Microstructure evolution of Chinese yam in multiphase microwave drying

-

摘要:

为明确怀山药在多相态微波干燥中发生收缩时其微观结构变化的具体过程,该研究通过改变第二升华干燥阶段(干燥90 min后,记为升华-II)的微波加载量(0.1(方案一)、0.5(方案二)、0.9 W/g(方案三))得到了不同干燥方案下的怀山药样品,并采用X射线显微计算机断层扫描技术(X-ray microscopic computed tomography,μCT)可视化怀山药的内部结构,获取了样品的收缩率、孔隙结构及孔径分布等相关信息。研究发现,方案一中样品在转换点处含水率最低,开孔孔隙率最高。蒸发干燥阶段样品体积无较大变化,说明升华干燥阶段采用较低的微波功率密度能够抑制样品发生较大的收缩。此外,当微波功率密度较低时,样品内部孔隙数目较多。非联通孔的平均孔径和体积在不同干燥方案的升华干燥阶段无明显差异(P > 0.05),但对于转换点含水率较高的样品(方案二和方案三),蒸发干燥阶段非联通孔孔径增加较为显著(P < 0.05)。在3种干燥方案中,干燥样品连通孔等效直径与转换点处相比分别降低了3.08%、8.37%和20.04%,说明蒸发干燥阶段含水率高的样品孔隙结构更容易受到破坏。微观结构的结果表明升华干燥阶段去除较多的水分有利于样品内部形成具有一定刚性的孔隙结构,能够减小蒸发干燥阶段水分去除对样品微观结构的不利影响。

Abstract:Microstructural evolution can often dominate the macroscopic shrinkage and deformation of plant-based food materials. It is very essential to clarify the evolution pattern of pore structure during drying, in order to evaluate the microstructural variations in the materials. Taking Chinese yam as a raw material, this study aims to investigate the conversion of the dehydration process during multiphase microwave drying. The samples of Chinese yam were also obtained under different drying schemes (Scheme 1, 2, and 3, i.e., microwave power densities of 0.1, 0.5, and 0.9 W/g). The microwave power density (0.1, 0.5, and 0.9 W/g) was adjusted at the drying stage of the second sublimation (after 90 min of drying, recorded as sublimation-II). X-ray microcomputed tomography (μCT) was used to visualize the internal structure of Chinese yam. The properties of samples were then acquired for the shrinkage ratio, pore structure, and pore size distribution. The results showed that the time required to reach the critical temperature at the phase transition point for the samples in Schemes 1, 2, and 3) was 195, 155, and 145 min, respectively. At the transition point, the sample of Scheme 1 exhibited the lowest water content (26.16%), the highest open pore rate (57.1%), and the highest number of pores. Furthermore, the smallest volume change of the samples was also observed during evaporation drying. Therefore, the lower microwave power density at the sublimation drying stage effectively reduced the moisture content of the sample at the transition point. Additionally, the open pores were formed to minimize the outstanding shrinkage that occurred in the sample. The sample exhibited a greater number of pores and a smaller volume change during evaporation drying. The open porosity in sublimation-II was reduced by 8.02% and 12.16%, respectively, for Schemes 2 and 3. Subsequently, the higher moisture content of the samples resulted in damage to the pore structure during sublimation drying. There was a notable reduction in the porosity of the samples. The pore diameters of the samples exhibited a non-normal distribution in the three drying schemes. An increasing trend of pores with diameters less than 20 μm was also observed in Schemes 1 and 2. In contrast, the tiny pores in the samples of Scheme 3 continued to decrease with drying, while the number of large pores increased. This trend was related to the larger microwave loading. The equivalent diameters of connected pores in the dried samples exhibited a reduction of 3.08%, 8.37%, and 20.04%, respectively, in three drying schemes, compared with the transition point. There was no significant difference (P > 0.05) in the mean diameter and volume of non-connected pores in the samples at the sublimation drying stage among the three drying schemes. In the samples with the higher water content at the transition point (Scheme 2 and 3), the removal of moisture resulted in a significant increase (P < 0.05) in the equivalent diameter of non-connected pores at the evaporation drying stage. The μCT analysis revealed that there were no significant variations in the internal structure of the sample in Scheme 1, the removal of more moisture at the sublimation drying stage was facilitated to form the more robust pore structure inside the samples. There was no impact of water removal on the microstructure of the samples during evaporation drying. These findings can provide empirical evidence and theoretical insights to efficiently process high-quality dehydrated fruits and vegetables by multiphase microwave drying.

-

Keywords:

- Chinese yam /

- pores /

- microstructure /

- multiphase microwave drying /

- μCT /

- shrinkage

-

0. 引 言

山药是一种富含生物活性物质的药食同源农作物,其果皮和块茎富含蛋白质、多糖、尿囊素、维生素C、钙、铁等营养物质[1-2]。中国山药种类众多,约占全球山药种类的六分之一[1]。怀山药作为河南焦作温县特有的优良品种,功能组分含量和营养价值尤为突出[3]。然而,新鲜怀山药水分含量较高且脆度较大,不利于储运。干燥则是延长怀山药保质期和减少其采后损失的有效方法[4-5]。

近年来,科研人员针对山药干燥开展了大量研究。热风干燥(hot air drying,HAD)是目前应用最广泛的主流干燥技术之一[6]。然而,受干燥过程中的高温和氧气环境的影响,产品质量往往难以保证[1]。真空冷冻干燥(vacuum freeze drying,FD)在保持样品质量方面具有显著优势,但高昂的干燥成本制约了其在果蔬干燥中的应用[7-8]。与FD相比,微波冷冻干燥(microwave freeze drying,MFD)已被证实可以有效减少干燥时间和能耗[9]。DUAN等[10]发现,MFD升华干燥的脱水比例低于FD[10],这意味着样品内更多的水分后续将通过蒸发而不是升华被去除。为减少干燥过程中的无效耗能,研究团队提出在MFD后期提高干燥室内压力,以真空微波干燥的方式快速去除样品中的残留水分,从而缩短干燥时间,降低干燥能耗。由于干燥过程涉及“升华-蒸发”的转换,水分存在固-液-汽多相态的变化,因此将这一干燥过程定义为多相态微波干燥(multiphase microwave drying,MMD)。REN等[11]在对怀山药多相态微波干燥的研究中设置了不同的微波加载方案,发现MMD升华脱水阶段向蒸发脱水阶段转换时,怀山药中的水分含量对其干燥质量影响显著,合适的工艺参数可以制备出与FD相当的高品质产品。然而,不恰当的微波加载方案则会导致样品出现体积收缩和中心塌陷的情况[11-13]。

植物性食品材料在宏观上的收缩变形是由微观结构变化引起的[14-15],而孔隙结构的演变对于评价物料微观结构变化至关重要。X射线显微计算机断层扫描技术(X-ray microscopic computed tomography,μCT)作为一种非破坏性的三维成像方法[16],逐渐被引入到胡萝卜[17]、蘑菇[18]、香蕉[19]、苹果[20]等果蔬干燥的研究中,用于表征样品的内部结构,量化孔隙空间特征,包括孔隙大小、分布和形态。张乐道等[15]使用μCT评估了MFD的干燥压力及微波加载量对怀山药的孔道结构的影响,LI等[21]采用μCT和扫描电子显微镜相结合的方法,对不同干燥方法制备的怀山药微观结构进行了对比分析。这些研究为理解山药干制品的微观结构特征提供了有价值的参考。然而,有关怀山药多相态微波干燥过程中微观结构动态变化的研究未见报道。为明确怀山药在MMD中发生干燥收缩的具体过程,有必要研究其干燥中孔隙结构的变化特征,从而为MMD的工艺设计和优化提供帮助。

本研究以怀山药多相态微波干燥中脱水过程的转换为切入点,采用μCT技术量化MMD中样品宏观和微观结构的变化,包括怀山药的收缩特性、孔隙率、孔径分布、孔径信息等,以期揭示干燥过程中孔隙结构演变的规律,为提高干燥工艺的控制精度提供理论支持。

1. 材料与方法

1.1 材 料

新鲜的怀山药购自河南省焦作市富熙源怀药有限公司。选取粗细均匀,表面无损伤的新鲜怀山药作为试验原料,储存在4 ℃的冰箱中,待用。通过烘箱法测得新鲜山药的含水率为76% ± 1%。干燥前,将山药冲洗干净并去皮,用模具将其切成块状(12 mm × 12 mm × 12 mm),以保证干燥样品形状和大小的均匀性,在−25 ℃条件下冷冻12 h。

1.2 干燥设备与程序

MMD的干燥过程按脱水形式可分为升华干燥和蒸发干燥。升华干燥阶段,样品在升华压力下去除一部分水,使样品内部形成具有一定刚性的骨架结构。当样品内部的冻结水出现大量融化时,升高干燥腔压力,干燥由升华转为蒸发。参考之前的研究[11, 13],本试验以怀山药共熔点温度作为干燥转换的临界温度(通过差示扫描量热仪测得该温度为−3 ℃)。

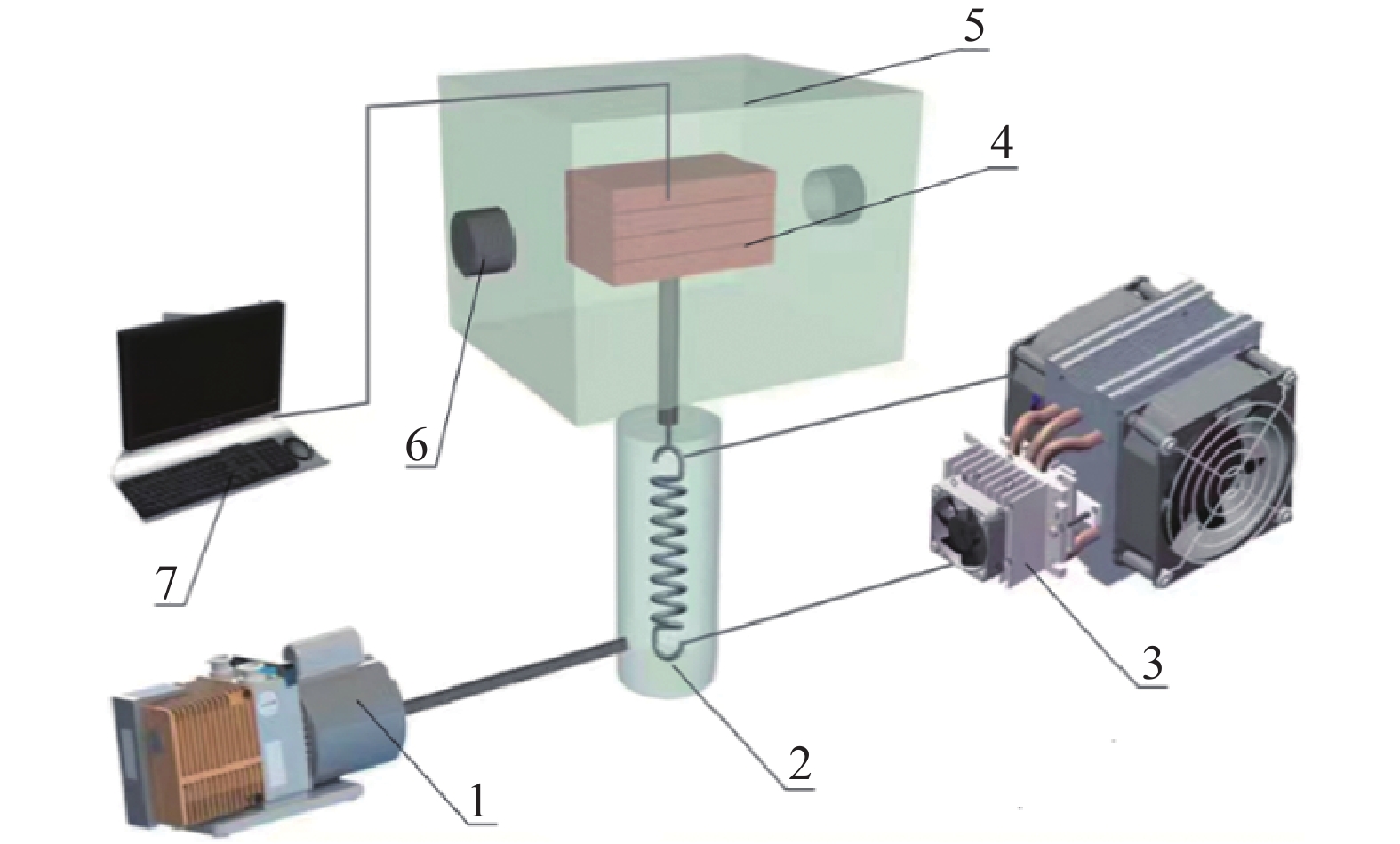

怀山药干燥在实验室自主研发设计的多相态微波干燥机中进行,如图1所示。

干燥前,多相态微波干燥机的冷阱温度降至−35 ℃时,将(100 ± 2)g样品平铺在聚丙烯干燥盘上放入设备干燥腔中,将设备中的光纤温度传感器插入样品芯部以实时监测温度变化。干燥腔中的真空压力在升华阶段控制在100 Pa以下,进入蒸发干燥阶段后调整为3 kPa。干燥过程中室内环境温度维持在25 ℃。为测定样品在干燥过程中的含水率变化情况,取样时迅速打开干燥腔,将样品取出称量。每次取样后,以同批次相同初始含水率和质量的新鲜山药重新开始干燥直到设定的取样时间。设备连续工作的时间随着取样时间的增加而增加,干燥直至样品含水率为10%时结束。

在干燥过程中,控制系统能够实现微波功率的连续调节。在前期试验的基础上,本研究设置了3种微波加载方案如表1所示。

表 1 多相态微波干燥不同微波加载方案Table 1. Different microwave loading schemes in MMD微波加载方案

Microwave loading

schemes升华干燥阶段微波功率密度

Microwave power density of sublimation drying stage /(W·g−1)蒸发干燥

阶段微波

功率密度

Microwave power

density of

evaporation drying

stage /(W·g−1)升华-I

Sublimation-I

(0-90 min)升华-II

Sublimation-II

(90 min后)方案一Scheme 1 0 0.1 3 方案二Scheme 2 0.5 方案三Scheme 3 0.9 1.3 X射线显微计算机断层扫描

1.3.1 样品处理

为明确怀山药在多相态微波干燥过程中微观结构的变化,采用μCT来获取怀山药孔隙结构的详细信息。在进行μCT扫描前,为避免残余水分对扫描质量造成影响,采用FD对样品进行脱水处理,设定板层温度为−25 ℃,干燥过程中升温至20 ℃。这种干燥方法不仅能够保持样品多孔结构的完整性,还能有效减少样品收缩,从而避免干燥对样品微观结构造成严重破坏[22-24]。

1.3.2 图像采集

将干燥样品置于高分辨透视成像分析设备(nanoVoxel 1200,天津三英精密仪器股份有限公司)中,固定射线源与平板探测器的距离为270 mm,射线源与样品台之间的距离为38 mm,像素尺寸为11.93 μm。扫描时设置曝光时间为1 s,图像合并数为3,在45 kV的X射线管电压和110 μA的电流下进行扫描。

1.3.3 图像重建与分析

采用Voxelstudio Recon软件对断层扫描获得的二维图像进行重建,得到样品的三维图像。在Dragonfly软件中对重建后的样品进行处理与分析。使用中值滤波器在三维空间中对图像进行降噪处理,随后创建与样品形状大小一致的感兴趣区域(region of interest,ROI),所得到的ROI的体积大小视为样品的真实体积,通过式(1)计算样品的收缩率(shrinkage ratio,SR)。

SR=V−VtV×100% (1) 式中V为干燥前样品的体积,mm3;Vt为干燥任意时刻样品的体积,mm3。

孔隙率的量化计算:对样品的三维图像进行阈值分割,通过软件中的大津算法区分样品的固体基质与孔隙结构,对分割出的孔隙结构创建ROI,样品的孔隙率定义为孔隙结构的ROI的体素数与样品ROI体素数的比值。将开孔孔隙定义为样品内部与外界相连通的孔隙,闭合孔隙为样品内部不与外部相连的独立孔隙。等效直径为与孔隙等体积的球体的直径。

1.4 数据处理

采用SPSS软件对试验数据在95%的置信水平进行ANOVA方差分析(P<0.05),根据Tukey检验确定试验结果在统计学上的显著性差异。

2. 结果与分析

2.1 MMD过程中怀山药的干燥特性

怀山药在MMD干燥过程中的含水率和温度变化如图2所示。

从图2a中可以看出,怀山药的含水率随干燥的进行而逐渐下降。在升华-I阶段(0~90 min),未施加微波,冰晶的升华通过从周围环境中吸收热量进行,不同干燥方案间样品的含水率变化无明显差异。施加微波后(升华-II阶段),3种干燥方案中的水分脱除速率较前一阶段有所提高,这是由于微波为冰晶升华提供了能量。此外,样品的温度随着干燥进行不断升高(图2b),这会导致样品的介电特性发生改变。介电常数和损耗因子的增加有助于吸收和耗散更多的微波能量,从而加速干燥[9, 25]。进入蒸发干燥阶段后,样品中残余的冰晶融化,水分以蒸发的形式被脱除,干燥速率逐渐减缓。然而,从图2a的结果来看,方案三蒸发干燥阶段后期水分脱除速率与方案二相比较慢,这可能与转换点样品中较高的含水率有关。由于蒸发干燥阶段微波功率密度较大,靠近样品表面的残余水分被迅速去除,但由于内部的水分无法及时迁移到表面,导致样品表面硬化,进而阻止水分的蒸发[26]。

干燥过程中样品的温度变化如图2b所示。随着水分不断被脱除,水分子对微波能量的耗散减少,而物料本身的微波吸收能力增强[27],因此样品温度升高。由于升华干燥阶段不同干燥方案中施加的微波功率密度不断增大,微波能量的差异导致样品在升华干燥阶段具有不同的升温速率。方案一(0.1 W/g)、方案二(0.5 W/g)和方案三(0.9 W/g)中的样品干燥到转换点的临界温度所用的时间分别为195、155和145 min。结合图2a来看,升华干燥阶段的快速结束也导致转换点处怀山药含水率的增加。在蒸发干燥的初始阶段,观察到样品温度的迅速升高,这是因为样品中大部分水在升华干燥阶段被去除,蒸发干燥阶段残余水分相对较少,由于微波功率密度较大,过剩的微波能量会被物料吸收引起温度迅速上升。

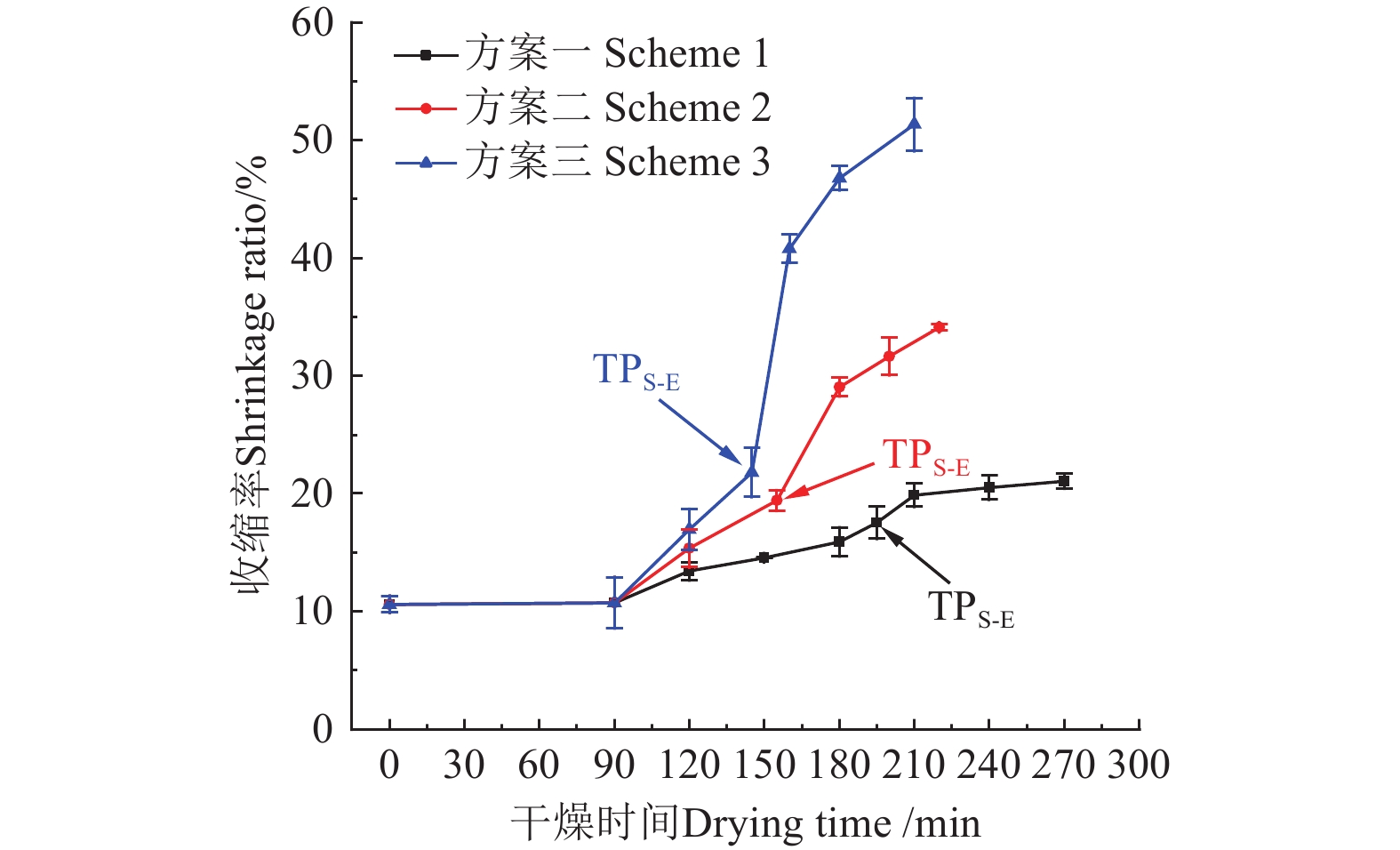

2.2 MMD过程中怀山药的收缩行为

物料的收缩是干燥过程中最常见的物理现象[14]。不同微波加载方案下,怀山药在干燥过程中的收缩率变化如图3所示。升华-I阶段无微波加载(0~90 min),样品内的冰晶在升华干燥压力下被去除,由于冰晶对样品的组织结构能够起到支撑作用,因此样品不会发生收缩[28-29]。施加微波后,样品的收缩率随着干燥的进行呈上升趋势。升华-II阶段和蒸发干燥阶段样品的体积变化快慢有所不同。升华-II阶段,3种干燥方案中样品体积变化相对较小,这是因为样品中的水分通过升华而非蒸发被去除,细胞壁在冰晶的支撑作用下具有的机械强度,能够抵抗微观结构应力的产生[28],因此样品收缩较少。方案一中由于微波功率密度最小,有效延长了升华干燥的时间,使大部分冰晶升华产生的气态水有更多时间向环境中扩散,减少了对物料细胞组织的损伤[22],因此方案一样品在转换点处具有最低的收缩率。

进入蒸发干燥阶段(转换点后),转换点含水率较高的样品的收缩与前一阶段相比明显增大(方案二和方案三)。在蒸发干燥初期,样品温度的快速升高加速了水分的扩散和蒸发。液态水发生迁移时会在组织内部的毛细管中形成弯液面,这种毛细现象产生的压力差会使样品的组织结构发生较大程度的收缩[17, 28]。此外,样品的收缩可能和玻璃化转变温度有关。样品含水率较高时,其玻璃化转变温度处于较低水平,当材料的温度高于玻璃化转变温度时,分子运动变得活跃,赋予材料更高的流动性,更容易发生干燥收缩[30]。不同的是,方案一中样品并未出现严重的收缩,这可能是由于样品在升华干燥阶段水分去除较多,材料的刚性骨架已经形成,增强了对干燥收缩的抵抗能力。

2.3 MMD过程中怀山药的孔隙结构变化

2.3.1 孔隙率

MMD不同微波加载方案下样品孔隙率的变化情况如图4所示。在干燥过程中,样品的开孔孔隙率不断降低,闭孔孔隙率则呈现先增加后降低的趋势,总孔隙率与开孔孔隙率变化趋势一致。

相对于升华-I,升华-II结束时,方案一、方案二和方案三中样品的开孔孔隙率分别降低了5.24%,8.02%和12.16%。与方案一相比,方案二和方案三在升华-II阶段的开孔孔隙率下降较多,这是由于冷冻样品内部的孔隙结构被冰晶填充,较高的微波能量会加速冰晶升华,在孔隙结构中产生膨胀压力[31],可能会破坏孔隙结构,从而导致样品孔隙率降低。此外,微波加热过程中的温度分布不均匀引起的局部过热会导致样品内部冰晶融化,造成结构坍塌,降低孔隙率[13, 32]。进入蒸发干燥阶段后,由于这两种方案中样品含水率较高,水分蒸发产生的张力使样品向内收缩[33],破坏了样品在升华干燥阶段形成的孔隙结构,样品的孔隙率明显降低。但与蒸发干燥阶段相比,升华干燥在低温下进行,脱水以冰晶升华为主,因此孔隙率变化相对较小。不同的是,方案一样品的开孔孔隙率在蒸发干燥阶段缓慢降低,且干燥结束时样品收缩最少(图3),说明样品在转换点处的开孔孔隙率维持在较高水平可以抑制蒸发干燥阶段样品的收缩。

2.3.2 孔隙结构特征

不同微波加载方案中怀山药的孔隙结构信息如表2所示。从表中可以看出,不同干燥方案中,干燥结束时物料内部的孔隙数目和连通孔体积较转换点处有所降低。在升华干燥中,冰晶通过升华以气态形式被去除,促进了样品多孔结构的形成,由于方案一升华干燥的时间最长(195 min),有利于更多孔隙在此阶段形成,因此方案一转换点处的孔隙数目显著高于方案二和方案三(P < 0.05)。干燥结束时各方案孔隙数目的减少与蒸发干燥阶段孔道结构的坍塌有关。在蒸发干燥阶段,残余冰晶融化后支撑作用失效,同时,伴随着物料温度的升高,样品处于黏弹态,固体基质具有较高的迁移率[34],当液态水从组织中去除时,固体基质受到张力的作用向内收缩,从而导致孔隙结构的坍塌,孔隙数目和连通孔的体积减少[33]。

表 2 多相态微波干燥转换点和终点处怀山药的孔隙结构特征Table 2. Pore structure characteristics of Chinese yam at the phase transition point and end of MMD干燥方案

Drying schemes干燥时间

Drying time/min孔隙数目/个

Number of pores连通孔体积

Connected pore volume/mm3非连通孔平均等效直径

Non-connected pore average

equivalent diameter/μm非连通孔平均体积

Non-connected pore

average volume/μm3方案一

Scheme 1195(TPS-E) 618306 ±6705 a759.50±57.28a 18.17±0.15c 6380.47 ±69.78c270(干燥终点) 485515 ±36879 b708.13±109.07ab 18.37±0.28c 7364.66 ±723.04c方案二

Scheme 2155(TPS-E) 452838 ±47638 b688.00±59.40ab 19.30±0.18bc 9628.24 ±593.45bc220(干燥终点) 409562 ±21164 bc540.00±60.81b 19.98±0.86b 15297.82 ±6219.39 ab方案三

Scheme 3145(TPS-E) 438212 ±28402 b673.50±40.31ab 19.26±0.07bc 8173.52 ±899.15bc210(干燥终点) 336267 ±55772 c345.50±47.38c 21.43±0.63a 17554.99 ±2556.83 a注:同列中不同上标字母表示样品具有显著性差异(P < 0.05)。 Note: Different superscript letters in the same column indicate that the samples are significantly different (P < 0.05). 怀山药的非联通孔平均等效直径和平均体积在不同干燥方案转换点处无显著差异(P > 0.05),说明升华干燥阶段的不同微波功率密度不会对怀山药的孔隙结构产生显著影响。干燥结束时,3种干燥方案中非联通孔平均等效直径和平均体积与转换点处相比有所增大,意味着样品内部形成了较大孔径的孔隙,可能是由于蒸发干燥阶段水分快速蒸发,水蒸气在孔道内部形成了较大的膨胀压力使孔隙结构发生扩张[31],从而导致非联通孔的平均等效直径和平均体积增大。而含水量的差异可能是导致方案二和方案三中非联通孔的结构与方案一中存在显著差异的原因。

2.4 MMD过程中怀山药的孔径分布情况

不同干燥方案中怀山药的等效孔径分布如表3所示。从表中可以看出样品在MMD过程中的等效孔径呈非正态分布,并以小于20 μm的孔隙为主。

表 3 多相态微波干燥过程中不同微波加载方案中怀山药等效孔径分布情况Table 3. Equivalent pore size distribution of Chinese yam in different microwave loading schemes during MMD干燥方案

Drying schemes干燥时间

Drying time/min孔隙等效直径分布相对频率Pore equivalent diameter distribution relative frequency/% 0~20 μm 20~40 μm 40~60 μm 60~80 μm 80~100 μm >100 μm 方案一

Scheme 190(升华-I结束) 77.591±0.359b 18.555±0.568a 2.984±0.148a 0.622±0.045a 0.151±0.003a 0.097±0.013b 195(TPS-E) 81.448±0.417a 15.777±0.057b 2.180±0.264b 0.437±0.095a 0.099±0.011a 0.062±0.009b 270(干燥结束) 81.686±0.036a 15.549±0.449b 1.811±0.199b 0.552±0.119a 0.223±0.056a 0.179±0.039a 方案二

Scheme 290(升华-I结束) 77.591±0.359a 18.555±0.568a 2.984±0.148a 0.622±0.045b 0.151±0.003b 0.097±0.013a 155(TPS-E) 77.164±1.084a 18.448±1.027a 3.156±0.014a 0.845±0.021a 0.234±0.021a 0.153±0.029a 220(干燥结束) 79.751±0.715a 17.179±0.563a 2.220±0.135b 0.534±0.009b 0.179±0.005b 0.137±0.002a 方案三

Scheme 390(升华-I结束) 77.591±0.359a 18.555±0.568c 2.984±0.148b 0.622±0.045b 0.151±0.003b 0.097±0.013b 145(TPS-E) 75.225±0.082a 21.063±0.213a 2.828±0.356b 0.609±0.076b 0.179±0.085b 0.096±0.064b 210(干燥结束) 72.041±1.453b 19.838±0.359b 4.897±0.513a 2.037±0.330a 0.761±0.157a 0.426±0.093a 注:不同干燥方案同列中不同上标字母表示处理具有显著性差异(P < 0.05)。 Note: Different superscript letters in the same column of different drying schemes indicate that the treatments are significantly different (P < 0.05). 在方案一和方案二中,直径小于20 μm的孔隙呈上升趋势。在MMD的升华干燥阶段,微波作为热源为冰晶的快速升华提供能量,从而促进微小孔隙的形成。与方案一和方案二不同的是,方案三样品中的微小孔隙(0~20 μm)随着干燥的进行不断降低,这可能与较大的微波加载量有关。过量的微波能量供应导致冰晶发生局部融化,液态水的存在加快了样品温度的升高,由此引发的热膨胀效应不利于微小孔隙的形成[12]。此外,较高的微波功率密度加速了冰晶的升华,在样品组织结构中产生更高的膨胀压力[31],导致样品的孔隙结构发生变化。

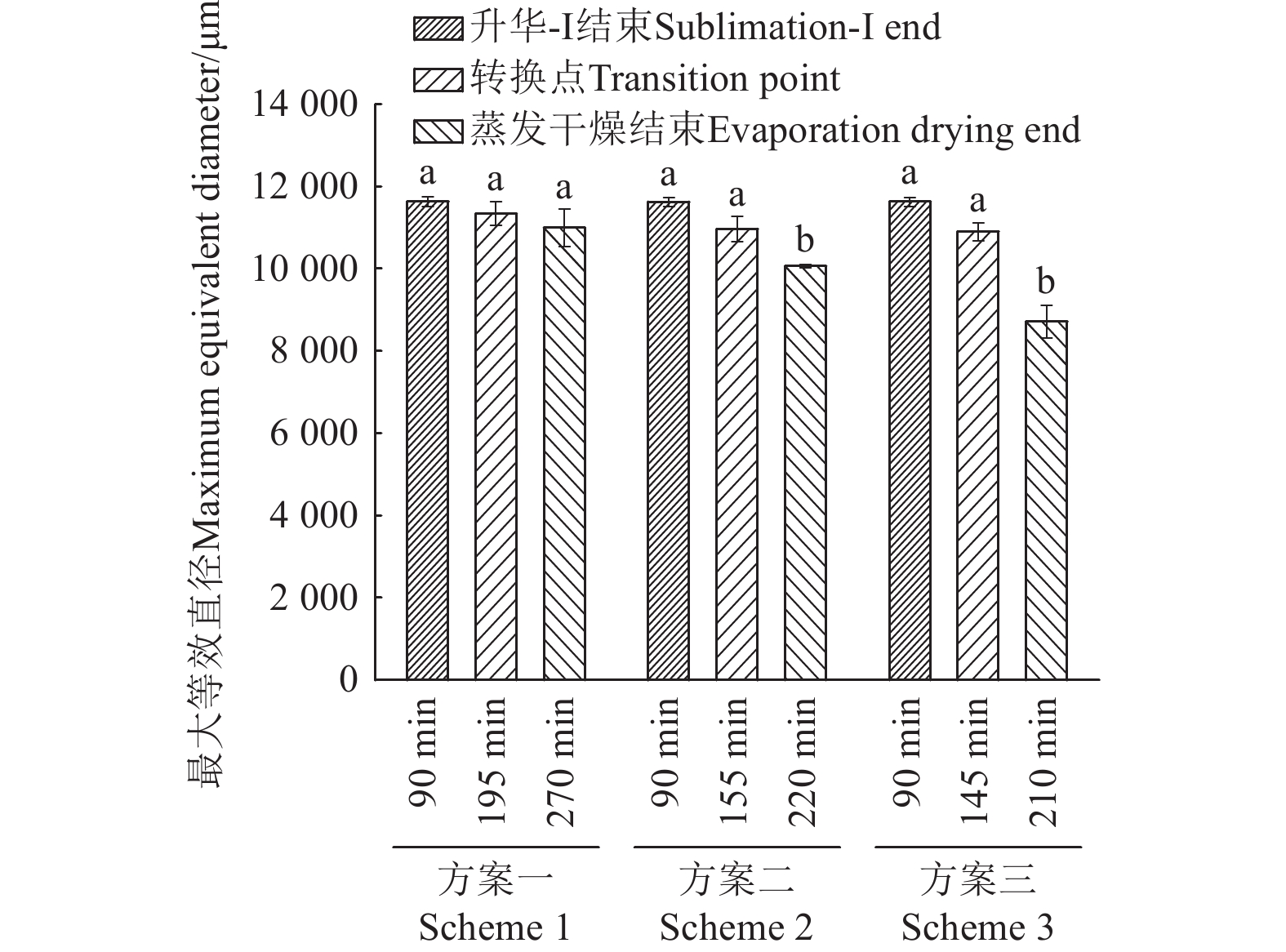

如图5所示,3种干燥方案中,干燥样品的最大孔隙等效直径均大于8 000 μm,这是由于样品在干燥过程中形成了互相连通的孔。随着干燥的进行,连通孔的等效直径不断减小。相较于转换点处(升华-II结束),干燥结束时3种方案中连通孔等效直径分别降低了3.08%、8.37%和20.04%。干燥结束时方案二和方案三中连通孔等效直径的显著降低(P < 0.05),可能与样品蒸发干燥阶段孔隙结构被破坏有关。

2.5 MMD过程中怀山药的微观结构变化

食品材料宏观上的收缩变形是由微观结构变化引起的[14]。为了进一步探究怀山药发生收缩变形时内部结构的变化情况,通过μCT得到山药样品重建后的三维立体图像及内部的微观结构图像如图6所示。

在升华干燥阶段,不同干燥方案中样品呈现多孔结构,这是因为这一阶段中的水分去除以冰晶升华为主,不会破坏周围的组织结构,从而能够形成较多孔隙[12]。而干燥结束时,从图中可以看出方案二和方案三中样品的表面向内凹陷,说明样品的收缩变形主要发生在蒸发干燥阶段。

由于样品在转换点处具有较高的含水率,在蒸发干燥过程中,较高的微波功率使组织内部的水分被迅速蒸发,水蒸气在组织结构内部产生压力,最终导致组织结构的变形[17]。

从方案二和方案三干燥结束时样品的微观结构图中能够观察到靠近外层干燥区域处样品的组织结构较为致密,这可能与蒸发干燥阶段样品内部的孔隙网路结构坍塌有关。升华干燥阶段样品表面的冰晶升华形成干燥层,进入蒸发干燥阶段残余水分在微波加热的作用下向外迁移。由于物料内部与表面存在较大的湿度差,同时样品温度不断升高,由此产生的应力会使细胞发生变形破裂,最终导致样品内部结构被破坏[35]。相比之下,方案一中样品在整个干燥过程中没有发生明显的形状变化,且始终保持着多孔结构,即使在蒸发干燥阶段,也并未观察到明显的结构塌陷,说明在升华干燥阶段去除较多的水分有利于维持样品内部孔隙结构的刚性。

综上所述,升华阶段去除的水越多,越有利于样品在干燥中保留较好的形状和结构。而在含水率较高时,孔隙结构的刚性并未形成,这就会导致样品在蒸发阶段孔道结构发生改变,收缩程度增大。

3. 结 论

本研究采用X射线显微计算机断层扫描技术可视化怀山药多相态微波干燥过程中的内部结构,通过量化孔隙结构来探究样品发生收缩时微观结构的变化情况,结果表明:

1)升华-II阶段采用较低微波功率密度能够有效降低转换点含水率。与升华-I相比,升华-II结束时方案一、方案二和方案三中样品的开孔孔隙率分别降低了5.24%,8.02%和12.16%,样品内部保留较多的开放孔道有利于减少蒸发干燥阶段样品的收缩。

2)升华干燥时间的延长有利于更多微小孔隙的形成,样品内部更倾向于形成刚性更强的孔隙结构,抵抗干燥收缩。相反,当微波能量较高时,即使在升华干燥阶段,样品内部的孔隙结构仍然会受到破坏。与升华-II结束相比,干燥完成时3种方案中连通孔等效直径分别减小了3.08%、8.37%和20.04%,说明对于转换点含水率较高的样品,蒸发干燥阶段孔隙结构更易受到破坏,不利于样品微观结构的发展。

基于本研究,可在后期研究中对蒸发干燥阶段样品发生收缩时组织结构的力学性能进行分析,结合微观结构演变进一步深入探讨收缩产生的原因,从而为MMD工艺的精准调控提供理论指导。

-

表 1 多相态微波干燥不同微波加载方案

Table 1 Different microwave loading schemes in MMD

微波加载方案

Microwave loading

schemes升华干燥阶段微波功率密度

Microwave power density of sublimation drying stage /(W·g−1)蒸发干燥

阶段微波

功率密度

Microwave power

density of

evaporation drying

stage /(W·g−1)升华-I

Sublimation-I

(0-90 min)升华-II

Sublimation-II

(90 min后)方案一Scheme 1 0 0.1 3 方案二Scheme 2 0.5 方案三Scheme 3 0.9 表 2 多相态微波干燥转换点和终点处怀山药的孔隙结构特征

Table 2 Pore structure characteristics of Chinese yam at the phase transition point and end of MMD

干燥方案

Drying schemes干燥时间

Drying time/min孔隙数目/个

Number of pores连通孔体积

Connected pore volume/mm3非连通孔平均等效直径

Non-connected pore average

equivalent diameter/μm非连通孔平均体积

Non-connected pore

average volume/μm3方案一

Scheme 1195(TPS-E) 618306 ±6705 a759.50±57.28a 18.17±0.15c 6380.47 ±69.78c270(干燥终点) 485515 ±36879 b708.13±109.07ab 18.37±0.28c 7364.66 ±723.04c方案二

Scheme 2155(TPS-E) 452838 ±47638 b688.00±59.40ab 19.30±0.18bc 9628.24 ±593.45bc220(干燥终点) 409562 ±21164 bc540.00±60.81b 19.98±0.86b 15297.82 ±6219.39 ab方案三

Scheme 3145(TPS-E) 438212 ±28402 b673.50±40.31ab 19.26±0.07bc 8173.52 ±899.15bc210(干燥终点) 336267 ±55772 c345.50±47.38c 21.43±0.63a 17554.99 ±2556.83 a注:同列中不同上标字母表示样品具有显著性差异(P < 0.05)。 Note: Different superscript letters in the same column indicate that the samples are significantly different (P < 0.05). 表 3 多相态微波干燥过程中不同微波加载方案中怀山药等效孔径分布情况

Table 3 Equivalent pore size distribution of Chinese yam in different microwave loading schemes during MMD

干燥方案

Drying schemes干燥时间

Drying time/min孔隙等效直径分布相对频率Pore equivalent diameter distribution relative frequency/% 0~20 μm 20~40 μm 40~60 μm 60~80 μm 80~100 μm >100 μm 方案一

Scheme 190(升华-I结束) 77.591±0.359b 18.555±0.568a 2.984±0.148a 0.622±0.045a 0.151±0.003a 0.097±0.013b 195(TPS-E) 81.448±0.417a 15.777±0.057b 2.180±0.264b 0.437±0.095a 0.099±0.011a 0.062±0.009b 270(干燥结束) 81.686±0.036a 15.549±0.449b 1.811±0.199b 0.552±0.119a 0.223±0.056a 0.179±0.039a 方案二

Scheme 290(升华-I结束) 77.591±0.359a 18.555±0.568a 2.984±0.148a 0.622±0.045b 0.151±0.003b 0.097±0.013a 155(TPS-E) 77.164±1.084a 18.448±1.027a 3.156±0.014a 0.845±0.021a 0.234±0.021a 0.153±0.029a 220(干燥结束) 79.751±0.715a 17.179±0.563a 2.220±0.135b 0.534±0.009b 0.179±0.005b 0.137±0.002a 方案三

Scheme 390(升华-I结束) 77.591±0.359a 18.555±0.568c 2.984±0.148b 0.622±0.045b 0.151±0.003b 0.097±0.013b 145(TPS-E) 75.225±0.082a 21.063±0.213a 2.828±0.356b 0.609±0.076b 0.179±0.085b 0.096±0.064b 210(干燥结束) 72.041±1.453b 19.838±0.359b 4.897±0.513a 2.037±0.330a 0.761±0.157a 0.426±0.093a 注:不同干燥方案同列中不同上标字母表示处理具有显著性差异(P < 0.05)。 Note: Different superscript letters in the same column of different drying schemes indicate that the treatments are significantly different (P < 0.05). -

[1] ZHANG J, ZHENG X, XIAO H, et al. Effect of combined infrared hot air drying on yam slices: drying kinetics, energy consumption, microstructure, and nutrient composition[J]. Foods, 2023, 12(16): 3048. doi: 10.3390/foods12163048

[2] ZHANG J, ZHENG X, XIAO H, et al. Quality and process optimization of infrared combined hot air drying of yam slices based on BP neural network and gray wolf algorithm[J]. Foods, 2024, 13(3): 434. doi: 10.3390/foods13030434

[3] 闫沛沛,杨文华,曹俊岭,等. 不同产地山药中总多糖及尿囊素的含量分析[J]. 环球中医药,2016,9(3):295-298. doi: 10.3969/j.issn.1674-1749.2016.03.010 YAN Peipei, YANG Wenhua, CAO Junling, et al. Content analysis of polysaccharide and allantoin of Dioscorea opposite Thunb. from different habitats[J]. Global Traditional Chinese Medicine, 2016, 9(3): 295-298. (in Chinese with English abstract) doi: 10.3969/j.issn.1674-1749.2016.03.010

[4] 杨涛庆,郑霞,肖红伟,等. 基于含水率变化的气体射流冲击干燥过程温度自适应控制系统[J]. 农业工程学报,2024,40(2):52-62. doi: 10.11975/j.issn.1002-6819.202310206 YANG Taoqing, ZHENG Xia, XIAO Hongwei, et al. Temperature adaptive control system for air-impingement drying process based on moisture content change[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2024, 40(2): 52-62. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.202310206

[5] 张继凯,郑霞,肖红伟,等. 山药片红外联合热风干燥热质传递收缩模拟与品质[J]. 农业工程学报,2024,40(6):134-145. doi: 10.11975/j.issn.1002-6819.202308074 ZHANG Jikai, ZHENG Xia, XIAO Hongwei, et al. Simulation of heat and mass transfer shrinkage and quality of yam slices dried using infrared combined hot air[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2024, 40(6): 134-145. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.202308074

[6] 段续,李格格,李琳琳,等. 基于转换点调控的怀山药多相态微波干燥及品质特性[J]. 农业工程学报,2024,40(2):134-143. doi: 10.11975/j.issn.1002-6819.202306111 DUAN Xu, LI Gege, LI Linlin, et al. Multiphase microwave drying and quality characteristics of Chinese yam based on conversion point regulation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2024, 40(2): 134-143. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.202306111

[7] CHEN B, LIN G, AMANI M, et al. Microwave-assisted freeze drying of pineapple: Kinetic, product quality, and energy consumption[J]. Case Studies in Thermal Engineering, 2023, 41: 102682. doi: 10.1016/j.csite.2022.102682

[8] ZHANG M, CHEN H, MUJUMDAR A S, et al. Recent developments in high-quality drying of vegetables, fruits, and aquatic products[J]. Critical Reviews in Food Science and Nutrition, 2017, 57(6): 1239-1255. doi: 10.1080/10408398.2014.979280

[9] LI L, ZHANG M, ZHOU L. A promising pulse-spouted microwave freeze drying method used for Chinese yam cubes dehydration: Quality, energy consumption, and uniformity[J]. Drying Technology, 2021, 39(2): 148-161. doi: 10.1080/07373937.2019.1624564

[10] DUAN X, LIU W, REN G, et al. Comparative study on the effects and efficiencies of three sublimation drying methods for mushrooms[J]. International Journal of Agricultural and Biological Engineering, 2015, 8: 91-97.

[11] REN X, LI L, CHEN J, et al. Drying characteristics and quality of Chinese yam by multiphase microwave drying based on fractal theory[J]. Drying Technology, 2022, 40(15): 3310-3323. doi: 10.1080/07373937.2021.2024220

[12] YANG M, LI L, LIU W, et al. An evaluation on the shrinkage deformation characteristics of Chinese yam during multiphase microwave drying based on digital image processing[J]. Innovative Food Science & Emerging Technologies, 2024, 95: 103725.

[13] LI L, REN X, CHEN J, et al. Changes and relationships of viscoelastic and physical properties of Chinese yam during a novel multiphase microwave drying process[J]. LWT-Food Science and Technology, 2022, 168: 113969. doi: 10.1016/j.lwt.2022.113969

[14] 常剑,杨德勇,路倩倩,等. 热风干燥对果蔬薄壁组织细胞结构的影响[J]. 农业工程学报,2012,28(14):262-268. doi: 10.3969/j.issn.1002-6819.2012.14.040 CHANG Jian, YANG Deyong, LU Qianqian, et al. Effect of hot-air drying on cell structure of fruit and vegetable parenchyma[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(14): 262-268. (in Chinese with English abstract) doi: 10.3969/j.issn.1002-6819.2012.14.040

[15] 张乐道,李才云,王雅博,等. 微波真空冷冻干燥时怀山药的微CT孔道分布[J]. 农业工程学报,2024,40(6):72-78. doi: 10.11975/j.issn.1002-6819.202306147 ZHANG Ledao, LI Caiyun, WANG Yabo, et al. Micro-CT pore distribution in Chinese yam under microwave freeze drying[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2024, 40(6): 72-78. (in Chinese withEnglish abstract) doi: 10.11975/j.issn.1002-6819.202306147

[16] SCHOEMAN L, WILLIAMS P, DU PLESSIS A, et al. X-ray micro-computed tomography (μCT) for non-destructive characterisation of food microstructure[J]. Trends in Food Science & Technology, 2016, 47: 10-24.

[17] ANDO Y, HAGIWARA S, NABETANI H, et al. Improvements of drying rate and structural quality of microwave-vacuum dried carrot by freeze-thaw pretreatment[J]. LWT - Food Science and Technology, 2019, 100: 294-299. doi: 10.1016/j.lwt.2018.10.064

[18] HU L, BI J, JIN X, et al. Microstructure evolution affecting the rehydration of dried mushrooms during instant controlled pressure drop combined hot air drying (DIC-HA)[J]. Innovative Food Science & Emerging Technologies, 2022, 79: 103056.

[19] LéONARD A, BLACHER S, NIMMOL C, et al. Effect of far-infrared radiation assisted drying on microstructure of banana slices: An illustrative use of X-ray microtomography in microstructural evaluation of a food product[J]. Journal of Food Engineering, 2008, 85(1): 154-162. doi: 10.1016/j.jfoodeng.2007.07.017

[20] ANDO Y, NEI D. Effects of different pre-freezing methods and pressure levels on the pore structure and mechanical properties of microwave-vacuum dried apple[J]. Journal of Food Engineering, 2024, 369: 111944. doi: 10.1016/j.jfoodeng.2024.111944

[21] LI G, LI L, LIU W, et al. Effects of multiphase microwave drying on the microstructure of Chinese yam: A study based on X-ray micro-computed tomography technology[J]. LWT-Food Science and Technology, 2024, 203: 116327. doi: 10.1016/j.lwt.2024.116327

[22] DADMOHAMMADI Y, DATTA A K. Food as porous media: A review of the dynamics of porous properties during processing[J]. Food Reviews International, 2022, 38(5): 953-985. doi: 10.1080/87559129.2020.1761376

[23] GAO M, JI P, MIAO Z, et al. Pore structure evolution and fractal characteristics of Zhaotong lignite during drying[J]. Fuel, 2020, 267: 117309. doi: 10.1016/j.fuel.2020.117309

[24] ANDO Y, WATANABE T. Mechanical properties of dehydrofrozen carrots as a function of cell membrane damage, ice crystal development, and rehydration[J]. Journal of Food Engineering, 2023, 357.

[25] LI L, ZHANG M, WANG W. Ultrasound-assisted osmotic dehydration pretreatment before pulsed fluidized bed microwave freeze-drying (PFBMFD) of Chinese yam[J]. Food Bioscience, 2020, 35: 100548. doi: 10.1016/j.fbio.2020.100548

[26] HOU H, CHEN Q, BI J, et al. Understanding appearance quality improvement of jujube slices during heat pump drying via water state and glass transition[J]. Journal of Food Engineering, 2020, 272: 109874. doi: 10.1016/j.jfoodeng.2019.109874

[27] DUAN X, REN G Y, ZHU W X. Microwave freeze drying of apple slices based on the dielectric properties[J]. Drying Technology, 2012, 30(5): 535-541. doi: 10.1080/07373937.2011.648783

[28] 任广跃,朱乐雯,段续,等. 苹果丁冷冻-热风联合干燥体积收缩机制[J]. 农业工程学报,2024,40(2):63-71. doi: 10.11975/j.issn.1002-6819.202306182 REN Guangyue, ZHU Lewen, DUAN Xu, et al. Volume shrinkage mechanism for combined vacuum freeze drying-hot air drying of diced apples[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2024, 40(2): 63-71. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.202306182

[29] SIEBERT T, ZUBER M, HAMANN E, et al. Micro-CT visualization of structure development during freeze-drying processes[J]. Drying Technology, 2020, 38(3): 376-384. doi: 10.1080/07373937.2019.1572619

[30] SUN Q, ZHANG M, MUJUMDAR A S, et al. Research on the vegetable shrinkage during drying and characterization and control based on LF-NMR[J]. Food and Bioprocess Technology, 2022, 15(12): 2776-2788. doi: 10.1007/s11947-022-02917-x

[31] PURLIS E, CEVOLI C, FABBRI A. Modelling volume change and deformation in food products/processes: An overview[J]. Foods, 2021, 10(4): 778. doi: 10.3390/foods10040778

[32] LIU W C, DUAN X, REN G Y, et al. Optimization of microwave freeze drying strategy of mushrooms (Agaricus bisporus) based on porosity change behavior[J]. Drying Technology, 2017, 35(11): 1327-1336. doi: 10.1080/07373937.2017.1319851

[33] APRAJEETA J, GOPIRAJAH R, ANANDHARAMAKRISHNAN C. Shrinkage and porosity effects on heat and mass transfer during potato drying[J]. Journal of Food Engineering, 2015, 144: 119-128. doi: 10.1016/j.jfoodeng.2014.08.004

[34] 李雅琪,张鹏起,蔡健荣,等. 马铃薯薄片干燥过程热变形量分析[J]. 食品科学,2021,42(23):123-128. doi: 10.7506/spkx1002-6630-20201217-201 LI Yaqi, ZHANG Pengqi, CAI Jianrong, et al. Analysis of warpage variations in potato slices during hot air drying[J]. Food Science, 2021, 42(23): 123-128. (in Chinese with English abstract) doi: 10.7506/spkx1002-6630-20201217-201

[35] JOARDDER M U H, KARIM A. Pore evolution in cell walls of food tissue during microwave-assisted drying: An in-depth investigation[J]. Foods, 2023, 12(13): 2497. doi: 10.3390/foods12132497

下载:

下载: