Path tracking algorithm of the dual motor tracked chassis considering skid and slip

-

摘要:

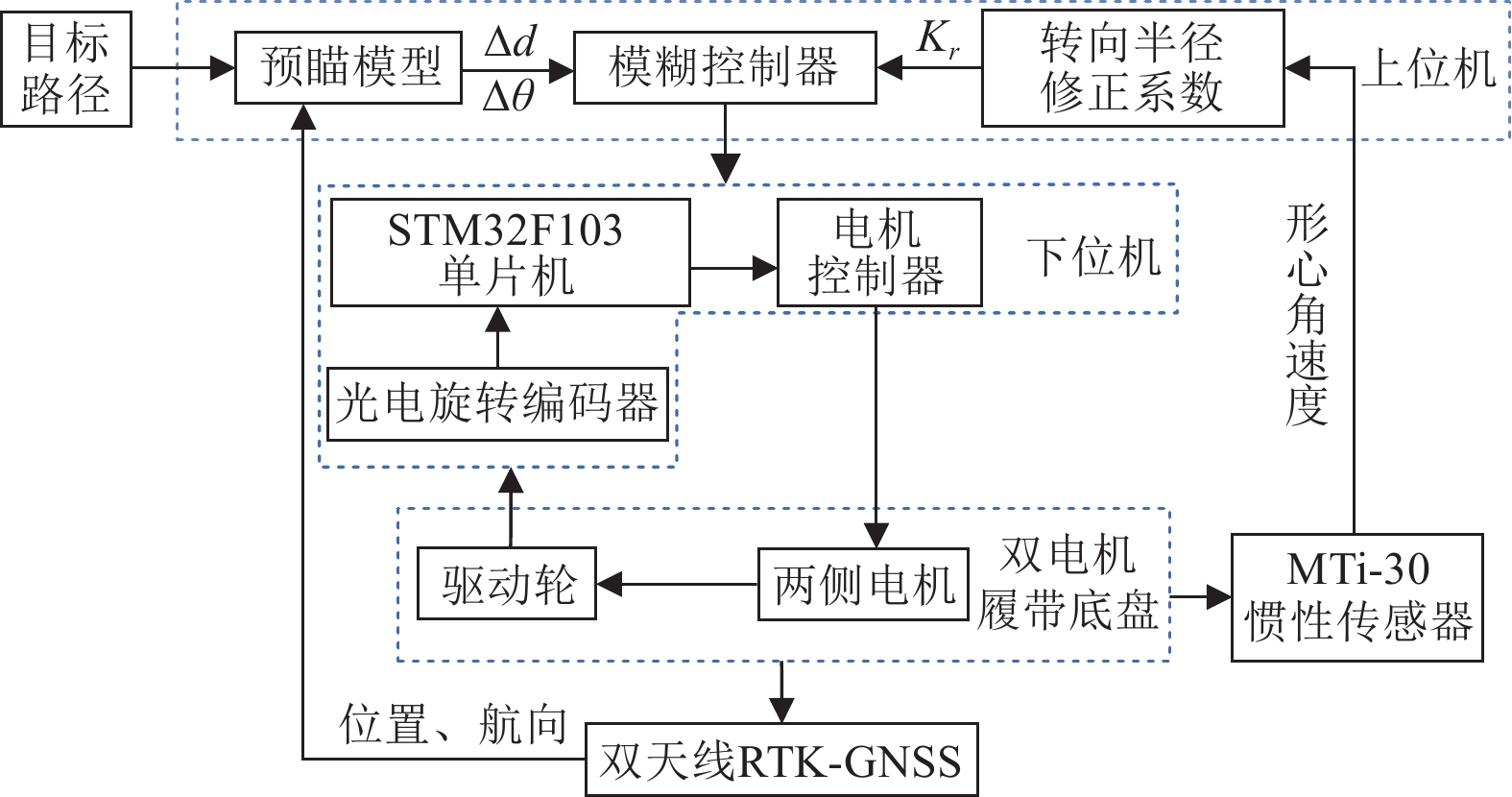

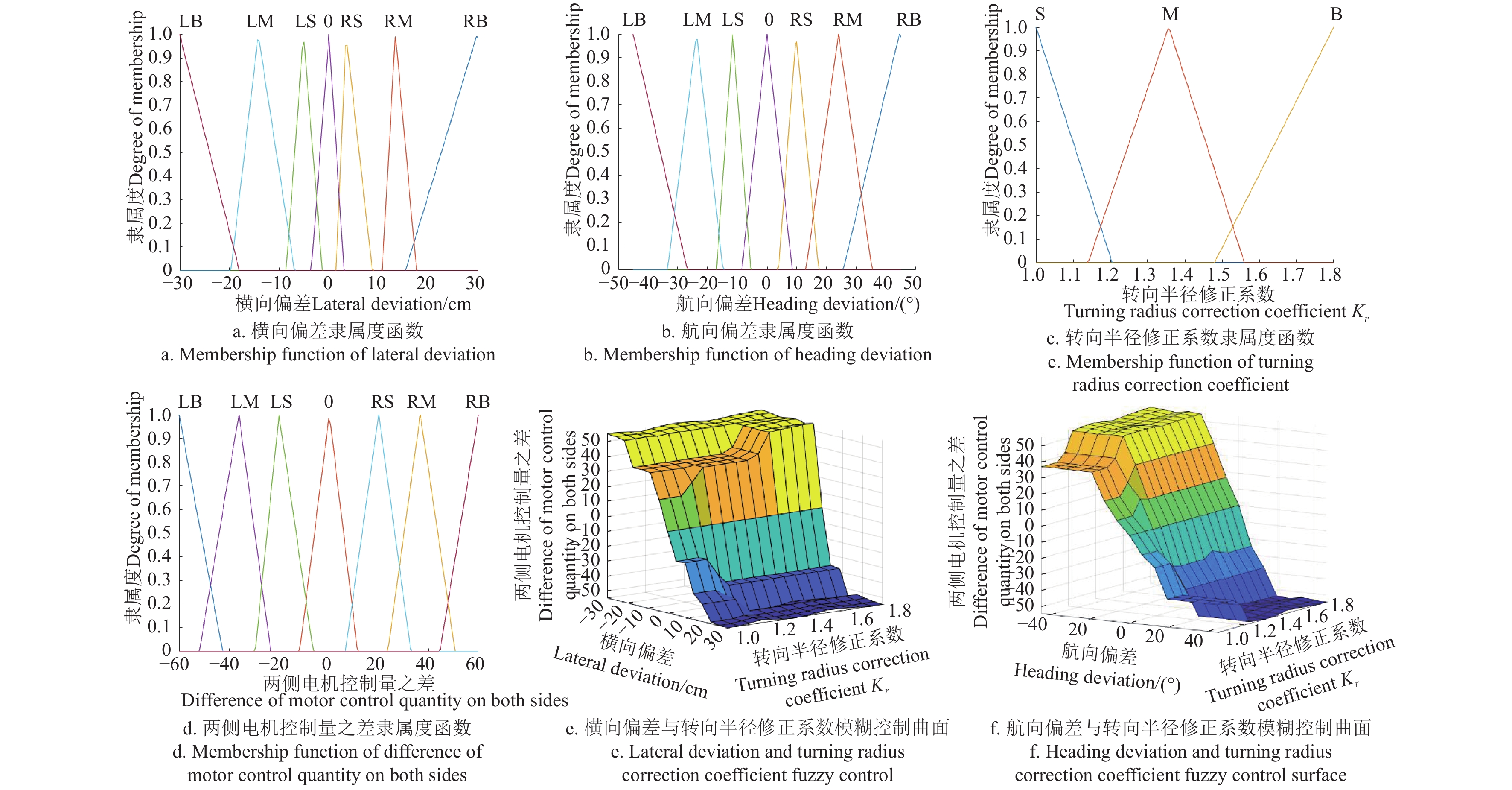

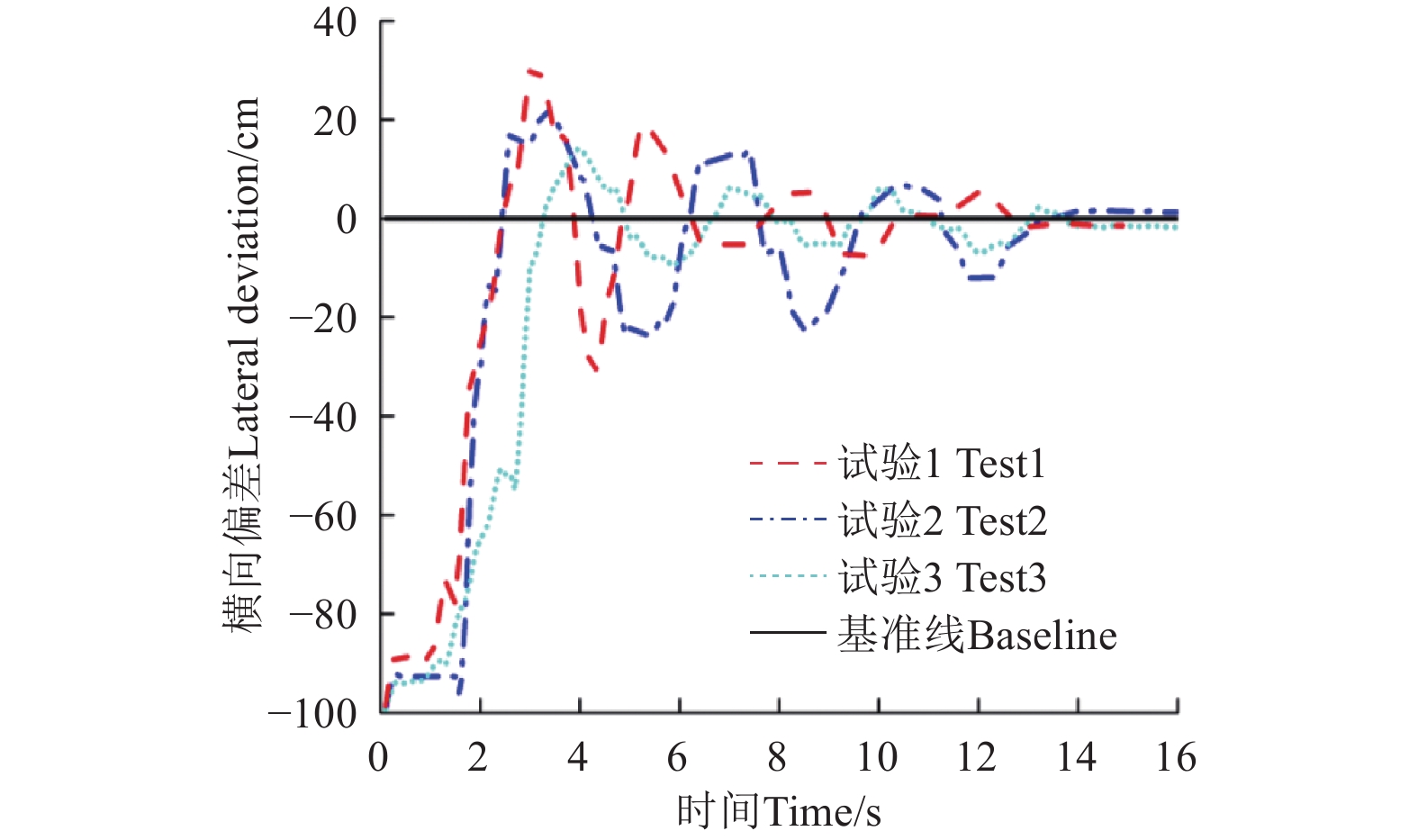

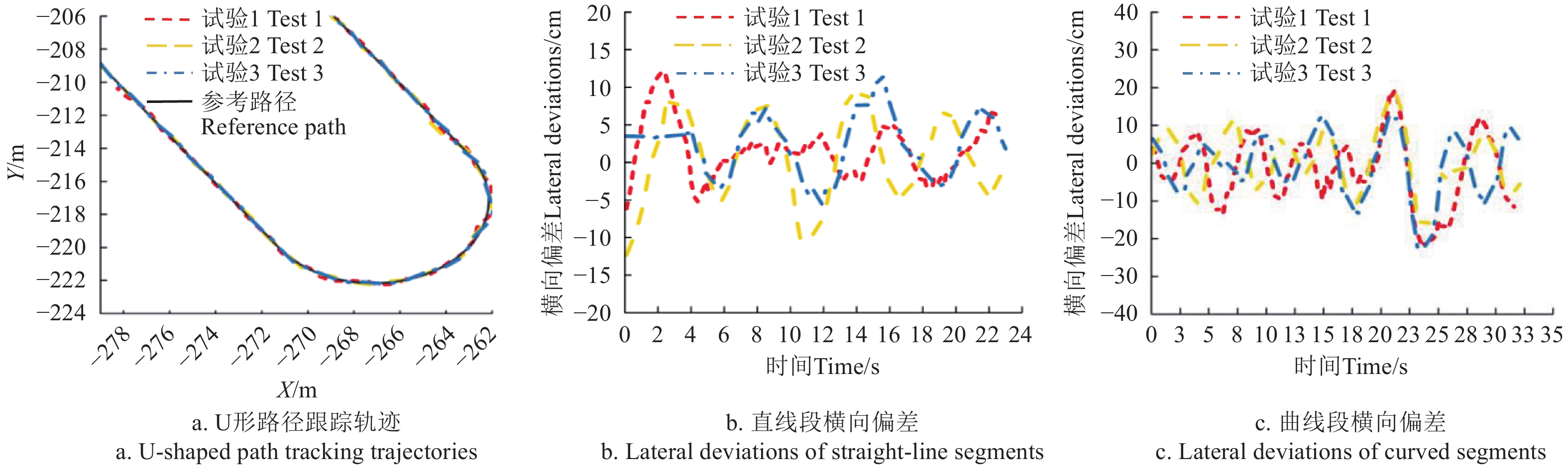

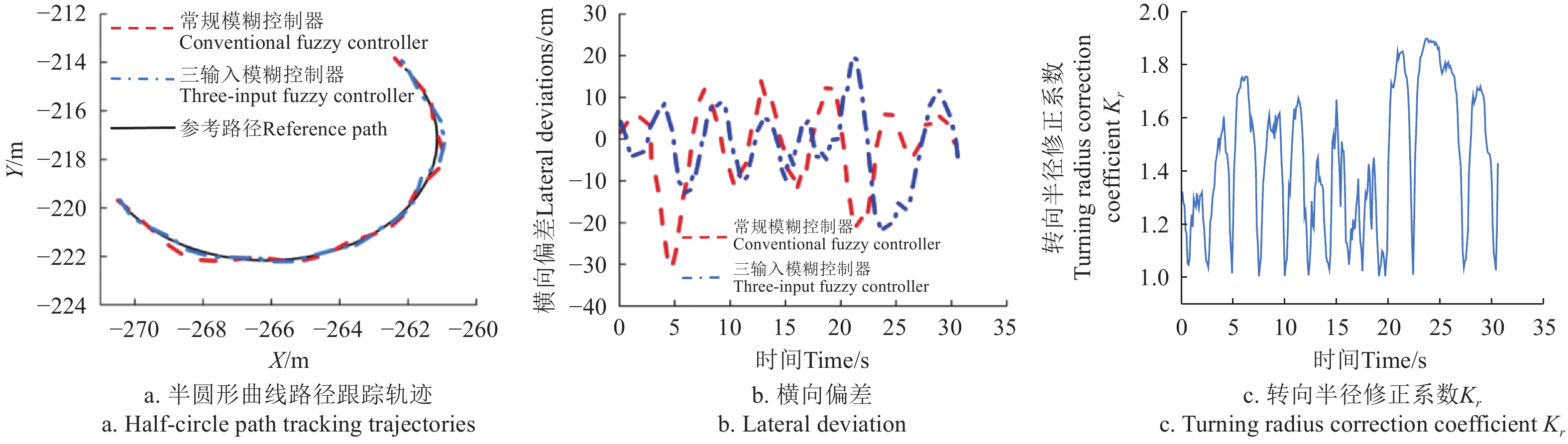

针对履带底盘田间作业时由于土壤松软、田面不平整导致履带滑移滑转、自动导航路径跟踪精度低的问题,该研究提出了考虑滑移滑转的履带底盘路径跟踪算法,基于履带底盘运动学模型推导出表征滑移滑转特性的转向半径修正系数,并设计了一种基于预瞄模型的模糊控制路径跟踪算法。该方法在纯模糊控制基础上通过预瞄模型确定预瞄点,进而得到横向偏差与航向偏差,同时在常规模糊控制器中引入转向半径修正系数,建立横向偏差、航向偏差、转向半径修正系数三输入模糊控制器。以双电机履带底盘为控制对象,采用高精度RTK-GNSS和MTi-30惯性传感器获取底盘实时位姿信息与角速度信息,进行组合导航。开展了三输入模糊控制器田间U型路径跟踪试验,结果表明,三输入模糊控制器的直线跟踪最大绝对偏差、平均绝对偏差和标准差分别为12.0、3.6和4.4 cm;三输入模糊控制的曲线跟踪最大绝对偏差、平均绝对偏差和标准差分别为21.3、8.6和8.4 cm;为进一步确定本研究算法在履带出现滑移滑转时对路径跟踪精度的提升效果,开展了常规模糊控制器与三输入模糊控制器曲线路径跟踪对比试验,结果表明:当作业速度为0.6 m/s时,常规模糊控制器的最大绝对偏差、平均绝对偏差和标准差分别为31.1、8.3和10.2 cm,三输入模糊控制器的最大绝对偏差、平均绝对偏差和标准差分别为22.4、7.4和9.1 cm,相较于常规模糊控制器,路径跟踪精度分别提高了27.95%、10.84%和10.78%,所设计的三输入模糊控制器可有效降低履带滑移滑转的影响,增强导航系统的控制性能,可为履带底盘在田间松软土壤环境下高精度导航作业提供参考。

Abstract:Track skid and slip often occur, when the tracking chassis work in soft soil and uneven field. The accuracy of curved path tracking can inevitably deteriorate in automatic navigation. In this work, path tracking was designed to consider the track skid and slip in field conditions. Firstly, the coefficient of turning radius correction was derived to describe the skid and slip characteristics using the kinematic model of the tracked chassis. Then, the lateral and heading deviations were determined by the look-ahead model. Finally, a three-input fuzzy controller was established with the controller inputs of lateral deviation, heading deviation and turning radius correction coefficient. A dual-motor tracked chassis was designed to validate the model. The control hardware included two brushless DC motors, a motor driver, an STM32 microcontroller, and two photoelectric rotary encoders. In navigation, the position, heading and angular velocity of the chassis were measured by a high-precision RTK-GNSS and an MTi-30 inertial sensor. The measurement values were sent to the upper-level computer using a serial port. The path tracking was carried out to calculate the control signal, and then sent into the lower-level microcontroller. The tracking of the reference path was realized by the motor driver of the lower-level microcontroller on both sides. A field experiment was conducted on automatic navigation to verify the performance of a three-input fuzzy controller. The field was selected with a lot of weeds, where the soil was wet and sticky with a moisture content of 22.4%. There was the low flatness with some pits, bulges and hardened soil blocks that scattered throughout the whole field. The speed of the chassis was set to 0.6 m/s in navigation. The look-ahead distance proportional coefficient of the look-ahead model was set to 1.5. An initial lateral deviation of about 1000 cm was set for the correction. The results showed that the average response time of the control system was 6.79 s, while the average distance was 4.08 m. The tracking test of the U-shaped path was performed on the three-input fuzzy controller. The maximum absolute deviation, average absolute deviation and standard deviation of the straight-line and curve tracking section were 12.0 and 21.3 cm, 3.6 and 8.6 cm, as well as 4.4 and 8.4 cm, respectively. The curve tracking with the three-input fuzzy controller was compared with the conventional one, in order to further determine the path tracking accuracy under track skid and slip. The maximum absolute deviation, average absolute deviation and standard deviation of the conventional and three-input fuzzy controller were 31.1 and 22.4 cm, 8.3 and 7.4 cm, as well as 10.2 and 9.1 cm, respectively. Compared with the conventional, the three-input fuzzy controller was improved by 27.95%, 10.84 % and 10.78 %, respectively, in the maximum absolute deviation, average absolute deviation and standard deviation. The better control performance of the navigation system was achieved in the three-input fuzzy controller, indicating the reduced influence of track skid and slip. This finding can also provide a strong reference for the high-precision navigation of tracked chassis in soft soil environments in the field.

-

Keywords:

- agricultural machinery /

- automatic navigation /

- path tracking /

- tracked chassis /

- fuzzy control /

- skid and slip

-

0. 引 言

2004年THOMPSON等[1]提出“微塑料”(microplastics,MPs)的概念,即粒径小于5 mm的塑料颗粒、纤维、碎片、薄膜等。有报道称,至2015年全球已产生约63亿t塑料垃圾,其中只有约9%被回收利用,而79%堆积在垃圾填埋场或进入自然环境[2]。进入农田中的塑料在耕作、紫外线辐射和生物降解等共同作用下逐渐分解成微塑料[3]。目前,已检测到某工业园区土壤中微塑料含量高达6.7%[4]。残留在土壤中的微塑料会对土壤结构、土壤微生物等造成影响,进而影响土壤肥力[5]。生物活动、耕作扰动和水分入渗等外界作用力会促进微塑料在土壤中迁移[6-7]。WAN等[8]的研究表明,土壤中微塑料薄膜会影响水稳性团聚体的大小分布、降低土壤容重、增加土壤通气量等。微塑料含有的添加剂在土壤中会进行转化引起土壤元素的变化[9]。LIU等[10]通过室内土壤培养试验发现,7%和28%的微塑料添加刺激了土壤中荧光素水解酶和苯酚氧化酶的活性,活化了有机氮库,促进了土壤中可溶性氮的积累。FEI等[11]的研究发现聚乙烯(polyethylene, PE)的添加增加了土壤中与固氮作用有关的细菌丰度,影响了有机氮的矿化。刘晨磊等[12]通过设置5个不同聚乙烯微塑料添加浓度的土壤培养试验,发现微塑料添加显著减少了土壤可溶性有机氮含量和铵态氮含量,显著增加了土壤硝态氮含量。

秸秆还田是传统的农田土壤培肥措施,会对土壤氮素库容产生影响[13–17]。李明嵘等[18]通过田间试验研究发现秸秆还田降低了施肥处理土壤硝态氮含量。徐祖祥[19]通过长期定位试验表明,秸秆添加会明显提高耕层土壤的全氮含量并且会促进土壤中碱解氮增加。隋鹏祥等[20]通过田间定位试验研究发现秸秆还田能提高0~60 cm土层硝态氮含量。朱启林等[21]通过室内土柱模拟淋洗试验,研究发现旱作条件下秸秆还田增加水稻土硝态氮和铵态氮的淋失。胡宏祥等[22]采用室内模拟装置淋溶土柱的方法,发现秸秆还田能够降低在优化施肥条件下黄褐土的氮素淋失。

目前关于微塑料对农田土壤养分含量影响的研究较多,但是对微塑料输入对农田土壤氮淋溶影响的相关研究还较少。土壤中微塑料的出现和农作物秸秆还田的广泛推广,导致农田中微塑料和秸秆的共存[23],二者的交互作用如何影响土壤氮淋溶的研究目前较少。基于此,本研究以潮土和黄棕壤两种土壤为研究对象,研究微塑料输入与秸秆添加下对农田土壤氮淋溶的影响,旨在探究微塑料输入与秸秆还田对农田土壤养分循环的影响,为农田土壤微塑料污染风险的评估和土壤氮素固持提供理论依据。

1. 材料与方法

1.1 供试材料

潮土采自河南省新乡市原阳县实验基地(35°3′57″N,113°56′23″E),该地区属于暖温带大陆性季风型气候,年平均气温为14.0 ℃,年均降雨量约573.4 mm,无霜期约205 d,年日照时数2 400 h。黄棕壤取自湖北省当阳市半月镇春光村(30°39′48″N,111°48′24″E),属亚热带季风性湿润气候,年平均气温16.6 ℃,年平均降雨量992.1 mm,年日照时数1 701.6 h。于试验区按“S”形采集深度为20 cm的耕层土壤,剔除植物残体及石头等杂物后风干过2 mm筛备用。试验所用微塑料为过100目筛的聚乙烯(PE)粉末,去离子水冲洗3次烘干后备用;试验所用秸秆为过1 mm筛的玉米秸秆,秸秆的TC、TN质量分数分别为626.00 g/kg、10.81 g/kg。供试土壤的基本理化性质如表1所示。

表 1 供试土壤基本性质Table 1. Basic properties of tested soil土壤类型

Soil typespH值

pH valueTC(Total carbon)/

(g·kg−1)TN(Total nitrogen)/

(g·kg−1)NH4+-N/

(mg·kg−1)NO3−-N/

(mg·kg−1)粉粒Silt/% 黏粒Clay/% 砂粒 Sand/% 潮土

Fuvo-aquic soil8.24 12.19 0.21 28.73 129.85 15.07 49.63 35.3 黄棕壤

Yellow-brown soil4.52 11.54 0.85 23.18 18.84 39.06 35.84 25.09 1.2 试验设计

本试验选用底面内径7 cm、高度30 cm并底部加盖的PVC圆柱管模拟淋滤土柱。于土柱底盖侧边钻1个孔径为0.2 cm的小孔以放置硅胶管,并在土柱下端铺2 cm厚的粒径为3 mm的石英砂(起过滤作用),并在底部灌口处垫上两层尼龙网(孔径0.2 mm)。每个土柱按约1.14 g/cm3的容重(质量含水率为21%)将土壤分两部分装,先装15 cm,然后将秸秆和微塑料与5 cm土壤混合后装入,每个土柱中干土质量为880 g,土柱上铺尼龙布和石英砂,以减少淋溶水对土壤表层的冲击。

两种土壤各设置8个处理:对照组(不添加微塑料与秸秆,CK);仅添加少量微塑料(0.2%干土重,PE1);仅添加中量微塑料(2%干土质量,PE2);仅添加高量微塑料(7%干土质量,PE3);)仅添加秸秆(全量还田,S);添加少量微塑料与秸秆(0.2%干土重的微塑料与秸秆混施,S+PE1);添加中量微塑料与秸秆(2%干土质量的微塑料与秸秆混施,S+PE2);添加高量微塑料与秸秆(7%干土质量的微塑料与秸秆混施,S+PE3),每个处理设置3个重复。每个土柱按当地施肥量371 kg N/hm2添加尿素,即每个柱子0.308 g尿素;每个土柱秸秆按全量还田9 000 kg/hm,即每个土柱加入3.42 g秸秆。

1.3 样品采集与测定方法

于淋溶开始前先加200 mL去离子水使土壤水分达到饱和后平衡1 d,并根据当地夏季平均降雨量480 mm左右,通过蠕动泵模拟降雨,采用间歇式淋溶法,每隔7 d淋溶一次,每次为40 mm(即153 mL去离子水),模拟的降雨强度为40 mm/h,淋溶5次,共29 d[24]。每次收集的淋溶液用洗净塑料瓶(300 mL)装好,将每瓶淋溶液摇匀后测定。水质指标按照纳氏试剂分光光度法测定铵态氮,紫外分光光度法测定硝态氮,碱性过硫酸钾消解紫外分光光度法测定总氮[25];淋溶液体积用量筒测量;淋溶液pH采用酸度计电位法测定。

1.4 数据统计与分析

土壤TN、NH4+-N和NO3−-N累计淋溶量分别为淋溶液中TN、NH4+-N和NO3−-N浓度与淋溶液体积乘积之和。计算式:

L=n∑t=1Ci×Vi1000 式中L为TN、NH4+-N和NO3−-N累计淋溶量,mg;Ci为第i次淋溶液中某种养分的浓度,mg/L;Vi为第i次淋溶液体积,mL。

采用Excel 2021对数据进行预处理。利用SPSS 24进行单因素方差分析(one-way ANOVA)、双因素方差分析(two-way ANOVA),显著性水平设置为0.05。采用R软件(4.3.0版本)中的“linkET”包进行Mantel’test分析。使用Smart PLS 3.0进行基于偏最小二乘法(PLS-PM,partial least-square method)的路径分析。

2. 结果与分析

2.1 微塑料输入与秸秆添加对土壤NO3−-N淋溶量的影响

秸秆添加与微塑料输入对潮土和黄棕壤NO3−-N淋溶量的影响存在差异(图1)。潮土中,各处理NO3−-N的淋溶量在24.83~36.07 mg之间。仅微塑料添加,相较于对照(CK),PE1、PE2、PE3处理NO3−-N淋溶量分别降低了20.00%、7.16%、6.15%。微塑料添加显著抑制了土壤NO3−-N的淋失,但微塑料输入量越多对土壤NO3−-N淋失的抑制作用越弱。秸秆添加下,与对照(CK)相比,NO3−-N淋溶量显著降低,S、S+PE1、S+PE2、S+PE3处理NO3−-N淋溶量分别降低了31.15%、11.00%、22.93%、9.58%。相较于对照(CK),微塑料与秸秆添加对土壤NO3−-N的淋失具有抑制作用。黄棕壤中,各处理NO3−-N的淋溶量在5.79~29.32 mg之间。仅微塑料添加,相较于对照(CK),PE1和PE3处理NO3−-N淋溶量分别增加了20.96%、17.32%,显著促进了土壤NO3−-N的淋失。秸秆添加下,相较于对照(CK),S+PE1和S+PE2处理NO3−-N淋溶量分别减少了51.65%、76.10%,显著抑制了NO3−-N的淋失。

![]() 图 1 土壤NO3−-N累计淋溶量注:不同小写字母表示不同处理之间差异显著(P<0.05),CK:不添加微塑料与秸秆,PE1:0.2%PE,PE2: 2% PE,PE3:7% PE,S:仅添加秸秆, S+PE1: 0.2% PE与秸秆, S+PE2:2% PE与秸秆,S+PE3: 7% PE与秸秆,下同。Figure 1. Cumulative leaching amount of NO3−-N in soilsNote : Different lowercase letters indicate significant differences between different treatments ( P < 0.05 ). CK : no microplastics and straw, PE1 : 0.2% PE, PE2 : 2% PE, PE3 : 7% PE, S : only straw, S + PE1 : 0.2% PE and straw, S + PE2 : 2% PE and straw, S + PE3 : 7% PE and straw, the same below.

图 1 土壤NO3−-N累计淋溶量注:不同小写字母表示不同处理之间差异显著(P<0.05),CK:不添加微塑料与秸秆,PE1:0.2%PE,PE2: 2% PE,PE3:7% PE,S:仅添加秸秆, S+PE1: 0.2% PE与秸秆, S+PE2:2% PE与秸秆,S+PE3: 7% PE与秸秆,下同。Figure 1. Cumulative leaching amount of NO3−-N in soilsNote : Different lowercase letters indicate significant differences between different treatments ( P < 0.05 ). CK : no microplastics and straw, PE1 : 0.2% PE, PE2 : 2% PE, PE3 : 7% PE, S : only straw, S + PE1 : 0.2% PE and straw, S + PE2 : 2% PE and straw, S + PE3 : 7% PE and straw, the same below.2.2 微塑料输入与秸秆添加对土壤NH4+-N淋溶量的影响

秸秆添加与微塑料输入对潮土和黄棕壤NH4+-N淋溶量的影响存在差异(图2)。潮土中,各处理NH4+-N的淋溶量在4.25~5.34 mg之间。PE1、PE2、PE3、S、S+PE1、S+PE2、S+PE3处理与对照(CK)之间具有显著差异,NH4+-N淋溶量分别降低了9.54%、12.18%、10.37%、13.45%、19.42%、16.68%、20.55%,秸秆添加与微塑料输入对土壤NH4+-N的淋失具有抑制作用。黄棕壤中,各处理NH4+-N的淋溶量在4.25~5.34 mg之间。PE1、PE2、PE3、S、S+PE1、S+PE2、S+PE3处理NH4+-N的淋溶量与对照(CK)无显著差异。秸秆添加下微塑料输入(S+PE1、S+PE2、S+PE3)处理相较于仅添加微塑料(PE1、PE2、PE3)处理,土壤NH4+-N的淋溶量有所增加,其中S+PE1相较于PE1处理NH4+-N的淋溶量增加了23.3%,秸秆添加增加了黄棕壤中NH4+-N的淋失。

2.3 微塑料输入与秸秆添加对土壤TN淋溶量的影响

秸秆添加与微塑料输入对潮土和黄棕壤TN淋溶量的影响存在差异(图3)。潮土中,各处理TN的淋溶量在72.30~86.50 mg之间。仅微塑料添加,相较于对照(CK),PE1、PE2、PE3处理TN的淋溶量无显著差异。秸秆添加下,与对照(CK)相比,S、S+PE1、S+PE2、S+PE3处理显著降低了TN淋溶量,分别降低了15.26%、8.90%、14.42%、8.40%。S+PE1、S+PE2、S+PE3处理相较于S处理降低了TN淋溶量。黄棕壤中,各处理TN的淋溶量在26.81~54.46 mg之间。仅微塑料添加,相较于对照(CK),PE1处理TN淋溶量增加了15.22%,PE2处理TN淋溶量增加了27.57%。秸秆添加下,相较于对照(CK),S处理TN淋溶量增加了22.56%,S+PE1处理TN淋溶量降低了10.05%。潮土中,除S+PE1处理外,其余处理相较于对照(CK),淋溶液pH降低;黄棕壤中,除S+PE2处理,其余处理相较于对照(CK),淋溶液pH显著升高(图4)。

2.4 微塑料输入与秸秆添加下对土壤氮淋溶量的影响

利用Mantel test进一步分析了微塑料输入与秸秆添加和土壤淋溶液各指标间的关系。(图5)。图中Mantel’s P表示Mantel test的相关关系的显著水平,Mantel’s r表示Mantel test的相关系数,Pearson’s r表示理化因子之间的Pearson相关系数。潮土中,TN淋溶量与土壤NO3−-N淋溶量、淋溶液pH呈极显著正相关,NO3−-N、NH4+-N淋溶量与淋溶液pH呈极显著正相关,NO3−-N淋溶量与微塑料添加量具有显著相关性,TN、NH4+-N、pH与秸秆是否添加具有显著相关性。黄棕壤中,TN淋溶量与土壤NO3−-N淋溶量、淋溶液pH呈极显著正相关,NO3−-N淋溶量与淋溶液pH呈极显著正相关,微塑料添加量与氮淋失之间没有显著相关性,NO3−-N、NH4+-N淋溶量与秸秆是否添加具有显著相关性。

![]() 图 5 微塑料输入与秸秆添加下土壤淋溶液各指标间的相关性分析注:TN、AN、NN分别为土壤TN、NH4+-N、NO3−-N淋溶量;pH、MPs、Straw分别为淋溶液pH、微塑料添加量、是否添加秸秆。Figure 5. Correlation analysis between the indexes of soil leaching solution under microplastic input and straw additionNote : TN, AN and NN were the leaching amounts of soil TN, NH4 + -N and NO3−-N, respectively. pH, MPs, and straw were the pH of the leaching solution, the amount of microplastics added, and whether straw was added.

图 5 微塑料输入与秸秆添加下土壤淋溶液各指标间的相关性分析注:TN、AN、NN分别为土壤TN、NH4+-N、NO3−-N淋溶量;pH、MPs、Straw分别为淋溶液pH、微塑料添加量、是否添加秸秆。Figure 5. Correlation analysis between the indexes of soil leaching solution under microplastic input and straw additionNote : TN, AN and NN were the leaching amounts of soil TN, NH4 + -N and NO3−-N, respectively. pH, MPs, and straw were the pH of the leaching solution, the amount of microplastics added, and whether straw was added.本研究通过PLS-PM构建微塑料输入量、是否添加秸秆影响淋溶液pH、NO3−-N、NH4+-N淋溶量,进而影响土壤氮淋溶的路径模型(图6)。在潮土中,模型拟合优度(goodness of fit,GoF)为0.7355>0.7[26],模型对氮淋溶量的解释度为68.9%。微塑料输入量对NH4+-N的影响较大,其路径系数分别为−0.394,达显著性水平(P<0.05);是否添加秸秆对淋溶液pH、NO3−-N、NH4+-N的影响较大,其路径系数分别为−0.849、−0.525、−0.641;土壤氮素淋溶受淋溶液pH(0.653)、NO3−-N淋溶量(0.289)影响较大。添加秸秆对土壤氮淋溶的间接效应系数为-0.706,其中添加秸秆主要通过影响淋溶液pH和NO3−-N淋溶量影响氮淋溶。在黄棕壤中,模型拟合优度(GoF)为0.7305>0.7,模型对氮淋溶量的解释度为75%,微塑料输入量对NH4+-N的影响较大,其路径系数为−0.314,达显著性水平(P<0.05);是否添加秸秆对淋溶液NO3−-N、NH4+-N的影响较大,其路径系数分别为−0.574、0.633;土壤氮素淋溶受淋溶液NO3−-N淋溶量(0.931)、NH4+-N淋溶量(0.549)影响较大。微塑料添加量对土壤氮淋溶的间接效应系数为−0.172,添加秸秆对土壤氮淋溶的间接效应系数为−0.188,其中微塑料添加量主要通过影响淋溶液NH4+-N淋溶量影响氮淋溶,添加秸秆主要通过影响淋溶液NO3−-N、NH4+-N淋溶量影响氮淋溶。

![]() 图 6 微塑料输入与秸秆添加影响土壤氮磷淋溶的偏最小二乘路径模型分析(PLS-PM)注:MPs、Straw、TN分别表示微塑料输入量、是否添加秸秆、氮淋溶量;单个箭头表示一个变量被假定为原因,对另一个变量的直接影响;箭头上的数字为标准化路径系数,黑色箭头表示路径系数为负,灰色箭头表示路径系数为正,实线表示路径系数显著,虚线表示路径系数不显著。GoF值为模型拟合度;R2为拟合系数;Q2为预测系数;***表示P<0.001。Figure 6. Partial least squares path model (PLS-PM) analysis of microplastic input and straw addition affecting soil nitrogen leachingNote : MPs, Straw, and TN represent the input of microplastics, whether to add straw, and nitrogen leaching, respectively ; a single arrow represents the direct effect of a variable assumed to be a cause on another variable ; the number on the arrow is the standardized path coefficient. The black arrow indicates that the path coefficient is negative, the gray arrow indicates that the path coefficient is positive, the solid line indicates that the path coefficient is significant, and the dotted line indicates that the path coefficient is not significant. GoF value is the model fitting degree ; R2 is the fitting coefficient ; Q2 is the prediction coefficient ; *** means P < 0.001.

图 6 微塑料输入与秸秆添加影响土壤氮磷淋溶的偏最小二乘路径模型分析(PLS-PM)注:MPs、Straw、TN分别表示微塑料输入量、是否添加秸秆、氮淋溶量;单个箭头表示一个变量被假定为原因,对另一个变量的直接影响;箭头上的数字为标准化路径系数,黑色箭头表示路径系数为负,灰色箭头表示路径系数为正,实线表示路径系数显著,虚线表示路径系数不显著。GoF值为模型拟合度;R2为拟合系数;Q2为预测系数;***表示P<0.001。Figure 6. Partial least squares path model (PLS-PM) analysis of microplastic input and straw addition affecting soil nitrogen leachingNote : MPs, Straw, and TN represent the input of microplastics, whether to add straw, and nitrogen leaching, respectively ; a single arrow represents the direct effect of a variable assumed to be a cause on another variable ; the number on the arrow is the standardized path coefficient. The black arrow indicates that the path coefficient is negative, the gray arrow indicates that the path coefficient is positive, the solid line indicates that the path coefficient is significant, and the dotted line indicates that the path coefficient is not significant. GoF value is the model fitting degree ; R2 is the fitting coefficient ; Q2 is the prediction coefficient ; *** means P < 0.001.3. 讨 论

3.1 微塑料输入对土壤氮淋溶的影响

中量微塑料添加对潮土和黄棕壤pH的影响存在差异,潮土仅添加中量微塑料降低了淋溶液的pH,而黄棕壤中量微塑料输入提高了淋溶液的pH。ZHANG等[27]的研究表明聚乙烯降低了土壤的pH,但是也有研究表明聚乙烯微塑料的输入会提高土壤pH[28-29],这可能与微塑料添加到土壤中会改变土壤的通气性、容重、持水能力以及土壤NH4+-N浓度等有关[30,11],从而进一步影响淋溶液的pH。CHEN等[31]研究发现微塑料会影响土壤中的厌氧反硝化过程,将硝酸盐和亚硝酸盐转化为气态形式的氮,从而减少土壤中硝态氮的含量,进而减少土壤中硝态氮的累积淋溶量,这与本研究中微塑料添加显著降低了潮土淋溶液中NO3−-N的累积量结果一致。微塑料添加显著降低了潮土NH4+-N的累积淋溶量,GUO等研究发现微塑料添加增加土壤的通气性,从而加速土壤硝化过程减少土壤NH4+-N的淋失[32]。值得注意的是,潮土中,微塑料的输入虽然减少了NO3−-N和NH4+-N的淋溶量,但是对TN的累计淋溶量没有显著影响,且NO3−-N累积淋溶量占TN累积淋溶量并未超过50%。LIU等[10]发现聚乙烯微塑料通过刺激荧光素二乙酸酯和酚氧化酶的活性,增加了土壤溶解有机氮的含量,微塑料还可以通过与土壤中的其他物质相互作用影响土壤有机氮的转化,促进了土壤矿质氮素及肥料向有机氮库的转化。微塑料输入增加了潮土中可溶性有机氮的含量,富余养分随土壤基质入渗向下层运移,造成有机氮淋溶量增加[33]。黄棕壤中,低量微塑料处理明显增加了NO3−-N、TN的淋溶量,这与赵群芳等[34]的研究结果一致。可能是微塑料输入降低了土壤容重,增加了土壤孔隙度,从而促进土壤水分运移,进而促进了氮的淋失[35]。也可能是微塑料累积改变了土壤细菌群落结构,抑制了土壤微生物活性,降低了微生物固氮能力,造成土壤氮损失[25,36-37]。

3.2 秸秆添加下微塑料输入对土壤氮淋溶的影响

秸秆还田是提升地力的有效措施[38]。仅添加秸秆(S)与对照(CK)相比,秸秆添加减少了潮土NO3−-N、NH4+-N、TN的淋溶量,这与黄绍敏等[39]的研究结果一致。秸秆还田具有增加土壤有机质、缓解土壤N流失的作用[40]。秸秆添加增加了黄棕壤NH4+-N、TN的淋溶量,因为秸秆添加增加了土壤NH4+-N的含量,进而导致NH4+-N、TN淋溶量的增加[41]。潮土微塑料添加相较于仅添加秸秆处理显著增加了土壤NO3−-N的累计淋溶量,与秸秆共存下,微塑料输入改变土壤孔隙度增加土壤氧气含量[30],增强了土壤硝化过程[42],增加了土壤中NO3−-N的含量,进而促进了NO3−-N的淋失。黄棕壤中,低量和中量微塑料输入相较于只添加秸秆处理显著降低了土壤NO3−-N淋失,微塑料添加提高了土壤有机碳的含量[43],有机碳含量的升高降低了土壤水和NO3−-N的下移速度[44]。施用氮肥可以加速聚乙烯微塑料的降解[45],有研究表明,微塑料可作为微生物可利用的碳源,微塑料添加后可提高土壤碳氮比,同时秸秆添加增加了土壤微生物数量,微生物为满足自身生长需求加速了土壤固氮过程[46-47]。潮土秸秆添加与秸秆不添加相比,对NH4+-N淋失的影响没有显著差异,添加秸秆加快土壤中尿素水解过程的同时,增加了土壤中NH4+-N的含量[47],在有机质含量和C/N适宜的土壤中微生物可能会同化更多的无机氮[48],从而导致添加秸秆与不添加秸秆相比,潮土中NH4+-N淋溶量变化不大。黄棕壤秸秆添加与秸秆不添加相比显著增加了NH4+-N淋溶量,在黄棕壤中秸秆添加对微生物活性的提高有限,微生物对NH4+-N的固持作用较弱。秸秆添加相较于秸秆不添加,显著降低了潮土的TN淋溶量,秸秆还田能有效延缓氮素向深层剖面的垂直运移[49],相反在黄棕壤中整体上增加了TN的淋溶量。PLS-PM分析表明,微塑料输入与秸秆添加条件下,微塑料输入量对潮土氮淋溶无显著影响,秸秆添加对潮土氮淋溶的间接效应系数为−0.706,添加秸秆主要通过影响淋溶液pH和NO3−-N淋溶量影响氮淋溶。微塑料添加量对黄棕壤氮淋溶的间接效应系数为−0.172,秸秆添加对黄棕壤氮淋溶的间接效应系数为−0.188,其中微塑料添加量主要通过影响淋溶液NH4+-N淋溶量影响氮淋溶,秸秆添加通过影响淋溶液NO3−-N、NH4+-N淋溶量影响氮淋溶。土壤氮淋失特征与土壤入渗性能、土壤理化性质以及土壤氮素背景值等密不可分,这造成了潮土和黄棕壤中氮素淋失的差异。

4. 结 论

1)仅添加微塑料处理,潮土TN累计淋溶量在各处理之间无显著差异;显著影响了黄棕壤TN累计淋溶量,相较于对照(CK),低量微塑料(PE1)处理TN累计淋溶量增加了15.22%,中量微塑料(PE2)处理TN累计淋溶量降低了27.57%。

2)微塑料输入与秸秆添加下,相较于仅添加秸秆(S)处理,潮土微塑料添加增加了NO3−-N、TN淋溶量;黄棕壤低量微塑料(S+PE1)和中量微塑料(S+PE2)处理降低了NO3−-N、TN的累计淋溶量。

3)秸秆添加相较于秸秆不添加,潮土各浓度微塑料输入下NO3−-N、NH4+-N、TN的累计淋溶量呈降低趋势,黄棕壤低量微塑料输入降低了TN淋溶量。

4)在潮土中添加秸秆主要通过影响淋溶液pH和NO3−-N淋溶量影响氮素淋溶,总效应为−0.706,微塑料添加量对氮淋溶无显著影响;在黄棕壤中添加秸秆主要通过影响淋溶液NO3−-N、NH4+-N淋溶量影响氮淋溶,总效应为−0.188,微塑料添加量主要通过影响淋溶液NH4+-N淋溶量影响氮淋溶,总效应为−0.172。

-

图 1 导航系统硬件结构

1. 电机驱动器 2. STM32F103单片机 3. RTK-GNSS天线 4. MTi-30惯性传感器 5. 上位机控制器 6. RTK-GNSS接收机 7. 直流无刷电机 8. 光电旋转编码器

Figure 1. Hardware structure of navigation system

1. Motor driver 2. STM32F103 microcontroller 3. RTK-GNSS mobile station 4. MTi-30 inertial sensor 5. Host controller 6. RTK-GNSS receiver 7. Brushless DC motor 8. Optical rotary encoders

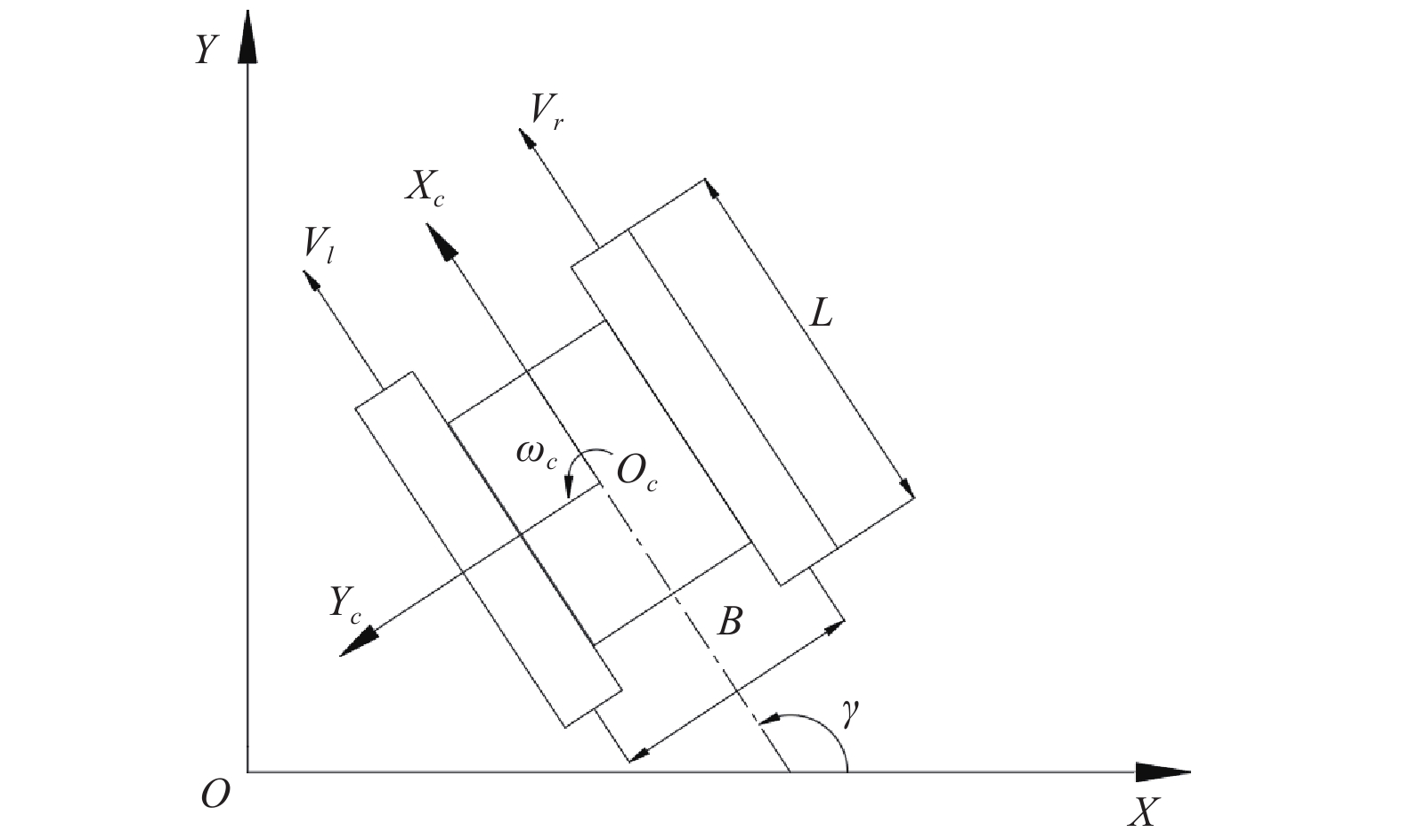

图 3 双电机履带底盘平面运动模型

注:OXY为惯性坐标系;Vl、 Vr分别为左右两侧履带理论速度,m·s−1;Oc为履带底盘形心;ωc为底盘绕形心的角速度,rad·s−1;L为履带接地段长度,m;B为底盘轨距,m;γ为履带底盘中轴线和X轴正向夹角,(°)。

Figure 3. Planar motion model of dual motor tracked chassis

Note: OXY is the inertial coordinate system; Vl and Vr are the theoretical speeds of the left and right tracks, m·s−1; Oc is the geometric center of the chassis ;ωc is the angular velocity of the chassis around its center, rad·s−1; L is the length of the grounded section of the track, m; B is the gauge of the chassis, m; γ is the angle between the center axis of the tracked chassis and the positive X-axis, (°).

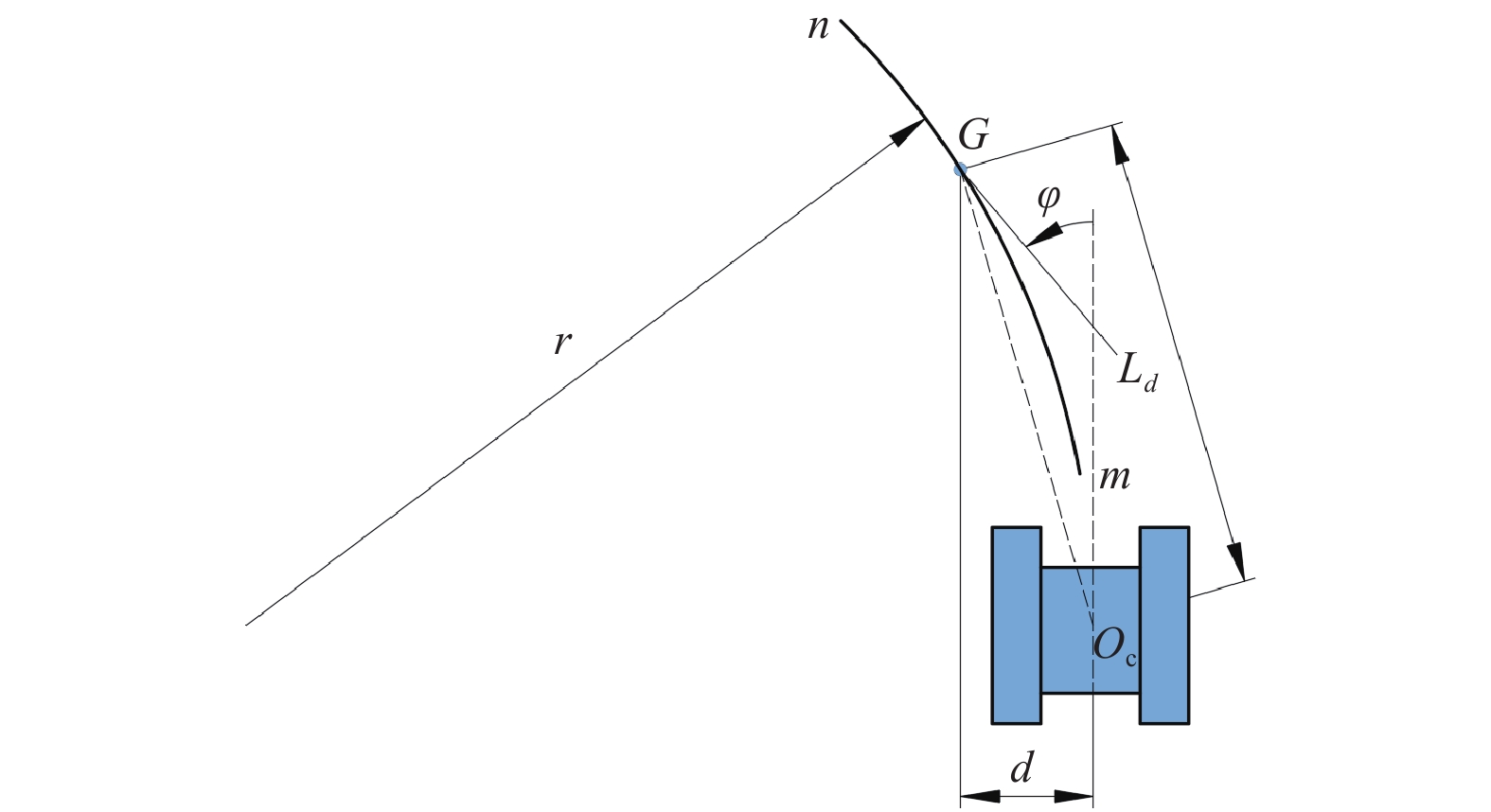

图 4 双电机履带底盘预瞄模型

注:曲线mn为目标路径;G为预瞄点;r为曲线mn的半径,m;Ld为前视距离,m;d为横向偏差,cm;φ 为航向偏差,(°)。

Figure 4. Look-ahead model of dual motor tracked chassis

Note: Curve mn is the target path; G is the look-ahead reference point; r is the radius of curve mn, m; Ld is the look-ahead distance, m; d is the lateral deviation, cm;φ is the heading deviation, (°).

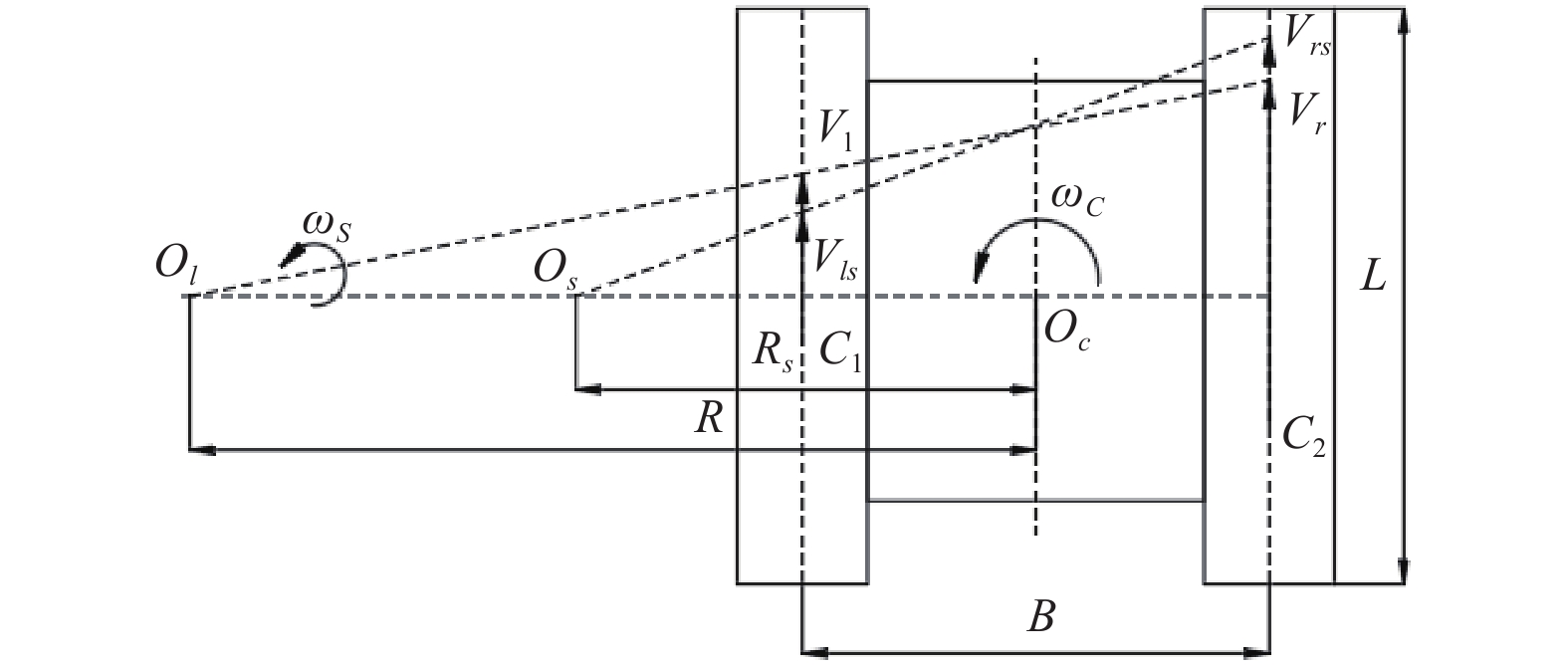

图 5 差速转向模型

注:C1、C2分别为两侧履带接地段中心;Ol为理论转向中心;Os为实际转向中心;R为理论转向半径,m;Rs为实际转向半径,m;Vls、Vrs分别为左右两侧履带考虑滑移滑转后的实际速度,m·s−1;ωs为转向角速度,rad·s−1。

Figure 5. Differential steering model

Note: C1 and C2 are the grounding centers of the two tracks; Ol is the theoretical turning center; Os is the actual turning center; R is the theoretical turning radius, m; Rs is the actual steering radius, m; Vls and Vrs are the actual speeds of the left and right tracks considering skid and slip, m·s−1; ωs is the turning angular speed, rad·s−1.

表 1 双电机履带底盘技术参数

Table 1 Main parameters of dual motor tracked chassis

参数Parameters 数值Values 驱动电机功率 Drive motor power/kW 1.5×2.0 轨距 Track gauge/m 0.5 接地长度 Grounding length/m 0.55 底盘尺寸 Chassis size/m×m×m 1.0×0.7×0.3 驱动轮直径Drive wheel diameter/m 0.097 最大前进速度Maximum forward speed/(m·s−1) 1.2 空载质量Unloaded mass/kg 150 表 2 上线试验结果

Table 2 Results of the on-line tests

序号

No.上线时间

On-line time/s上线距离

On-line distance/m1 6.90 4.14 2 7.31 4.39 3 6.16 3.70 平均值Average 6.79 4.08 表 3 田间试验路径跟踪横向偏差结果

Table 3 Lateral deviations of path tracking in field tests

cm 目标路径

Target path序号

No.最大

绝对偏差

Maximum

deviation平均

绝对偏差

Mean absolute deviation标准差

Standard deviations直线路径

Straight path1 12.0 2.7 3.7 2 12.3 4.9 5.7 3 11.8 3.3 3.9 平均值 12.0 3.6 4.4 曲线路径

Curved path1 22.4 7.4 9.1 2 18.6 6.4 7.8 3 22.9 6.6 8.2 平均值 21.3 8.6 8.4 表 4 曲线路径跟踪对比试验结果

Table 4 Results of curve path tracing comparative tests

cm 算法

Algorithms最大绝对偏差

Maximum

deviation平均绝对偏差

Mean absolute deviation标准差

Standard deviation常规模糊控制器

Conventional fuzzy controller31.1 8.3 10.2 三输入模糊控制器

Three-input fuzzy controller22.4 7.4 9.1 -

[1] 李道亮,李震. 无人农场系统分析与发展展望[J]. 农业机械学报,2020,51(7):1-12. doi: 10.6041/j.issn.1000-1298.2020.07.001 LI Daoliang, LI Zhen. System analysis and development prospect of unmanned farming[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(7): 1-12. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2020.07.001

[2] 罗锡文,廖娟,胡炼,等. 我国智能农机的研究进展与无人农场的实践[J]. 华南农业大学学报,2021,42(6):8-17. doi: 10.7671/j.issn.1001-411X.202108040 LUO Xiwen, LIAO Juan, HU Lian, et al. Research progress of intelligent agricultural machinery and practice of unmanned farm in china[J]. Journal of South China Agricultural University, 2021, 42(6): 8-17. (in Chinese with English abstract) doi: 10.7671/j.issn.1001-411X.202108040

[3] 张漫,季宇寒,李世超,等. 农业机械导航技术研究进展[J]. 农业机械学报,2020,51(4):1-18. doi: 10.6041/j.issn.1000-1298.2020.04.001 ZHANG Man, JI Yuhan, LI Shichao, et al. Research progress of agricultural machinery navigation technology[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(4): 1-18. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2020.04.001

[4] 王韦韦,陈黎卿,杨洋,等. 农业机械底盘技术研究现状与展望[J]. 农业机械学报,2021,52(8):1-15. doi: 10.6041/j.issn.1000-1298.2021.08.001 WANG Weiwei, CHEN Liqing, YANG Yang, et al. Development and prospect of agricultural machinery chassis technology[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(8): 1-15. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2021.08.001

[5] 郑永军,江世界,陈炳太,等. 丘陵山区果园机械化技术与装备研究进展[J]. 农业机械学报,2020,51(11):1-20. doi: 10.6041/j.issn.1000-1298.2020.11.001 ZHENG Yongjun, JIANG Shijie, CHEN Bingtai, et al. Review on technology and equipment of mechanization in hilly orchard[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(11): 1-20. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2020.11.001

[6] 黎永键,赵祚喜,黄培奎,等. 基于CAN总线的拖拉机导航控制系统设计与试验[J]. 农业机械学报,2016,47(s1):35-42. LI Yongjian, ZHAO Zuoxi, HUANG Peikui, et al. Design and experiment of navigation control system for tractor based on can bus[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(s1): 35-42. (in Chinese with English abstract)

[7] 何杰,朱金光,张智刚,等. 水稻插秧机自动作业系统设计与试验[J]. 农业机械学报,2019,50(3):17-24. doi: 10.6041/j.issn.1000-1298.2019.03.002 HE Jie, ZHU Jinguang, ZHANG Zhigang, et al. Design and experiment of automatic operation system for rice transplanter[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(3): 17-24. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2019.03.002

[8] 丁幼春,詹鹏,周雅文,等. 北斗定位田间信息采集平台运动控制器设计与试验[J]. 农业工程学报,2017,33(12):178-185. doi: 10.11975/j.issn.1002-6819.2017.12.023 DING Youchun, ZHAN Peng, ZHOU Yawen, et al. Design and experiment of motion controller for information collection platform in field with beidou positioning[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(12): 178-185. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2017.12.023

[9] 周明宽,夏俊芳,郑侃,等. 基于变增益单神经元PID的秸秆旋埋还田导航系统研制[J]. 农业工程学报,2021,37(5):31-40. doi: 10.11975/j.issn.1002-6819.2021.05.004 ZHOU Mingkuan, XIA Junfang, ZHENG Kan, et al. Development of rotary straw burying and returning navigation system based on variable-gain single-neuron PID[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(5): 31-40. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2021.05.004

[10] LI S, XU H, JI Y, et al. Development of a following agricultural machinery automatic navigation system[J]. Computers and Electronics in Agriculture, 2019, 158: 335-344. doi: 10.1016/j.compag.2019.02.019

[11] 吴才聪,吴思贤,文龙,等. 拖拉机自动导航变曲度路径跟踪控制[J]. 农业工程学报,2022,38(21):1-7. doi: 10.11975/j.issn.1002-6819.2022.21.001 WU Caicong, WU Sixian, WEN Long, et al. Variable curvature path tracking control for the automatic navigation of tractors[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2022, 38(21): 1-7. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2022.21.001

[12] 王辉,王桂民,罗锡文,等. 基于预瞄追踪模型的农机导航路径跟踪控制方法[J]. 农业工程学报,2019,35(4):11-19. doi: 10.11975/j.issn.1002-6819.2019.04.002 WANG Hui, WANG Guimin, LUO Xiwen, et al. Path tracking control method of agricultural machine navigation based on aiming pursuit model[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(4): 11-19. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2019.04.002

[13] 刘兆朋,张智刚,罗锡文,等. 雷沃ZP9500高地隙喷雾机的GNSS自动导航作业系统设计[J]. 农业工程学报,2018,34(1):15-21. LIU Zhaopeng, ZHANG Zhigang, LUO Xiwen, et al. Design of automatic navigation operation system for Lovol ZP9500 high clearance boom sprayer based on GNSS[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(1): 15-21. (in Chinese with English abstract)

[14] 唐小涛,陶建峰,李志腾,等. 自动导航插秧机路径跟踪系统稳定性模糊控制优化方法[J]. 农业机械学报,2018,49(1):29-34. TANG Xiaotao, TAO Jianfeng, LI Zhiteng, et al. Fuzzy control optimization method for stability of path tracking system of automatic transplanter[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(1): 29-34. (in Chinese with English abstract)

[15] 刘林,张华强,秦昌礼,等. 改进模型预测控制的农机轨迹跟踪算法研究[J]. 哈尔滨理工大学学报,2023,28(11):29-36. LIU Lin, ZHANG Huaqiang, QIN Changli, et al. Research on trajectory tracking algorithm of agricultural machinery based on model predictive control[J]. Journal of Harbin University of Science and Technology, 2023, 28(11): 29-36. (in Chinese with English abstract)

[16] 张万枝,白文静,吕钊钦,等. 线性时变模型预测控制器提高农业车辆导航路径自动跟踪精度[J]. 农业工程学报,2017,33(13):104-111. ZHANG Wanzhi, BAI Wenjing, LYU Zhaoqin, et al. Linear time-varying model predictive controller improving precision of navigation path automatic tracking for agricultural vehicle[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(13): 104-111. (in Chinese with English abstract)

[17] 吴永刚,梁华为. 基于自适应模型预测的无人车跟踪控制方法研究[J]. 制造业自动化,2023,45(2):198-202. doi: 10.3969/j.issn.1009-0134.2023.02.040 WU Yonggang, LIANG Huawei. Research on obstacles avoidance control method of unmanned ground vehicles based on adaptive model prediction[J]. Manufacturing Automation, 2023, 45(2): 198-202. (in Chinese with English abstract) doi: 10.3969/j.issn.1009-0134.2023.02.040

[18] 王伟康,罗承铭,张国忠,等. 双电机履带式水稻收获机底盘自动导航系统设计与试验[J]. 华中农业大学学报(自然科学版),2022,41(22):199-207. WANG Weikang, LUO Chengming, ZHANG Guozhong, et al. Design and experiment of automatic navigation system for rice harvester with dual-motor crawler chassis[J]. Journal of Huazhong Agricultural University, 2022, 41(22): 199-207. (in Chinese with English abstract)

[19] 丁幼春,何志博,夏中州,等. 小型履带式油菜播种机导航免疫PID控制器设计[J]. 农业工程学报,2019,35(7):12-20. doi: 10.11975/j.issn.1002-6819.2019.07.002 DING Youchun, HE Zhibo, XIA Zhongzhou, et al. Design of navigation immune controller of small crawler-type rape seeder[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(7): 12-20. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2019.07.002

[20] 何杰,满忠贤,胡炼,等. 履带式花生联合收获机路径跟踪控制方法与试验[J]. 农业工程学报,2023,39(1):9-17. doi: 10.11975/j.issn.1002-6819.202208067 HE Jie, MAN Zhongxian, HU Lian, et al. Path tracking control method and experiments for the crawler-mounted peanut combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2023, 39(1): 9-17. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.202208067

[21] 芮强,王红岩,王钦龙,等. 基于剪应力模型的履带车辆转向力矩分析与试验[J]. 兵工学报,2015,36(6):968-977. doi: 10.3969/j.issn.1000-1093.2015.06.002 RUI Qiang, WANG Hongyan, WANG Qinlong, et al. Analysis and experiment of tracked vehicle steering torque based on shear stress model[J]. Acta Armamentarii, 2015, 36(6): 968-977. (in Chinese with English abstract) doi: 10.3969/j.issn.1000-1093.2015.06.002

[22] SAID A M, LAKMAL D S, KASPAR A. Track-terrain modelling and travers ability prediction for tracked vehicles on soft terrain[J]. Journal of Terramechanics, 2010, 47(3): 151-160. doi: 10.1016/j.jterra.2010.02.001

[23] EHLERT W, HUG B, SCHMID I C. Field measurements and analytical models as a basis of test stand simulation of the turning resistance of tracked vehicles[J]. Journal of Terramechanics, 1992, 29(1): 57-69. doi: 10.1016/0022-4898(92)90014-B

[24] MARTINEZ J L, MANDOW A, MORALES J, et al. Approximating kinematics for tracked mobile robots[J]. The International Journal of Robotics Research, 2005, 24(10): 867-878. doi: 10.1177/0278364905058239

[25] 刘伟健,罗锡文,曾山,等. 履带式再生稻收获机田间转弯机理研究和性能试验[J]. 吉林大学学报(工学版),2023,53(9):2695-2705. LIU Weijian, LUO Xiwen, ZENG Shan, et al. Field turning mechanism and performance test of crawler reclaimed rice harvester[J]. Journal of Jilin University(Engineering and Technology Edition), 2023, 53(9): 2695-2705. (in Chinese with English abstract)

[26] 关卓怀,沐森林,吴崇友,等. 履带式联合收获机水田作业转向运动学分析与试验[J]. 农业工程学报,2020,36(13):29-38. doi: 10.11975/j.issn.1002-6819.2020.13.004 GUAN Zhuohuai, MU Senlin, WU Chongyou, et al. Steering kinematic analysis and experiment of tracked combine harvester working in paddy field[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(13): 29-38. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2020.13.004

[27] 盖江涛,刘春生,马长军,等. 考虑履带滑移滑转的电驱动履带车辆转向控制[J]. 兵工学报,2021,42(10):2092-2101. doi: 10.3969/j.issn.1000-1093.2021.10.005 GAI Jiangtao, LIU Chunsheng, MA Changjun, et al. Steering vontrol of electric drive tracked vehicle considering tracks' skid and slip[J]. Acta Armamentarii, 2021, 42(10): 2092-2101. (in Chinese with English abstract) doi: 10.3969/j.issn.1000-1093.2021.10.005

[28] 张仕杰,张国忠,赵胜华,等. 水稻联合收获机双电机履带式底盘设计与驱动功率试验[J]. 安徽农业大学学报,2019,46(8):1075-1082. ZHANG Shijie, ZHANG Guozhong, ZHAO Shenghua, et al. Design of dual-electric motors crawler chassis for rice harvester and drive power test[J]. Journal of Anhui Agricultural University, 2019, 46(8): 1075-1082. (in Chinese with English abstract)

[29] 邢赫,张国忠,韩宇航,等. 双腔气力式水稻精量水田直播机设计与试验[J]. 农业工程学报,2020,36(24):29-37. doi: 10.11975/j.issn.1002-6819.2020.24.004 XING He, ZHANG Guozhong, HAN Yuhang, et al. Development and experiment of double cavity pneumatic rice precision direct seeder[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(24): 29-37. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.2020.24.004

[30] 康启新,张国忠,郑侃,等. 勺夹式藠头排种器设计与试验[J]. 农业工程学报,2023,39(5):15-25. KANG Qixin, ZHANG Guozhong, ZHENG Kan, et al. Design and experiment of the spoon clip type seed metering device for Allium chinense[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2023, 39(5): 15-25. (in Chinese with English abstract)

[31] 张妮. 辣椒穴盘苗自动移栽机关键部件设计与试验[D]. 武汉:华中农业大学,2023. ZHANG Ni. Design and Experiment of Key Components of Automatic Transplanter for Chili Plug Seedlings[D]. Wu han: Huazhong Agricultural University, 2023. (in Chinese with English abstract)

[32] 刘文龙,郭锐,赵静一. 基于预瞄模型的农机路径跟踪预测控制方法[J]. 农业工程学报,2023,39(17):39-50. doi: 10.11975/j.issn.1002-6819.202303109 LIU Wenlong, GUO Rui, ZHAO Jingyi. Predictive control method for the path tracking of agricultural machinery based on preview model[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2023, 39(17): 39-50. (in Chinese with English abstract) doi: 10.11975/j.issn.1002-6819.202303109

[33] 张朝宇,董万静,熊子庆,等. 履带式油菜播种机模糊自适应纯追踪控制器设计与试验[J]. 农业机械学报,2021,52(12):105-114. doi: 10.6041/j.issn.1000-1298.2021.12.011 ZHANG Chaoyu, DONG Wanjing, XIONG Ziqing, et al. Design and experiment of fuzzy adaptive pure pursuit control of crawler-type rape seeder[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(12): 105-114. (in Chinese with English abstract) doi: 10.6041/j.issn.1000-1298.2021.12.011

-

期刊类型引用(3)

1. 刘环宇,邹顺,唐嘉城,韩志航,于浩,王霜. 基于参数预调型超螺旋滑模控制的履带农用底盘路径跟踪算法研究. 农业机械学报. 2025(02): 136-144 .  百度学术

百度学术

2. 罗承铭,朱星宇,王宁,谢勇进,钟婧,夏俊芳. 农田土壤采样车点跟踪自动取土控制系统设计与试验. 农业机械学报. 2024(12): 180-190 .  百度学术

百度学术

3. 秦维贤,张光强,胡书鹏,周豫鸽,温昌凯,付卫强,孟志军. 单HST履带式拖拉机差速转向控制系统研究. 农业机械学报. 2024(S1): 405-411+426 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: