Effects of precision feedback microwave heating on the physicochemical properties of myofibrillar proteins in Nemipterus virgatus

-

摘要:

为探究精准反馈微波加热(precision feedback microwave heating,PFMH)对金线鱼肌原纤维蛋白理化特性的影响,该研究以金线鱼肌原纤维蛋白为研究对象,并以传统水浴加热作为对照,测定PFMH不同温度和加热时间下肌原纤维蛋白的浊度、表面疏水性、荧光强度、紫外吸收度、热稳定性、凝胶电泳图谱、表面形貌和鱼糜凝胶化学作用力的变化。结果表明,与对照组相比,PFMH在85 ℃加热1 min后肌原纤维蛋白浊度和表面疏水性分别提高了129.41%和52.51%,荧光光谱呈下降趋势,紫外光谱呈现上升趋势,表明其三级结构发生了改变;差示扫描量热仪结果显示,PFMH处理的肌原纤维蛋白的降解温度(Td)提高了13.65%,焓变值(ΔH)降低了93.02%,提高了肌原纤维蛋白的热稳定性,防止肌原纤维蛋白的热变性和降解。同时,凝胶电泳图谱和原子力图像表明,85 ℃加热1 min有利于肌原纤维蛋白展开,形成致密的凝胶网络结构。化学作用力结果表明,在85 ℃加热1 min后,鱼糜凝胶的疏水相互作用和二硫键含量显著增加(P < 0.05),促进了肌原纤维蛋白的交联和聚集。综上所述,该研究可为PFMH技术在鱼糜制品加工中的应用提供理论参考。

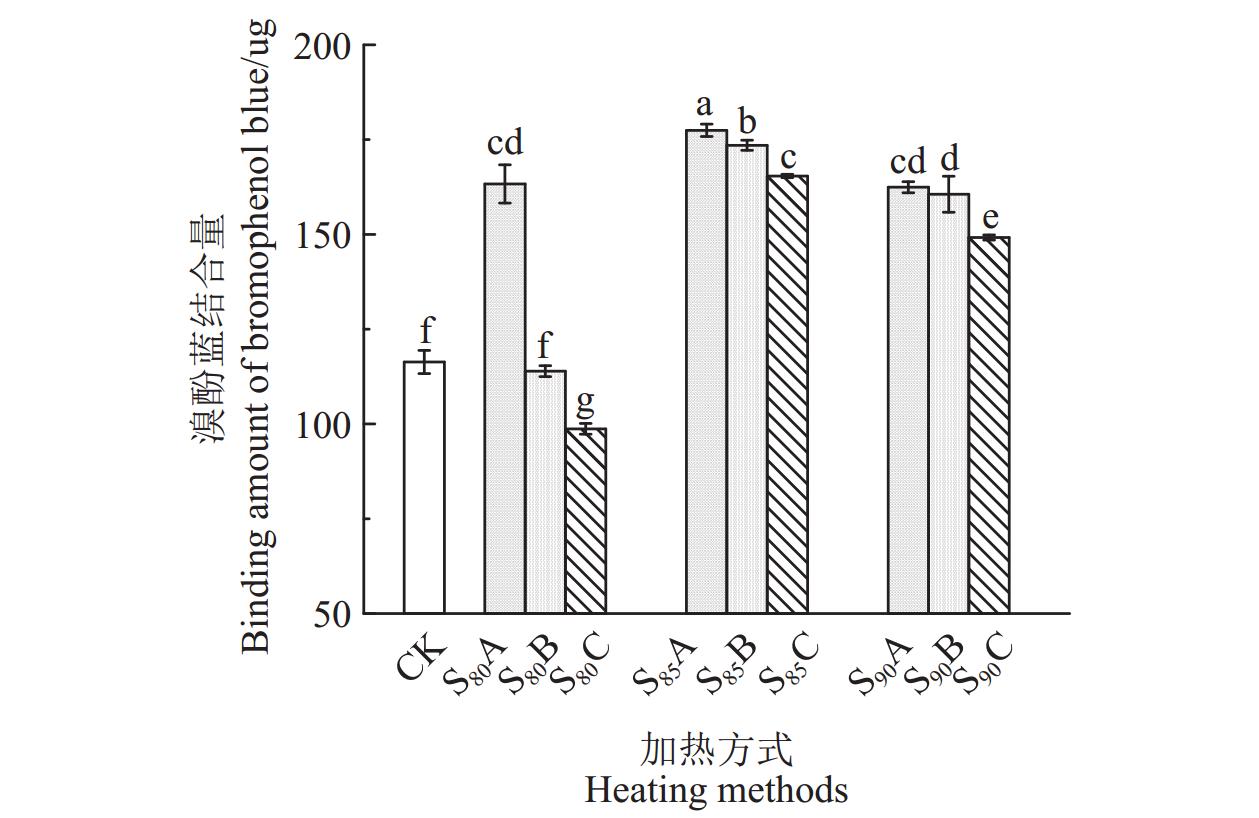

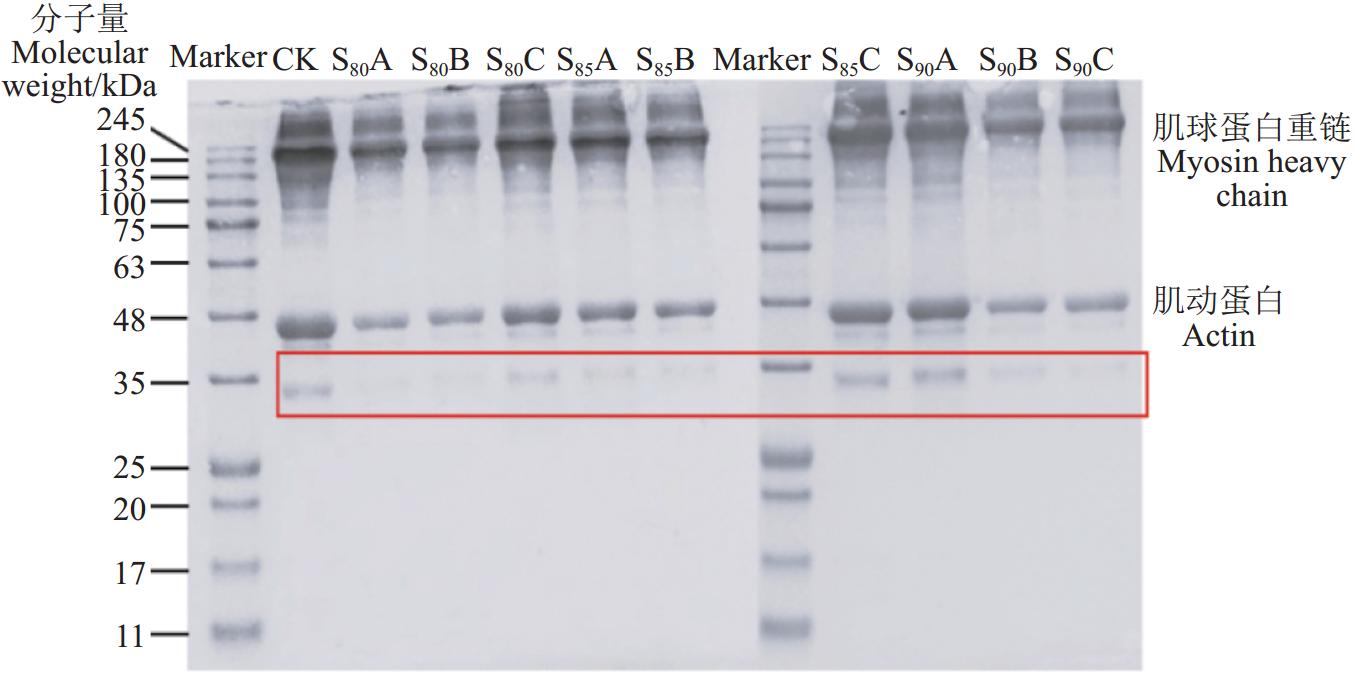

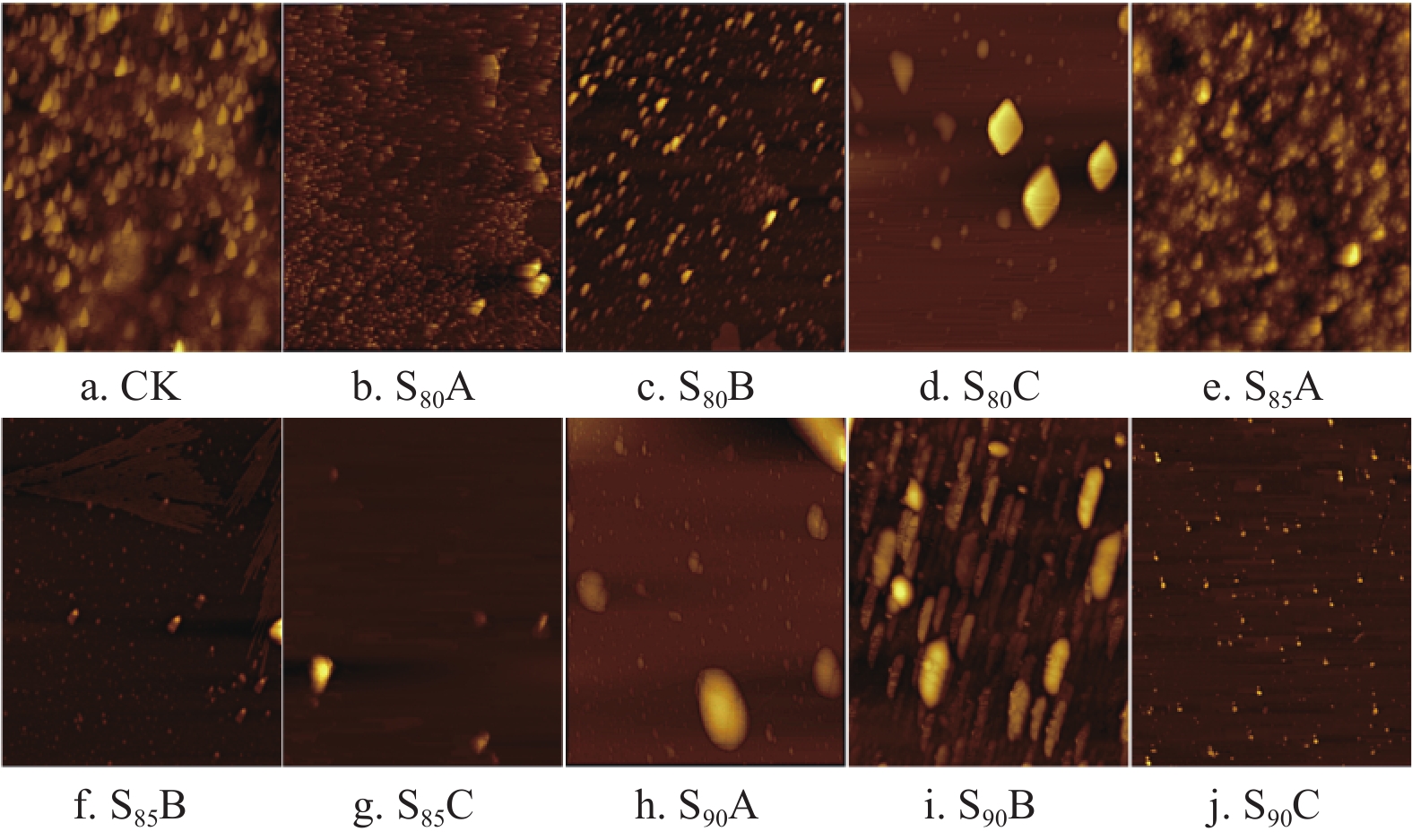

Abstract:This study aims to explore the effects of precision feedback microwave heating (PFMH) on the physicochemical properties of myofibrillar proteins (MPs) of Nemipterus virgatus. The MPs were collected from the Nemipterus virgatus as the research subject. Traditional water bath heating (40 ℃ for 30 min, and 90 ℃ for 20 min) was taken as the control. A systematic investigation was also made on the impacts of PFMH on the protein's turbidity, surface hydrophobicity, fluorescence intensity, ultraviolet (UV) absorbance thermal stability, gel electrophoresis patterns, surface morphology, and surimi gel chemical interactions under various temperatures and heating durations. Results showed that the turbidity and surface hydrophobicity of MPs significantly increased after PFMH treatment, compared with the control group. Both increases also indicated protein aggregation and denaturation, which were critical to understanding the variations in the internal structure of the protein. Specifically, the turbidity of MPs reached 0.78 when heated under S85A conditions, which was an increase of 129.41%, compared with the control group (0.34). Meanwhile, the surface hydrophobicity increased to 177.45 μg, representing a 52.51% increase, compared with the control group (116.35 μg). As such, the PFMH treatment altered the tertiary structure of the protein. The lowest intensity of fluorescence was at S85A, indicating that the PFMH treatment enhanced intermolecular interactions within the protein. Specifically, the PFMH treatment led to the dynamic fluorescence quenching of protein oxidative aggregates in the excited state, resulting in reduced fluorescence intensity. There was a higher fluorescence intensity of myofibrillar protein treated with PFMH at low temperatures (80 °C for 2 and 3 min), compared with the control. The reason was possibly that the rapid PFMH treatment caused some tryptophan residues to be buried within the MPs molecules. Conversely, the UV absorbance exhibited an upward trend, indicating that the PFMH heating induced the conformational changes in the protein structure. The exposure of more aromatic residues led to more effective UV light. Thermal stability was assessed using differential scanning calorimetry (DSC). The results showed that the PFMH treatment significantly enhanced the thermal stability of MPs. Furthermore, the degradation temperature (Td) of the MPs under S85A conditions reached the maximum of 62.20 ℃, an increase of 13.65%, compared with the control group (54.73 ℃). The enthalpy change (ΔH) decreased from 0.43 J/g in the control group to 0.03 J/g, representing a 93.02% reduction. As such, the PFMH treatment effectively prevented the thermal denaturation and degradation of MPs at elevated temperatures. Gel electrophoresis patterns and atomic force microscopy (AFM) images further revealed the structural changes induced by PFMH treatment. The MPs also unfolded to form a dense gel network structure under the S85A condition. Additionally, the AFM images indicated that the size of MPs aggregates increased, while the quantities decreased after PFMH treatment at 90 °C. Chemical interactions revealed that the maximum content of hydrogen bond was 3.06 g/L after heating at S85A conditions, which was 14.61% higher than that of the control group (2.67 g/L). Meanwhile, the hydrophobic interactions and disulfide bonds increased by 105.60% and 97.80%, respectively. However, the ionic bonds decreased after PFMH treatment, compared with the control group. The cross-linking and aggregation of MPs were promoted to form a more stable and compact protein structure. In conclusion, these findings demonstrated that the PFMH treatment significantly affected the physicochemical properties of MPs in Nemipterus virgatus. The protein denaturation and aggregation also induced the structural changes to enhance the thermal stability and the formation of dense gel networks. The heating processing of surimi products can also offer potential reference data for the future application of PFMH technology.

-

0. 引 言

生物炭是一种环保的有机碳源肥料,由于其特殊的理化性质,在改善土壤质量和功能等方面的应用已备受关注[1]。生物炭的多孔性和较大比表面积可吸附土壤有机碳,将微生物及其胞外酶与这部分有机碳隔离,减缓有机碳分解[2];生物炭可加快土壤形成有机无机结合体,增强有机碳稳定性[3],虽然生物炭施用可能会形成土壤有机碳激发效应,但从长远来看,其在土壤有机碳中发挥着积极作用。持续多年使用生物炭,土壤有机碳含量高且作物产量和质量稳定[4],但作用效果存在一定的异质性[5-6]。多项整合分析结果表明,施炭后土壤有机碳的增幅为14.3%~101.6%,生物炭通过参与土壤中的生物地球化学循环,不仅具有“固碳”作用,更有“增加碳汇”和“稳定汇”的潜力[7]。

北疆灌区是绿洲农业的典型代表地,其较高的粮食生产力也伴随着土壤有机质含量降低,肥力不足以支撑产量的可持续增长等问题。因此,农田地力培肥及土壤有机碳固持相关研究受到学者们的普遍关注。关于不同肥料管理方式下有机物料还田对灌区农田生产力及土壤有机碳周转与稳定的相关研究相继展开。越来越多的证据表明,生物炭施于土壤后有利于土壤团聚体的形成并降低土壤容重[8],提高土壤养分及水分吸收[9];改善土壤微生物群落结构[10],增加N、P转化,促进作物对N、P的吸收[11],缓解作物土传病害发生[12];显著提高作物的产量及生物量[13]。本团队前期研究了氮肥(低量、常规)配施生物质炭(30 t/hm²)对小麦土壤养分、土壤团聚体稳定性及产量的影响,结果表明适当的减施氮肥(低量)配施生物炭有利于增加小麦土壤养分、提高土壤团聚体稳定性及产量[14]。尽管在提高灌溉绿洲农田的土壤肥力、增加小麦籽粒品质及产量方面生物炭已被广泛应用,但现有研究仍存在很多不足,如:尚不清楚生物炭施用所产生的固碳减排效应及其对农田土壤质量的作用,其在绿洲灌溉农田生态系统中的应用潜力有待客观综合评价。

基于此,本研究进一步分析优化氮肥施用量并配施生物炭情况下麦田土壤有机碳库及小麦产量及品质的变化,旨在探明生物炭在北疆灌区农田促进化肥减施增效、固碳减排及作物稳产增产综合效应,以期为北疆灌区制定合理的化肥减量及生物炭施用措施,综合评价生物炭在灌区农田的应用价值提供参考。

1. 材料与方法

1.1 供试土壤和材料

于2021年4月—2022年7月在新疆奇台麦类试验站(89°13'E~91°22'E,42°25'N~45°29'N,海拔895.00 m)开展试验。奇台属于温带大陆性气候,年平均气温5.5 ℃,7月平均气温22.6 ℃,极端最高气温39 ℃,1月平均气温−18.9 ℃,年平均相对湿度60%,无霜期年平均153 d(4月下旬—10月上旬),年平均降水量269.4 mm。试验地土壤为壤质灰漠土,pH值为8.3,有机质含量13.9 g/kg,全磷含量1.3 g/kg,全钾含量18.1 g/kg,碱解氮含量128.7 mg/kg,有效磷含量11.4 mg/kg,速效钾含量147.0 mg/kg。

供试生物炭为玉米秸秆炭,由辽宁金和福农业科技股份有限公司提供,将玉米秸秆自然风干后碾碎,在450 ℃缺氧条件下炭化4 h,出炉后,将其制备成0.05~2.00 cm的颗粒,生物炭基本性质:pH 值为9.3,比表面积3.3 m2/g,固定碳含量68.7%,碳质量分数75.76%,挥发成分含量20.6%,灰分含量10.6%(质量分数)。

供试氮肥为尿素(质量分数98.5%),施用量为纯氮量。供试两季作物分别为春小麦和冬小麦,其中2021年4月—2021年8月为春小麦(新春37号),2021年9月—2022年7月为冬小麦(新冬22号)。

1.2 试验设计与试验过程

田间试验采用随机区组设计,设置7个处理:常规施氮(N1:300 kg/hm2)、氮肥减量15%(N2:255 kg/hm2)、氮肥减量30%(N3:210 kg/hm2)、单施生物炭(B:20 t/hm2)、常规施氮+生物炭(N1B)、氮肥减量15%+生物炭(N2B)、氮肥减量30%+生物炭(N3B)。氮肥与生物炭均作为底肥施入耕层30 cm,并以常规施氮为对照,每个处理设3次重复。

小麦播种方式为0.2 m无覆膜等行距条播,播种量为4.5×106株/hm2,每个小区面积为9 m2(3 m×3 m)。灌溉方式为滴灌,每间隔40 cm一个滴灌带,管道口径为20 mm,滴头型号为¢16,流量为2.2~2.4 L/h,全生育期灌水8次,每次灌水量为562.5 m3/hm2(相当于56.25 mm)。所有试验处理的管理措施均参照当地高产田的管理模式执行。2021年春小麦各生育时期如下:拔节期(5月22日)、孕穗期(6月1日)、开花期(6月10日)、灌浆期(7月3日)、成熟期(7月30日),2022年冬小麦各生育时期如下:拔节期(5月2日)、孕穗期(5月15日)、开花期(5月24日)、灌浆期(6月4日)、成熟期(7月2日)。在小麦生育时期内试验地的气温和降水量情况如图1所示,2021年生育期降雨量为186.4 mm,2022年年生育期降雨量为168.6 mm,2 a平均气温为19.7 ℃,2 a均属于干旱年。

1.3 测量项目与方法

1.3.1 土壤呼吸的测定

土壤呼吸通量采用Li-8100土壤碳通量自动测量系统测定,自制直径为20 cm、高为10 cm的PVC环垂直插入土壤中,将其安装在行间裸地,其下部插入土壤5 cm,自苗期起,于晴朗无风的08:00―11:00之间,每7 d测定一次,每次观测前一天提前清理出PVC环内植物残体,检查底座是否紧实插入土壤中,以防止漏气影响测定结果,浇水雨天不进行观测。

1.3.2 土壤指标的测定

2021年和2022年在小麦成熟后进行土样的选取,采用“S”型5点取样法在各小区选择5个点,每个点用土钻取0~20 cm土样,将取得的土样剔除沙砾及可见植物残留,混合均匀带回实验室。

采用常规法测定各指标,土壤总有机碳(soil total organic carbon,SOC)采用重铬酸钾- 浓硫酸外加热氧化法测定;土壤活性有机碳(soil active organic carbon,AOC)测定采用333 mmol/L KMnO4氧化法;土壤非活性有机碳含量(soil inactive organic carbon content,NAOC)为SOC与AOC的差值;容重采用环刀法测定。

1.3.3 碳库管理指数计算

碳库指数(carbon stock index,CPI)为样品中全碳含量与参照土壤全碳含量的比值;碳库活度(carbon pool activity,CA)为活性与非活性碳含量的比值;碳库活性指数(carbon pool activity index,AI)为样品碳库活度与参考土壤碳库活度的比值;碳库管理指数(carbon pool management index,CPMI)为CPI与AI的乘积(%),碳库管理指数计算详见参考文献[9]。

1.3.4 小麦品质测定

小麦品质包括水分、蛋白、面筋、Zeleny沉降值、淀粉等指标,采用瑞典 Perten IM 9500 型多功能谷物近红外分析仪测定,结果由系统软件自动分析。

1.3.5 小麦产量测定

小麦成熟后,于每小区选取长势一致的1 m2(1 m×1 m)样区测定有效穗数,并于各小区选取10株代表性小麦进行考种,并实收测定千粒质量,折算产量。

1.4 数据分析

采用Microsoft Excel 2019、Origin 2021作图,SPSS26.0软件数据统计分析。

2. 结果与分析

2.1 氮肥配施生物炭对土壤碳库管理指数的影响

由表1可知,适量氮肥配施生物炭对提升土壤中活性有机碳含量具有显著促进作用(P<0.05),与单施相同氮肥(N1~N3)处理相比,施生物炭后,AOC分别提高了17.27%(N1B)、27.43%(N2B)、21.82%(N3B)。与常规施氮(N1)相比,单施生物炭(B)、氮肥减量处理(N2、N3)均未显著提高或降低土壤中活性有机碳含量(P>0.05),而氮肥配施生物炭后,AOC显著提高(P<0.05),以N2B处理土壤活性有机碳含量最高,达到1.44 g/kg,较常规施氮(N1)显著增加30.91%。

表 1 2022年不同处理下土壤碳库指标Table 1. Soil carbon pool indicators under different treatments in 2022处理

Treatment土壤活性有机碳

Soil active organic

carbon(AOC)/(g·kg−1)碳库指数

Carbon stock

index(CPI)碳库活度

Carbon pool

activity(CA)碳库活性指数

Carbon pool activity

index(AI)碳库管理指数

Carbon pool management

index(CPMI)容重 Bulk

density/(g·cm−3)B 1.13c 1.29cd 0.05ab 0.91ab 117.15c 1.25 d N1 1.10c 1.17 d 0.06a 0.98a 114.79c 1.47ab N1B 1.29b 1.53a 0.05b 0.88b 134.27b 1.41bc N2 1.13c 1.39bc 0.05bc 0.85bc 117.68c 1.41bc N2B 1.44a 1.53a 0.06a 0.98a 150.17a 1.36c N3 1.10c 1.48ab 0.04c 0.76c 113.16c 1.49a N3B 1.34b 1.57a 0.05b 0.89b 139.81b 1.41bc 注:N1:常规施氮;N2:氮肥减量15%;N3:氮肥减量30%;B:单施生物炭;N1B:N1+ B;N2B:N2+B;N3B:N2+B。不同小写字母表示处理之间差异显著(P<0.05),下同。 Note: N1: Conventional nitrogen application; N2: 15% reduction in nitrogen fertilizer; N3: 30% reduction in nitrogen fertilizer, B: single application of biochar; N1B: N1+B; N2B: N2+B; N3B: N2+B. Different lowercase letters indicate significant differences between treatments (P<0.05), the same below. 土壤碳库管理指数(CPMI)作为表征土壤碳库变化的重要指标,能够反映增施生物炭对土壤质量的影响效果,CPMI值大说明增施生物炭可以维持和提高土壤质量,其值减小则表明土壤肥力在下降。与常规施氮(N1)相比,单施生物炭(B)处理、氮肥减量处理(N2、N3)均未显著改变CPMI,而氮肥配施生物炭后,CPMI显著提升(P<0.05),且以氮肥减量15%配施生物炭处理(N2B)CPMI最高,较常规施氮(N1)提升约30.82%(P<0.05)。

单施生物炭(B)处理土壤容重为1.25 g/cm3,显著低于其他处理(P<0.05);氮肥减量处理下土壤容重较与常规施氮(N1)相比处理间差异不显著,仅N2处理配施生物炭(N2B)后,土壤容重显著降低,说明减少15%的施氮量不影响土壤容重,但此时若施加生物炭则可有效降低土壤容重。

2.2 氮肥配施生物炭对土壤有机碳的影响

氮肥配施生物炭对土壤有机碳的影响见图2,2021年土壤总有机碳含量明显高于2022年。大多数施肥措施能显著增加土壤总有机碳含量(P<0.05)。2021年,常规施氮(N1)与单施生物炭(B)差异不显著,但其SOC显著低于氮肥减量处理(N2、N3)。N1和N2处理配施生物炭后,土壤SOC含量较单施氮肥显著增加,分别提高30.01%、9.99%。2022年,与单施氮肥处理相比,单施生物炭及氮肥与生物炭配施均显著提高SOC含量(P<0.05),所有施生物炭处理均差异不显著,其中在N2B处理与N2处理相比,显著提高了23.07%。

2.3 氮肥配施生物炭对麦田土壤呼吸的影响

不同施肥处理下麦田土壤呼吸速率差异显著(图3),氮肥优化及生物炭的施用改变了土壤CO2累积排放量,整体上,2022年各处理下土壤CO2累积排放量低于2021年,2 a均在单施生物炭(B)处理下降低土壤CO2累积排放量,并且降低效果最大,说明生物炭施用能降低土壤CO2排放。2021年各处理下土壤CO2累积排放量均呈2个不同的增长阶段:小麦生育前期(0~48 d)土壤CO2排放量增长迅速,生育后期(48~77 d)土壤CO2排放量增长趋势缓慢。除单施生物炭(B)处理外,与常规单施氮肥相比,各处理土壤CO2累积排放量呈现增强趋势,其中常规施氮配施生物炭(N1B)及氮减量30%单施(N3)处理下增加排放最大,土壤CO2累积排放量显著高于对照常规单施氮肥处理(P<0.05)。与氮减量15%单施(N2)处理相比,氮减量15%配施生物炭降低了CO2累积排放量,有助于固碳减排。2022年各处理下土壤CO2累积排放量在小麦出苗的0~26 d土壤CO2排放量增长迅速,并且氮肥与生物炭配施处理下的土壤CO2累积排放量高于单施氮肥处理和单施生物炭处理。其中在氮肥减量15%和氮肥减量30%配施生物炭(N2B、N3B)处理下增加排放,且增加效果最大。

2.4 氮肥配施生物炭对小麦品质及产量的影响

氮肥和生物炭施用对品质的影响如表2所示。在2021年,与单施生物炭(B)处理相比,单施氮肥处理均显著降低了春小麦籽粒水分含量(P<0.05),其中N1处理下降低4.66%。与单施氮肥相比,配施生物炭后小麦籽粒蛋白(干基)含量,2021年仅N1B处理提高2.81%,2022年N1B和N2B均显著提高7.60%、9.16%。单施氮肥处理下,2021年小麦面筋(湿基)含量表现为N1和N2显著高于N3,2022年N1、N2、N3无显著差异。与单施氮肥处理相比,小麦籽粒Zeleny沉降值在2021年仅N1B处理显著提高7.02%。2021年春小麦淀粉(湿基)含量随氮肥施用量的减少而下降,N1处理达62.19%。在氮肥减量30%(N3、N3B)处理显著降低淀粉(湿基)含量,较N1处理相比,降低了2.67%、2.28%,而2022年冬小麦淀粉(湿基)含量在N2B处理下较低,为61.83%,各处理差异不大。常规氮肥与生物炭配施较单施氮肥处理相比,降低了小麦籽粒硬度,小麦籽粒硬度在单施氮肥条件下,各处理均随氮肥施用量降低而升高。

表 2 2021−2022不同处理对小麦籽粒品质及产量的影响Table 2. Effects of different treatments on wheat grain quality and yield in 2021 and 2022年份

Year处理

Treatment水分

Moisture

content/%蛋白

(干基)

Protein

(dry basis)/%面筋

(湿基)

Gluten

(wet base)/%Zeleny

沉降值

Zeleny

settlement

value/mL淀粉

(湿基)

Starch

(wet basis)/%硬度

Hardness穗数

Spike number

/(×104穗·hm−2)穗粒数

Grains

per spike千粒质量

1000-grain

weight/g产量

Yield/

(kg·hm−2)2021 B 10.72a 16.45ab 30.88b 46.45b 61.96a 64.45b 500.00bc 36.00ab 41.83cd 6 558.43bc N1 10.22bc 16.39b 30.91b 46.42b 62.19a 64.59b 521.00abc 35.21ab 42.35bc 6 797.93bc N1B 10.13c 16.85a 31.98a 49.68a 62.02a 62.55c 552.00ab 36.96ab 42.60b 7 561.92ab N2 10.30bc 16.35b 30.88b 46.38b 61.99a 65.32ab 509.67bc 30.38cd 42.33bc 5 693.01cd N2B 10.27bc 16.59ab 31.31b 46.95b 62.12a 63.79bc 576.33a 38.08a 43.47a 8 301.35a N3 10.37bc 16.47ab 29.60c 45.72b 60.53b 66.63a 489.67c 29.00 d 41.73 de 5 192.69 d N3B 10.47b 16.70ab 29.85c 46.15b 60.77b 65.02ab 523.00abc 33.92bc 43.27a 6 682.55bc 2022 B 8.97ab 14.60b 27.00 d 35.22b 62.67ab 36.90 d 601.33ab 32.84bc 41.56c 7 138.27bc N1 8.87ab 14.47b 31.90bc 39.72ab 62.53ab 38.30cd 623.00ab 34.96ab 41.90bc 7 920.12bc N1B 9.03a 15.57a 33.33ab 44.88a 62.07bc 37.53 d 640.67ab 37.60a 44.06ab 9 258.65ab N2 8.90ab 14.63b 31.20c 37.75ab 62.57ab 39.30c 617.00ab 34.04b 40.68c 7 423.23bc N2B 8.93ab 15.97a 34.30a 42.70a 61.83c 39.63bc 709.00a 38.11a 45.55a 10 784.76a N3 8.83ab 14.43b 30.80c 38.12ab 62.77a 41.47a 551.00b 30.31c 40.66c 5 932.67c N3B 8.70b 15.20ab 31.93bc 41.75ab 62.53ab 41.10ab 561.33b 32.33bc 42.58bc 6 747.72c 与单施生物炭(B)相比,2021年氮肥减量15%配施生物炭(N2B)处理穗数和千粒质量显著提高15.27%、3.92%,2022年千粒质量显著提高9.60%。在2021年,N2和N3处理配施生物炭均显著提高了千粒质量。与常规施氮(N1)相比,氮肥减量30%(N3)处理下小麦产量显著降低23.61%(P<0.05),而减氮15%并未显著降低产量。在N2和N3基础上配施生物炭可显著提高小麦产量,其中,氮肥减量15%配施生物炭(N2B)春小麦产量达8 301.35 kg/hm2,较常规施肥(N1)显著增加22.12%(P<0.05)。较单施常规氮肥(N1)相比,N2B显著提高2022年冬小麦千粒质量和产量(P<0.05),分别提高8.71%、36.17%。2 a在N1B和N2B处理下穗粒数和产量均较高,且2个处理间差异不显著(P>0.05)。

3. 讨 论

长期过量施用氮肥使中国土壤的氮素背景值较高,短期适量减少氮肥施用不会使作物减产[15]。生物炭施用可同时促进小麦产量提高小麦籽粒品质,其中蛋白质和淀粉含量是决定小麦籽粒品质好坏的关键因素[16]。本研究中,与常规施氮相比,氮肥减量15%均未显著降低小麦产量和品质指标,与单施氮肥处理相比,适量氮肥配施生物炭能提高小麦籽粒蛋白质含量。2021年常规施氮和2022年常规施氮和氮肥减量15%时,适合此规律。这可能是由于生物炭具有吸附性,能够有效吸附氮素转化为氨基酸,促进蛋白质的合成。适量减少氮肥可增加土壤速效养分含量,提高作物养分利用效率,增加作物产量[17]。尽管如此,氮肥的作用不可替代,过量控制氮肥输入会因氮素产投不平衡而使作物产量降低[18],本研究中,与常规施氮相比,氮肥减量30%时2021年小麦产量减产23.61%。可见,减氮对产量的影响与减少比例密切相关,适宜减氮比例才能保证产量不显著减低,关于优化氮肥输入的量与作物生产力及产量的关系还需进行长期综合评估。

土壤呼吸是土壤中有机体和植物的地下部分产生CO2的过程,包括地下部分植物呼吸(根呼吸)和异养呼吸(微生物呼吸)[19],本研究所测呼吸为二者之和。关于生物炭对土壤CO2排放影响研究存在争议,多数研究认为生物炭可以将大气中CO2固定到土壤中,同时还可以减少CO2的排放[20],也有研究指出施用生物炭可通过改善土壤理化性质和生物学性质,促进土壤CO2排放[21]。本研究中,不同量氮肥与生物炭配施土壤呼吸速率不同,除单施生物炭处理外,与常规单施氮肥处理相比均有所上升。土壤活性有机碳含量直接影响着土壤CO2排放量[22-23]。生物炭施用提高了土壤孔隙度及土壤含水量[24-25],使得易矿化可溶性有机质含量增加[26],促进矿化从而提高土壤CO2排放量。团队前期研究发现,适量生物炭输入能够提高土壤团聚体稳定性[27],对土壤有机碳形成物理隔离[28],减少微生物和酶对有机碳的分解,而当生物炭用量较高时,其巨大的比表面积以及良好的吸附性能为微生物提供更疏松的环境,提高微生物活性[29],将促进土壤微生物呼吸。在本团队同期研究中,土壤CO2累积排放量随生物炭添加量增加呈先下降后上升趋势,进一步说明生物炭添加对土壤呼吸的影响存在阈值。有研究发现,减少氮肥施用量可以降低土壤呼吸速率[30],本研究2022年结果与此相反,这可能是由于较少的氮肥投入促使微生物与植物对氮素的竞争,进而使土壤呼吸速率提高。单施生物炭条件下土壤呼吸速率最低,因生物炭具有较大的比表面积和一定含量的钙铁离子,对CO2有较强的物理、化学固定作用,使生物炭与土壤和有机质形成较为稳定的有机-无机复合体,减少了土壤CO2排放[31]。另外,生物炭含有较多高度稳定性的碳组分,一定程度上阻止微生物对其分解,使得生物炭中的原有的碳得以保存,增加土壤有机碳的同时降低土壤碳矿化[32],或未能引起土壤碳矿化,对土壤呼吸无影响[33],因而具有固碳效应。

生物炭富含碳源,施入农田土壤后可快速提高土壤有机碳含量,与氮肥配施后增加土壤微生物的活性和功能,加速有机碳的周转[34]。本研究中,适量氮肥配施生物炭处理(N1B、N2B、N3B)均提高了土壤SOC含量,这与罗梅等[35]的研究结果相似。活性有机碳含量与土壤SOC含量变化规律一致,且土壤SOC含量与活性有机碳含量呈显著正相关[36]。土壤碳库管理指数表征土壤养分及碳素动态变化,比土壤有机碳更具有敏感性,反映有机碳被微生物和植物利用的难易程度,其值越大表示碳库活度和质量也越高[37]。本试验中,在施氮量相同时配施生物炭可显著提高土壤活性有机碳含量,生物炭施入土壤后能够增加土壤的孔隙度和含氧量,为真菌以及微生物的生长繁殖提供良好环境,进而增加土壤活性有机碳含量。

此外,土壤有机碳含量与容重密切相关,表层土壤容重小时,水气交换条件良好,土壤有机碳富集在表层转化分解较快,相应的土壤活性有机碳含量及碳库活度也较高,为小麦生长提供更多的养分[38]。生物炭疏松多孔的性质能显著增加土壤孔隙度,降低土壤容重。其多孔结构,使得土壤水分和降水等更多地被其吸附而存留在耕层土壤中,提高了土壤含水量[39],促进作物养分水分吸收,有利于作物产量形成。

4. 结 论

为明确氮肥配施生物炭在北疆灌区农田促进化肥减施增效、固碳减排及作物稳产增产提质的综合效应,开展试验研究,结论如下:

1) 适量氮肥配施生物炭后,与常规施氮相比,土壤总有机碳含量提高。单施生物炭能降低土壤CO2排放量,且减排效果最好。

2) 与常规施氮(300 kg/hm2)相比,2021年减氮30%降低淀粉(湿基)含量,2022年减氮15%配施生物炭显著提高小麦籽粒的蛋白(干基)和面筋(湿基)含量(P<0.05)。

3)与常规施氮相比,2 a减氮15%时配施生物炭均显著提高产量,而减氮30%时降低产量(P<0.05)。

综上,在本试验条件下,氮肥减量15%配施20 t/hm2生物炭,可有效提高麦田土壤SOC含量,促进小麦产量品质提升,与氮减量15%相比,具备固碳减排效应,为本试验区麦田土壤固碳减排及化肥减施增效的较好选择。

-

图 1 加热方式对金线鱼肌原纤维蛋白浊度的影响

注:CK为对照组(水浴加热);S80A、S80B、S80C分别为80 ℃微波加热加热2、3、4 min;S85A、S85B、S85C分别为85 ℃微波加热1、2、3 min;S90A、S90B、S90C分别为90 ℃微波加热15、30、45 s。不同小写字母表示不同加热方式间具有显著性差异(P < 0.05),下同。

Figure 1. Effects of heating methods on the turbidity of myofibrillar proteins (MPs) in Nemipterus virgatus

Note: CK is the control group (water bath heating); S80A, S80B, and S80C represent microwave heating at 80 ℃ for 2, 3, 4 min, respectively; S85A, S85B, and S85C represent microwave heating at 85 ℃ for 1, 2, 3 min, respectively; S90A, S90B, and S90C represent microwave heating at 90 ℃ for 15, 30, 45 s, respectively. Distinct lowercase letters signify that there are statistically significant differences among various heating methods. (P < 0.05), the same below.

表 1 加热方式对金线鱼肌原纤维蛋白热稳定性的影响

Table 1 Effects of heating methods on the thermal stability of MPs in Nemipterus virgatus

加热方式

Heating methods加热条件

Heating conditionsTd/℃ ΔH/(J·g−1) 水浴加热

Water-bath heatingCK 54.73±0.22b 0.43±0.02b PFMH S80A 59.36±4.87ab 0.45±0.07b S80B 56.30±0.54ab 0.75±0.18a S80C 55.49±2.48ab 0.66±0.06a S85A 62.20±5.91a 0.03±0.01e S85B 57.09±1.94ab 0.17±0.03de S85C 62.06±1.14a 0.23±0.02cd S90A 60.89±1.17ab 0.24±0.01cd S90B 59.86±0.72ab 0.33±0.03bcd S90C 62.10±1.17a 0.39±0.09bc 注:PFMH为精准反馈微波加热,同一指标中,不同小写字母表示差异显著(P < 0.05),Td值为降解温度,ΔH为焓变值,下同。 Note: PFMH is precision feedback microwave heating, in the same indicator, different lowercase letters indicate significant differences. (P < 0.05), Td value is the degradation temperature, ΔH is the enthalpy change value, the same below. 表 2 加热方式对金线鱼鱼糜凝胶化学相互作用力的影响

Table 2 Effects of heating methods on the chemical interaction forces of surimi gel in Nemipterus virgatus

g·L−1 加热方式

Heating methods加热条件

Heating conditions离子键含量

Ionic bond content疏水相互作用

Hydrophobic interaction氢键含量

Hydrogen bond content二硫键含量

Disulfide bond content水浴加热

Water-bath heatingCK 1.04±0.46a 1.25±0.30bcd 2.67±0.20ab 0.91±0.11e PFMH S80A 0.87±0.11bc 0.87±0.23def 2.91±0.30a 0.84±0.22e S80B 0.94±0.31ab 1.27±0.24bcd 2.03±0.42bcd 1.43±0.04bc S80C 0.33±0.02de 1.70±0.30b 1.50±0.35de 1.37±0.25c S85A 0.56±0.12bcd 2.57±0.26a 3.06±0.15a 1.80±0.14a S85B 0.55±0.26bcd 1.41±0.44bc 0.59±0.06f 0.71±0.01e S85C 0.51±0.10cde 1.49±0.31bc 1.83±0.08cde 1.61±0.04ab S90A 1.20±0.01a 1.19±0.13cde 1.61±0.10cde 1.14±0.03d S90B 0.15±0.02e 0.64±0.10f 2.36±0.53abc 0.86±0.07e S90C 0.48±0.08cde 0.68±0.10ef 1.16±0.50ef 0.31±0.01f -

[1] 钟坦君,洪鹏志,周春霞,等. 没食子酸对金线鱼鱼糜凝胶特性及其体外消化产物活性的影响[J]. 食品科学,2022,43(14):76-84. doi: 10.7506/spkx1002-6630-20211022-239 ZHONG Tanjun, HONG Pengzhi, ZHOU Chunxia, et al. Effect of gallic acid on gel properties and in vitro activity of digested products of Nemipterus virgatus surimi[J]. Food Science, 2022, 43(14): 76-84. (in Chinese with English abstract) doi: 10.7506/spkx1002-6630-20211022-239

[2] 常珂欣,范馨茹,于双,等. 水产动物肌原纤维蛋白结构、功能特性与改性机制研究进展[J]. 大连海洋大学学报,2024,39(3):529-538. CHANG Kexin, FAN Xinru, YU Shuang, et al. Progress in research on steucture, functional properties and modification myofibrillar proteins from aquatic animals: A review[J]. Journal of Dalian Ocean University, 2024, 39(3): 529-538. (in Chinese with English abstract)

[3] XIONG Z Y, SHI T, JIN W G, et al. Gel performance of surimi induced by various thermal technologies: A review[J]. Critical Reviews in Food Science and Nutrition, 2022, 64(10): 3075-3090.

[4] 韩柯颖,魏苏萌,杨玉玲,等. 响应面法优化微波加热制备肌原纤维蛋白凝胶工艺[J]. 肉类研究,2020,34(9):31-38. doi: 10.7506/rlyj1001-8123-20200628-163 HAN Keying, Wei Sumeng, YANG Yuling, et al. Optimization of microwave-assisted preparation of heat-induced myofibrillar protein gel by response surface methodology[J]. Meat Research, 2020, 34(9): 31-38. (in Chinese with English abstract) doi: 10.7506/rlyj1001-8123-20200628-163

[5] CAO H W, FAN D M, JIAO X D, et al. Effects of microwave combined with conduction heating on surimi quality and morphology[J]. Journal of Food Engineering, 2018, 228: 1-11. doi: 10.1016/j.jfoodeng.2018.01.021

[6] FU X J, KHIZAR H, LI Z H, et al. Effect of microwave heating on the low-salt gel from silver carp (Hypophthalmichthys molitrix) surimi[J]. Food Hydrocolloids, 2012, 27(2): 301-308. doi: 10.1016/j.foodhyd.2011.09.009

[7] FENG D D, XUE Y, LI Z J, et al. Effects of microwave radiation and water bath heating on the physicochemical properties of actomyosin from silver carp (Hypophthalmichthys molitrix) during setting[J]. Journal of Food Processing and Preservation, 2017, 41(4): 13031. doi: 10.1111/jfpp.13031

[8] WANG Q, JIAO X D, YAN B W, et al. Inhibitory effect of microwave heating on cathepsin l-induced degradation of myofibrillar protein gel[J]. Food Chemistry, 2021, 357: 129745. doi: 10.1016/j.foodchem.2021.129745

[9] CAO H W, JIAO X D, FAN D M, et al. Microwave irradiation promotes aggregation behavior of myosin through conformation changes[J]. Food Hydrocolloids, 2019, 96: 11-19. doi: 10.1016/j.foodhyd.2019.05.002

[10] LI Z Y, WANG J Y, ZHENG B D, et al. Impact of combined ultrasound-microwave treatment on structural and functional properties of golden threadfin bream (Nemipterus virgatus) myofibrillar proteins and hydrolysates[J]. Ultrasonics Sonochemistry, 2020, 65: 105063. doi: 10.1016/j.ultsonch.2020.105063

[11] LIU X J, CHI J H, LIN Y W, et al. Mechanistic insights into combined effects of continuous microwave heating and tremella powder addition on physiochemical properties of Nemipterus virgatus surimi gel[J]. Food Chemistry, 2024, 460: 140752. doi: 10.1016/j.foodchem.2024.140752

[12] MI H B, YANG Y C, YI S M, et al. Effect of γ-oryzanol/β-sitosterol-based oleogels on the physicochemical and gel properties of Nemipterus virgatus myofibrillar protein[J]. Journal of the Science of Food and Agriculture, 2024, 104(13): 8120-8129. doi: 10.1002/jsfa.13642

[13] 朱文慧,郭慧芳,单春雨,等. 微波纳米解冻对秘鲁鱿鱼保水性和蛋白结构的影响[J]. 中国食品学报,2022,22(8):146-151. ZHU Wenhui, GUO Huifang, SHAN Chunyu, et al. Effects of microwave nanoparticles thawing on water holding capacity and protein structure of jumbo squid (Dosidicus gigas)[J]. Journal of Chinese Institute of Food Science and Technology, 2022, 22(8): 146-151. (in Chinese with English abstract)

[14] 张丽,王惠惠,宋艳艳,等. IOS和MOS对牦牛肌原纤维蛋白生化与功能特性的影响[J]. 农业工程学报,2020,36(9):308-314. doi: 10.11975/j.issn.1002-6819.2020.09.035 ZHANG Li, WANG Huihui, SONG Yanyan, et al. Effects of MOS and IOS on the biochemical and functional traits of myofibrillar proteins of yak[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(9): 308-314. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2020.09.035

[15] 王振国,高育哲,时家峰,等. 挤压温度对大豆分离蛋白与原花青素复合物结构和功能特性的影响[J]. 农业工程学报,2022,38(21):279-286. doi: 10.11975/j.issn.1002-6819.2022.21.032 WANG Zhenguo, GAO Yuzhe, SHI Jiafeng, et al. Effects of extrusion temperature on the functional and structural properties of soybean protein isolate and proanthocyanidin complex[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022, 38(21): 279-286. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2022.21.032

[16] 刘丽莉,于影,苏克楠,等. 植物多酚-牛血清白蛋白相互作用及对蛋白质结构的影响[J]. 农业工程学报,2023,39(13):290-298. doi: 10.11975/j.issn.1002-6819.202305004 LIU Lili, YU Ying, SU Kenan, et al. Polyphenol-bovine serum albumininteraction and its influence on protein structure[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2023, 39(13): 290-298. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.202305004

[17] 任娟蕊,傅婧,赵习爱. 亚麻籽分离蛋白结构表征及其性能分析[J]. 农业工程学报,2024,40(5):326-336. doi: 10.11975/j.issn.1002-6819.202312060 REN Juanrui, FU Jing, ZHAO Xiai. Structural characterization and performance analysis of flaxseed isolate protein[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2024, 40(5): 326-336. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.202312060

[18] 王艳敏,于加美,石彤,等. 原子力显微镜研究L-半胱氨酸对鲢肌球蛋白溶液热聚集行为的影响[J]. 食品科学,2018,39(14):1-8. doi: 10.7506/spkx1002-6630-201814001 WANG Yanmin, YU Jiamei, SHI Tong, et al. Influence of L-Cysteine on the heat-Induced aggregation of bighead carp myosin studied by atom force microscope[J]. Food Science, 2018, 39(14): 1-8. (in Chinese with English abstract) doi: 10.7506/spkx1002-6630-201814001

[19] 刘欣,姜鹏飞,傅宝尚,等. 高压均质化改性竹笋膳食纤维对虾糜凝胶特性及化学作用力的影响[J]. 食品科学,2023,45(11):192-200. LIU Xin, JIANG Pengfei, FU Baoshang, et al. Effect of high-pressure homogenization modified bamboo shoot dietary fiber on gelation properties and chemical Interactions of shrimp surimi[J]. Food Science, 2023, 45(11): 192-200. (in Chinese with English abstract)

[20] 李艳青,孔保华,杨赫鸿,等. 自由基氧化引起鲤鱼肌原纤维蛋白结构的变化[J]. 食品科学,2012,33(13):70-74. LI Yanqing, KONG Baohua, YANG Hehong, et al. Structural changes of common carp myofibrillar (MPI) influenced by hydroxyl radical system[J]. Food Science, 2012, 33(13): 70-74. (in Chinese with English abstract)

[21] 王天泽,杨平,黄峰,等. 热处理过程中肌肉蛋白与萜类化合物相互作用机制[J]. 农业工程学报,2023,39(17):286-294. doi: 10.11975/j.issn.1002-6819.202305248 WANG Tianze, YANG Ping, HUANG Feng, et al. Interaction mechanisms for the muscle proteins with terpenoid compounds during heat treatment[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2023, 39(17): 286-294. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.202305248

[22] 党慧杰,郑远荣,刘振民. 超高压处理对乳清分离蛋白结构及致敏蛋白含量的影响[J]. 食品与发酵工业,2021,47(6):56-61. DANG Huijie, ZHENG Yuanrong, LIU Zhenmin. Effects of ultra-high pressure on the structure of whey protein isolate and the content of allergenic protein[J]. Food and Fermentation Industries, 2021, 47(6): 56-61. (in Chinese with English abstract)

[23] 张燕,李升升,赵立柱,等. 烹饪温度对牦牛肉蛋白质氧化和体外消化特性的影响[J]. 食品科学,2024,45(2):9-16. doi: 10.7506/spkx1002-6630-20230430-293 ZHANG Yan, LI Shengsheng, ZHAO Lizhu, et al. Effect of cooking temperature on protein oxidation and in vitro digestive properties of yak meat[J]. Food Science, 2024, 45(2): 9-16. (in Chinese with English abstract) doi: 10.7506/spkx1002-6630-20230430-293

[24] CONG H H, LYU H, LIANG W W, et al. Changes in myosin from silver carp (Hypophthalmichthys molitrix) under microwave-assisted water bath heating on a multiscale[J]. Foods, 2022, 11(8): 1071. doi: 10.3390/foods11081071

[25] 江连洲,王一畅,马依彤,等. 微波对大豆蛋白氧化聚集体结构及功能特性的影响[J]. 农业工程学报,2022,39(9):261-269. doi: 10.11975/j.issn.1002-6819.2022.09.029 JIANG Lianzhou, WANG Yichang, MA Yitong, et al. Effects of microwave treatment on the structural and functional properties of oxidized aggregated soybean proteins[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022, 39(9): 261-269. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2022.09.029

[26] 刘珍,王金厢,李学鹏,等. 大豆分离蛋白与金线鱼肌球蛋白的相互作用对其凝胶特性的影响[J]. 食品工业科技,2023,44(16):122-130. LIU Zhen, WANG Jinxiang, LI Xuepeng, et al. Effect of interaction between soy protein isolate and Nemipterus virgatus myosin on its gel properties[J]. Science and Technology of Food Industry, 2023, 44(16): 122-130. (in Chinese with English abstract)

[27] HUANG Y, DU H Y, KAMA G M, et al. Studies on the binding Interactions of grass carp (Ctenopharyngodon idella) myosin with chlorogenic acid and rosmarinic acid[J]. Food and Bioprocess Technology, 2020, 13(8): 1421-1434. doi: 10.1007/s11947-020-02483-0

[28] WANG K Q, LUO S Z, ZHONG X Y, et al. Changes in chemical interactions and protein conformation during heat-induced wheat gluten gel formation[J]. Food Chemistry, 2017, 46(16): 393-399.

[29] ZHANG M, ZHU S R, LI Q, et al. Effect of thermal processing on the conformational and digestive properties of myosin[J]. Foods, 2023, 12(6): 1249. doi: 10.3390/foods12061249

[30] CHEN X, ZHOU R Y, XU X L, et al. Structural modification by high-pressure homogenization for improved functional properties of freeze-dried myofibrillar proteins powder[J]. Food Research International, 2017, 100: 193-200. doi: 10.1016/j.foodres.2017.07.007

[31] WANG B, KONG B H, LI F F, et al. Changes in the thermal stability and structure of protein from porcine longissi-mus dorsi induced by different thawing methods[J]. Food Chemistry, 2020, 316: 126375. doi: 10.1016/j.foodchem.2020.126375

[32] 李颖畅,师丹华,赵淞民,等. 超声波辅助没食子酸对鲈鱼肌原纤维蛋白结构特性的影响[J]. 中国食品学报,2023,23(7):88-98. LI Yingchang, SHI Danhua, ZHAO Songmin, et al. Effect of gallic acid on structural properties of lateolabrax japonicas myofibrillar protein under ultrasonic treatment[J]. Journal of Chinese Institute of Food Science and Technology, 2023, 23(7): 88-98. (in Chinese with English abstract)

[33] 李京九,宋明菲,牛越,等. 超高压处理过程中卤鸭腿肌原纤维蛋白结构变化[J]. 食品工业科技,2025,46(2):1-8. LI Jingjiu, SONG Mingfei, NIU Yue, et al. Structural changes of myofibrillar proteins in marinated duck drumsticks during high pressure processing treatment[J]. Science and Technology of Food Industry, 2025, 46(2): 1-8. (in Chinese with English abstract)

[34] XUE S W, YANG H J, WANG H H, et al. High-pressure effects on the molecular aggregation and physicochemical properties of myosin in relation to heat gelation[J]. Food Research International, 2017, 99: 413-418. doi: 10.1016/j.foodres.2017.06.014

[35] HE X L, LV Y N, LI X P, et al. Improvement of gelation properties of silver carp surimi through ultrasound-assisted water bath heating[J]. Ultrasonics Sonochemistry, 2022, 83: 105942. doi: 10.1016/j.ultsonch.2022.105942

[36] ZHANG T, WANG J, FENG J Q, et al. Effects of ultrasonic–microwave combination treatment on the physicochemical, structure and gel properties of myofibrillar protein in Penaeus vannamei (Litopenaeus vannamei) surimi[J]. Ultrasonics Sonochemistry, 2022, 90: 106218. doi: 10.1016/j.ultsonch.2022.106218

[37] YAN B W, JIAO X D, ZHU H P, et al. Chemical interactions involved in microwave heat-induced surimi gel fortified with fish oil and its formation mechanism[J]. Food Hydrocolloids, 2020, 105: 105779. doi: 10.1016/j.foodhyd.2020.105779

下载:

下载: