Analysis and test of black fungus stick piercing and laying falling process based on discrete element

-

摘要:

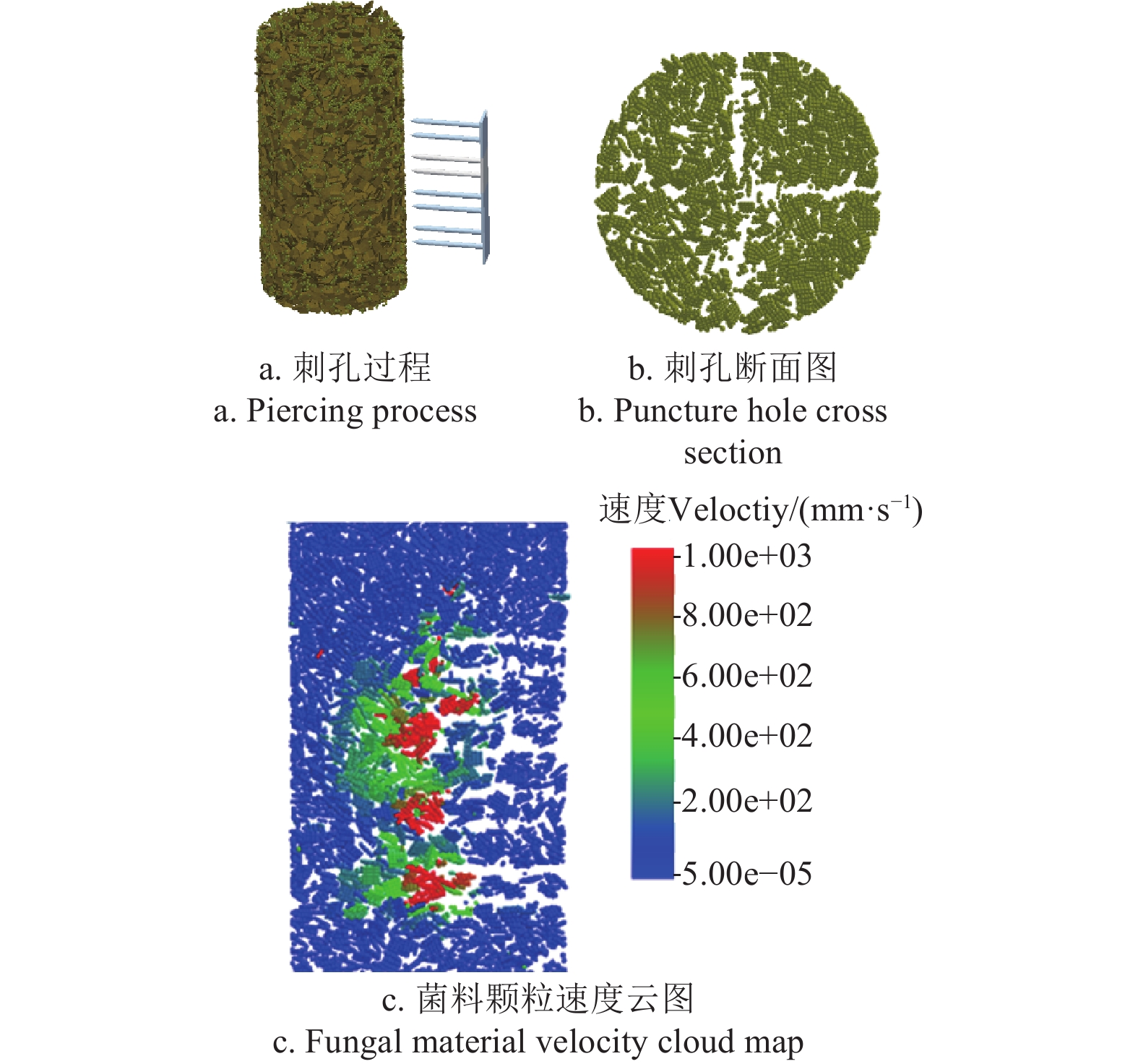

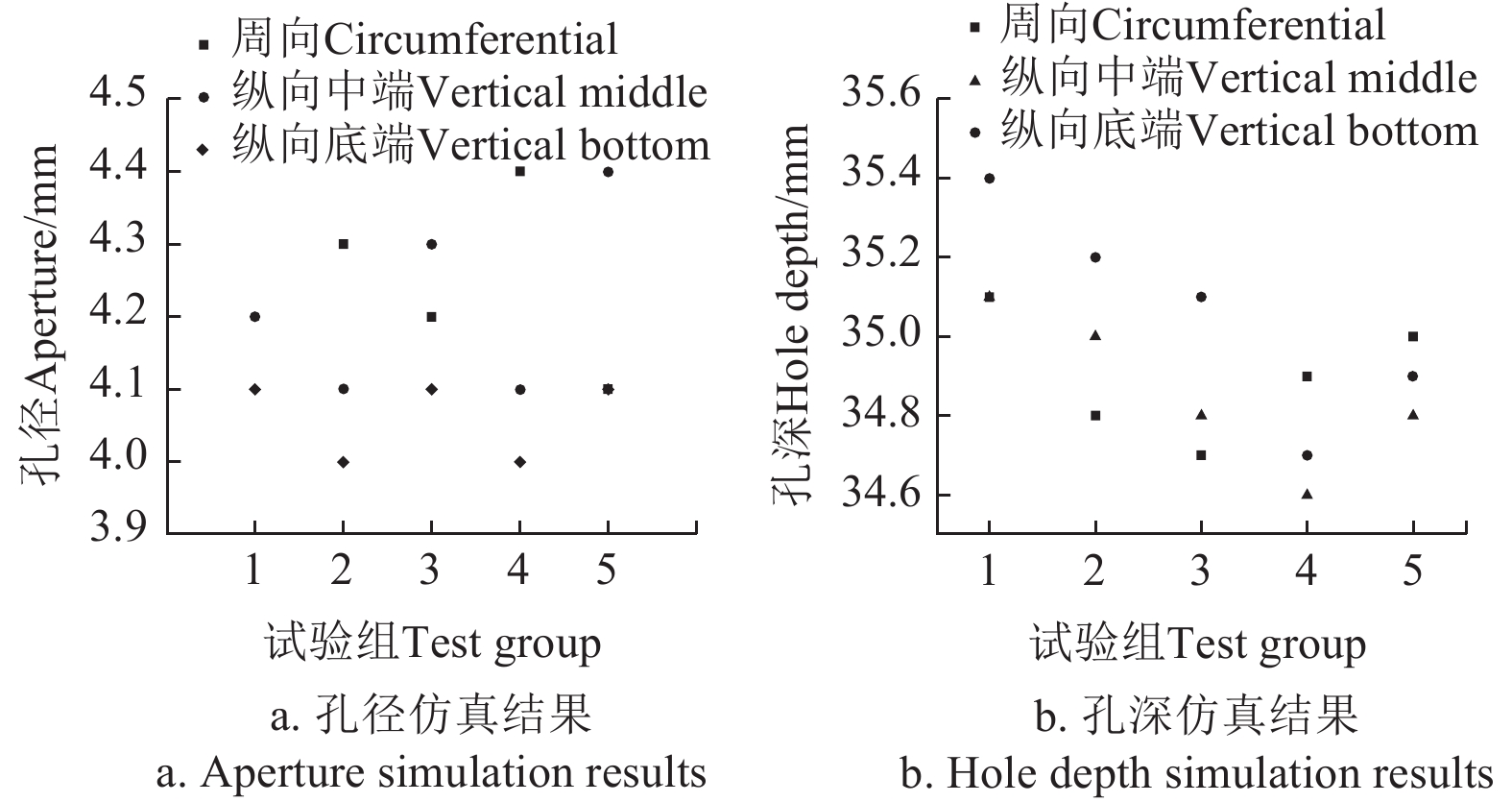

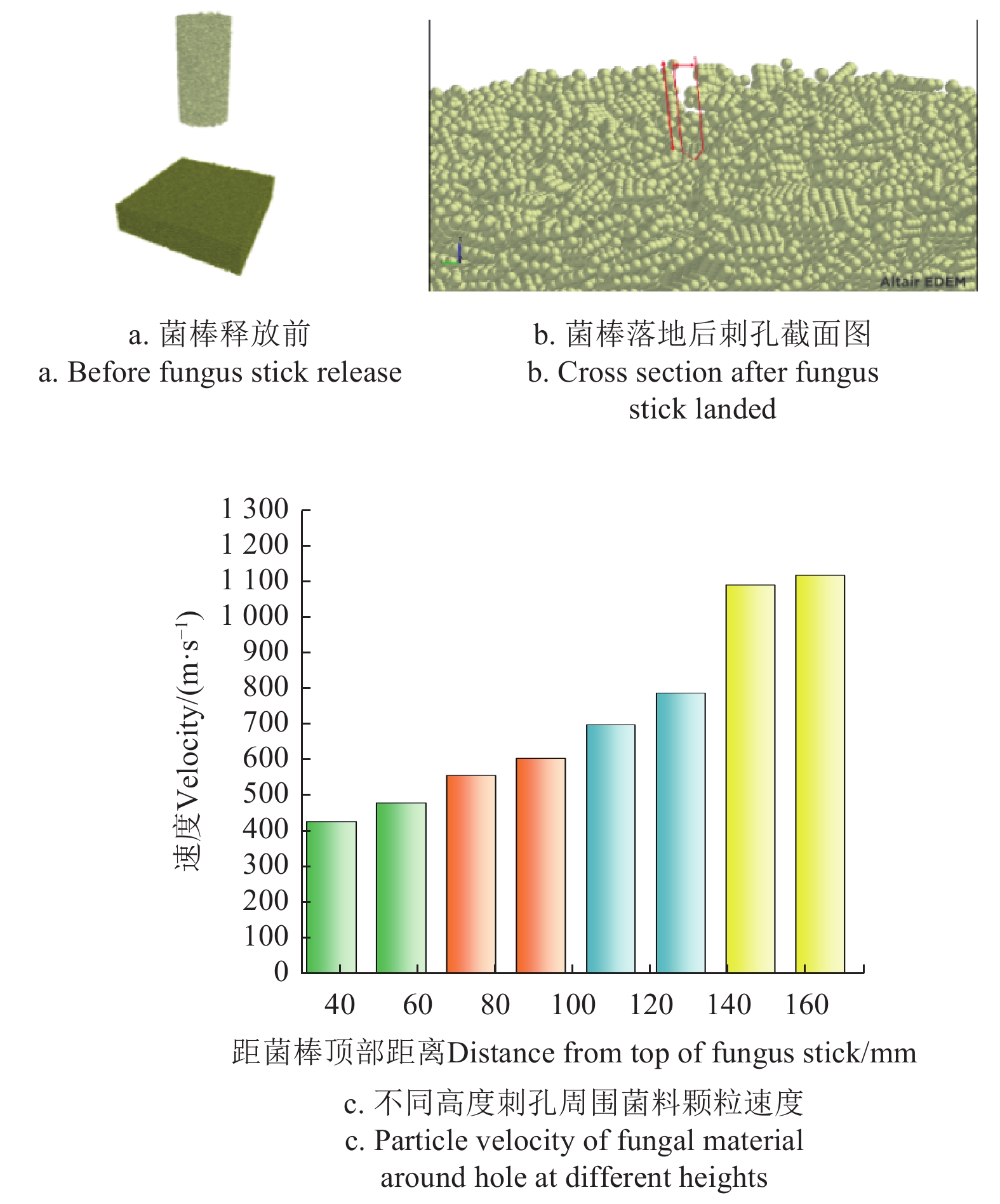

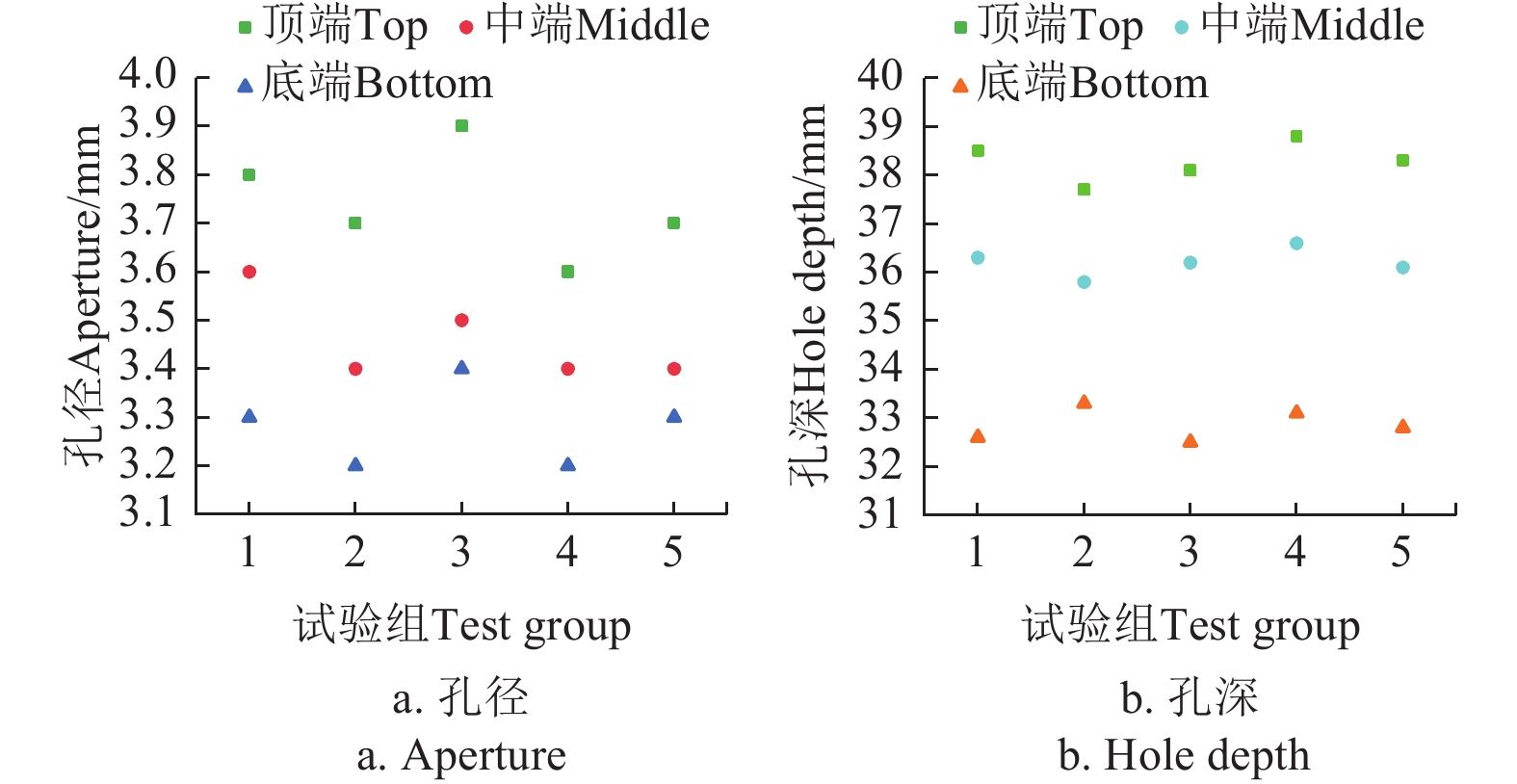

针对黑木耳菌棒在刺孔和摆场作业时内部菌料运动难以观测的问题,同时为实现准确模拟菌料受载情况和运动规律,该研究基于离散元法对菌棒内不同尺寸菌料的本征参数与接触参数进行标定,通过测定菌料参数,基于堆积角最优参数组合,进行菌棒刺孔仿真与实验,仿真与试验结果的孔深相对误差和孔径相对误差分别为3.6%和4.5%,验证了仿真的有效性。为了评估落地冲击对菌棒出耳孔变形的影响,模拟半自动摆场机工作时菌棒下落的过程,得到相较于顶端出耳孔,底端出耳孔孔径和孔深分别减小12.3%和14.3%,表明落地冲击使菌棒不同高度部位出耳孔变形呈现出自下而上逐渐减弱,底端出耳孔的变形最大。仿真得到孔径和孔深最小值分别为3.2和32.5 mm,满足发耳要求。

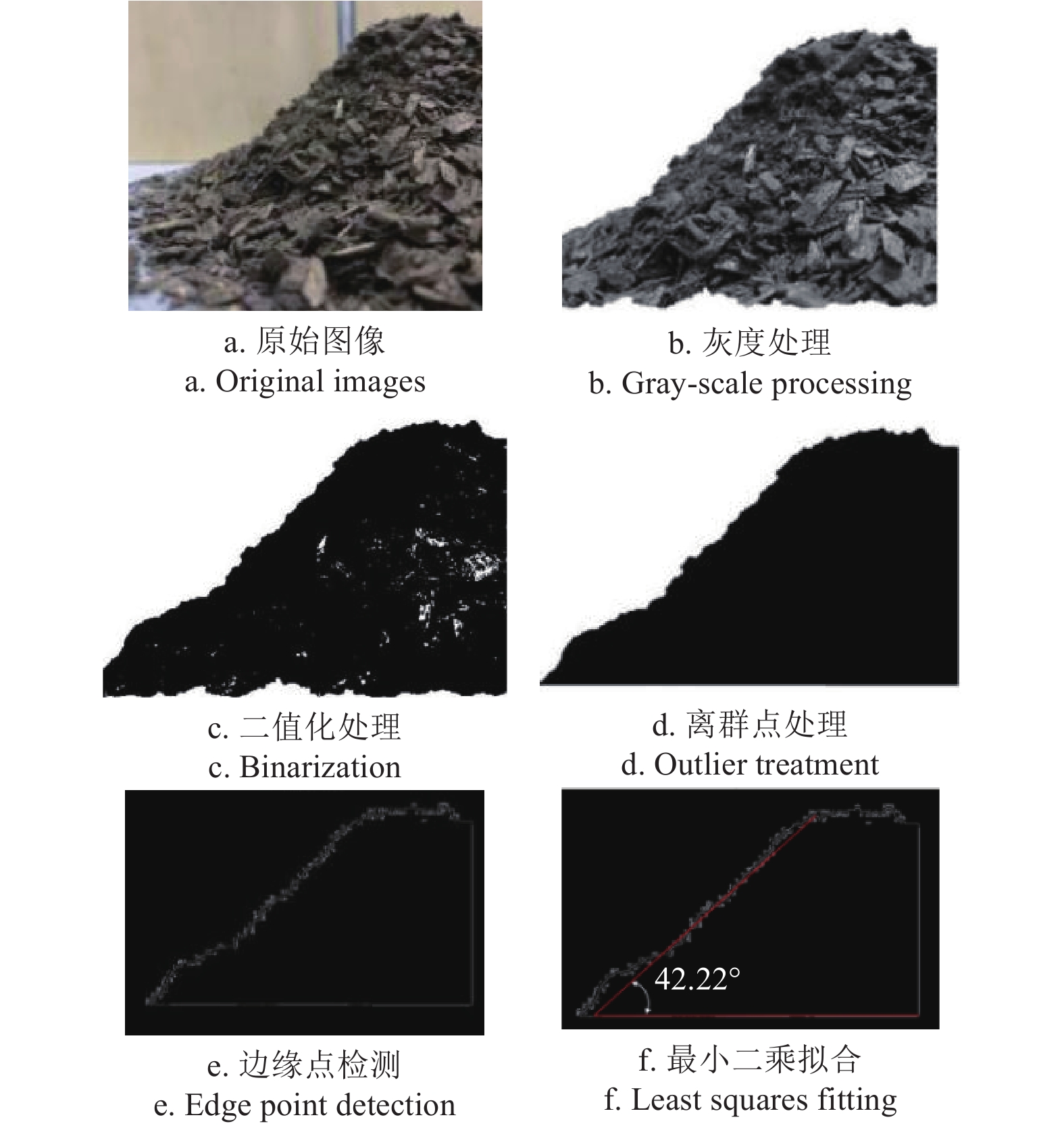

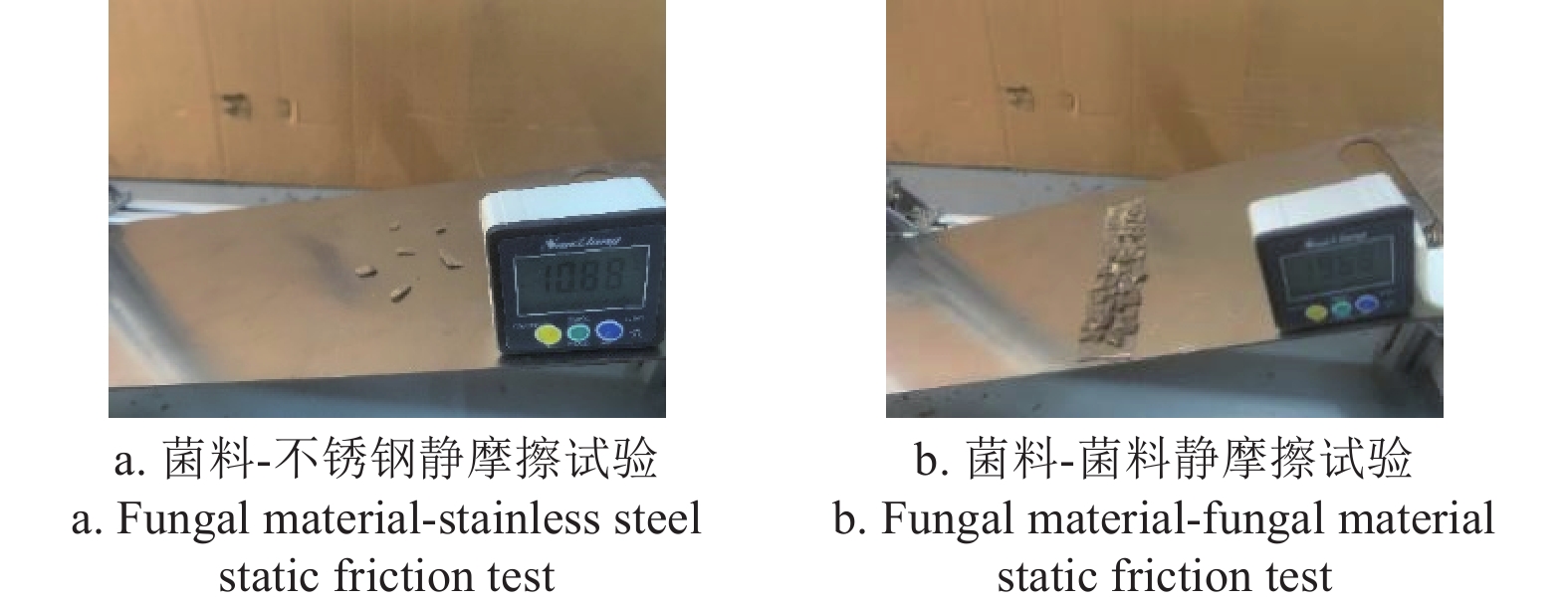

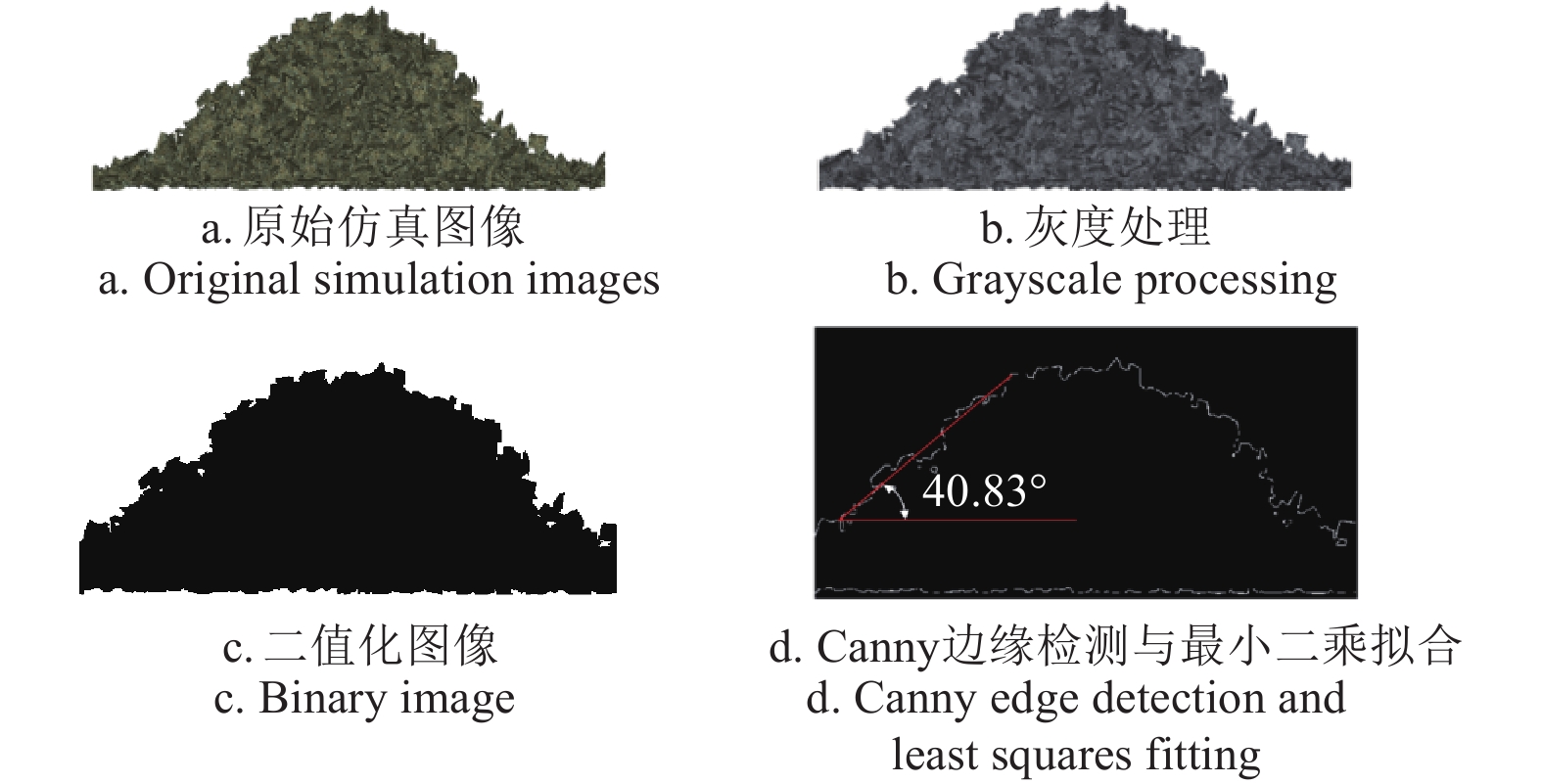

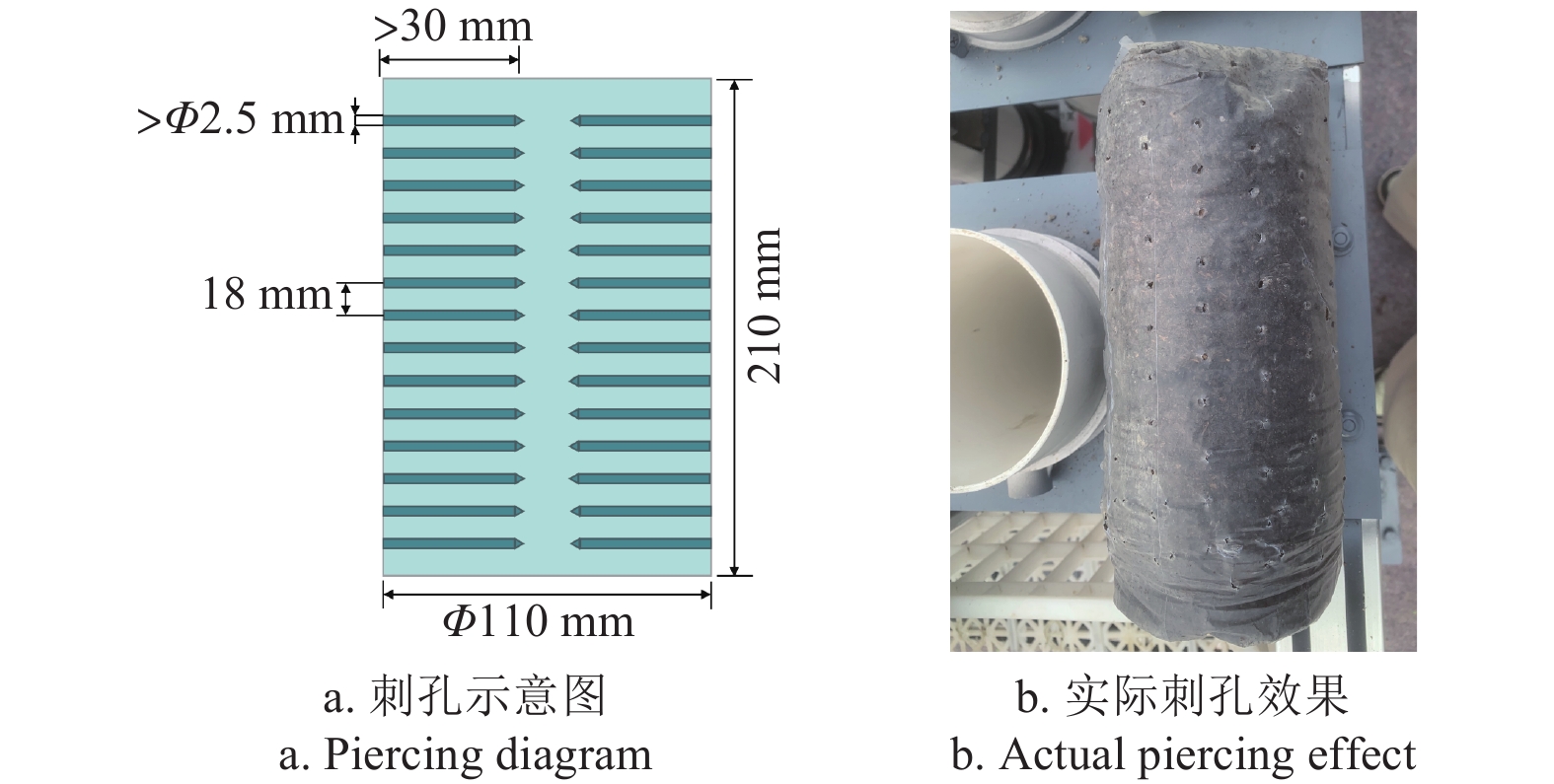

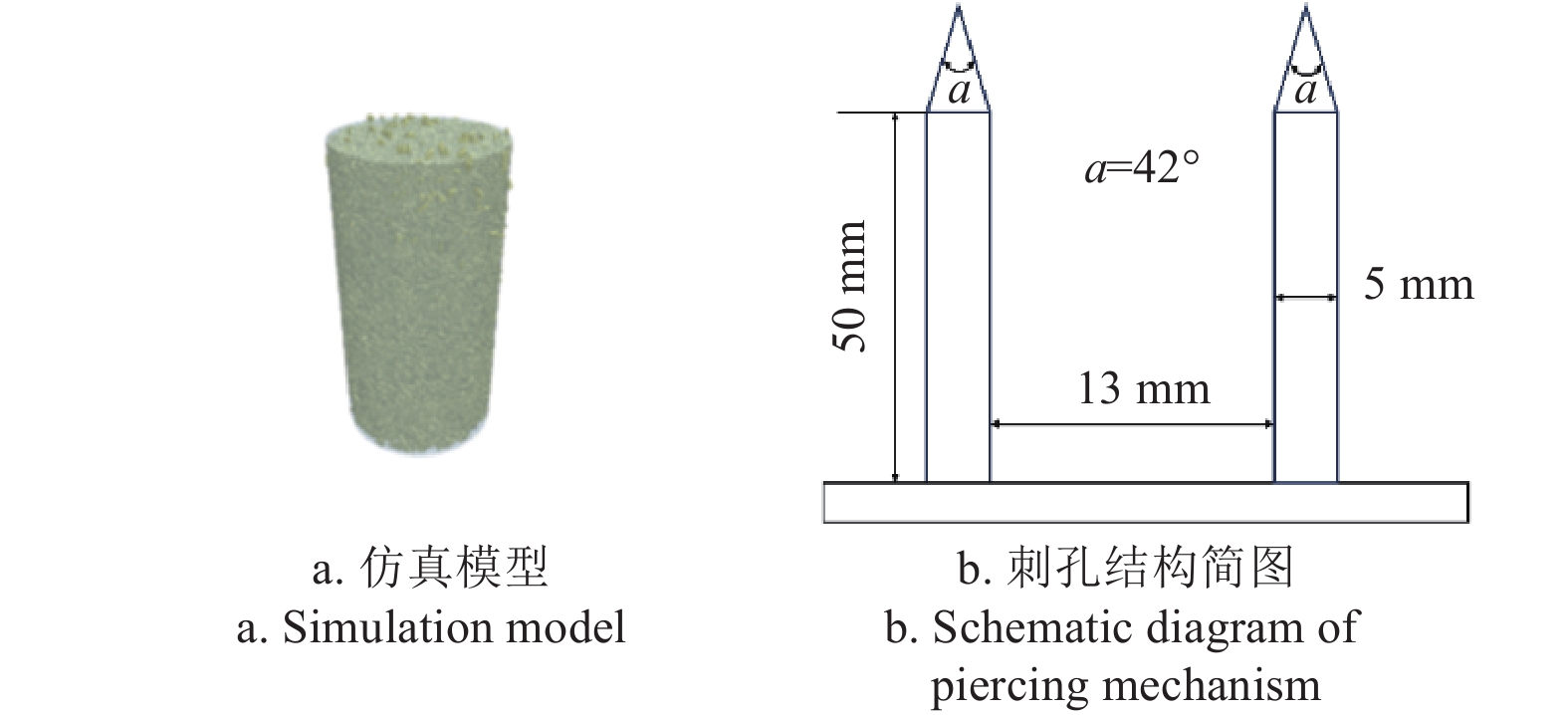

Abstract:This study aims to observe and simulate the internal movement of fungal material substrate during the piercing and laying of black fungal sticks using the discrete element method (DEM). The contact parameters of fungi were calibrated on the different sizes within the cultivation sticks. Key parameters, such as particle stiffness, friction coefficients, and damping factors, were adjusted to replicate the interactions among fungal particles. DEM simulations were used to accurately reflect real-world mechanical behavior. Both physical experiments and DEM simulations were conducted on piercing after calibration. The physical experiments were conducted to measure the key substrate parameters, particularly for the influences of repose angle on the substrate settles. The DEM simulations were fine-tuned to closely match the real-life scenarios after measurements. In simulations, virtual tools were inserted into the modeled fungal sticks, in order to observe substrate behavior under controlled conditions. The comparison was performed on the depth and diameter of the holes created during piercing, in order to validate the accuracy of the DEM model. The simulation results were compared with experimental data obtained from a fully automatic piercing machine. The relative errors between the simulation and experimental data were 3.6% for the hole depth and 4.5% for the hole diameter. The low error margins confirmed that the high accuracy of the model was achieved to replicate the real-world conditions, providing for the reliability of the DEM model in the subsequent simulations. In addition to the piercing simulations, a systematic investigation was also made to explore the impact of landing shock on the deformation of fruiting holes within the fungal sticks. The falling behavior of fungal sticks was simulated in a semi-automatic laying machine. Displacement velocities of substrate particles around the ear holes were measured at three positions along the fungal stick: the top, middle, and bottom. The velocities were recorded as 441, 621, and 1 115 mm/s, respectively. There was the most significant deformation at the bottom of the stick and then decreased towards the top. The diameter and depth of the bottom ear holes were 12.3% and 14.3% smaller, respectively, compared with the top ones. The minimum aperture diameter and depth were 3.28 and 32.9 mm after simulation, respectively, fully meeting the requirements for ear production. Therefore, the fungal sticks remained suitable for agricultural use, even after deformation under landing shock. The semi-automatic laying machine was effective with the acceptable deformation for practical agricultural production. In conclusion, the DEM model was validated to accurately simulate the piercing and laying in the internal movement of fungal material within black fungal sticks. The insights were gained on the deformation caused by landing shock. The findings can greatly contribute to the design and operation of machinery in mushroom cultivation. The quality and functionality of fungal sticks were maintained throughout the production. The DEM model can be expected to improve agricultural practices in mushroom cultivation.

-

Keywords:

- discrete element method /

- simulation /

- parameter calibration /

- fungal stick /

- piercing /

- black fungus

-

0. 引 言

土壤胶体是土壤组成中最为微小、最为活跃的组分,通常是有机组分与矿物组分相互吸附胶结形成的复合体[1]。其表面的电化学性质(电荷数量、比表面积、电荷密度以及电场强度)深刻地影响着土壤中离子的吸附解吸、元素的迁移转化以及水动力特征等一系列土壤物理和化学过程,进而影响到土壤水肥保持、土壤侵蚀、污染物防治以及农业面源污染等问题[2-4]。因此,深入研究土壤表面电化学性质对土壤的可持续利用和生态环境保护具有重要意义。

土壤的电化学性质既受气候、环境、植被及施肥方式等诸多外部因素的影响,又受土壤的矿物组成、有机质、pH值、黏粒等内部因素的影响[5-6]。在农田生态系统中,施用有机肥是提高土壤肥力水平、改善土壤环境的有效措施。有机肥可通过2种方式对土壤表面电化学性质产生影响,一方面,施用有机肥可以提高土壤结构的稳定性,促进土壤黏化过程,减小黏粉颗粒的流失[7-8],黏粉粒的富集有效增加土壤的电荷数量和比表面积;另一方面,有机肥可提高土壤有机质的含量,有机质自身带有大量的可变电荷,可有效地改变土壤表面电化学性质[9]。当然,有机肥进入土壤中后会形成颗粒态有机物和矿物质结合态有机物,颗粒态有机物是未分解或半分解状态的有机残体,易分解,生物活性较高;矿物质结合态有机物多为腐殖化的有机物质,与土壤矿物相结合,性质较为稳定[10]。这些不同组分的有机碳在土壤颗粒的团聚、有机质的周转、肥力提升等过程中具有重要作用[11]。相关研究认为,相比与颗粒态有机物,矿物质结合态有机物对土壤表面电化学性质的影响更为重要[12]。土壤矿物质结合态有机物组分既包含了比表面积和表面电荷数量较大的黏土矿物,还包含了土壤中绝大部分的腐殖物质。并且,这些腐殖物质与黏土矿物相互作用,形成性质各异的有机-无机复合体,进而改变了土壤表面电化学性质[13]。不同类型的有机物进入土壤后的腐殖化过程以及形成的腐殖物质并不相同,例如腐殖物质的芳香度、官能团种类、有机碳链大小都会直接影响其与黏土矿物的吸附过程以及有机-无机复合体的稳定性[14],但是关于腐殖物质的特性和官能团类型与土壤表面电化学性质之间的内在关系并不清晰,制约全面了解有机培肥措施对土壤表面电化学性质的影响机制。

本文基于16 a的有机肥和秸秆还田的定位培肥试验,分析了土壤表面电化学性质、机械组成、有机碳组分、矿物质结合态腐殖质的光学特性等指标,并利用X射线光电子能谱仪分析了腐殖质-矿物复合体表面的官能团组成,揭示施用有机肥和秸秆还田的培肥措施下土壤表面电化学性质的变化,探究土壤环境因子(如pH值、EC、机械组成)、有机碳组分以及矿物质结合态腐殖质结构特性对土壤表面电化学性质的影响机制,以期为不同培肥模式措施对土壤电化学的影响机制研究以及合理的培肥方案提供科学依据。

1. 材料与方法

1.1 试验区概况与试验设计

试验设在山西省运城市山西农业大学水头试验基地,试验地属暖温带大陆性季风气候,年均气温13.4℃,年均降雨量525 mm,雨热同期,日照时长2040 h,无霜期212 d,试验区土壤类型为褐土,试验前土壤耕层基础肥力为:有机质含量10.9 g/kg,速效氮含量89.6 mg/kg,速效磷含量13.1 mg/kg,速效钾167 mg/kg,pH值为8.4。试验开始于2007年,共设置4个施肥处理:单独施用化肥(F)、有机肥+化肥(MF)、秸秆还田+化肥(SF)以及秸秆还田+有机肥+化肥(MSF)。每个施肥处理3次重复,小区面积为60 m2。化肥为尿素(N 46%)和重过磷酸钙(P2O5 46%),施用量分别为165 N kg/hm2和150 P2O5 kg/hm2;有机肥为腐熟的鸡粪,有机质含量21%,于小麦播种前施入MF和MSF处理,施用量为15 t/hm2。每年6月小麦收获后,SF和MSF处理的秸秆粉碎全量还田,F和MF处理的秸秆移除试验田。

1.2 样品采集与分析

1.2.1 土壤样品采集

于2023年6月小麦收获后五点法采集各小区0~20 cm土层的土壤样品,除去可见的石块、植物残渣等杂物,自然风干后过2 mm和0.15 mm筛,用于土壤理化性质和有机碳分组的测定。

1.2.2 土壤基本理化性质的测定

土壤总有机碳含量采用重铬酸钾氧化-硫酸亚铁滴定法测定;土壤全氮含量采用半微量凯氏法测定;有效磷含量采用0.5 mol/L碳酸氢钠溶液浸提,钼锑抗比色法测定;速效钾含量采用1 mol/L乙酸铵溶液浸提,火焰光度法测定;土壤pH和电导率采用电极法测定,水土比为2.5∶1;土壤黏粒、粉粒和砂粒含量采用激光粒度分析仪(Mastersizer 2000)测定。

1.2.3 土壤有机碳分组的测定

称取过2 mm筛的土壤样品20 g,加入100 mL去离子水,振荡离心,上清液过0.45 μm滤膜,滤液采用TOC自动分析仪测定含碳量,即为土壤可溶性有机碳的含量。向残留的土壤中加入100 mL浓度为0.5%的六偏磷酸钠溶液,振荡后过0.053 mm的标准筛,残留在筛中的残渣为颗粒态有机碳,采用元素分析仪(vario PYRO cube Elementar Analyser)测定含碳量,过滤的土壤残渣在45℃条件下烘干,即为重组土样。称取5.0 g的上述重组土样,加入50 mL浓度为0.1 mol/L氢氧化钠和0.1 mol/L焦磷酸钠的混合溶液,振荡离心,上清液即为腐殖质溶液,调节腐殖质溶液pH值,分离获得胡敏酸和富里酸,采用重铬酸钾氧化法测定上述腐殖质、胡敏酸含量,富里酸含量由腐殖质与胡敏酸含量相减获得[15]。

1.3 土壤表面化学性质测定与计算

1.3.1 土壤表面化学性质测定

根据土壤表面性质联合测定的方法[16-17],首先制备氢饱和土壤样品,向200 g土壤样品中加入2 L浓度为0.2 mol/L的HCl溶液,振荡24 h,离心弃去上清液,继续重复上述过程3次,向离心后的土样中加入2 L的去离子水,振荡离心,将离心后的土样在45℃条件下烘干,研磨过0.25 mm筛,获得氢饱和土壤样品。然后称取5 g上述氢饱和土壤样品,加入50 mL浓度为0.01 mol/L Ca(OH)2和NaOH混合溶液,振荡24 h后测其pH值,根据pH值继续加入氢饱和土壤样品或Ca(OH)2和NaOH混合溶液(pH值>10,加入氢饱和土壤样品;pH值<9,加入Ca(OH)2和NaOH混合溶液),振荡直至悬浮液pH值在9~10之间。然后用浓度为0.1 mol/L的HCl溶液调节土壤悬浮液pH值至7左右,离心,测定上清液Ca和Na离子浓度。

1.3.2 土壤表面化学性质计算

表面电位φ0(mV):

φ0=2RT2(βCa−βNa)Flna0CaNNaa0NaNCa (1) 表面电荷密度σ0(c/m2):

σ0=sgn(φ0)√εRT2π(a0NaeβNaFφ0RT+a0Cae2βCaFφ0RT) (2) 表面电场强度E0(V/m):

E0=4πεσ0 (3) 比表面积S(m2/g):

S=NNaκma0NaeβNaFφ02RT=NCaκma0CaeβCaFφ0RT (4) 表面电荷数量XSCN(cmol/kg):

SCN=105Sσ0F (5) κ为德拜参数(L/dm):

κ=√8πF2C0εRT (6) 式中T为绝对温度,K;R为理想气体常数,J/(K·mol);F为为法拉第常数,C/mol;βNa和βCa分别为Na+和Ca2+的有效电荷系数;a0Na和a0Ca分别为Na+和Ca2+的活度,mol/L;NNa和NCa分别为Na+和Ca2+在土壤中的吸附量,mol/g;ε为水的介电常数,8.9×10−9,C2/(J·dm);m=0.525 9ln(c0Na/c0Ca)+1.992;c0Na和c0Ca分别为溶液中 Na+和Ca2+浓度。

1.4 土壤腐殖质结构特性测定

1.4.1 X射线光电子能谱仪(XPS)测定

对腐殖质提取前的重组土壤颗粒进行XPS(UIVAC-PHI5000 Versa Probe)测试,定量分析土壤颗粒表面有机碳的结构组成。将1.2.3中的重组土壤颗粒进行XPS扫描,获取C(1s)高分辨光谱,用脂肪碳(284.5 eV)进行校准,C (1s)结合能的特征为:287.8 eV为C=O/C(O)N,286.7 eV为C-O-C,286.2 eV为C-O/C-N,285 eV为C-C/C-H,284.4 eV为C=C。利用软件XPS peak 41对光谱进行分峰拟合,并获得上述有机官能团的峰面积,然后根据峰面积计算其相对含量。

1.4.2 土壤腐殖质光学性质的测定

腐殖质的光学特性用色调系数(ΔlgK)和光密度(E4/E6)来表示,即ΔlgK和E4/E6的值越高,表明腐殖质的分子量越小,分子结构越简单[18]。利用紫外分光光度计(723型分光光度计)测定腐殖质在400、465、600和665 nm处的吸光值,并计算ΔlgK和E4/E6值。

ΔlgK=lgK400−lgK600 (7) E4/E6=K465/K665 (8) 式中K400、K465、K600和K665分别为在波长400、465、600和665 nm处的吸光值。

1.5 数据处理

采用SPSS 24.0软件单因素方差分析(One-way ANOVA)对不同施肥处理之间的土壤基本性质、土壤表面电化学性质、有机碳组分等指标进行显著性比较(Duncan, P<0.05),运用Canoco 5软件对土壤表面电化学性质和有机碳组分间的关系进行冗余分析,采用Origin 2018软件进行绘图。

2. 结果与分析

2.1 不同施肥处理对土壤基本理化性质的影响

不同施肥处理对土壤理化性质有显著影响(表1)。与不施肥处理(F)相比,有机肥处理(MF)、秸秆还田处理(SF)和有机肥+秸秆还田处理(MSF)显著提高了土壤全氮、有效磷、速效钾含量,其中以MSF处理最高。各处理对土壤pH值无显著影响,而MSF处理的EC值较F和SF处理分别提高了31.3%和24.1%。各处理对土壤黏粒和粉粒含量无显著影响,但MSF处理的砂粒含量显著低于F处理。

表 1 不同施肥处理对土壤基本性质的影响Table 1. Effects of different fertilization treatments on the basic properties of soils处理

Treatments全氮

Total nitrogen/

(g·kg−1)有效磷

Available phosphorus/

(mg·kg−1)速效钾

Available potassium/

(mg·kg−1)pH值

pH value电导率

Electrical conductivity

EC/(µs·cm−1)黏粒质量分数

Clay mass

fraction/%粉粒质量分数

Silt mass fraction /%砂粒质量分数

Sand mass

fraction /%F 0.97±0.06c 63.1±19.1b 104.3±16.3c 8.2±0.1a 126.7±14.0b 19.6±0.4a 29.1±0.5a 51.3±0.9a SF 1.62±0.06b 191.4±27.2a 190.7±52.4ab 8.1±0.1a 134.1±14.3b 19.8±0.5a 29.6±0.9a 50.5±0.9ab MF 1.42±0.25b 68.4±4.1b 152.7±14.5bc 8.2±0.1a 155.7±4.9ab 20.0±0.2a 30.0±0.8a 50.0±0.8ab MSF 1.80±0.31a 252.5±117.2a 220.7±26.7a 8.2±0.2a 166.4±23.1a 20.4±0.5a 30.3±0.5a 49.3±0.5b 注:数据为平均值±标准差(n=3),同列数据后不同小写字母表示处理间差异显著(P<0.05)。F、SF、MF和MSF分别代表单独施用化肥、秸秆还田+化肥、有机肥+化肥以及秸秆还田+有机肥+化肥处理。下同。 Note: The data are means ± standard error (n=3). Values followed by different lowercase letters in the same column are significantly different (P<0.05). F, SF, MF, and MSF indicate chemical fertilizer, straw returning + chemical fertilizer, organic fertilizer + chemical fertilizer, straw returning + organic fertilizer + chemical fertilizer, respectively. Same as below. 2.2 不同施肥处理对土壤表面电化学性质的影响

不同施肥处理对土壤表面电化学性质有显著影响(表2)。各施肥处理的土壤表面电荷密度变幅为0.20~0.25 c/m2,其中SF、MF和MSF处理均显著高于F处理。

表 2 不同施肥处理对土壤表面电化学性质的影响Table 2. Effects of different fertilization treatments on soil surface electrochemical properties处理

Treatments表面电荷密度

Surface charge density

σ0/(c·m−2)表面电场强度

Surface electric field intensity

E0/(108 V·m−1)比表面积

Specific surface area

S/(m2·g−1)表面电荷数量

Surface charge number

SCN/(cmol·kg−1)表面电位

Surface potential

φ0/(mV)F 0.20±0.00b 1.46±0.11 d 57.52±2.85b 11.70±0.46c −81.40±2.04c SF 0.22±0.00a 2.58±0.61c 60.61±4.05ab 14.09±1.48b −86.00±2.10b MF 0.23±0.00a 4.24±0.39b 62.92±5.12ab 15.14±0.29b −87.83±1.55ab MSF 0.25±0.00a 5.12±0.44a 67.02±2.65a 17.07±0.97a −91.14±1.59a 各施肥处理的土壤表面电场强度变幅为1.46×108~5.12×108 V/m,且各处理的表面电场强度大小排序为MSF、MF、SF、F。各施肥处理的土壤比表面积变幅为57.52~67.02 m2/g,其中MSF处理最高,较F处理显著提高了16.5%。各施肥处理的土壤表面电荷数量和表面电位的变幅分别为11.70~17.07 cmol/kg和−81.40~−91.14 mV,不同处理间均以MSF处理最高,且显著高于SF和F处理。

2.3 不同施肥处理对土壤有机碳的影响

不同施肥处理对各有机碳组分有显著影响(图1)。对于土壤总有机碳、可溶性有机碳、颗粒态有机碳、腐殖质和胡敏酸含量,不同处理间均以MSF处理最高,分别为21.5 g/kg、96.6 mg/kg、12.1 g/kg、5.51 g/kg和3.32 g/kg。MSF和MF处理的富里酸含量分别为2.20 g/kg和2.10 g/kg显著高于F处理。MSF处理有较高的胡敏酸/富里酸比值,为1.51,且显著高于F、SF和MF处理,其中MF和SF之间无显著差异,但显著高于F处理。

![]() 图 1 不同施肥处理对土壤有机碳组分的影响注:不同大写字母表示处理间差异显著(P<0.05),误差线表示三个重复测定的标准差,f图中的点线图为胡敏酸/富里酸比值。下同。Figure 1. Effects of different fertilization treatments on the soil organic carbon fractionsNote: Different capital letters indicate significant differences between treatments (P<0.05). The error line shows the standard deviation of the three repeated measurements. The curve in f figure is the ratio of humic acid and fulvic acid content. Same as below.

图 1 不同施肥处理对土壤有机碳组分的影响注:不同大写字母表示处理间差异显著(P<0.05),误差线表示三个重复测定的标准差,f图中的点线图为胡敏酸/富里酸比值。下同。Figure 1. Effects of different fertilization treatments on the soil organic carbon fractionsNote: Different capital letters indicate significant differences between treatments (P<0.05). The error line shows the standard deviation of the three repeated measurements. The curve in f figure is the ratio of humic acid and fulvic acid content. Same as below.2.4 影响土壤表面电化学性质的因素

有机碳组分和土壤质地与土壤表面电化学性质密切相关(表3)。土壤总有机碳、颗粒态有机碳、腐殖质、胡敏酸、富里酸以及胡敏酸/富里酸比值均与土壤表面电荷密度、电场强度、比表面积、电荷数量和电位呈显著或极显著的正相关关系;可溶性有机碳与比表面积之间的相关性并不显著,但与其余表面电化学性质呈极显著的正相关关系。土壤黏粒含量与土壤表面电荷密度、电场强度、电荷数量和电位均呈显著正相关关系;粉粒含量仅与表面电荷数量呈显著的正相关关系;砂粒含量则与各土壤表面电化学性质呈显著的负相关关系。

表 3 有机碳组分、土壤质地与表面电化学性质的相关性Table 3. Correlation analysis between different organic carbon fractions and surface electrochemical properties参数Parameter SOC DOC POC HM HA FA HA:FA Clay Silt Sand σ0 0.81** 0.89** 0.87** 0.91** 0.87** 0.93** 0.70* 0.69* 0.45 −0.66* E0 0.80** 0.83** 0.84** 0.95** 0.95** 0.84** 0.86** 0.68* 0.50 −0.69* S 0.60* 0.53 0.65* 0.67* 0.67* 0.58* 0.61* 0.38 0.56 −0.61* SCN 0.84** 0.86** 0.92** 0.94** 0.91** 0.90** 0.77** 0.64* 0.59* −0.74** φ0 0.86** 0.91** 0.93** 0.95** 0.92** 0.94** 0.76** 0.69* 0.54 −0.73** 注:*和**分别表示在0.05和0.01水平上显著相关(n=12)。SOC、DOC、POC、HM、HA、FA、Clay、Silt、Sand和HA:FA分别表示土壤有机碳、可溶性有机碳、颗粒态有机碳、腐殖质、胡敏酸、富里酸、黏粒、粉粒、砂粒含量和胡敏酸与富里酸的比值;σ0、E0、S、SCN和φ0分别代表表面电荷密度、表面电场强度、比表面积、表面电荷数量和表面电位。下同。 Note: * and ** respectively indicate the significant correlation at the 0.05 and 0.01 levels (n=12). SOC, DOC, POC, HM, HA, FA, Clay, Silt, Sand and HA/FA respectively indicate soil organic carbon, dissolved organic carbon, particulate organic carbon, humus, humic acid, fulvic acid, clay, silt, and sand contents, and HA : FA ratio. σ0, E0, S, SCN and φ0 respectively indicate surface charge density, surface electric field intensity, specific surface area, surface charge number, and surface potential. Same as below. 冗余分析结果表明(图2),RDA1和RDA2对土壤表面电化学性质的解释度分别为77.97%和11.76%,其中腐殖质是影响土壤表面电化学性质的最重要的因素,解释度为67.0%,其次为土壤黏粒含量(5.9%)和胡敏酸/富里酸比值(4.9%)。

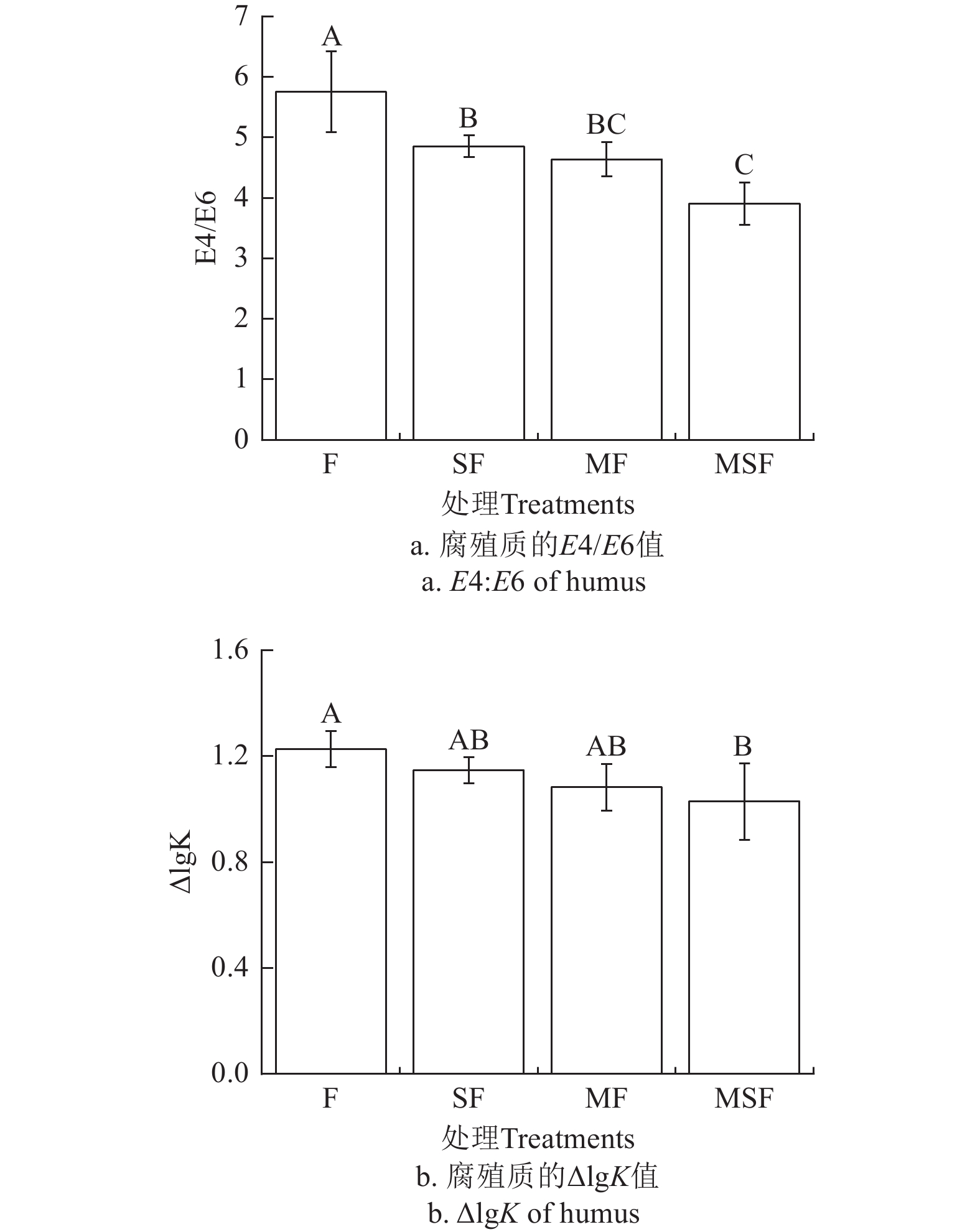

2.5 土壤腐殖质的光学特征及与表面电化学性质之间的关系

不同施肥处理对土壤腐殖质的E4/E6和ΔlgK有显著的影响(图3)。MSF处理的E4/E6最低,为3.90,显著低于F和SF处理,但与MF处理无显著差异。MSF、MF和SF处理的ΔlgK无显著差异,分别为1.03、1.08和1.15,其中MSF处理显著低于F处理。

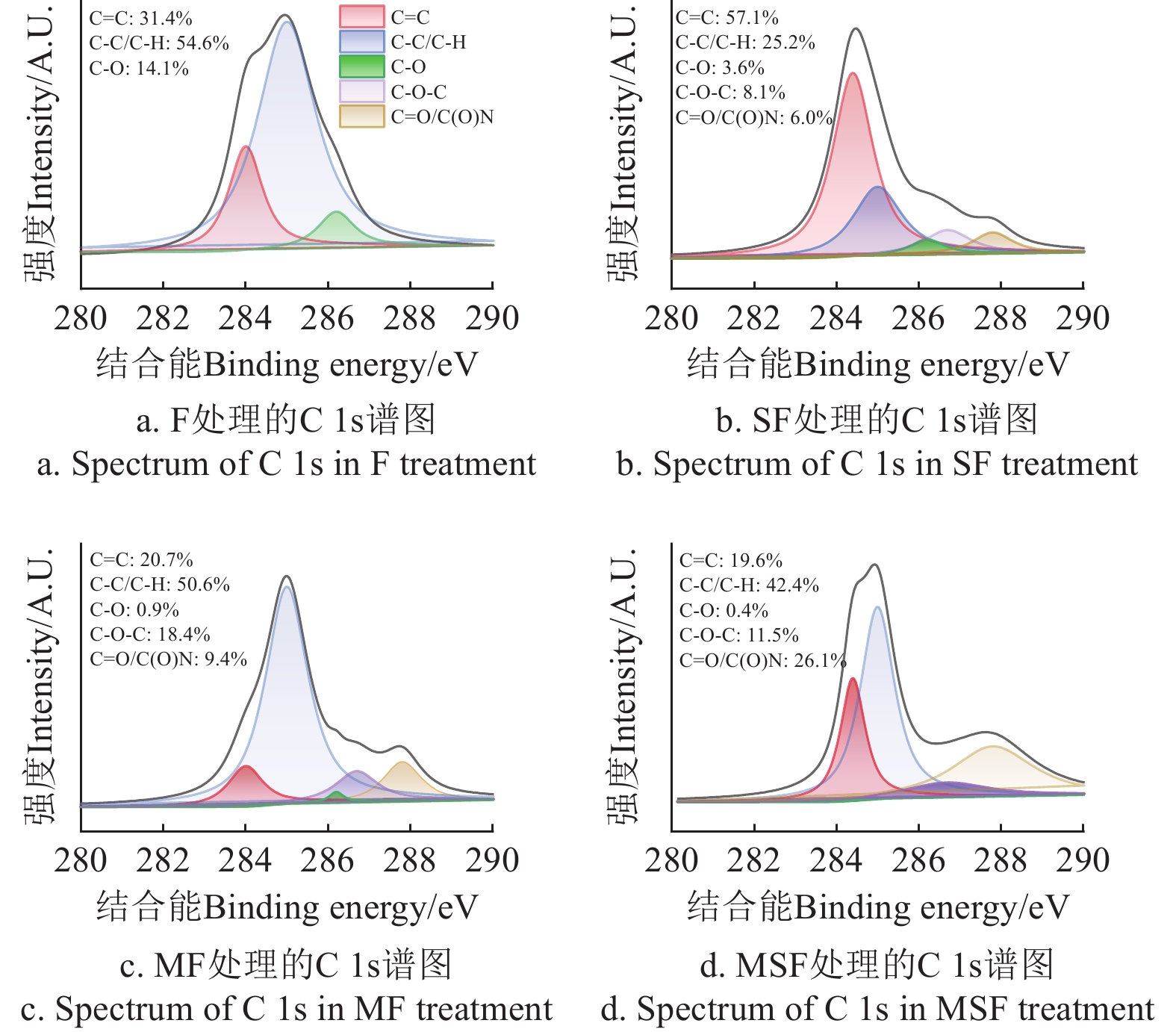

对腐殖质提取前的重组土壤颗粒进行XPS测试,分析腐殖质的结构组成(图4)。各处理C=C的相对含量表现为SF(57.1%)>F(31.4%)>MF(20.7%)≈MSF(19.6%);C-C/C-H的相对含量在F和MF处理中最高,分别为54.6%和50.6%,高于MSF(42.4%)和SF(25.2%)处理;各处理C-O的相对含量在14.1%~0.4%之间,低于其他类型的有机官能团;C-O-C的相对含量表现为MF(18.4%)>MSF(11.5%)>SF(8.1%),在F处理并未检测;C=O/C(O)N的相对含量在MSF处理中最高,为26.1%,高于MF(9.4%)和SF(6.0%)处理。

土壤腐殖质的E4/E6、ΔlgK以及有机官能团的相对含量与表面电化学性质密切相关(表4)。

表 4 土壤腐殖质的E4/E6、ΔlgK以及XPS表征的有机官能团与表面电化学性质的相关性Table 4. Correlation analysis of E4/E6 and ΔlgK of soil humus, and organo-functional group measured by XPS with surface electrochemical properties参数Parameter E4/E6 ΔlgK C=C C-C/C-H C-O C-O-C C=O/C(O)N σ0 −0.79* −0.49 −0.38 −0.19 −0.18 0.23 0.66* E0 −0.69* −0.37 −0.69* −0.04 −0.11 0.23 0.89** S −0.86** −0.64* −0.39 −0.12 0.05 −0.02 0.65* SCN −0.75* −0.66* −0.45 −0.17 −0.06 0.10 0.77* φ0 −0.84** −0.58* −0.46 −0.16 −0.09 0.14 0.74* E4/E6与土壤表面电荷密度、电场强度、比表面积、电荷数量和电位呈显著和极显著负相关关系;ΔlgK则与比表面积、表面电荷数量和电位呈显著的负相关关系,与表面电荷密度和电场强度呈负相关关系,但并不显著;C=O/C(O)N与土壤表面电荷密度、电场强度、比表面积、电荷数量和电位呈显著的正相关关系;C=C则与各土壤表面电化学性质指标呈负相关关系。

3. 讨 论

3.1 施肥对土壤表面电化学性质的影响

施肥通过改变土壤结构、pH、氧化还原电位、有机碳含量等理化性质[19],进而影响土壤表面电化学性质[20]。秸秆还田和施用有机肥可显著提高土壤表面电荷密度、电场强度、比表面积、表面电荷数量和表面电位(表2)。这主要是由于秸秆和有机肥腐解过程中形成的有机质对土壤表面电化学属性有较为深刻的影响[21],多孔结构的有机质具有较大的比表面积,显著提高土壤颗粒的比表面积,并且其表面富含羧基、羟基等活性有机基团能够提供大量的阳离子交换位点[5],同时可以解离H+使土壤颗粒表面呈负电荷[22]。丁武泉等[23]研究认为,有机质自身带有大量的电荷,随着有机质含量的增加,土壤表面电荷密度、电荷数量以及比表面积显著增加,与本研究结果相一致。另一方面,有机质与黏土矿物颗粒通过吸附、共沉淀等方式相互作用,形成有机无机复合体,稳定土壤团粒结构,减少土壤粘粒的侵蚀流失,从而对土壤表面电化学性质产生间接的影响[21,24]。并且,秸秆和有机肥在腐解过程中产生的柠檬酸、草酸等有机酸可以促进土壤黏粒矿物的转化[25]。本研究中,土壤黏粒含量与土壤表面电化学性质之间呈显著的正相关关系(表3),虽然各处理之间的黏粒含量并无显著差异,但是MSF处理的砂粒含量显著低于F处理(表1),表明长期的秸秆还田和施用有机肥可以通过影响土壤的机械组成来影响土壤表面电化学性质。

3.2 有机碳对土壤表面电化学性质的影响

将土壤有机碳分为可溶性有机碳、颗粒态有机碳以及矿物质结合态腐殖质等组分,每个有机碳组分在土壤环境中有不同功能[26]。本研究中,虽然上述各组分有机碳与土壤表面电化学性质均呈显著的正相关关系(表3),但是通过冗余分析发现矿物质结合态腐殖质是影响土壤表面电化学性质最主要的因素(图2)。这主要是由于腐殖质表面含有丰富的有机官能团,可以通过官能团的解离产生大量的负电荷,增加土壤表面电荷数量[27]。并且腐殖质的比表面积巨大,约为800~900 m2/g,是无机矿物的10倍,因此腐殖质含量增加,土壤颗粒比表面积增加[22]。张晓媛[12]研究认为,与颗粒态有机碳相比,矿物质结合态有机碳包含了土壤中绝大部分腐殖物质,是引起土壤表面电位、电荷数量以及比表面积变化的根本原因。在本研究中,胡敏酸/富里酸比值与土壤表面电化学属性呈显著的正相关关系(表3),是影响土壤表面电化学性的另一重要因素(图2)。胡敏酸/富里酸比值是反应腐殖质品质的重要指标之一[28],有机肥的投入可提高土壤胡敏酸/富里酸比值,有利于分子量较大且以杂环结构为特征的胡敏酸的积累,加速土壤腐殖化进程,使腐殖质内结构复杂化,增强有机质的稳定性[29],从而对土壤表面电化学性质产生更为持久的影响。可见,腐殖质的结构特征与土壤表面电化学性质密切相关。同时,本研究发现腐殖质的E4/E6和ΔlgK值与各土壤表面电化学性质属性之间呈显著的负相关关系(表4),说明腐殖质的分子量越大,分子结构越复杂,对土壤表面电化学性质的影响越显著。土壤中多数腐殖质是与矿物表面的金属离子相互作用,形成“腐殖质-金属离子-矿物”复合体[14]。腐殖质的分子量可影响其与金属离子的作用效果,大分子量的腐殖质与土壤金属离子络合形成更为稳定的复合体[30-31],从而对土壤表面电化学性质的影响更为持久。并且,腐殖质的分子量主要是由疏水键和氢键的决定[32],而这些键能的强弱又受腐殖质表面的电化学性质的影响。可见,腐殖质的结构特征与土壤表面电化学存在密切的联系。

腐殖质含有大量的羧基、酚羟基、氨基等多种官能团[33],并且不同分子量的腐殖质的官能团组成也有较大差异[34]。这些丰富的有机官能团可以与多种阴阳离子相互作用,进而调节土壤表面电化学性质[35-36]。对腐殖质-矿物复合体进行XPS扫描,结果发现有机肥处理(MF和MSF)中腐殖质-矿物复合体含有更丰富的C=O/C(O)N基团(图4),且与各表面电化学属性成显著的正相关关系(表4)。这可能是由于有机肥自身腐质化程度较高,腐解过程中释放更多富含芳香族的含氮有机基团,容易在土壤矿物中累积[37]。而富含氮素的有机基团可以与被固持在矿物表面的有机官能团通过共价键或者电子交换的方式相互吸附[38]。腐殖质的芳香族、脂肪族等化合物会产生含有大量羧酸、醌类的有机小分子,增加纳米颗粒的稳定性,去质子化后可以大量增加土壤颗粒表面的负电荷数量[39-40]。并且,腐殖质中的有机链存在芳香环之间相互作用,可以将有机链中未与土壤黏土矿物结合的部分约束起来,在土壤胶体表面形成稳固的有机层[41],从而影响胶体表面的电化学性质。

4. 结 论

1)秸秆还田配施有机肥的措施可显著提高表面电荷数量、比表面积、表面电荷密度、表面电场强度以及表面电位,其值分别可达17.07 cmol/kg、67.02 m2/g、0.25 c/m2、5.12×108 V/m和−91.14 mV,这主要是因为有机肥和秸秆还田显著提高了土壤各组分有机碳含量(总有机碳、可溶性有机碳、颗粒有机碳以及矿物质结合态腐殖质、胡敏酸和富里酸),降低了土壤砂粒含量。

2)土壤矿物质结合态腐殖质对土壤表面电化学性质的影响效果最强。并且,腐殖质的光密度E4/E6和色调系数ΔlgK值以及C=O/C(O)N基团的含量与各土壤表面电化学性质属性呈显著的正相关关系,说明腐殖质化学特性与土壤表面电化学性质密切相关。研究结果阐释了长期施用有机肥、秸秆等有机物对土壤表面电化学的影响机理,对于耕地质量提升和健康土壤培育具有重要意义。

-

表 1 菌料特征尺寸

Table 1 Fungal material characteristic size

菌料形状

Fungal material shape特征尺寸

Characteristic size/mm质量占比

Quality percentage/%块状

Bulk长Lk 5.9~8.3

52.75厚Tk 1.4~2.7 宽Wk 4.8~7.2 片状

Sliced长Lp 3.3~6.7

36.13厚Tp 0.9~2.1 宽Wp 1.4~2.0 粒状

Granular长Ll 0.2~1.0

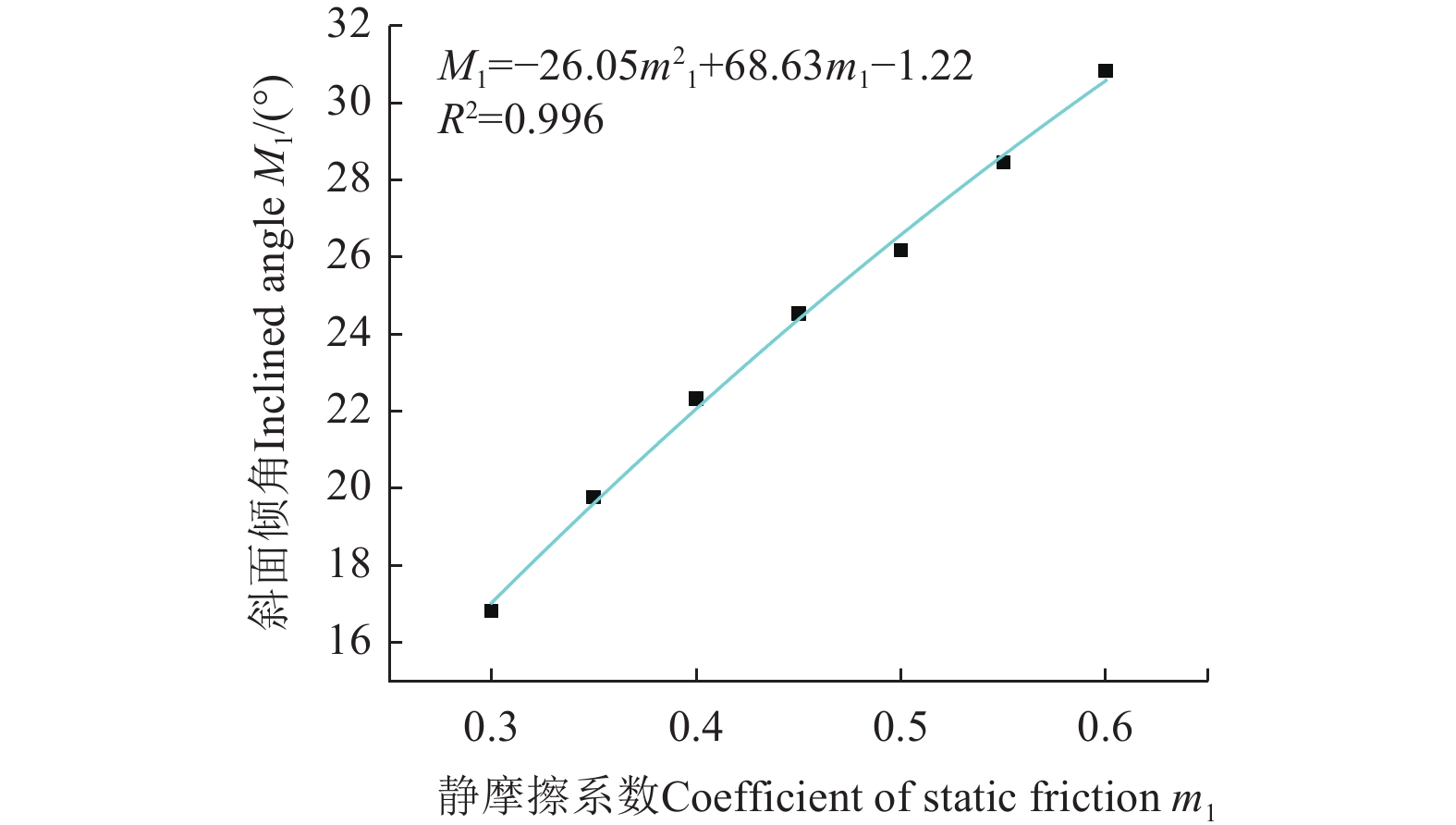

11.12厚Tl 0.2~1.1 宽Wl 0.2~1.0 表 2 静摩擦系数仿真试验方案与结果

Table 2 Static friction coefficient simulation test scheme and results

序号

No.静摩擦系数

Static friction coefficient m1倾角

Inclined angle/(°)1 0.30 16.812 2 0.35 19.7716 3 0.40 22.3226 4 0.45 24.5343 5 0.50 26.1818 6 0.55 28.462 7 0.60 30.8248 表 3 EDEM仿真参数

Table 3 Simulation parameters of EDEM

仿真参数

Simulation parameter数值

Value菌料泊松比 0.3 不锈钢板泊松比 0.28 菌料剪切模量/Pa 5.4×108 不锈钢剪切模量/Pa 8.2×1010 菌料密度/(kg·m−3) 420 不锈钢密度 /(kg·m−3) 7850 菌料-菌料碰撞恢复系数 0.1~0.3 菌料-菌料静摩擦系数 0.8~1.1 菌料-菌料滚动摩擦系数 0.01~0.15 菌料-不锈钢碰撞恢复系数 0.1~0.3 菌料-不锈钢静摩擦系数 0.443 菌料-不锈钢滚动摩擦因数 0.01~0.1 菌料表面能/J 2~14 表 4 Plackett-Burman试验参数

Table 4 Plackett-Burman test parameters

参数

Parameter低水平

Low level高水平

High level菌料-菌料碰撞恢复因数X1 0.2 0.3 菌料-菌料静摩擦因数X2 0.8 1.0 菌料-菌料滚动摩擦因数X3 0.01 0.2 菌料-不锈钢板碰撞恢复因数X4 0.01 0.3 菌料-不锈钢板滚动摩擦因数X5 0.01 0.05 菌料表面能X6/J 2 14 表 5 Placket-Burman试验方案与结果

Table 5 Placket-Burman test scheme and results

序号

No.X1 X2 X3 X4 X5 X6 堆积角

Stacking angle/ (°)1 0.3 0.8 0.20 0.30 0.01 14 59.98 2 0.3 1.0 0.20 0.30 0.05 2 43.29 3 0.2 0.8 0.20 0.01 0.05 14 70.15 4 0.3 1.0 0.01 0.01 0.01 14 52.48 5 0.3 0.8 0.01 0.01 0.05 2 29.68 6 0.3 1.0 0.01 0.30 0.05 14 37.29 7 0.2 1.0 0.20 0.30 0.01 2 44.75 8 0.2 0.8 0.01 0.30 0.01 14 50.95 9 0.2 0.8 0.01 0.01 0.01 2 33.12 10 0.2 1.0 0.01 0.30 0.05 2 27.61 11 0.3 1.0 0.20 0.01 0.01 2 45.97 12 0.2 1.0 0.20 0.01 0.05 14 75.05 表 6 Placket-Burman试验中参数显著性分析

Table 6 Parameter significance analysis in Placket-Burman test

来源

Sources标准化效应

Standardized effect平方和

Sum of squares贡献率

Contribution rateF P 模型 — 12.980 — 23.28 0.0017 X1 −0.296 0.265 1.950 2.85 0.1523 X2 −0.018 0.001 0.007 0.011 0.9199 X3 1.346 5.436 40.179 58.51 0.0006 **X4 −0.427 0.547 4.044 5.89 0.0496 *X5 −0.122 0.044 0.330 0.48 0.5182 X6 1.492 6.684 49.400 71.94 0.0004 **注:**表示极显著(P< 0.01),*表示显著(0.01<P< 0.05) 。下同。 Note: **means extremely significant (P < 0.01), *means significant (0.01<P< 0.05), The same as below. 表 7 最陡爬坡试验方案和结果

Table 7 The steepest climbing test scheme and results

序号

No.X6 X3 X4 堆积角

Stacking angle/ (°)误差

Error/%1 2 0.01 0.30 18.17 56.76 2 4 0.04 0.25 33.24 20.89 3 6 0.07 0.20 40.09 4.59 4 8 0.10 0.15 52.84 25.75 5 10 0.13 0.10 59.46 41.50 6 12 0.16 0.05 65.05 54.81 7 14 0.20 0.01 71.95 71.23 表 8 Box-Behnken试验方案与结果

Table 8 Box-Behnken test scheme and results

序号

No.X6 X3 X4 堆积角

Stacking angle/ (°)1 6 0.07 0.20 37.02 2 4 0.07 0.15 33.34 3 8 0.07 0.25 45.97 4 8 0.07 0.15 49.67 5 6 0.07 0.20 37.98 6 6 0.04 0.15 53.52 7 6 0.10 0.15 58.16 8 4 0.10 0.20 47.14 9 6 0.07 0.20 41.41 10 6 0.07 0.20 39.13 11 8 0.04 0.20 53.32 12 4 0.07 0.25 38.01 13 6 0.07 0.20 39.54 14 6 0.04 0.25 51.79 15 8 0.10 0.20 63.77 16 4 0.04 0.20 39.01 17 6 0.10 0.25 66.23 表 9 Box-Behnken检验二次模型的方差分析

Table 9 Analysis of variance of Box-Behnken test quadratic model

源

Source平方和

Sum

of squares自由度

Degrees of

freedom均方

Mean

squareF P 模型 1529.10 9 169.89 58.76 < 0.0001 **X6 381.29 1 381.29 131.87 < 0.0001 **X3 177.28 1 177.28 61.31 0.0001 **X4 6.68 1 6.68 2.31 0.1723 X6X3 1.35 1 1.35 0.47 0.5162 X6X4 17.51 1 17.51 6.06 0.0434 *X4X3 24.01 1 24.01 8.30 0.0236 *X62 15.88 1 15.88 5.49 0.0516 X32 794.40 1 794.40 274.75 < 0.0001 **X42 91.95 1 91.95 31.80 0.0008 **残差 20.24 7 2.89 失拟项 9.16 3 3.05 1.1 0.4453 纯误差 11.08 4 2.77 总计 1549.30 16 表 10 EDEM薄膜仿真参数设置

Table 10 Film simulation parameter settings in EDEM

参数Parameter 值Value 聚乙烯薄膜泊松比 0.49 薄膜密度/(kg·m−3) 1050 薄膜剪切模量/Pa 6×106 菌料-薄膜碰撞恢复因数 0.3 菌料-薄膜静摩擦因数 0.42 菌料-薄膜滚动摩擦因数 0.34 -

[1] 李文枫,毕洪文,黄峰华,等. 我国黑木耳产业发展现状及对策建议[J]. 北方园艺,2021 (7):142-147. LI Wenfeng, BI Hongwen , HUANG Fenghua, et al. Present situation and countermeasures and recommendations of development of Auricularia auricula industry in China[J]. Northern Horticulture, 2021, (7): 142-147. (in Chinese with English abstract)

[2] 郑焕春,付静,杨燕超,等. 黑木耳产业标准化现状及高质量发展对策[J]. 北方园艺,2024(4):121-128. ZHENG Huanchun, FU Jing, YANG Yanchao, et al. Standardization status and high-quality development strategy of auricularia heimuer industry[J]. Northern Horticulture, 2024(4): 121-128. (in Chinese with English abstract)

[3] 耿新军,冯继虎,杨建杰,等. 袋栽黑木耳不同品种与刺孔数量对出耳的影响[J]. 寒旱农业科学,2023,2(12):1126-1132. GENG Xinjun, FENG Jihu, YANG Jianjie, et al. Effects of different varieties and puncture hole numbers on the emergence of auricularia auricula in bag cultivation[J]. Journal of Cold-Arid Agricultural Sciences, 2023, 2(12): 1126-1132. (in Chinese with English abstract)

[4] PENG D, WANG LG, LIN YQ, et al. Oblique impact breakage unification of nonspherical particles using discrete element method[J]. Particuology, 2024, 3(90): 61-71.

[5] ZENG Y, JIA F G, XIAO Y W, et al. Discrete element method modeling of impact breakage of ellipsoidal agglomerate[J]. Powder Technology, 2019, 3(46): 57-69.

[6] SALMAN A D, REYNOLD G K, FU J S, et al. Descriptive classification of the impact failure modes of spherical particles[J]. Powder Technology, 2004, 2(32): 19-30.

[7] DAI Z W, WU M L, FANG Z C, et al. Calibration and verification test of lily bulb simulation parameters based on discrete element method[J]. Applied Sciences, 2021, 11: 10749. doi: 10.3390/app112210749

[8] WANG Y, ZHANG D, YANG T, et al. Modeling the interaction of soil and a vibrating subsoiler using the discrete element method[J]. Computers and electronics in Agriculture, 2020, 18: 174.

[9] ZENG F, CUI, LI X, et al. Establishment of the interaction simulation model between plug seedlings and soil[J]. Agronomy, 2024, 14: 4-6.

[10] CUI J, LI X, ZENG F, et al. Parameter calibration and optimization of a discrete element model of plug seedling pots based on a collision impact force[J]. Applied Sciences, 2023, 13: 62-78.

[11] 盛立柱,何建芬,吴志鹏,等. 黑木耳‘黑山’菌株在龙泉市栽培的表现与技术要点[J]. 食药用菌,2022,30(1):75-77. SHENG Lizhu, HE Jianfen, WU Zhipeng, et al. Cultivation performance and key points of cultivation techniques of Auricularia auricularia ‘heishan’ strain in Longquan city[J]. Edible and Medicinal Mushroom, 2022, 30(1): 75-77. (in Chinese with English abstract)

[12] 中华人民共和国农业部. 无公害食品 食用菌栽培基质安全技术要求:NY 5099-2002 [S]. 北京:中国标准出版社,2002. [13] HORABIK J, MOLENDA M. Parameters and contact models for DEM simulations of agricultural granular materials: A review[J]. Biosystems Engineering, 2016, 2(147): 206-225.

[14] 张兆国,徐红伟,薛浩田,等. 三七茎秆离散元参数标定与试验[J]. 农业机械学报,2023,54(11):61-70,91. doi: 10.6041/j.issn.1000-1298.2023.11.006 ZHANG Zhaoguo, XU Hongwei, XUE Haotian, et al. Calibration and experiment of discrete element parameters of panax notoginseng stem[J]. Transactions of the Chinese Society for Agricultural Machinery, 2023, 54(11): 61-70,91. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2023.11.006

[15] IM D G, LEE H, KIM J, et al. Bucket size optimization for metering device in garlic planter using discrete element method[J]. Agriculture. 2023, 13(6): 1199.

[16] CHEN Z R, XUE D M, GUAN J B, et al. Performance optimization of a spoon precision seed metering device based on a maize seed assembly model and discrete element method[J]. Processes, 2023, 11(11): 3076. doi: 10.3390/pr11113076

[17] LI D D, WANG R Y, ZHU Y P, et al. Calibration of simulation parameters for fresh tea leaves based on the discrete element method[J]. Agriculture, 2024, 14(1): 148. doi: 10.3390/agriculture14010148

[18] ZHOU L, LAN Y B, YU J Q, et al. Validation and calibration of soil parameters based on the EEPA contact model[J]. Computational Particle Mechanics, 2023, 10: 1295-1307. doi: 10.1007/s40571-023-00559-0

[19] CHEN X L, GU F W, HU Z T, et al. The calibration of soil simulation parameters for wheat grown after rice in the yangtze river basin of China[J]. Sustainability, 2023, 15(11): 71-79.

[20] 李蒙良,王立宗,廖庆喜,等. 油菜机直播微垄种床制备过程旋耕后土壤离散元参数标定[J]. 农业工程学报,2023,39(20):10-19. LI Mengliang, WANG Lizong, LIAO Qingxi, et al. Calibration of rototilled soil discrete element parameters after rotary tillage in the preparation process of rapeseed mechanized direct seeding micro-ridge seed bed[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2023, 39(20): 10-19. (in Chinese with English abstract)

[21] RACKL M, TOP F, MOLHOEK C, et al. Feeding system for wood chips: A DEM study to improve equipment performance[J]. Biomass and Bioenergy, 2017, 2(98): 43-52.

[22] 崔涛,荆茂盛,张东兴,等. 玉米果穗离散元模型构建与脱粒仿真验证[J]. 农业工程学报,2023,39(24):33-46. CUI Tao, JING Maosheng, ZHANG Dongxing, et al. Construction of the discrete element model for maize ears and verification of threshing simulation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2023, 39(24): 33-46. (in Chinese with English abstract)

[23] 宋刚,张鹏,连文伟,等. 基于离散元的双齿辊农村厨余垃圾粉碎机性能仿真研究[J]. 农业工程学报,2023,13(11):93-97. SONG Gang, ZHANG Peng, LIAN Wenwei, et al. Performance simulation study of rural kitchen waste crusher with double-toothed rollers based on discrete element method[J]. Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE), 2023, 13(11): 93-97. (in Chinese with English abstract)

[24] 赵智豪,吴明亮,谢双鹏,等. 土壤-水稻前茬离散元仿真参数标定及其旋耕轨迹分析[J]. 农业工程学报,2024,40(7):72-82. ZHAO Zhihao, WU Mingliang, XIE Shuangpeng, et al. Parameter calibration for the discrete element simulation of soil-preceding rice stubble and its rotary tillage trajectory[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2024, 40(7): 72-82. (in Chinese with English abstract)

[25] 张彪,杨鑫三,王京云,等. 基于甘蔗耕地黏土离散元参数标定的流变模型构建[J]. 农业工程学报,2024,40(13):36-44. ZHANG Biao, YANG Xinsan, WANG Jingyun, et al. Construction of a rheological model based on discrete element parameters calibration of clay from sugarcane cultivated land[J] Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2024, 40(13): 36-44. (in Chinese with English abstract)

[26] 周华,车海龙,耿端阳,等. 玉米田耕层典型土壤离散元模型建立与参数标定[J]. 农业机械学报,2023,54(11):49-60. ZHOU Hua, CHE Hailong, GENG Duanyang, et al. Discrete element modeling and parameter calibration of typical soil in maize field tillage layer[J]. Transactions of the Chinese Society for Agricultural Machinery, 2023, 54(11): 49-60. (in Chinese with English abstract)

[27] 李旭东,臧家俊,高翔,等. 果园秸秆覆盖机宽幅覆土装置设计与试验[J]. 农业机械学报,2023,54(12):70-78. LI Xudong, ZANG Jiajun, GAO Xiang, et al. Design and test of broad soil-covering device for orchard straw mulching machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2023, 54(12): 70-78. (in Chinese with English abstract)

[28] 陈永,高晓勋,金鑫,等. 油莎豆排种离散元仿真参数标定与试验[J]. 农业机械学报,2023,54(12):58-69. CHEN Yong, GAO Xiaoxun, JIN Xin, et al. Calibration and Analysis of seeding parameters of cyperus esculentus seeds based on discrete element simulation[J]. Transactions of the Chinese Society for Agricultural Machinery, 2023, 54(12): 58-69. (in Chinese with English abstract)

下载:

下载: