优化设计与试验[J]. 农业机械学报,2020,51(S1):113-122. doi: 10.6041/j.issn.1000-1298.2020.S1.013 LIU Shuangxi, XU Chunbao, ZHANG Hongjian, et al. Optimization design and experiment for rack of orchard ditching-fertilizer machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(S1): 113-122. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2020.S1.013

[22] LITTLE J, ADAM C. Geometric sensitivity of patient-specific finite element models of the spine to variability in user-selected anatomical landmarks[J]. Computer Methods in Biomechanics and Biomedical Engineering, 2015, 18(6): 676-688. doi: 10.1080/10255842.2013.843673

[23] 蒙建国,杨国欣,王亮,等. 基于TRIZ理论的马铃薯联合收获机机架设计与分析[J]. 内蒙古科技大学学报,2023,42(3):210-214. MENG Jianguo, YANG Guoxin, WANG Liang, et al. Design and analysis of potato combine harvester frame based on TRIZ theory[J]. Journal of Inner Mongolia University of Science and Technology, 2023, 42(3): 210-214. (in Chinese with English abstract)

[24] 邵文洋,张袁元,郭世杰,等. 基于CATIA和ANSYS的可伸缩车车架强度仿真分析[J]. 机电工程技术,2024,53(2):187-192. SHAO Wenyang, ZHANG Yuanyuan, GUO Shijie, et al. Scalable vehicle frame strength simulation analysis based on CATIA and ANSYS[J]. Mechanical & Electrical Engineering Technology, 2024, 53(2): 187-192. (in Chinese with English abstract)

[25] 任德志,于浩林,张任,等. 榛子捡拾收获机分选装置拓扑优化设计与模态分析[J]. 农机化研究,2024,46(5):19-25. doi: 10.3969/j.issn.1003-188X.2024.05.004 REN Dezhi, YU Haolin, ZHANG Ren, et al. Topology optimization design and modal analysis of hazelnut picking and sorting machine[J]. Journal of Agricultural Mechanization Research, 2024, 46(5): 19-25. (in Chinese with English abstract) doi: 10.3969/j.issn.1003-188X.2024.05.004

[26] 郭俊先,刘颖灿,魏远俊,等. 秸秆还田残膜回收一体机振动特性分析与结构优化[J]. 农业工程学报,2024,40(2):155-163. doi: 10.11975/j.issn.1002-6819.202308013 GUO Junxian, LIU Yingcan, WEI Yuanjun, et al. Vibration characteristics analysis of the optimal structure of integrated straw returning and residual film recycling machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2024, 40(2): 155-163. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.202308013

[27] 黄小珊,王增辉,姜鑫铭,等. 指夹式排种器振动模拟与试验分析[J]. 农机化研究,2019,41(4):149-153. doi: 10.3969/j.issn.1003-188X.2019.04.027 HUANG Xiaoshan, WANG Zenghui, JIANG Xinming, et al. Vibration simulation and experimental analysis of picker finger seedmeter[J]. Journal of Agricultural Mechanization Research, 2019, 41(4): 149-153. (in Chinese with English abstract) doi: 10.3969/j.issn.1003-188X.2019.04.027

[28] 陈振,吴春笃,张波,等. 无人驾驶替代农药喷雾车机架动静态特性分析[J]. 农业装备与车辆工程,2022,60(7):10-14. doi: 10.3969/j.issn.1673-3142.2022.07.003 CHEN Zhen, WU Chundu, ZHANG Bo, et al. Analysis of dynamic and static characteristics of unmanned alternative pesticide spraying vehicle frame[J]. Agricultural Equipment & Vehicle Engineering, 2022, 60(7): 10-14. (in Chinese with English abstract) doi: 10.3969/j.issn.1673-3142.2022.07.003

[29] 王奇,朱龙图,李名伟,等. 指夹式玉米免耕精密播种机振动特性及对排种性能的影响[J]. 农业工程学报,2019,35(9):9-18. doi: 10.11975/j.issn.1002-6819.2019.09.002 WANG Qi, ZHU Longtu, LI Mingwei, et al. Vibration characteristics of corn no-tillage finger-type precision planter and its effect on seeding performance[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(9): 9-18. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2019.09.002

[30] 李博誉. 丘陵地带拖曳助力运输车的研制与试验研究[D]. 杭州:浙江科技大学,2024. LI Boyu. Development and Experimental Research of Towing Power Assisted Transport Vehicles in Hilly Areas[D]. Hangzhou: Zhejiang University of Science and Technology, 2024. (in Chinese with English abstract)

[31] 毛家稳,周俊,梁洋洋. 电驱动高地隙车辆滑移率滑模控制研究[J]. 中国农业大学学报,2017,22(2):129-134. doi: 10.11841/j.issn.1007-4333.2017.02.016 MAO Jiawen, ZHOU Jun, LIANG Yangyang. Research on sliding mode control of slip rate for electric high-clearance vehicle[J]. Journal of China Agricultural University, 2017, 22(2): 129-134. (in Chinese with English abstract) doi: 10.11841/j.issn.1007-4333.2017.02.016

[32] 韩明兴,徐琨,廖宜涛,等. 液电混动履带底盘电液系统联合仿真与试验[J]. 农业机械学报,2024,55(1):396-408,418. doi: 10.6041/j.issn.1000-1298.2024.01.038 HAN Mingxing, XU Kun, LIAO Yitao, et al. Co-simulation and test of electro-hydraulic system for novel hybrid track[J]. Transactions of the Chinese Society of Agricultural Machinery, 2024, 55(1): 396-408,418. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2024.01.038

[33] ZHAI C, LONG J, TAYLOR R, et al. Field scale row unit vibration affecting planting quality[J]. Precision Agriculture, 2020, 2020(21): 589-602.

[34] KUS E. Field-scale evaluation of parameters affecting planter vibration in single seed planting[J]. Measurement, 2021, 184: 109959. doi: 10.1016/j.measurement.2021.109959

[35] GAO Y, YANG Y, HU Y, et al. Study on operating vibration characteristics of different no-tillage planter row units in wheat stubble fields[J]. Agriculture, 2024, 14(11): 1878. doi: 10.3390/agriculture14111878

[36] 中华人民共和国农业部. 玉米免耕播种机 作业质量:NY/T1628-2008[S]. 北京:中国标准出版社,2008. [37] 中华人民共和国农业部. 玉米免耕播种机 质量评价技术规范:NY/T1768-2009[S]. 北京:中国标准出版社,2009. [38] 姜鑫铭. 玉米免耕播种机精确播种关键技术研究[D]. 长春:吉林大学,2017. JIANG Xinming. Study on Key Technologies of Precision Seeding for Maize No-tillage Planter[D]. Jinlin: Jilin University, 2017. (in Chinese with English abstract)

[39] 中华人民共和国工业和信息化部. 单粒(精密)播种机技术条件:JB/T10293-2013[S]. 北京:机械工业出版社,2013. -

期刊类型引用(1)

1. 郭伟玲,徐刘洋,贾纪昂,高畅,夏小林,汪邦稳,张靖雨,陈磊,陈应健. 耦合PLUS-CSLE模型预测淮河流域多情景土地利用变化与土壤侵蚀. 水土保持学报. 2024(06): 234-243+252 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: